ASTM A252: Standard Specification for iuncta et seamless Steel Pipe Pile.

Haec specificatio tegit nominalem (medium) muri ferrei fistulae cylindricae figurae et applicat strues fistularum in quibus cylindrus ferreus agit ut membrum onus permanente portans, vel sicut concha ad formandum strues concretas in loco.Fistulae strues gignuntur ut producta et iuncta et inconsutilis.

Navigation Buttons

ASTM A252 Grade

ASTM A252 grades collocantur ut Grade I Grade II etGradus 3.

Rudis Material Processus Productio

Ferrum unum vel plures ex his processibus fiet: focis apertis, basic-oxygeni, vel fornax electrica.

Materiae et Fabricación

Sublicae ab inconsutilis, electricae resistentiae iuncta, ictui iuncta, vel processu fusione iuncta fient.

Tibiae commissurae iunctae strues longitudinales, sinum helicum vel helicum.

ASTM A252 Chemical Composition

Methodus experimentalis: ASTM A751.

Ferrum non plus quam 0.050% phosphoris continebit.Hoc est, quia gradus phosphorus summus potest efficere ferrum ut fragilis fiat ad low temperaturas, reducendo duritiem materiae.

ASTM A252 specificatio limitata requisita pro compositione chemica habet: hoc est, quia ASTM A252 principaliter applicatur ad applicationes structurales, praesertim ut elementa onera portantes, ubi proprietates physicae (ut vires, distrahentes vires et elongationem cedunt) potiores sunt quam compositio chemica. .Hae physicae proprietates perfici possunt per processus curationis et fabricationis caloris proprias absque stricta moderatione chemicae compositionis praeter phosphorum.

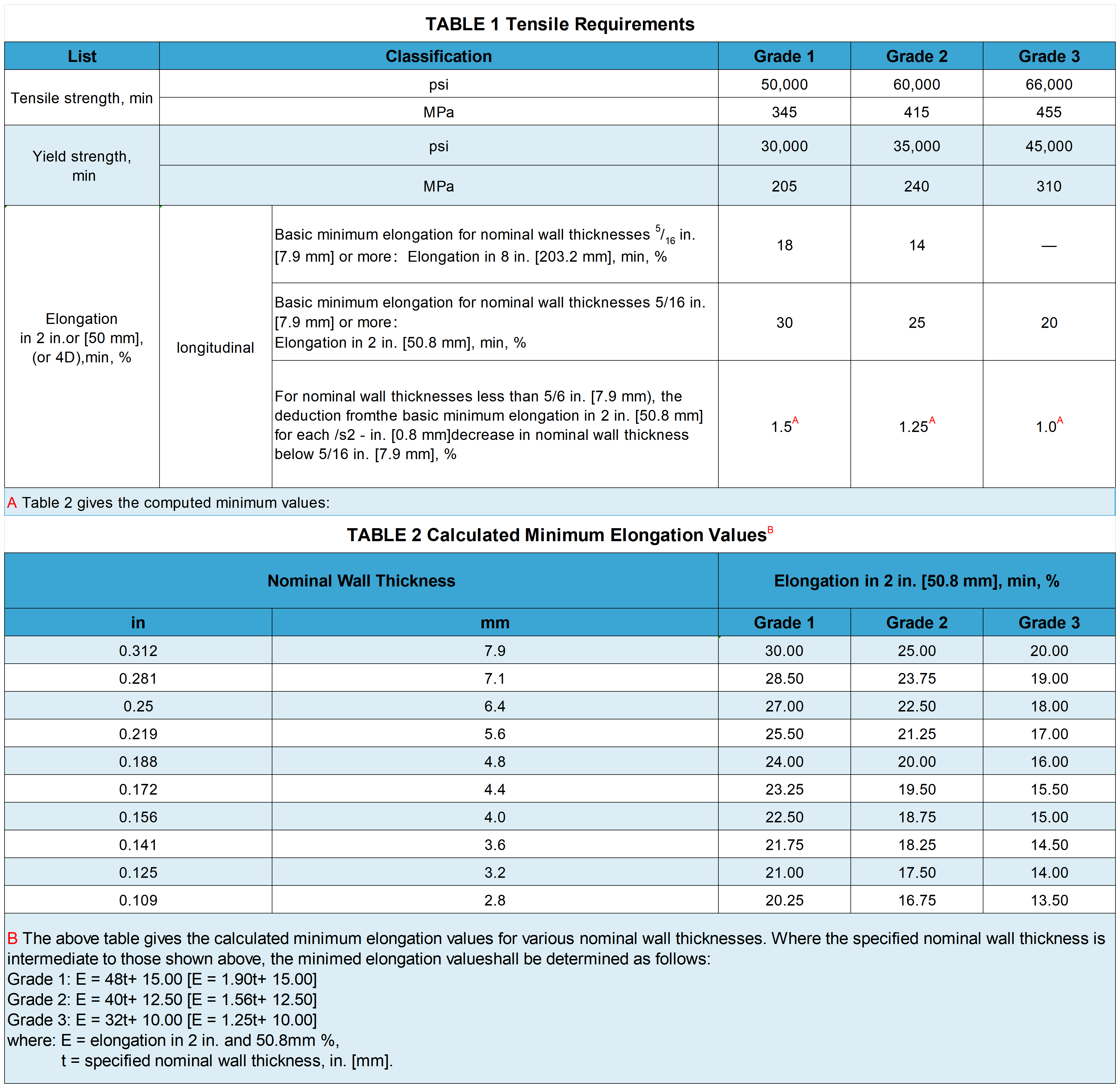

ASTM A252 Tensile Requirements

Methodus experimentalis: ASTM A370.

Hydrostatic Pressura Test

Ratio, quam ASTM A52 non declarat probationem hydraulicam, praesertim ob applicationes notarum et consiliorum postulatorum harum fistularum.

Ad strues ferri fistulae specificationis ASTM A252, propositum principale est onera axialis sustinere, non pressuras internas.Hoc discrepat ut limbis ad translationem liquorum vel vaporum, quales sunt sub API 5L specificatione, quae subici debet directo pressioni internae ut eius emissiones et vires in tuto collocet.

Dimensiva tolerantiae

| tolerances dimensiva | ||

| List | sort | scope |

| Pondus | Theoretical Pondus | 95%-125% |

| Diameter | Specificatur extra Diameter | ±1% |

| Crassitudo | certum nomen muri crassitudine | min 87.5% |

| Longitudo | Una temere longitudines | 16 ad 25 ft [4.88 ad 7.62 m] |

| Duplex temere longitudines | supra 25 ft [7.62 m] cum minimum mediocris of 35 ft [10.67 m] | |

| Uniform longitudines | longitudo certa cum licita variatione ± 1 in. | |

| Beveled | Tibiae strues planis finibus praebebuntur; Fines designantur ut beveled | 30°- 35° |

Pipe pondus Charts

Si plus velis discere de thepondus chartis et schedulain vexillo;preme hic!

| Extra Diameter | Nominal Wall Crassitudo | Pondus per Unit Longitudines | |||

| IN | MM | IN | MM | IN | MM |

| 6 | 152.4 | 0.134 | 3.40 | 8.40 | 12.50 |

| 6 | 152.4 | 0.141 | 3.58 | 8.83 | 13.10 |

| 6 | 152.4 | 0.149 | 3.96 | 9.75 | 14.50 |

| 6 | 152.4 | 0.164 | 4.17 | 10.23 | 15.20 |

| 6 | 152.4 | 0.172 | 4.37 | 10.72 | 16.00 |

| 8 | 203.2 | 0.141 | 3.58 | 11.85 | 17.60 |

| 8 | 203.2 | 0.172 | 4.37 | 14.39 | 21.40 |

| 8 5/8 | 2191 | 0.109 | 2.77 | 9.92 | 14.80 |

| 8 5/8 | 2191 | 0.141 | 3.58 | 12.79 | 19.00 |

| 8 5/8 | 2191 | 0.172 | 4.37 | 15.54 | 23.10 |

| 8 5/8 | 2191 | 0.188 | 4.78 | 16.96 | 25.30 |

| 8 5/8 | 2191 | 0.203 | 5.16 | 18.28 | 27.20 |

| 8 5/8 | 2191 | 0.219 | 5.56 | 19.68 | 29.30 |

| 8 5/8 | 2191 | 0.250 | 6.35 | 22.38 | 33.30 |

| 8 5/8 | 2191 | 0.277 | 7.04 | 24.72 | 36.80 |

| 8 5/8 | 2191 | 0.312 | 7.92 | 27.73 | 41.20 |

| 8 5/8 | 2191 | 0.322 | 8.18 | 28.58 | 42.50 |

| 8 5/8 | 2191 | 0.344 | 8.74 | 30.45 | 45.30 |

| 8 5/8 | 2191 | 0.375 | 9.53 | 33.07 | 49.30 |

| 8 5/8 | 2191 | 0.438 | 11.13 | 38.33 | 57.10 |

| 8 5/8 | 2191 | 0.500 | 12.70 | 43.43 | 64.60 |

| 10 | 254.0 | 0.109 | 2.77 | 11.53 | 17.20 |

| 10 | 254.0 | 0.120 | 3.05 | 12.67 | 18.90 |

| 10 | 254.0 | 0.134 | 3.40 | 14.13 | 21.00 |

| 10 | 254.0 | 0.141 | 3.58 | 14.86 | 22.10 |

| 10 | 254.0 | 0.150 | 3.81 | 15.79 | 23.50 |

| 10 | 254.0 | 0.164 | 4.17 | 17.24 | 25.70 |

| 10 | 254.0 | 0.172 | 4.37 | 18.07 | 26.90 |

| 10 | 254.0 | 0.179 | 4.55 | 18.79 | 28.00 |

| 10 | 254.0 | 0.188 | 4.78 | 19.72 | 29.40 |

| 10 | 254.0 | 0.203 | 5.16 | 21.26 | 31.70 |

| 10 | 254.0 | 0.219 | 5.56 | 22.90 | 34.10 |

| 10 | 254.0 | 0.230 | 5.84 | 24.02 | 35.70 |

| 10 | 254.0 | 0.250 | 6.35 | 26.06 | 38.80 |

| 10 3/4 | 273.1 | 0.109 | 2.77 | 12.40 | 18.50 |

| 10 3/4 | 273.1 | 0.120 | 3.05 | 13.64 | 20.30 |

| 10 3/4 | 273.1 | 0.134 | 3.40 | 15.21 | 22.60 |

| 10 3/4 | 273.1 | 0.141 | 3.58 | 15.99 | 23.80 |

| 10 3/4 | 273.1 | 0.150 | 3.81 | 17.00 | 25.30 |

| 10 3/4 | 273.1 | 0.164 | 4.17 | 18.56 | 27.70 |

| 10 3/4 | 273.1 | 0.172 | 4.37 | 19.45 | 29.00 |

| 10 3/4 | 273.1 | 0.179 | 4.55 | 20.23 | 30.10 |

| 10 3/4 | 273.1 | 0.188 | 4.78 | 21.23 | 31.60 |

| 10 3/4 | 273.1 | 0.203 | 5.16 | 22.89 | 34.10 |

| 10 3/4 | 273.1 | 0.219 | 5.56 | 24.65 | 36.70 |

| 10 3/4 | 273.1 | 0.230 | 5.84 | 25.87 | 38.50 |

| 10 3/4 | 273.1 | 0.250 | 6.35 | 28.06 | 41.80 |

| 10 3/4 | 273.1 | 0.279 | 7.09 | 31.23 | 46.50 |

| 10 3/4 | 273.1 | 0.307 | 7.80 | 34.27 | 51.00 |

| 10 3/4 | 273.1 | 0.344 | 8.74 | 38.27 | 57.00 |

| 10 3/4 | 273.1 | 0.365 | 9.27 | 40.52 | 60.30 |

| 10 3/4 | 273.1 | 0.438 | 11.13 | 48.28 | 71.90 |

| 10 3/4 | 273.1 | 0.500 | 12.70 | 54.79 | 81.60 |

| 12 | 304.8 | 0.134 | 3.40 | 17.00 | 25.30 |

| 12 | 304.8 | 0.141 | 3.58 | 17.87 | 26.60 |

| 12 | 304.8 | 0.150 | 3.81 | 19.00 | 28.30 |

| 12 | 304.8 | 0.164 | 4.17 | 20.75 | 30.90 |

| 12 | 304.8 | 0.172 | 4.37 | 21.75 | 32.40 |

| 12 | 304.8 | 0.179 | 4.55 | 22.62 | 33.70 |

| 12 | 304.8 | 0.188 | 4.78 | 23.74 | 35.40 |

| 12 | 304.8 | 0.203 | 5.16 | 25.60 | 38.10 |

| 12 | 304.8 | 0.219 | 5.56 | 27.58 | 41.00 |

| 12 | 304.8 | 0.230 | 5.84 | 28.94 | 43.10 |

| 12 | 304.8 | 0.250 | 6.35 | 31.40 | 46.70 |

| 12 | 304.8 | 0.281 | 7.14 | 35.20 | 52.40 |

| 12 | 304.8 | 0.312 | 7.92 | 38.98 | 58.00 |

| 12 3/4 | 323.9 | 0.109 | 2.77 | 14.73 | 21.90 |

| 12 3/4 | 323.9 | 0.134 | 3.40 | 18.07 | 26.90 |

| 12 3/4 | 323.9 | 0.141 | 3.58 | 19.01 | 28.30 |

| 12 3/4 | 323.9 | 0.150 | 3.81 | 20.20 | 30.10 |

| 12 3/4 | 323.9 | 0.164 | 4.17 | 22.07 | 32.90 |

| 12 3/4 | 323.9 | 0.172 | 4.37 | 23.13 | 34.40 |

| 12 3/4 | 323.9 | 0.179 | 4.55 | 24.05 | 35.80 |

| 12 3/4 | 323.9 | 0.188 | 4.78 | 25.25 | 37.60 |

| 12 3/4 | 323.9 | 0.203 | 5.16 | 27.23 | 40.60 |

| 12 3/4 | 323.9 | 0.219 | 5.56 | 29.34 | 43.70 |

| 12 3/4 | 323.9 | 0.230 | 5.84 | 30.78 | 45.80 |

| 12 3/4 | 323.9 | 0.250 | 6.35 | 33.41 | 49.70 |

| 12 3/4 | 323.9 | 0.281 | 7.14 | 37.46 | 55.80 |

| 12 3/4 | 323.9 | 0.312 | 7.93 | 41.48 | 61.80 |

| 12 3/4 | 323.9 | 0.330 | 8.38 | 43.81 | 65.20 |

| 12 3/4 | 323.9 | 0.344 | 8.74 | 45.62 | 67.90 |

| 12 3/4 | 323.9 | 0.375 | 9.53 | 49.61 | 73.90 |

| 12 3/4 | 323.9 | 0.438 | 11.13 | 57.65 | 85.80 |

| 12 3/4 | 323.9 | 0.500 | 12.70 | 65.48 | 97.50 |

| 14 | 355.6 | 0.134 | 3.40 | 19.86 | 29.50 |

| 14 | 355.6 | 0.141 | 3.58 | 20.89 | 31.10 |

| 14 | 355.6 | 0.150 | 3.81 | 22.21 | 33.10 |

| 14 | 355.6 | 0.164 | 4.17 | 24.26 | 36.10 |

| 14 | 355.6 | 0.172 | 4.37 | 25.43 | 37.90 |

| 14 | 355.6 | 0.179 | 4.55 | 26.45 | 39.40 |

| 14 | 355.6 | 0.188 | 4.78 | 27.76 | 41.40 |

| 14 | 355.6 | 0.203 | 5.16 | 29.94 | 44.60 |

| 14 | 355.6 | 0.219 | 5.56 | 32.26 | 48.00 |

| 14 | 355.6 | 0.230 | 5.84 | 33.86 | 50.40 |

| 14 | 355.6 | 0.250 | 6.35 | 36.75 | 54.70 |

| 14 | 355.6 | 0.281 | 7.14 | 41.21 | 61.40 |

| 14 | 355.6 | 0.312 | 7.93 | 45.65 | 68.00 |

| 14 | 355.6 | 0.344 | 8.87 | 50.22 | 74.80 |

| 14 | 355.6 | 0.375 | 9.53 | 54.62 | 81.30 |

| 14 | 355.6 | 0.438 | 11.13 | 63.50 | 94.60 |

| 14 | 355.6 | 0.469 | 11.91 | 67.84 | 100.90 |

| 14 | 355.6 | 0.500 | 12.70 | 72.16 | 107.50 |

| 16 | 406.4 | 0.134 | 3.40 | 22.73 | 33.80 |

| 16 | 406.4 | 0.141 | 3.58 | 23.90 | 35.60 |

| 16 | 406.4 | 0.150 | 3.81 | 25.42 | 37.80 |

| 16 | 406.4 | 0.164 | 4.17 | 27.76 | 41.40 |

| 16 | 406.4 | 0.172 | 4.37 | 29.10 | 43.30 |

| 16 | 406.4 | 0.179 | 4.55 | 30.27 | 45.10 |

| 16 | 406.4 | 0.188 | 4.78 | 31.78 | 47.30 |

| 16 | 406.4 | 0.203 | 5.16 | 34.28 | 51.10 |

| 16 | 406.4 | 0.219 | 5.56 | 36.95 | 55.00 |

| 16 | 406.4 | 0.230 | 5.84 | 38.77 | 57.70 |

| 16 | 406.4 | 0.250 | 6.35 | 42.09 | 62.60 |

| 16 | 406.4 | 0.281 | 7.14 | 47.22 | 70.30 |

| 16 | 406.4 | 0.312 | 7.93 | 52.32 | 77.90 |

| 16 | 406.4 | 0.344 | 8.87 | 57.57 | 87.00 |

| 16 | 406.4 | 0.375 | 9.53 | 62.64 | 93.50 |

| 16 | 406.4 | 0.438 | 11.13 | 72.86 | 108.50 |

| 16 | 406.4 | 0.469 | 11.91 | 77.87 | 115.90 |

| 16 | 406.4 | 0.500 | 12.70 | 82.85 | 123.30 |

| 18 | 457.2 | 0.141 | 3.58 | 26.92 | 40.00 |

| 18 | 457.2 | 0.172 | 4.37 | 32.78 | 48.80 |

| 18 | 457.2 | 0.188 | 4.78 | 35.80 | 53.30 |

| 18 | 457.2 | 0.219 | 5.56 | 41.63 | 61.90 |

| 18 | 457.2 | 0.230 | 5.84 | 43.69 | 65.00 |

| 18 | 457.2 | 0.250 | 6.35 | 47.44 | 70.60 |

| 18 | 457.2 | 0.281 | 7.14 | 53.23 | 79.20 |

| 18 | 457.2 | 0.312 | 7.93 | 58.99 | 87.90 |

| 18 | 457.2 | 0.344 | 8.74 | 64.93 | 96.70 |

| 18 | 457.2 | 0.375 | 9.53 | 70.65 | 105.20 |

| 18 | 457.2 | 0.438 | 11.13 | 82.23 | 122.40 |

| 18 | 457.2 | 0.469 | 11.91 | 87.89 | 130.80 |

| 18 | 457.2 | 0.500 | 12.70 | 93.54 | 139.20 |

| 20 | 508.0 | 0.141 | 3.58 | 29.93 | 44.50 |

| 20 | 508.0 | 0.172 | 4.37 | 36.46 | 54.30 |

| 20 | 508.0 | 0.188 | 4.78 | 39.82 | 59.30 |

| 20 | 508.0 | 0.219 | 5.56 | 46.31 | 68.90 |

| 20 | 508.0 | 0.250 | 6.35 | 52.78 | 78.60 |

| 20 | 508.0 | 0.281 | 7.14 | 59.23 | 88.20 |

| 20 | 508.0 | 0.312 | 7.93 | 65.66 | 97.80 |

| 20 | 508.0 | 0.344 | 8.87 | 72.28 | 107.60 |

| 20 | 508.0 | 0.375 | 9.53 | 78.67 | 117.20 |

| 20 | 508.0 | 0.438 | 11.13 | 91.59 | 136.40 |

| 20 | 508.0 | 0.469 | 11.91 | 97.92 | 145.70 |

| 20 | 508.0 | 0.500 | 12.70 | 104.23 | 155.10 |

| 22 | 558.8 | 0.172 | 4.37 | 40.13 | 59.80 |

| 22 | 558.8 | 0.188 | 4.78 | 43.84 | 65.30 |

| 22 | 558.8 | 0.219 | 5.56 | 50.99 | 75.90 |

| 22 | 558.8 | 0.250 | 6.35 | 58.13 | 86.50 |

| 22 | 558.8 | 0.281 | 7.14 | 65.24 | 97.10 |

| 22 | 558.8 | 0.312 | 7.93 | 72.34 | 107.70 |

| 22 | 558.8 | 0.375 | 9.53 | 86.69 | 129.10 |

| 22 | 558.8 | 0.438 | 11.13 | 100.96 | 150.30 |

| 22 | 558.8 | 0.469 | 11.91 | 107.95 | 160.60 |

| 22 | 558.8 | 0.500 | 12.70 | 114.92 | 171.00 |

| 24 | 609.6 | 0.172 | 4.37 | 43.81 | 65.20 |

| 24 | 609.6 | 0.188 | 4.78 | 47.86 | 71.30 |

| 24 | 609.6 | 0.219 | 5.56 | 55.67 | 82.80 |

| 24 | 609.6 | 0.250 | 6.35 | 63.47 | 94.50 |

| 24 | 609.6 | 0.281 | 7.14 | 71.25 | 106.10 |

| 24 | 609.6 | 0.312 | 7.93 | 79.01 | 117.70 |

| 24 | 609.6 | 0.375 | 9.53 | 94.71 | 141.00 |

| 24 | 609.6 | 0.438 | 11.13 | 110.32 | 164.30 |

| 24 | 609.6 | 0.469 | 11.91 | 117.98 | 175.60 |

| 24 | 609.6 | 0.500 | 12.70 | 125.62 | 186.90 |

Pipa Surface Defectus

1. Superficies imperfectiones profunditatem habente non excedentem 12.5% muri nominalis determinati crassitudinis acceptabile erit.

Licebit harum imperfectionum altitudinem molendo vel interpositione condere.

2. Superficies imperfectiones altae in excessu 12.5% muri nominalis specificati crassitudinis censentur defectus esse.

Licebit defectibus non profundioribus quam 33,3% ex crassitudine parietis nominalis determinati glutino reparari, dummodo defectus ante glutino totaliter tollatur.

Appliance

ASTM A252 Grade 1 Applications

Incepta leviter onusta in generalibus terrae condicionibus, ut fundamenta pro parvis aedificiis vel structuris.

Fundationes pro structuris temporariis, ut sunt subsidia vel pontes temporales construendi.

Environmentales remediationes inceptas in solo bono condiciones ubi nimiae passiones non requiruntur.

ASTM A252 Grade 2 Applications:

Incepta machinalis cum modica oneratione requiruntur, in quibus fundamenta pro multi-fabularum aedificiorum vel facultatum facultates.

Pontes, columpna, et incepta maritima in condicionibus terrae mediocriter duris.

In conditionibus uti cum aliquo periculo corrosionis chemicae vel exesis.

ASTM A252 Grade 3 Applications:

Incepta critica sub magni ponderis, terrae complexu conditiones ut magni pontes, aedificia alta surgunt, magnas facultates industriales.

Ambitus summus periculo, ut structurae vehementi exesi, corrosioni chemicae vel tempestatum extremae obnoxiae sunt.

Magna extrahendi incepta, ut fundamenta aquarum profundorum getticiarum, magnae aquae apertiones, et oleum et suggesta gasi.

Signa Related

ASTM A252 gradus 1

EN.

BS EN 10219 S235JRH - fistulae et tibiae ad fabricam fabricam fabricatae et sesutilem chalybem, frigidum formatae.

CSA G40.21 300W - Ferri qualitas structuralis.

AS/NZS 1163 C250L0

GB/T 3091 Q235B - Tibia ferri iuncta pro low-pressione fluidi translationis.

JIS G3444 STK400 - Tibiae carbonis ferreae ad usum structurarum.

IS 4923 YST 210 - Tibiae ferreae cavum ad fabricas pertinentes.

GOST 10704-91 - Tibiae ferreae electrice conflati.

ISO 11960 - Ferro tibiae pro industria oleum et gas.

ASTM A36 - Structural Carbon Steel pro Applications Non Standard.

ASTM A252 Grade 2

EN 10219 S275J0H - Organum chalybeum structuris frigidum conflatum conflatum.

CSA G40.21 350W - Ferri qualitas structuralis.

AS/NZS 1163 C350L0 - Organum chalybis fabricatum Frigidum.

GB/T 3091 Q345B - Tibia ferrea iuncta pro low-pressione fluidi translationis.

JIS G3444 STK490 - Tibiae ferreae carbonis ad usum structurarum.

IS 4923 YST 310 - Caule Steel Pipe pro structuris propositis.

ASTM A252 Grade 3

EN 10219 S355J2H - Fabricae ferreae tibiae frigido-formatae iunctae.

CSA G40.21 350W - Qualitas structuralis chalybs, figurae specificae Gradu 3 requisita occurrere possunt.

AS/NZS 1163 C450L0 - Tubulae et tibiae ferreae fabricatae frigidae formatae, gradus altitudinis in serie virium.

GB/T 3091 Q460C - Tibia ferrea iuncta pro low-pressione fluidi translationis ad applicationes ad vires altiores requirendas.

JIS G3444 STK540 - Tibia carbonis chalybea ad usum structurarum, in promptu vi optiones altae.

Our Related Products

Botop Steel est Sinarum Professional iuncta Carbon Ferro Pipes Fabrica & Suppliers super 16 Annos cum 8000+ Tons Seamless Linea pipe in Stock Singulis Mensibus.Praebebimus tibi qualitatem et low-pretium chalybeis fistulae productorum, si nobis placere debes, amplis fistulae ferreae solutiones tibi dabimus.

tags: astm a252.commeatus, fabrica, officinas, stockistae, manipulos, Lupum, emptum, pretium, scntentia, mole, venale, sumptus.

Post tempus: Mar-29-2024