Pasokan Baja BotopPipa Baja ERWsakaGR.B,X42,X46,GR.1,GR.2,S355J0H,S275JRH,SGP,dll

| Gaya | Standar | sasmita | Panggunaan |

| Pipa Baja ERW | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70, lsp | Transportasi lenga lan gas |

| ASTM A53 | GR.A,GR.B | ||

| ASTM A252 | GR.1, GR.2, GR.3 | Kanggo Struktur (Piling) | |

| BS EN10210 | S275JRH, S275J0H, S355J0H, S355J2H, lsp | ||

| BS EN10219 | S275JRH, S275J0H, S355J0H, S355J2H, lsp | ||

| JIS G3452 | SGP, lsp | Transportasi saka Cairan tekanan rendah | |

| JIS G3454 | STPG370, STPG410, lsp | Transportasi saka Cairan tekanan dhuwur | |

| JIS G3456 | STPG370, STPG410, STPG480, lsp | Pipa baja suhu dhuwur |

Pipa End Beveling

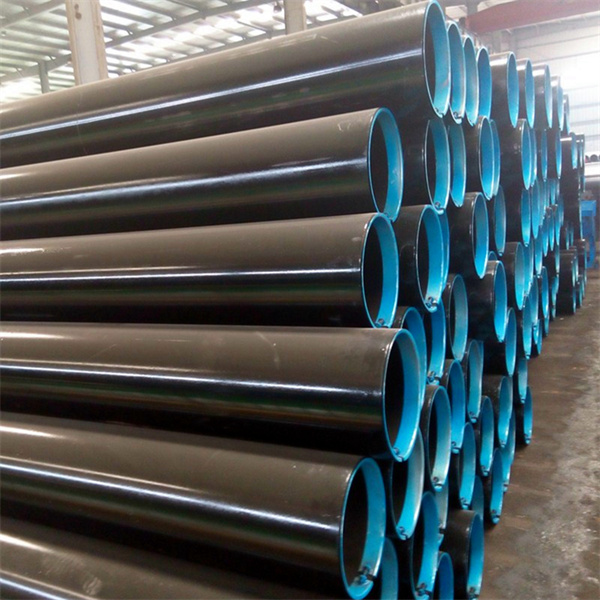

Black Painting karo Marking

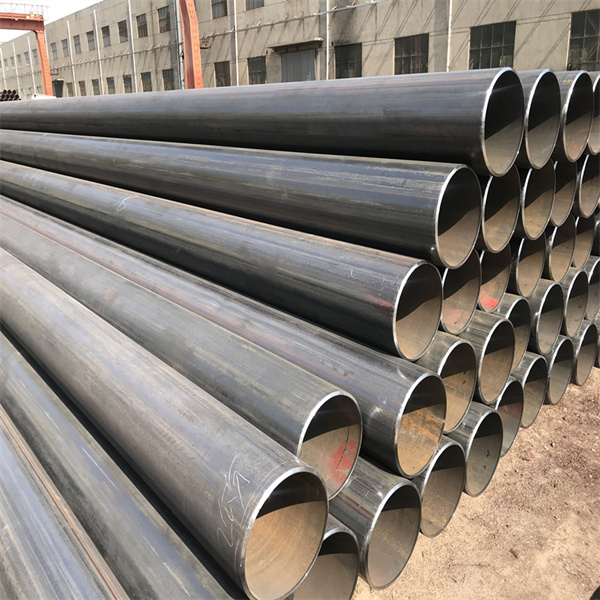

Bundling lan Sling

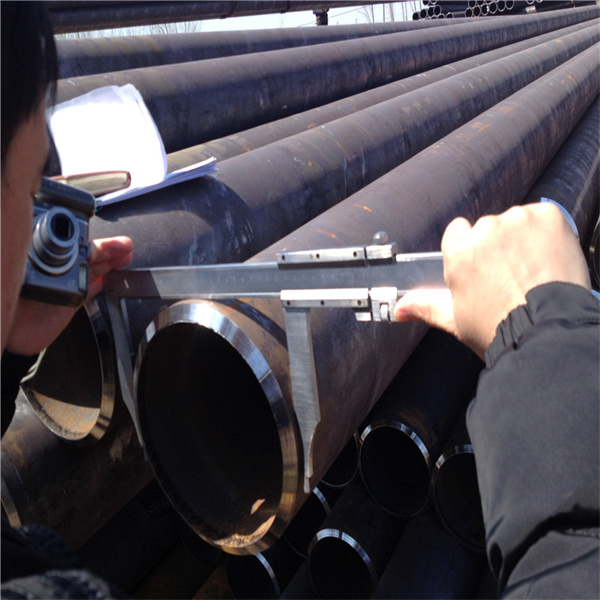

Inspeksi Diameter Metu

Inspeksi Kekandelan Tembok

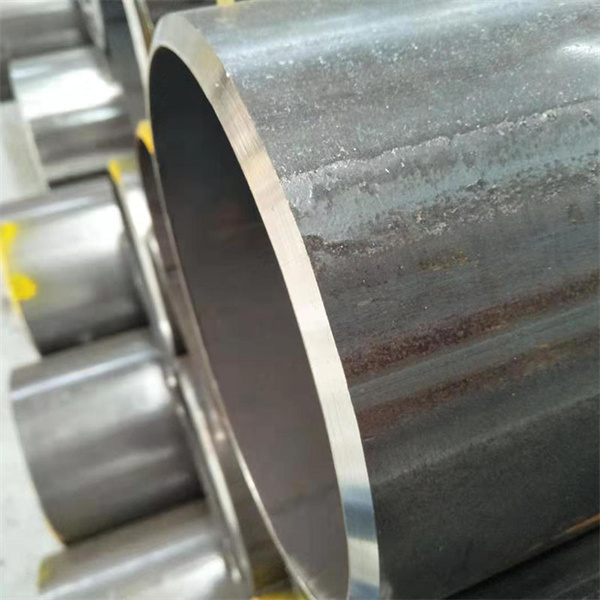

End Inspeksi

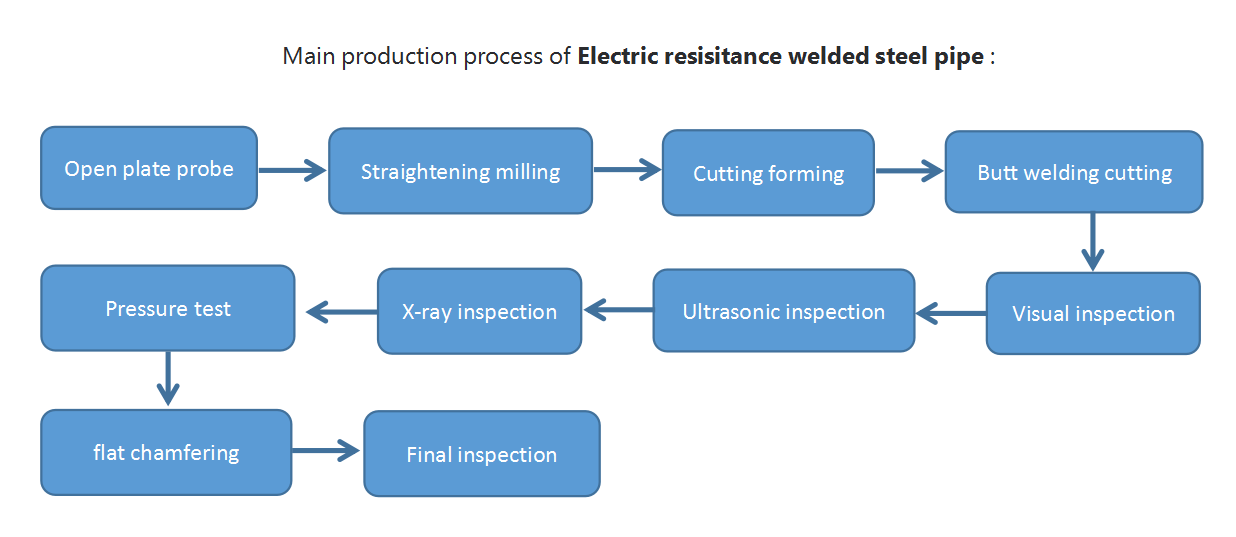

Ketahanan listrik dilas (Cara manufaktur yaiku welding resistance listrik utawa welding butt. Cara finish bisa dadi panas utawa rampung kadhemen. Pipa sing wis rampung adhem kudu anil sawise manufaktur.)

Toleransi OD lan WT

| Divisi | Toleransi ing OD | Toleransi ing WT | |

| Pipa Baja ERW | 10.5mm≤D≤48.6mm | ± 0,5 mm | -12,5% + Ora kasebut |

| D = 60,5 mm | ± 0,5 mm | ||

| D = 76,3 mm | ± 0,7 mm | ||

| 89.1mm≤D≤139.8mm | ± 0,8 mm | ||

| D = 165,2 mm | ± 0,8 mm | ||

| D 190,7 mm | ± 0,9 mm | ||

| D = 216,3 mm | ± 1,0 mm | ||

| D = 241,8 mm | ± 1,2 mm | ||

| D = 267,4 mm | ± 1,3 mm | ||

| D = 318,5 mm | ± 1,5 mm | ||

| 355.6mm≤D≤508.0mm | - | ||

| Pipa ERW Astm A252 Kab | Pipa ERW Bulat |

| Pipa Astm A53 B ERW | ERW Welded Steel Pipe |

| Pipa Baja ERW | Pipa Baja Hitam ERW |

| Pipa ERW Baja Ringan | Pipa Baja Karbon ERW |

ASTM A53 Gr.A & Gr. B Carbon ERW Steel Pipe Kanggo Suhu Dhuwur

EN10210 S355J2H STRUKTUR ERW STEEL PIPE

Layanan Tekanan Pipa Baja Karbon ERW JIS G3454

JIS G3452 Carbon ERW Steel Pipe Kanggo Piping Biasa

EN10219 S275J0H S275J2H / S275JRH STRUKTUR ERW Pipa Baja