Seamless and welded steel tubes play a vital role as basic components of modern industry.

The specifications of these tubes are primarily defined by the outer diameter (OD), wall thickness (WT) and length (L), while calculating the weight of a steel tube is based on these dimensional parameters plus the density (ρ) of the material. For project planning, cost control and logistics, accurate calculation of the weight of steel pipe is essential. This article presents three methods for calculating the weight of steel tubing and shows how to use them with practical examples.

Basic Calculation of Pipe Weight

The weight of a steel pipe can be estimated by calculating its volume multiplied by the density of steel.

For round steel pipes (including seamless and welded steel pipes), the weight is calculated as follows:

Weight(kg)=×(OD2-(OD-2×WT)2)×L×ρ

OD is the outer diameter of the steel pipe in meters (m);

WT is the wall thickness of the steel pipe in meters (m);

L is the length of the steel pipe in meters (m);

ρ is the density of the steel, for ordinary carbon steel, it is about 7850kg/m3.

Simplified algorithm: imperial units

Weight(lb/ft)=(OD (in)−WT (in))×WT (in)×10.69

where 10.69 is a factor calculated from the density of the steel and the unit conversion used to convert dimensions from inches to pounds per foot of length.

Example Calculations

Assuming a section of ERW steel pipe with an outside diameter of 10 inches and a wall thickness of 0.5 inches, calculate the weight per foot of length: Weight (lb/ft) = (10-0.5) x 0.5 x 10.69

The weight per foot of length of this steel pipe is approximately 50.7775 pounds.

Simplified algorithm: metric units

Weight (kg)=(OD−WT)×WT×L×0.0246615

OD is the outer diameter of the steel pipe, in meters (mm);

WT is the wall thickness of the steel pipe in meters (mm);

L is the length of the tube in meters (m);

0.0246615 is based on the density of steel (approximately 7850 kg/m³) and a unit conversion factor.

Example Calculations

Suppose we have a seamless steel pipe with an outside diameter of 114.3 mm, a wall thickness of 6.35 mm, and a length of 12 m. Calculate the weight of the pipe using the simple formula above:

1. Calculate the difference between the diameter and the wall thickness: 114.3 - 6.35 = 107.95. 2.

2. Calculate the weight by substituting the formula: 107.95 × 6.35 × 12 × 0.0246615. 3.

3. The result is: 202.86

Therefore, the total weight of the pipe is approximately 202.86 kg.

The coefficients 10.69 and 0.0246615 in the formula are based on the average density of steel. Different types of steel (e.g. stainless steel, alloy steel, etc.) may have different densities and the factors must be adjusted accordingly.

These calculations provide an estimate of the weight of seamless and welded steel tubing. Due to varying material densities, manufacturing tolerances, and other factors, actual weights may vary.

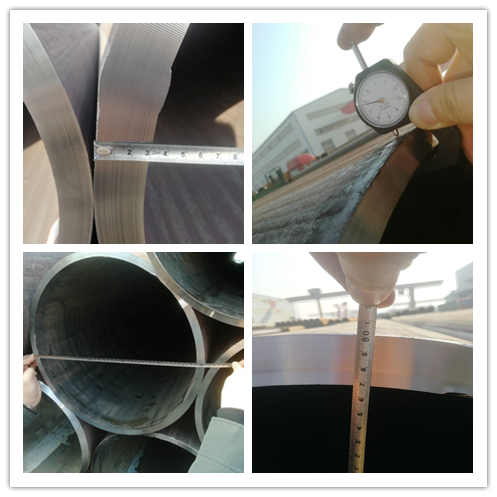

Actual weights may vary depending on manufacturing tolerances and material density, so this formula is an estimate. For an accurate calculation of the weight, it is recommended that you refer to the data provided by the manufacturer or that you take actual measurements.

For accurate engineering calculations or commercial quotations, it is recommended that more detailed data be used or that steel pipe suppliers be contacted for accurate weight information.

Pipe weight calculations are a fundamental part of engineering design and cost control, and proper understanding and application of these calculations This calculation method is applicable to seamless steel pipe with relatively thin wall thicknesses. In the case of very thick wall seamless steel tubing, more complex calculations may need to be considered.

tags: pipe weight, steel pipe, seamless, welded.

Post time: Feb-27-2024