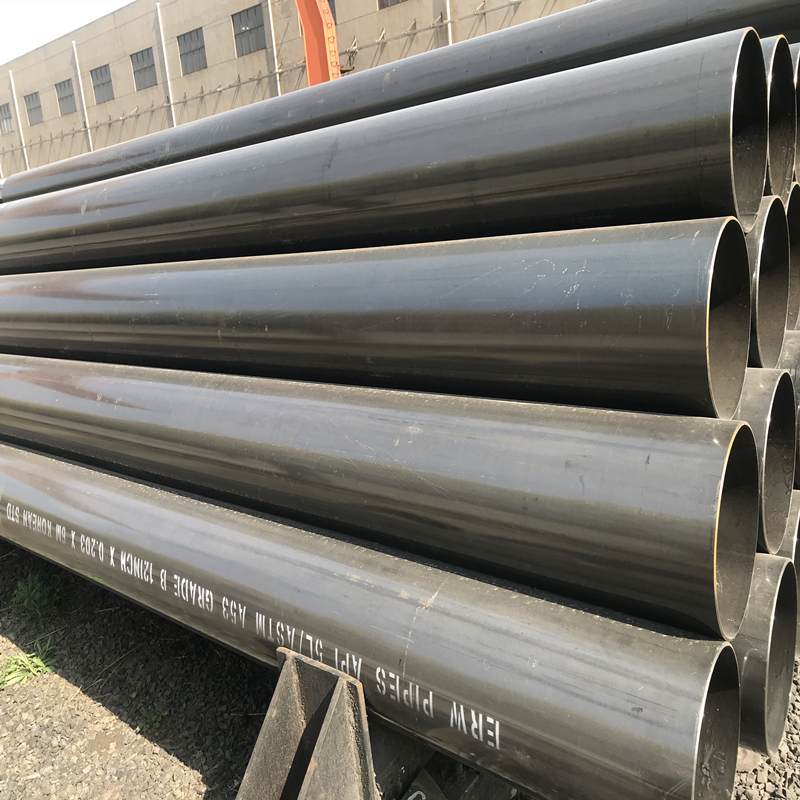

In the field of steel pipes, the standards for arc welded straight seam steel pipes are crucial. One of the standards is GB/T3091-2008, which covers different types of straight seam steel pipes, such as high-frequency resistance welded (ERW) steel pipes, submerged arc welded (SAWL) steel pipes and spiral seam submerged arc welded (SAWH) steel pipes. )Steel Pipe.

For low-pressure fluid transportation, GB/T3091-2008 also stipulates the use of galvanized welded steel pipes. These electric welded steel pipes, commonly known as white pipes, are used to transport water, gas, air, oil, heating steam, warm water, etc. The specifications of these steel pipes are expressed in nominal diameter, and the outer diameter and wall thickness comply with the regulations of GB/T21835. Moreover, the length of the steel pipe can range from 300mm to 1200mm, and it can be fixed length or double length.

When it comes to quality issues, the temperature during the piercing process has a big impact. Thermal expansion steel pipes typically reach temperatures around 1200°C, although carbon content and alloying elements can reduce temperatures slightly. Another key aspect to consider is reducing the amount of scale during hot bending, as this can affect tool life and surface quality.

Heating operation is a crucial process in the production of 16Mn straight seam steel pipe. Since most processing occurs in a hot state, precise control of heating temperature is crucial to ensure the quality of the final product.

To maintain quality and standards, controlling the temperature during piercing processing is crucial. The straight seam steel pipe standard GB/T3091-2008 specifies the allowable deviations in size, shape, weight and outer diameter and wall thickness. The allowable deviation of standardized wall thickness varies according to the deviation grade, ranging from S1 to S5, and each grade specifies the corresponding percentage and minimum deviation.

In addition to the standardized wall thickness tolerances, non-standardized wall thickness tolerances are also considered. Deviation levels (eg NS1 to NS4) include specific percentage deviations to ensure quality control. It should be noted that S represents the nominal wall thickness of the steel pipe, and D represents the nominal outer diameter of the steel pipe.

Ensuring compliance with these standards is critical to the production of high quality longitudinal submerged arc welded steel pile pipes. By maintaining precise control of temperature and paying attention to allowable deviations, manufacturers can meet customer expectations and provide reliable and durable products.

Post time: Nov-10-2023