| Descriptio | Norma | Gradus |

| Tubus Sine Sutura Chalybis Carbonis/Tubus sine suturis ex chalybe mixto | API 5L PSL1 et PSL2 | GR.B, X42, X46, X52, X60, X65, X70, et cetera. |

| ASTM A53 | Gradus A, Gradus B | |

| ASTM A106 | Gradus A, Gradus B, Gradus C | |

| API 5CT | J55, K55, N80, L80, P110, et cetera. | |

| ASTM A179 | A179 | |

| ASTM A192 | A192 | |

| ASTM A210/SA210 | GRADUS A-1, GRADUS C | |

| ASTM A252 | Gradus Primus, Gradus Secundus, Gradus Tertius | |

| BS EN10210 | S275JRH, S275J0H, S355J0H, S355J2H, et cetera. | |

| JIS G3454 | STPG370, STPG410 | |

| DIN2391 | ST35, ST37, ST37.4, ST45, ST52, ST52.4 | |

| DIN1629 | ST37, ST44, ST52 | |

| JIS G3456 | STPG370, STPG410, STPG480 | |

| ASTM A213 | GR.T11, GR.T12, GR.T13 | |

| ASTM A519 | GR.1020, GR.1026, GR.1045, GR.4130, et cetera. | |

| ASTM A335 | GR.P9, GR.P11, GR.P5, GR.P22, GR.P91, et cetera. | |

| ASTM A333 | GR.1, GR.3, GR.4, GR.6, et cetera |

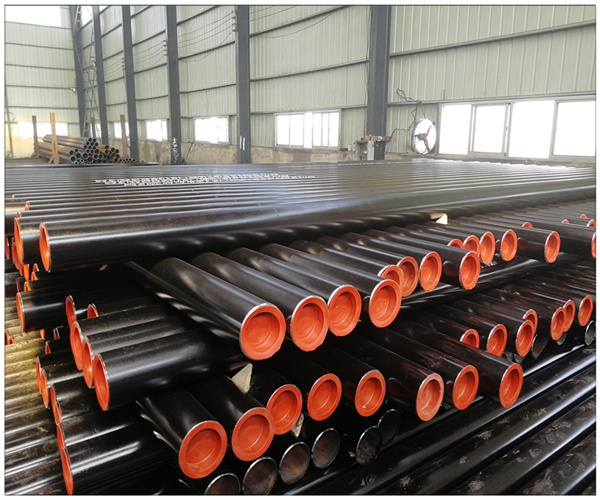

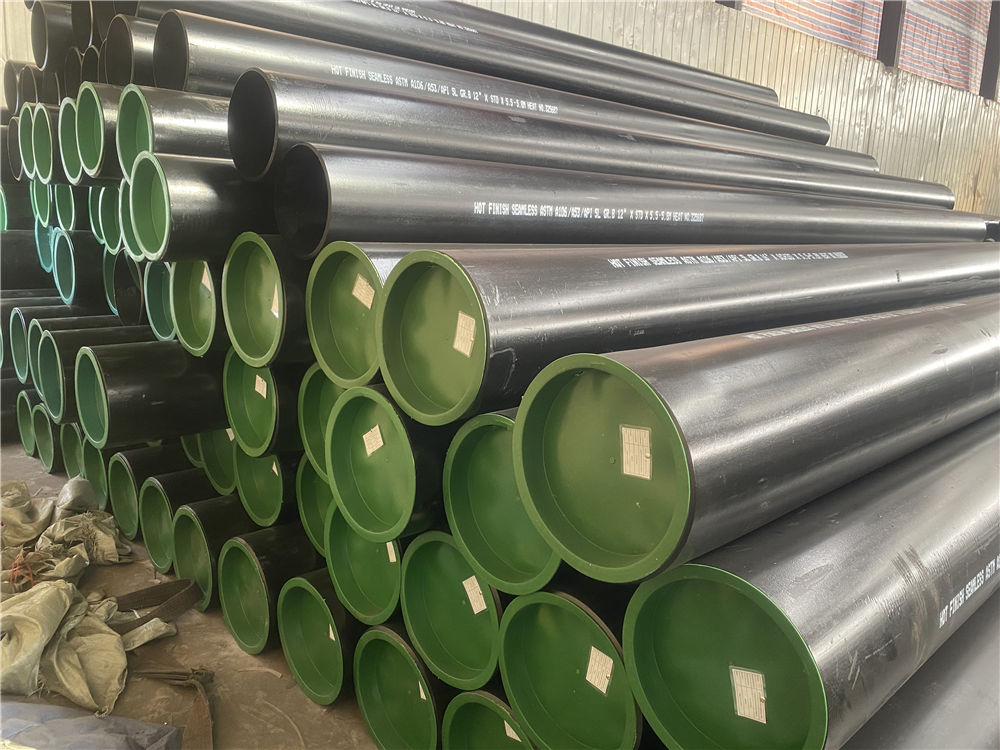

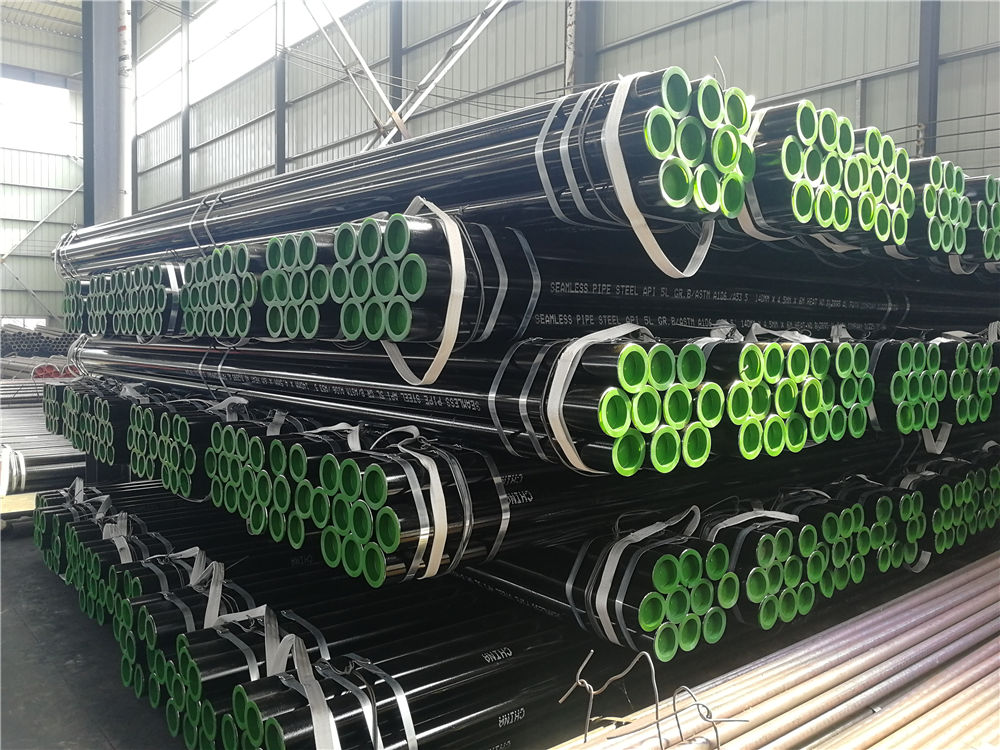

Botop Steel est princeps fabricator et venditor tuborum ferreorum et tuborum in Sinis. Tubos circulares ferreos carbonicos sine suturis ad usus liquidorum et petrolei, magnitudinibus ab 10 mm ad 660 mm et crassitudinibus ab 1 mm ad 100 mm, in promptu habemus et suppeditamus. Tubos ferreos carbonicos LSAW stricte secundum normas internationales, ut ASTM, API et DIN, fabricamus. Plus quam 8000 tonnas tuborum ferreorum sine suturis in promptu menstruo habemus; plerumque merces statim tradere possumus. Attamen in casibus specialibus, si in promptu...fistulae chalybis carbonisSi non praesto est, merces brevissimo tempore per officinas locales vel importationem tradere possumus.

Omnes nostrifistulae ferreaeEt producta tubularia cum testimoniis probationum specificis 3.1, secundum EN 10204, praebentur. Certificatio secundum 3.2 tempore ordinationis conveniri potest. Inspectio a tertia parte acceptatur (BV, SGS, etc.).

Numerus sufficiens imperfectionum superficiei visualis ad

fiducia opportuna praebere necessaria est.

Vitium intra tempus removendum vel resecandum est

Limites requisitorum longitudinis. Tubus perfectus

rationabiliter recta erit.

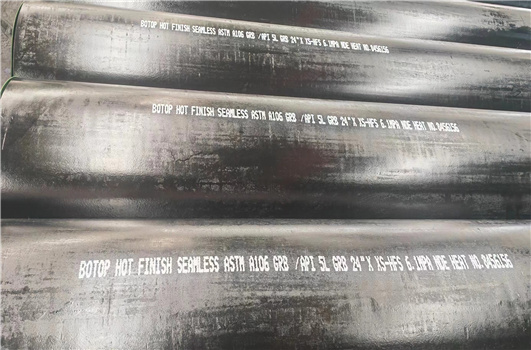

Nomen vel nota fabricatoris

Numerus specificationis (annus-dies vel requisitus)

Magnitudo (OD, WT, longitudo)

Gradus (A vel B)

Genus tubi (F, E, vel S)

Pressio probationis (fistula ferrea sine suturistantum)

Numerus Caloris

Quaevis informatio addita in mandato emptionis specificata.

Gradus et Compositio Chemica (%)

| Gradus | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Cu≤ | Mo≤ | Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Proprietates Mechanicae:

|

|

|

| A/C |

|

| A | ≥330 | ≥205 | 20 | Recoctum |

| B | ≥415 | ≥240 | 20 | Recoctum |

| C | ≥485 | ≥275 | 20 | Recoctum |

Inspectio Diametri Extra

Inspectio Crassitudinis Muri

Finis Inspectionis

Inspectio Rectitudinis

Inspectio UT

Inspectio Aspectus

Beveling Extremitatis Tubi

Opercula plastica

Pictura Nigra cum Notatione

Involucrum

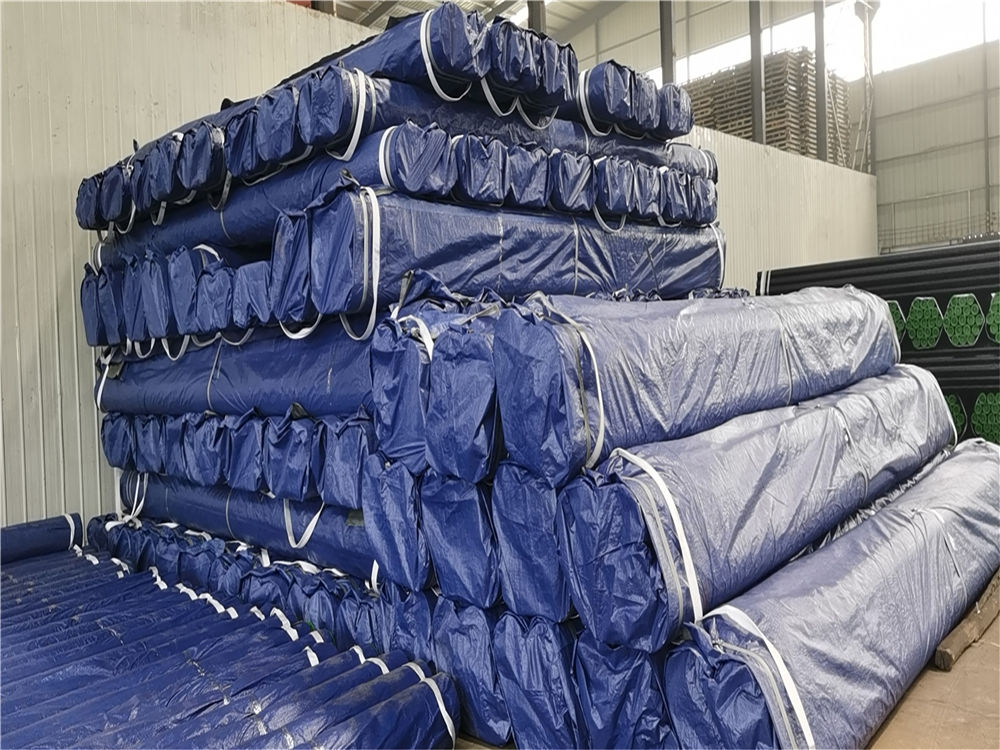

Fasciculatio et Funda

Aspectus Sarcinae

Navis Tuborum Sinuum ad Quatar

Navis fistularum sine suturis ad Pakistan

Navis fistularum sine suturis ad Africam Australem

Navis fistularum sine suturis ad Aequatoriam