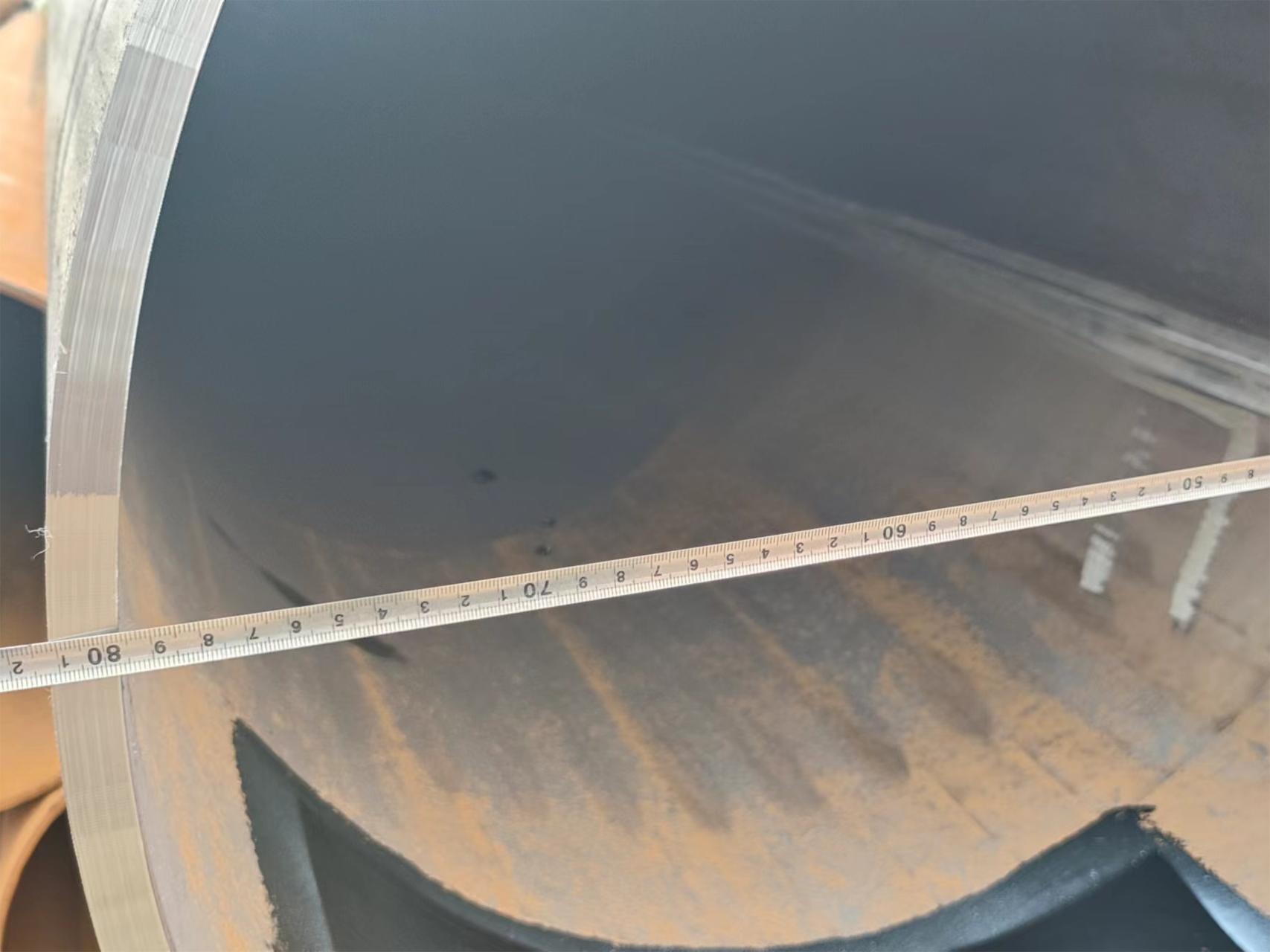

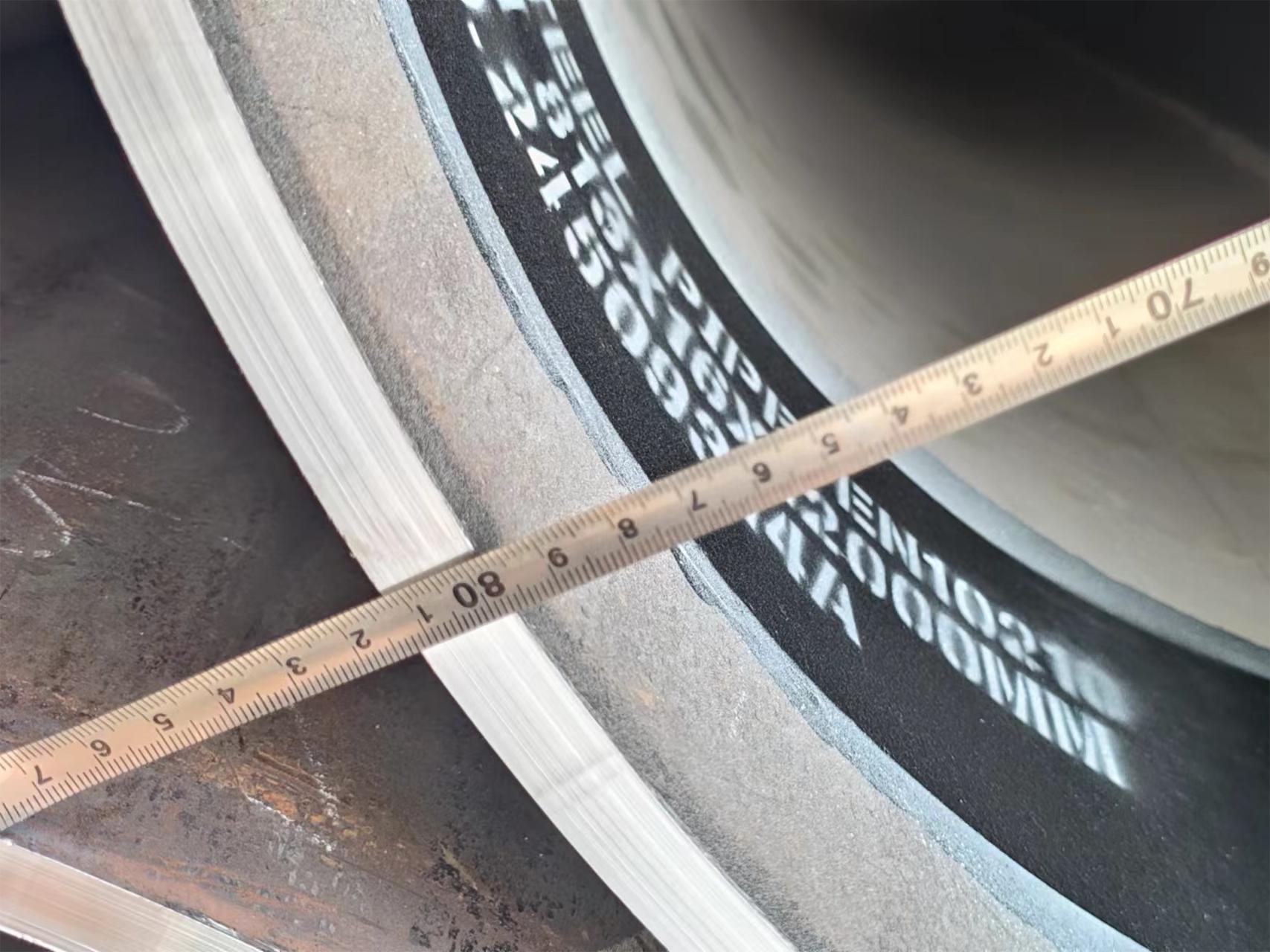

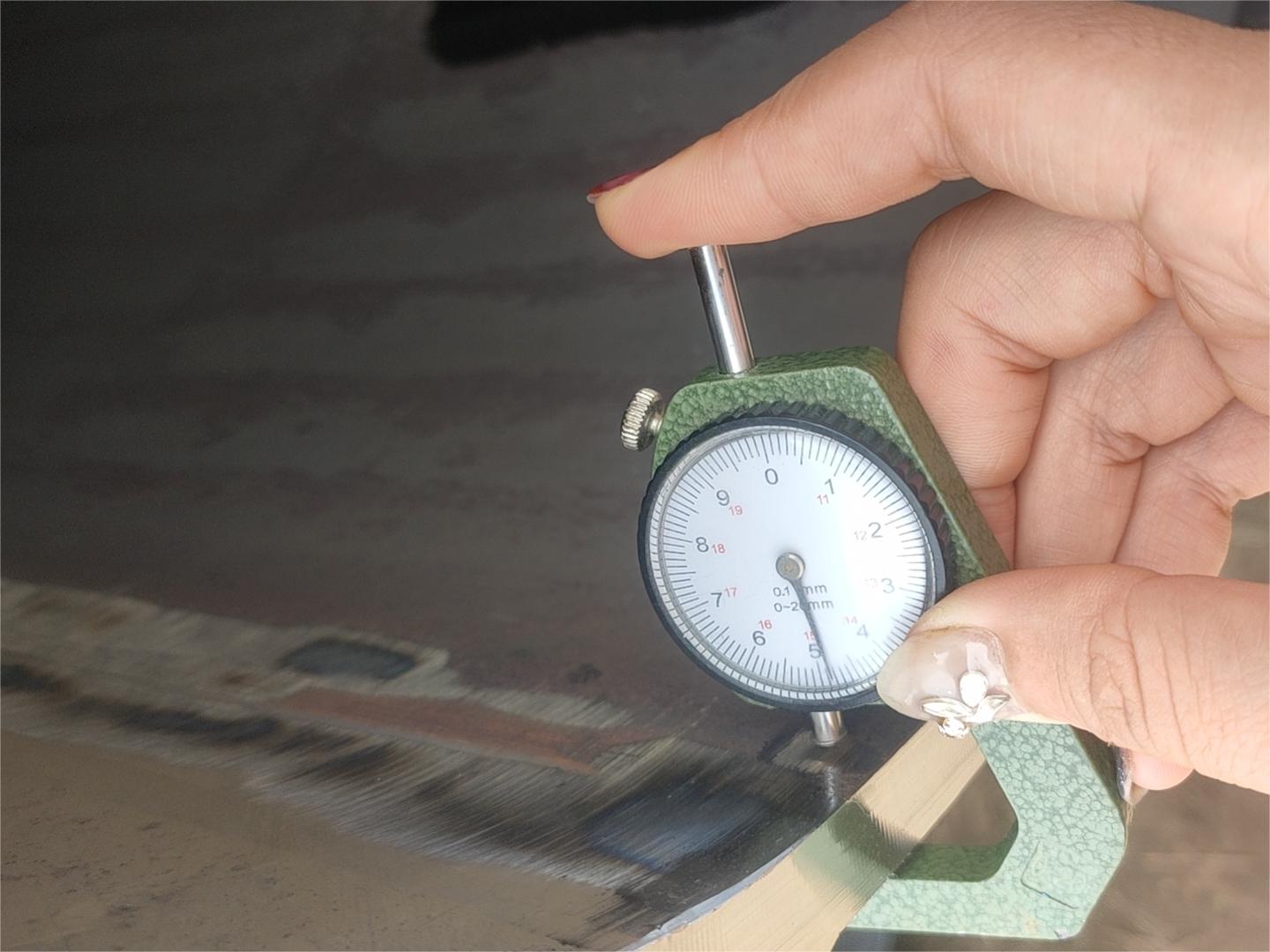

120 pcs of 813 mm×16mm×12m EN 10210 S355J0H LSAW welded steel pipes were packed in the port and shipped to Hong Kong.

EN 10210 S355J0H is a hot-finished hollow structural steel pipe with a minimum yield strength of 355 MPa when the wall thickness of the pipe is ≤ 16 mm and a minimum impact resistance of 27J at 0 ℃. It is commonly used in structures requiring high strength and toughness.

The EN 10210 S355J0H LSAW steel pipe produced not only undergoes strict quality control and inspection during the production process but also before shipment, Botop again arranges professional quality personnel to inspect the steel pipe to ensure the quality of the steel pipe, which is in line with the requirements of customers and standards.

Botop is the manufacturer and supplier of LSAW steel pipe in China and has obtained many certifications such as ISO, CE, API, etc. We always insist on providing you with high-quality steel pipe products at favorable prices.

If you have the need for steel pipe, you can contact us at any time, the professional team is always ready to provide you with services.

EN 10210 S355J0H is a structural carbon steel pipe with high strength and toughness, commonly used for bridges, building frames, and other infrastructure projects, especially where high strength and durability are required. The steel number is 1.0547.

EN 10210 S355J0H Manufacture Process

- Seamless;

- ERW;

- LSAW (SAWL);

- SSAW (HSAW);

EN 10210 S355J0H Chemical Composition

| Steel grade | % by mass, maximum | |||||

| C | Si | Mn | P | S | N | |

| EN 10210 S355J0H | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

EN 10210 S355J0H Mechanical Properties

| Steel name | Minimum yield strength ReH, MPa | Tensile strength Rm, MPa | Minimum elongation A, % | Minimum impact energy KV, J | ||||||||||

| Specified thickness mm | Specified thickness mm | Specified thickness mm | At the test temperature of | |||||||||||

| ≤ 16 | > 16 ≤ 40 |

> 40 ≤ 63 |

> 63 ≤ 80 |

> 80 ≤ 100 |

> 100 ≤ 120 |

≤ 3 | > 3 ≤ 100 |

> 100 ≤ 120 |

≤ 40 | > 40 ≤ 63 |

> 63 ≤ 100 |

> 100 ≤ 120 |

0℃ | |

| EN 10210 S355J0H | 355 | 345 | 335 | 325 | 315 | 295 | 510 - 680 | 470 - 630 | 450 - 600 | 22 | 21 | 20 | 18 | 27 |

Post time: Oct-28-2024