JIS G 3454yaiku standar industri Jepang kanggo pipa baja karbon kanggo sistem tekanan kanthi suhu operasi maksimal 350°C. Standar kasebut kalebu rong kelas:STPG 370lanSTPG 410. Iki ditrapake kanggo resistensi listrik sing dilas (ERW) utawa pipa lancar kanthi diameter nominal 10,5 mm nganti 660,4 mm (yaiku 6A nganti 650A, utawa 1/8B nganti 26B).

JIS G 3454 Pipa baja kudu diprodhuksi nggunakake kombinasi metode manufaktur pipa baja lan metode finishing sing cocog ing tabel ing ngisor iki.

| Simbol kelas | Simbol saka proses manufaktur | ||

| Proses produksi pipa | Metode finishing | Klasifikasi zinc-coating | |

| STPG370 STPG410 | mulus: S Ketahanan listrik dilas: E | Rampung panas: H Dingin-rampung: C Minangka resistance listrik gandheng: G | Pipa ireng: pipa ora diwenehi lapisan seng Pipa putih: pipa diwenehi lapisan seng |

Secara khusus, ana limang cara manufaktur:

SH: Pipa baja mulus sing wis rampung panas;

SC: Pipa baja mulus kadhemen;

EH: Panas-rampung resistance listrik gandheng pipe baja;

EC: Cold-rampung resistance listrik gandheng pipa baja;

EG: Pipa baja las tahan listrik liyane saka pipa panas lan kadhemen.

Baja Botopminangka produsen lan pemasok pipa baja karbon sing dilas saka China, uga minangka stok pipa baja sing mulus. Yen sampeyan duwe kabutuhan, hubungi kita lan kita bakal menehi dhukungan teknis profesional gratis.

| Simbol kelas | C | Si | Mn | P | S |

| maks | maks | — | maks | maks | |

| STPG 370 | 0,25% | 0,35 % | 0,30-0,90% | 0,040 % | 0,040% |

| STPG 410 | 0,30% | 0,35 % | 0,30-1,00% | 0,040 % | 0,040% |

Ngidini tambahan unsur alloying liyane.

Kekuwatan Tensile, Titik Ngasilake utawa Stress Bukti, lan Elongasi

| Simbol saka kelas | Kekuwatan tensile | titik ngasilaken utawa bukti stress | Elongation min,% | |||

| Potongan uji tarik | ||||||

| No.11 utawa No.12 | No.5 | No.4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Arah tes tarik | ||||

| min | min | Paralel menyang sumbu pipa | Jejeg sumbu pipa | Paralel menyang sumbu pipa | Jejeg sumbu pipa | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Tes Flattening

Nalika jarak antarane rong piring tekan jarak sing ditemtokake H, ora ana cacat utawa retak ing permukaan pipa baja.

Kanggo tabung baja mulus: H = (1+e)t/(e + t/D);

Kanggo pipa baja ERW: H = 1/3 D (kanggo las) utawa H = 2/3 D (kanggo bagean tanpa las);

H: jarak antarane piring flattening (mm);

е: pancet individu ditetepake kanggo saben kelas saka pipe, 0,08 kanggo STPG 370, 0,07 kanggo STPG 410;

t: kekandelan tembok pipa (mm);

D: diameteripun njaba pipa (mm);

Tes Flattening ditrapake kanggo pipa baja kanthi diameter nominal luwih saka 40A (48.6mm).

Bendability

Bendability ditrapake kanggo pipa kanthi diameter nominal 40 A (48.6) utawa luwih cilik.

Pipa kudu mbengkongaken 90 ° ing radius 6 kaping diameteripun njaba. Tembok pipa kudu bebas saka cacat utawa retak.

Saben pipa baja kudu ngalami tes tekanan hidrostatik utawa tes non-destruktif.

Tes Hidrostatik

Njaga tekanan tartamtu paling sethithik 5 detik tanpa bocor.

Nilai tekanan ana hubungane karo jadwal No. saka pipa baja.

| Kekandelan tembok nominal | Nomer Jadwal: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Tekanan uji hidrolik minimal, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Test Non-destruktif

Yen inspeksi ultrasonik digunakake, kudu adhedhasar standar sing luwih ketat tinimbang sinyal kelas UD ing JIS G 0582.

Yen tes eddy saiki digunakake, kudu adhedhasar standar sing luwih ketat tinimbang sinyal kelas EY ing JIS G 0583.

| diameteripun nominal | Dhiameter njaba | Ketebalan tembok | Unit massa | Nomer jadwal (Sch No.) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

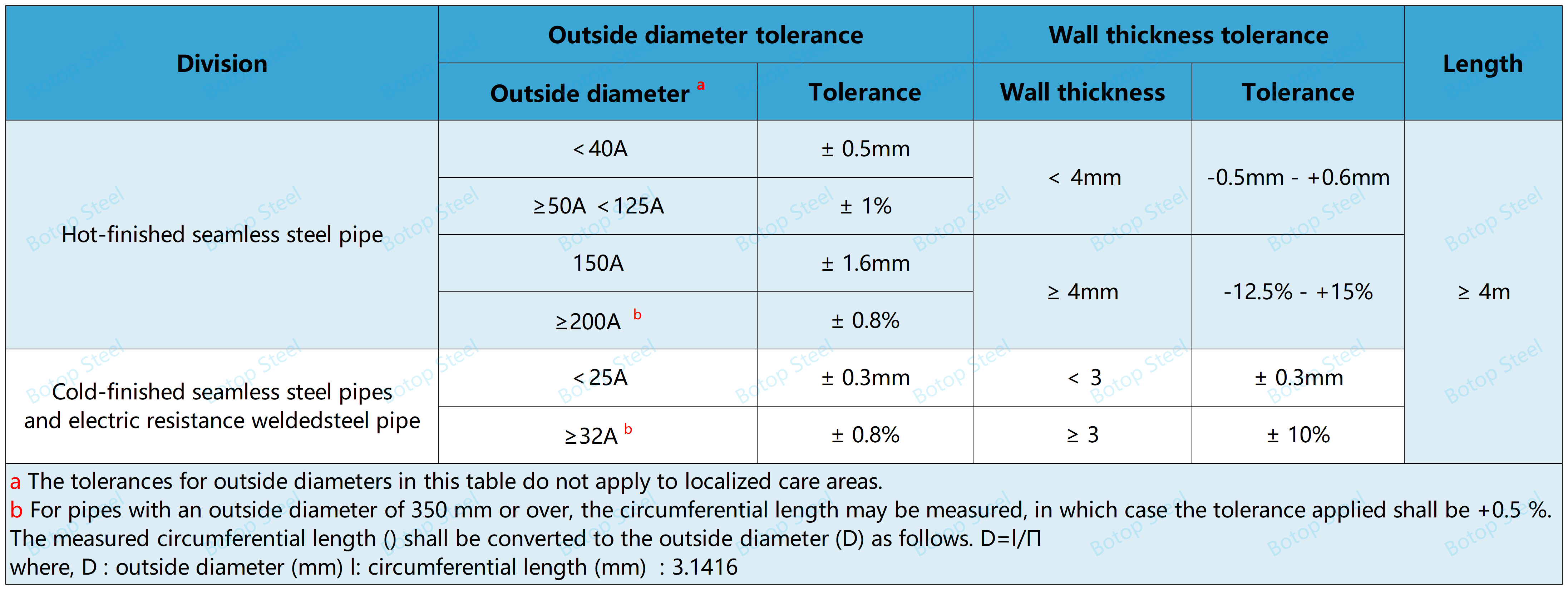

JIS G 3454 Toleransi kanggo diameter njaba, ketebalan tembok, eksentrisitas, lan dawa kudu nyukupi syarat ing ngisor iki.

Wiwit diadegaké ing 2014, Botop Steel wis dadi supplier anjog saka pipa baja karbon ing China Lor, dikenal kanggo layanan banget, produk kualitas, lan solusi lengkap.

Perusahaan nawakake macem-macem pipa baja karbon lan produk sing gegandhengan, kalebu pipa baja mulus, ERW, LSAW, lan SSAW, uga jajaran lengkap fitting pipa lan flanges.

Produk khusus uga kalebu paduan kelas dhuwur lan baja tahan karat austenitik, sing dirancang kanggo nyukupi panjaluk macem-macem proyek pipa.

Hubungi kita, kita bakal nyedhiyani sampeyan karo kualitas dhuwur, pipa baja standar karo layanan profesional lan efisien. Botop ngarepake ngladeni sampeyan.