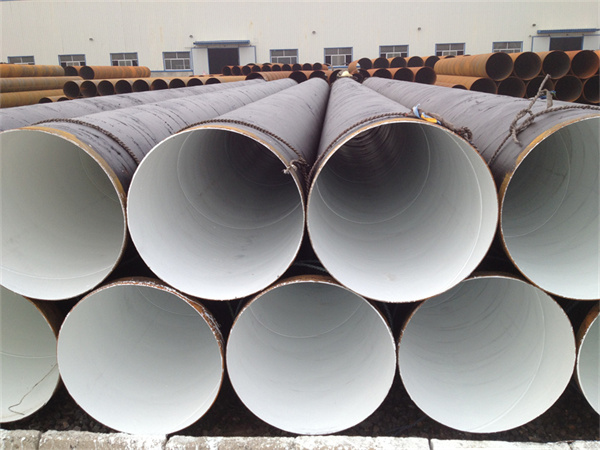

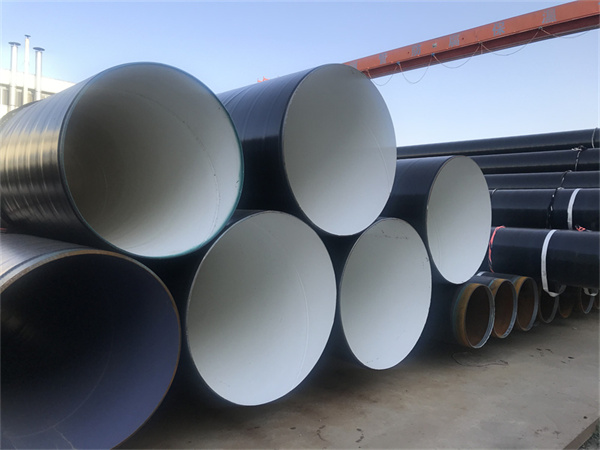

In the global market, seamless black steel pipe or alloy seamless steel pipes and carbon submerged-arc welded pipes are widely used in various industries, including oil and gas, construction, and mining. However, the transportation of these pipes over long distances could be affected by various environmental factors, including humidity and salt spray. This often leads to the pipes getting corroded, which significantly affects their quality and lifespan.To address this challenge, various anti-corrosion processing technologies have been developed, including the popular3LPPanti-corrosion processing technology. This technology is currently being used in exporting steel pipes which is one kind of corrosion technologies based on the customers' requirements and are delivered in time.The3LPPanti-corrosion processing technology involves a three-layer system, including an adhesive layer, a polyethylene layer, and a polypropylene layer.The adhesive layer enhances bonding between the steel pipe's surface and the polyethylene layer. The polyethylene layer has a low water permeability rate, which prevents water molecules from penetrating the inner pipe surface, thus preventing corrosion. The polypropylene layer provides high mechanical resistance, effectively protecting the pipeline's surface from impact and environmental risks.

At Botop Steel, we understand the importance of producing high-quality pipe and the importance of anti-corrosion of the steel pipes. We manufacture submerged-arc welded pipes that have the added strength and resistance necessary to stand up to harsh environments When exporting steel pipes coated with the 3LPP anti-corrosion processing technology, it is important to ensure that they meet the relevant standards such as a252 grade 3 and en10219. It is imperative that the pipes comply with these standards to ensure their quality and safety.. Besides,we employ state-of-the-art processing technology to ensure that we are able to process accurately by the other needs of our customers to manufacture pipes.Delivery time is another critical factor when exporting steel pipes. Customers expect timely deliveries, and any delays could lead to losses. Therefore, it is essential to work with reliable shipping companies that are experienced in transporting steel pipes over long distances. And the companies cooperating with Botop can ensure that.They have necessary equipments, including trucks and ships, to transport the pipes safely and efficiently.

In conclusion, the 3LPP anti-corrosion processing technology has revolutionized the exporting of steel pipes. It guarantees that the pipes remain in excellent condition during transportation, reducing the risk of corrosion. What's more,we also produces pipes like 3PE LSAW Weld Steel Tube .Botop has exported a number of 3PLL anti-corrosion steel pipes and they all have excellent responds.Contact us now and you will have a big surprise!

Post time: May-25-2023