ASTM A500 and ASTM A501 both specifically address requirements related to the fabrication of carbon steel structural pipe.

While there are similarities in certain aspects, they also have their own unique characteristics and applications.

Next we will look at the key differences between ASTM A500 and ASTM A501 and how they are used in different applications.

Manufacturing Processes

ASTM A500 Manufacturing Processes

ASTM A50 pipe shall be manufactured by seamless or welded processes.

Welded tubing shall be made from flat-rolled steel by the electric-resistance-welding (ERW) process.

ASTM A501 Manufacturing Processes

Pipes shall be fabricated by one of the following processes: seamless, furnace butt welding (continuous welding); resistance welding or submerged arc welding.

It shall then be reheated over the entire cross-section and thermoformed by reduction or forming processes, or both.

The final shape formation shall be made by a hot forming process.

Different Manufacturing Processes

Both standards allow the use of seamless pipe manufacturing techniques;

If a welding process is used for manufacturing, ASTM A500 uses electric-resistance-welded (ERW), while ASTM A501 allows a variety of welding techniques, including electric-resistance-welded (ERW), submerged arc welding (SAW), etc.

However, ASTM A501 requires the pipe to be heat treated, which helps to improve the uniformity and mechanical properties of the material. The purpose of thermoforming is to improve material properties by heat treating the pipe before its shape is finalized.

ASTM A500 does not have such detailed requirements.

Classification of Grades

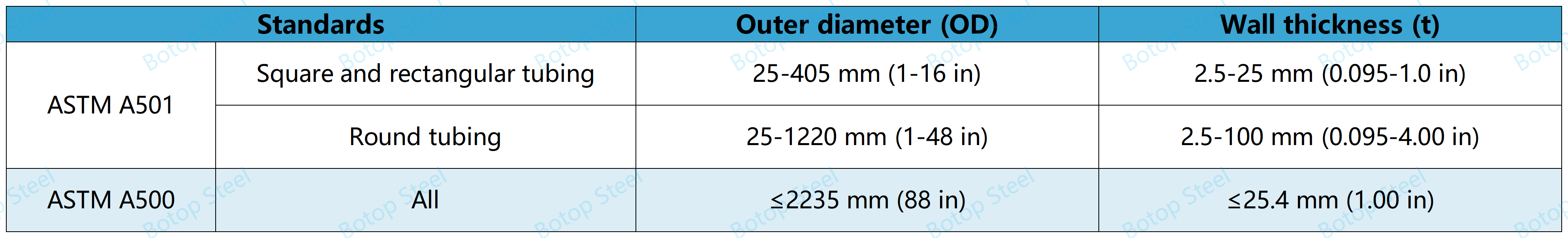

Applicable Size Range

Chemical Components

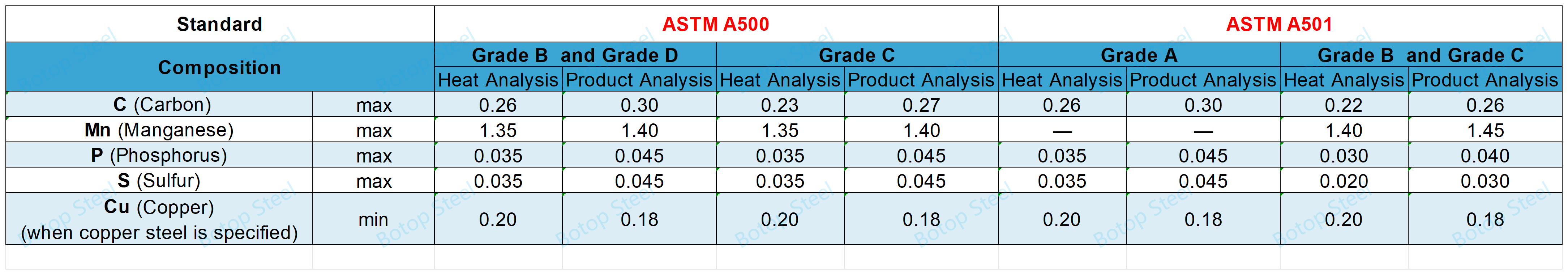

Taken together, there are some differences in the chemical compositions of carbon steel structural tubes specified in the two standards, ASTM A500 and ASTM A501.

In ASTM A500, Grade B and Grade D have the same chemical composition requirements, while Grade C has a reduced carbon content relative to B and D. In ASTM A501, the chemical composition of Grade A is the same as that of Grade B, while Grade C has a reduced carbon content relative to Grade B.

In ASTM A501, the chemical composition of Grade A is similar to that of Grades B and D of A500, but in Grades B and C the carbon content is reduced, the manganese content is slightly increased, and the phosphorus and sulfur content is lower than in Grade A.

Copper content remains a consistent minimum requirement across all grades.

The different chemical composition requirements reflect the specific needs of the two standards for different production processes and applications, ensuring that the material meets the performance criteria for a wide range of engineering and structural applications.

Mechanical Performance

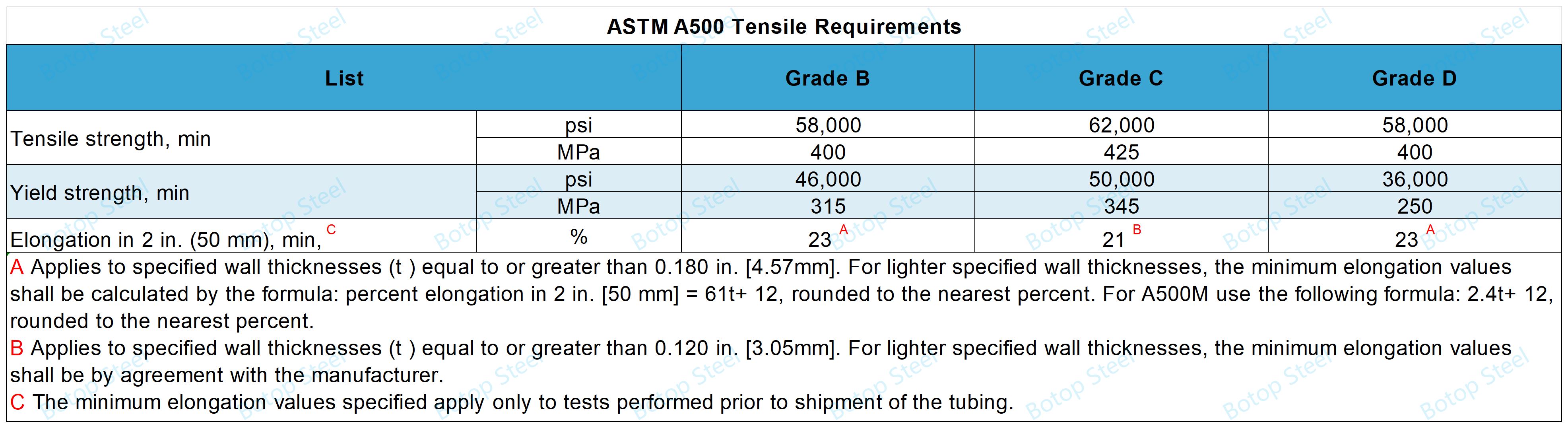

ASTM A500 Mechanical Performance

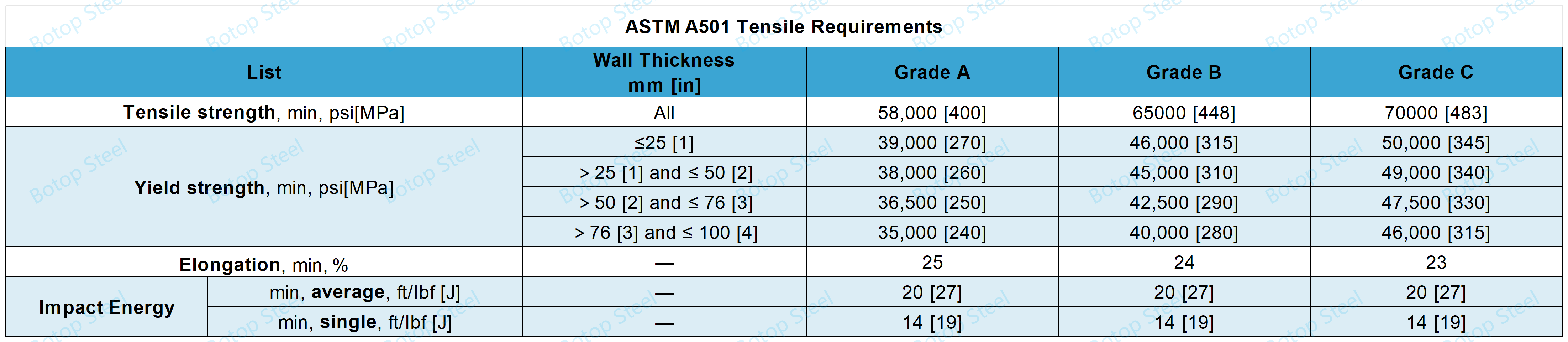

ASTM A501 Mechanical Performance

Different Mechanical Properties

Materials in A501 typically offer higher levels of strength due to the increased strength of the steel from the hot forming process.

Experimental Projects

The different requirements for experimental items in the two standards reflect the manufacturing processes and intended uses of these two different tubes.

The ASTM A500 standard requires Thermal Analysis, Product Analysis, and Mechanical Properties in addition to Flattening Test, Flaring Test, and Wedge Crush Tes to ensure that the cold forming process does not negatively impact material properties.

The ASTM A501 standard emphasizes the thermoforming process, and since thermoformed products are already heat-treated during the manufacturing process, these tests may be considered redundant because the heat treatment has already ensured the plasticity and toughness of the material.

Areas of Applicatio

Although both play a structural role, the emphasis will be different.

ASTM A500 tubing is widely used in building structures, machinery manufacturing, vehicle frames, and agricultural equipment due to its good cold bending and welding properties.

ASTM A501 tubing is more suitable for building and structural applications that require higher strength and toughness, such as bridge construction and large support structures, due to its excellent toughness and strength.

Both standards provide guidance for fabricating high-quality carbon steel tubing, but the best choice depends on the requirements and constraints of a specific project.

If a structure needs to perform well in a low-temperature environment, ASTM A501 may be preferred because the increased toughness from hot forming provides better resistance to brittle fracture. Conversely, if the structure is to be built for an indoor environment, then ASTM A500 may be sufficient, as it can provide the required strength and workability, while potentially costing less.

Tags: a500 vs a501, astm a500, astm a501, carbon steel, structural pipe.

Post time: May-06-2024