ASTM A671 and A672 are both standards for steel tubing made from pressure vessel-quality plates by electric fusion welding(EFW) techniques with the addition of filler metals.

Although they are similar in many aspects, such as welding requirements, heat treatment, and dimensional tolerances, they differ in their scope of application, grade, class, dimensions, and specific applications.

Scope of Application

ASTM A671:Standard Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures

ASTM A672: Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures

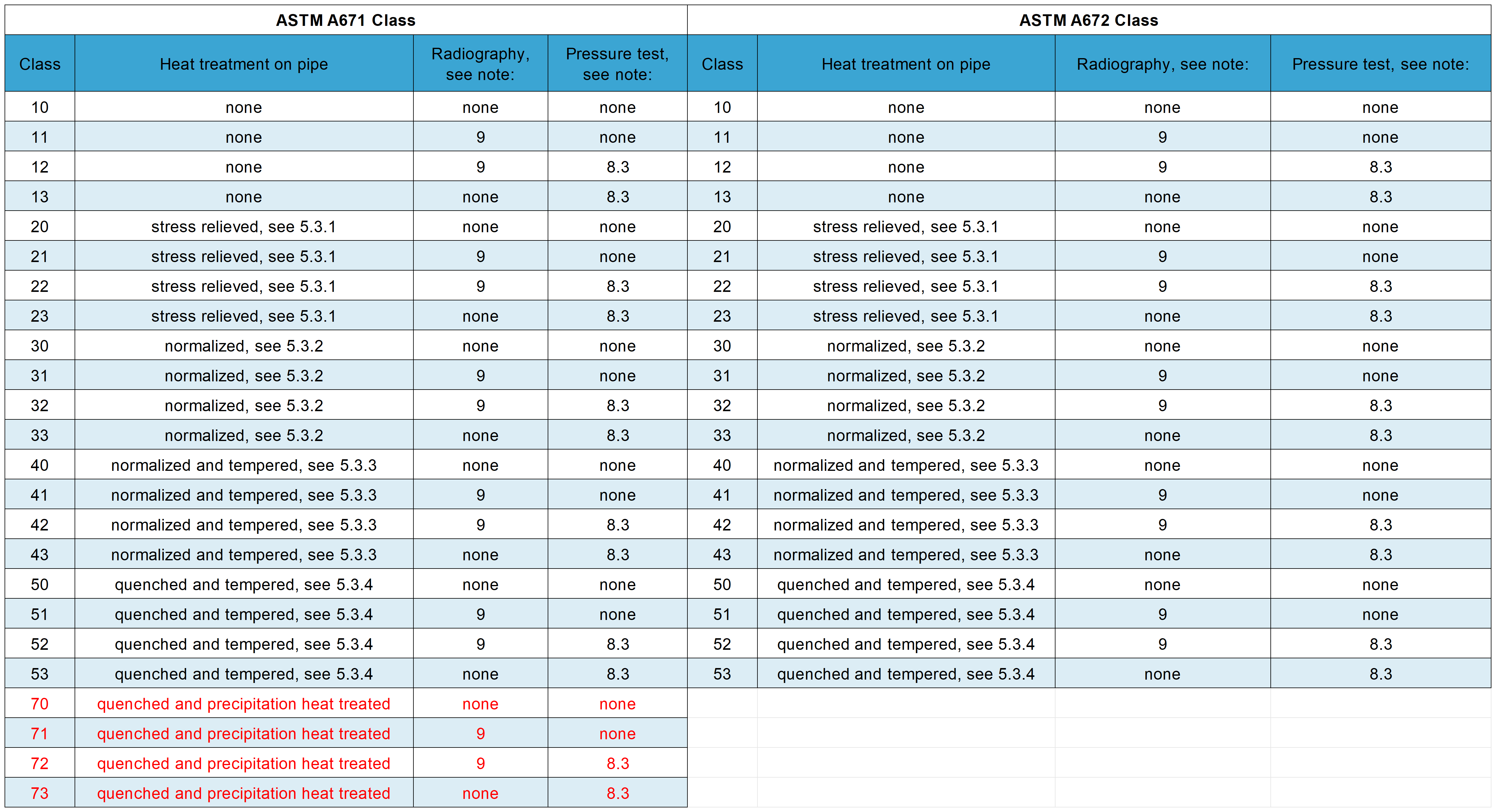

Class Comparison

The tubes are classified according to the type of heat treatment they receive during the manufacturing process and whether or not they are radiographically inspected and pressure tested.

ASTM A671 has a broader range of categories than ASTM A672, reflecting A671's more nuanced approach to categorizing materials for brittleness and failure modes that can occur in low-temperature environments.

This is because the A671 standard provides a detailed breakdown of low-temperature properties designed to ensure that the pipe will continue to perform well in cold conditions. In contrast, ASTM A672 focuses on adapting to different pressures and moderate temperature conditions, which involves facing and managing different types of stresses.

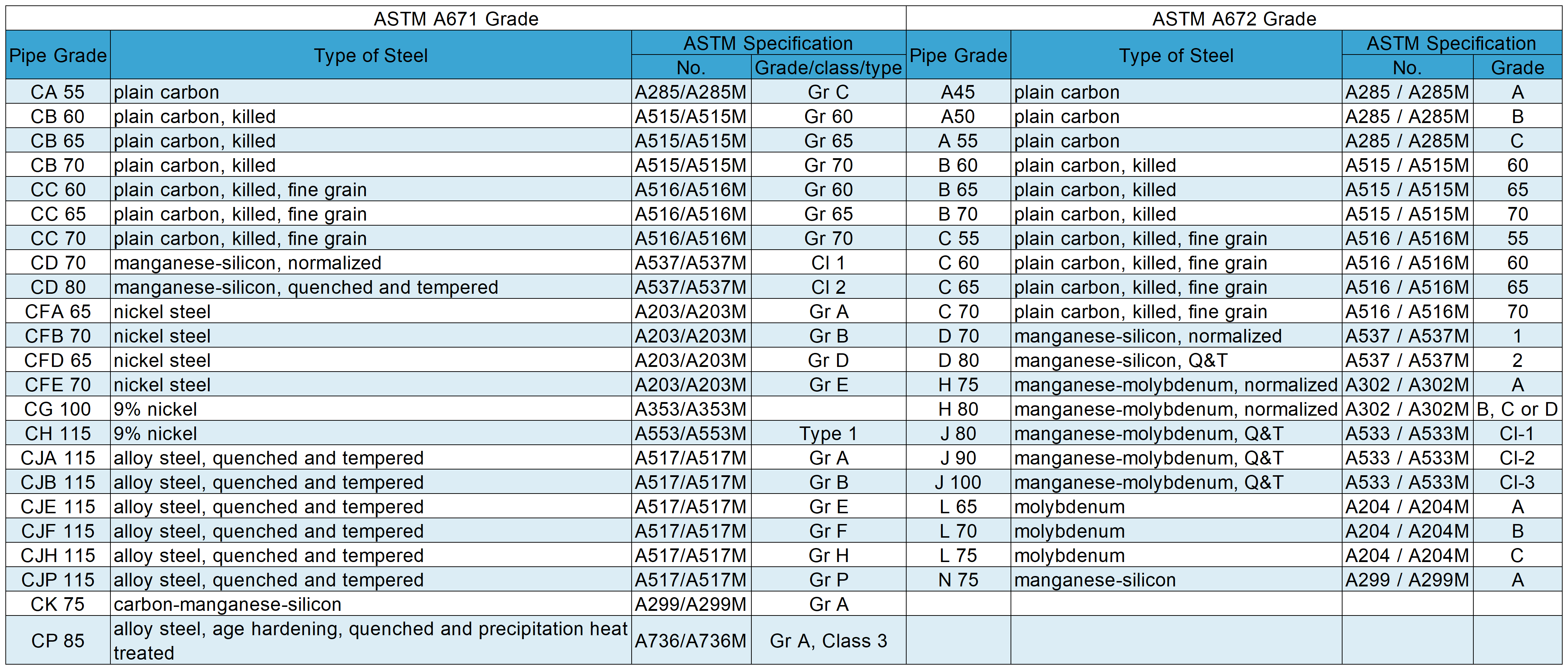

Grade Comparison

Classified according to the type of plate used to manufacture steel tubes.

Different grades represent different chemical compositions and mechanical properties for different pressure and temperature conditions.

Different grades may affect the cost and performance of a project.

Using a higher grade of steel pipe usually means higher material costs, but proper material selection can reduce maintenance costs and extend service life in the long run.

Specific Applications

Applications for ASTM A671 Steel Tubing

Cryogenic services: such as liquefied natural gas (LNG) handling and transportation systems, require tubes capable of maintaining good mechanical properties at very low ambient temperatures.

City gas supply systems: In these systems, pipelines may need to operate at low winter temperatures, so specific grades of steel pipe are required to ensure safety and efficiency.

Chemical processing facilities: In chemical processing and cooling systems, certain fluids are handled at very low temperatures, requiring the use of ASTM A671 pipe to prevent pipe rupture due to brittleness at low temperatures.

Offshore platforms and oil drilling facilities: These facilities are often located in cold waters, and the use of A671 pipe ensures reliability and durability in cold marine environments.

Applications for ASTM A672 Steel Tubing

Power plants: Especially in boiler and steam systems, these systems require piping that is resistant to high temperatures and pressures for the safe transfer of steam and hot water.

Refineries: In the refining process, piping is needed to efficiently transfer crude oil and products between different processing stations, and these pipes must be able to withstand the high temperatures and chemical attack of the process.

High-Pressure Transmission Lines: High-pressure transmission lines are used to transport high-pressure fluids or gases such as natural gas and oil.

Industrial Pressure Systems: In manufacturing and other industrial applications, many pressure systems require reliable high-pressure piping to ensure production safety and efficiency.

By differentiating between these properties and applications, it becomes apparent that while the ASTM A671 and A672 pipe standards overlap in some technical respects, they serve different purposes depending on specific environmental and operational requirements.

tags:astm a671, astm a672, efw,class, grade.

Post time: Apr-23-2024