LSAW Pipe is a longitudinally welded steel pipe produced using submerged arc welding technology.

LSAW steel pipes are characterized by longitudinal welds running the entire length of the pipe, which protrude from the inner and outer surfaces of the pipe.

The advantage of LSAW steel pipe is that it can provide large-diameter, thick-walled, and high-pressure pipes.

| Name | Cangzhou Botop International Co., Ltd. |

| Information | Located in Cangzhou, China, with a total investment of 500 million yuan and an area of 600,000 square meters |

| Equipment | Equipped with advanced JCOE molding process and DSAW welding technology, complete production and testing equipment |

| Production capacity | Annual production of more than 200,000 tons |

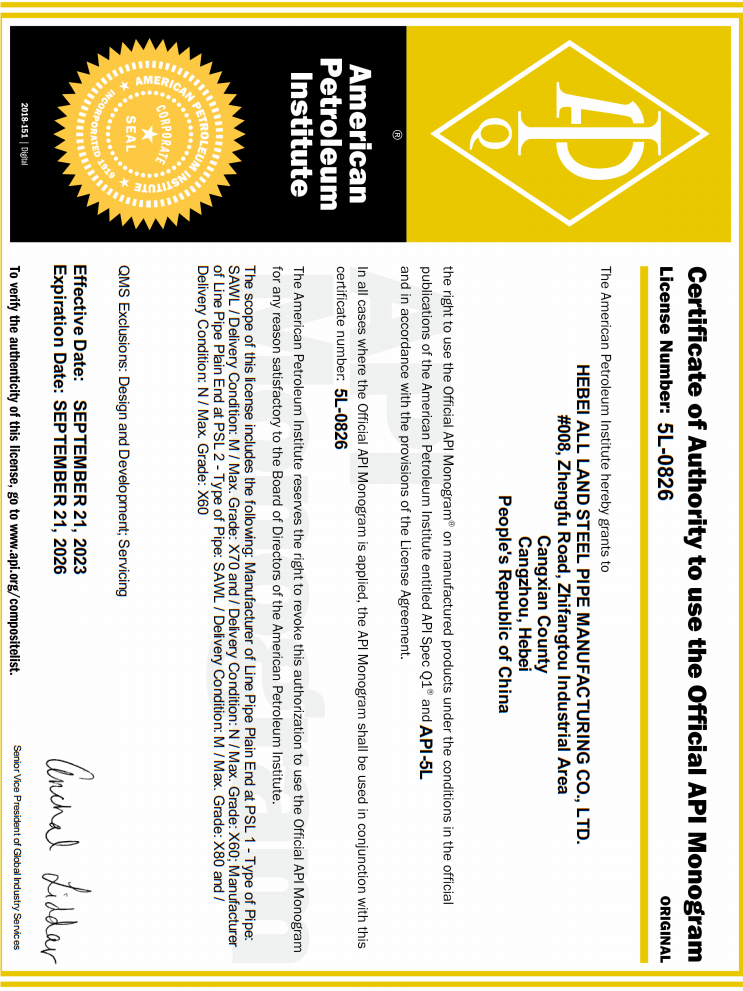

| Certification | API 5L, ISO 9001, ISO 19001, ISO 14001, ISO 45001, etc. |

| Participating projects | Ranawala Mini Hydropower Plant; Transit gas pipeline NO.2 to Turkey; Ranawala Mini Hydropower Plant; City Construction Project; etc. |

| Exported countries | Australia, Indonesia, Canada, Saudi Arabia, Dubai, Egypt, Europe, and other countries and regions |

| Advantages | LSAW Steel Pipe Factory and Manufacturer; LSAW steel pipe wholesalers; LSAW steel pipe stockists; Factory direct sales, quality guaranteed, and cheaper prices. |

In simple terms, the LSAW production process involves curling steel plates into a tube shape and then using submerged arc welding to weld the edges of the steel plates together to form a steel pipe.

Next, we will take you through the key steps in the production of LSAW steel pipes, giving you a clear understanding of the process.

1. Plate inspection and cutting: Depending on the steel pipe implementation standards and required dimensions, qualified plates will be cut into appropriate sizes.

2. Edge milling: Process the edge of the steel pipe to form a shape suitable for welding, such as a V shape. This step is crucial for the quality of the weld.

3. Forming: Our company uses the JCOE forming process, in which the steel plate is formed into a continuous tubular structure by rollers and a press.

4. Welding: In the longitudinal seam of the tubular structure, submerged arc welding is performed to fuse the edges of the steel plates to form the steel pipe. This is the most critical step in the entire process.

5. Inspection: A number of inspections, including 100% non-destructive testing and hydrostatic leak testing of the steel pipes, ensure that the finished product meets the standard requirements.

In the actual production process of LSAW steel pipes, in addition to the key processes mentioned above, there are many other fine and complex steps. These steps require precise control and strict quality monitoring to ensure the production of high-quality LSAW steel pipes that meet standards.

1. Highly adaptable: LSAW steel pipes are often used in high-temperature and high-pressure working environments. With the appropriate coating, these pipes can maintain reliable performance even in extreme climates and complex geological conditions.

2. Welding quality: In the production of LSAW, the double-sided submerged arc welding (DSAW) process is used. This process ensures that the weld is completely penetrated, thus achieving a high standard of welding quality. The weld is uniform and consistent, further enhancing the overall performance and reliability of the steel pipe.

3. Large diameter thick-walled steel pipe:

| Abbreviations | Name | Outer Diameter | Wall Thickness |

| SSAW (HSAW, SAWH) | Spiral Submerged Arc Welding | 200 - 3500 mm | 5 - 25 mm |

| LSAW (SAWL) | Longitudinal Submerged Arc Welding | 350 - 1500 mm | 8 - 80 mm |

| ERW | Electric Resistance Welded | 20 - 660 mm | 2 - 20 mm |

| SMLS | Seamless | 13.1 - 660 mm | 2 - 100 mm |

As can be seen from the above production size comparison, LSAW steel pipes have obvious advantages in the production of large-diameter thick-walled steel pipes, meeting the needs of large-scale projects and industrial applications.

4. Widely used: LSAW steel pipes are widely used in oil and gas transmission, structural engineering, bridge construction, and other fields that require high-strength steel pipes due to their high strength and excellent performance.

| Standard | Usage | Grade |

| API 5L / ISO 3183 | line pipe | Grade B, X42, X52, X60, X65, X72, etc. |

| GB/T 9711 | line pipe | L245, L290, L360, L415, L450, etc. |

| GB/T 3091 | Conveying low-pressure fluids | Q195, Q235A, Q235B, Q275A, Q275B, etc. |

| ASTM A252 | Piling pipe | Grade 1, Grade 2, and Grade 3 |

| ASTM A500 | Cold-formed structural pipe | Grade B, Grade C, and Grade D |

| ASTM A501 | Hot-formed structural pipe | Grade A, Grade B, and Grade C |

| EN 10219 | Cold-formed structural pipe | S275J0H, S275J2H, S355J0H, S355J2H |

| EN 10210 | Hot-finished structural pipe | S275J0H, S275J2H, S355J0H, S355J2H |

In addition to the common steel pipe standards listed above, the material and standard of the steel plate, such as SS400, are also involved in the manufacture of steel pipes using the LSAW process. They are not listed here.

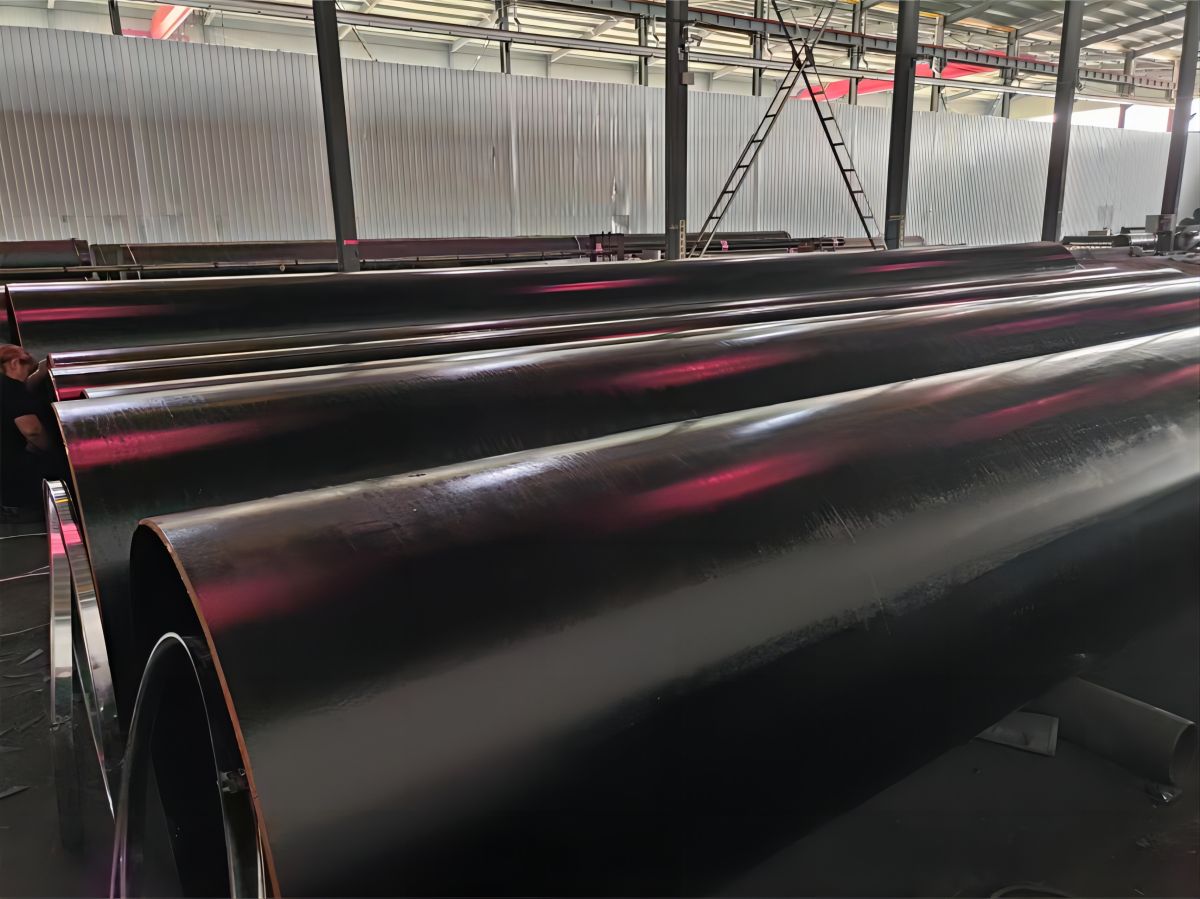

The inner and outer surfaces of LSAW steel pipes are often coated to suit different operating environments.

These coatings can be temporary protective coatings or long-term anti-corrosion coatings. Common coating types include paint, galvanization, 3LPE, FBE, TPEP, epoxy coal tar, etc.

These coatings effectively protect the steel pipes from corrosion, extend their service life, and ensure their stability and reliability under various environmental conditions.

LSAW steel pipe is an important industrial material. In order to ensure its smooth circulation in different national and regional markets, LSAW steel pipe needs to obtain a series of certification documents when importing and exporting. Common ones include API 5L certification, ISO 9001 certification, ISO 19001 certification, ISO 14001 certification, and ISO 45001 certification.