“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Leading Manufacturer for 219-2020 mm Large Size Spiral Welded Black Carbon Steel Pipe SSAW, We sincerely hope to establish some satisfactory relationships with you in the near future. We will keep you informed of our progress and look forward to building steady business relations with you.

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China Carbon Welded Steel Pipe and Mild Steel SSAW Pipe, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal solutions. In his way, We can enrich our life style and promote a better living environment for the global community.

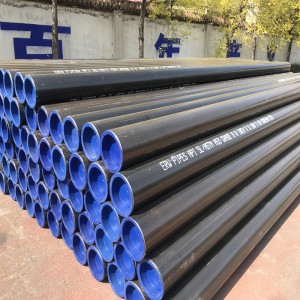

By fusion welded process.

Manufacture: Carbon SSAW Steel Pipe.

Size: O.D.: 219~2500mm W.T.: 6~30mm.

Grade: Gr1, Gr2, Gr3.

Length: 6M or specified length as required.

Ends: Plain End, Beveled End.

The steel shall contain no more than 0.050 % phosphorous.

|

Tensile Requirements |

|||

|

Grade 1 |

Grade 2 |

Grade 3 |

|

| Tensile strength, min, psi (MPa) |

50 000 (345) |

60 000 (415) |

66 000 (455) |

| Yield point or yield strength, min, psi(MPa) |

30 000 (205) |

35 000 (240) |

45 000 (310) |

| Basic minimum elongation for nominal wall thicknesses %6 in. (7.9 mm) or more: | |||

| Elongation in 8 in. (203.2 mm), min, % |

18 |

14 |

… |

| Elongation in 2 in. (50.8 mm), min, % |

30 |

25 |

20 |

| For nominal wall thicknesses less than %6 in. (7.9 mm), the deduction from the basic minimum elongation in 2 in. (50.08 mm) for each Vzi – in. (0.8 mm) decrease in nominal wall thickness below %6 in. (7.9 mm), in percentage points |

1.5A |

1.25A |

1.0A… |

| Calculated Minimum Elongation Values | ||||

|

Nominal Wall Thickness |

Elongation in 2 in. (50.8 mm), min, % |

|||

|

in. |

mm. |

Grade 1 |

Grade 2 |

Grade 3 |

|

5/16 (0.312) |

7.9 |

30.00 |

25.00 |

20.00 |

|

9/32 (0.281) |

7.1 |

28.50 |

23.75 |

19.00 |

|

1/4 (0.25) |

6.4 |

27.00 |

22.50 |

18.00 |

|

7/32 (0.219) |

5.6 |

25.50 |

21.25 |

17.00 |

|

3/16 (0.188) |

4.8 |

24.00 |

20.00 |

26.00 |

|

11/6 (0.172) |

4.4 |

23.25 |

19.50 |

15.50 |

|

5/32 (0.156) |

4.0 |

22.50 |

18.75 |

15.00 |

|

9/64 (0.141) |

3.6 |

21.75 |

18.25 |

14.50 |

|

1/8 (0.125) |

3.2 |

21.00 |

17.50 |

14.00 |

|

7/64 (0.109) |

2.8 |

20.25 |

16.75 |

13.50 |

| The above table gives the calculated minimum elongation values for various nominal wall thicknesses. Where the specified nominal wall thickness is intermediate to those shown above, the minimum elongation value shall be determined as follows: | ||||

| Grade | ||||

| 1. E=48t+15.00 | ||||

| 2. E=40t+12.50 | ||||

| 3. E=32t+10.00 | ||||

| where: | ||||

| E = elongation in 2 in., %, and | ||||

| T = specified nominal wall thickness, in. | ||||

Outside Diameter

The outside diameter of pipe piles shall not vary more than ±1% from the specified outside diameter.

Wall thickness

The wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness.

Lengths

Pipe piles shall be furnished in single random lengths, double random lengths, or in uniform lengths as specified in the purchase order, in accordance with the following limits:

a.Single random lengths: 16 to 25ft (4.88 to 7.62mm), inch

b.Double random lengths: Over 25ft (7.62m) with a minimum average of 35ft (10.67m)

c.Uniform lengths: length as specified with a permissible variation of ±1 in.

Weight

Each length of pipe pile shall be weighed separately and its weight shall not vary more than 15% over or 5% under its theoretical weight, calculated using its length and its weight per unit length.

A. Manufacture’s name or its identifying brand.

B. Dimensions(nominal diameter and nominal wall thickness,length and weight per unit length).

C. Heat number.

D. The process of manufacture(seamless).

E. Grade.

F. Specification designation.

● Bare pipe or Black / Varnish coating ( customized);

● In loose;

● Both ends with end protectors;

● Plain end , bevel end;

● Marking.

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Leading Manufacturer for 219-2020 mm Large Size Spiral Welded Black Carbon Steel Pipe SSAW, We sincerely hope to establish some satisfactory relationships with you in the near future. We will keep you informed of our progress and look forward to building steady business relations with you.

Leading Manufacturer for China Carbon Welded Steel Pipe and Mild Steel SSAW Pipe, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal solutions. In his way, We can enrich our life style and promote a better living environment for the global community.

11