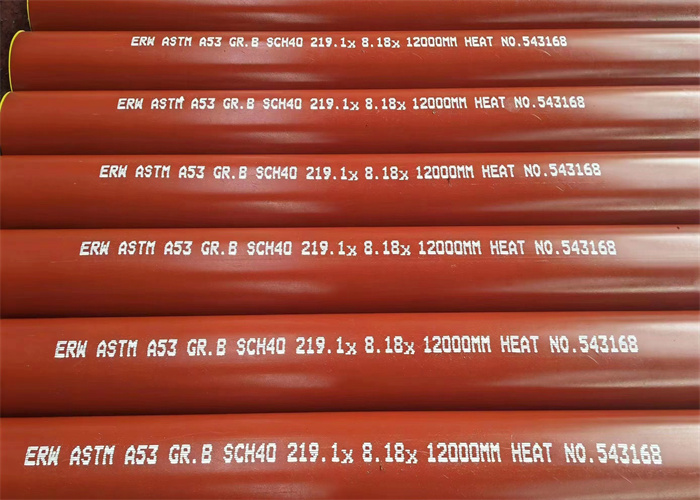

Botop Steel Pipe recently made a significant export of 500 tons of red paint ERW welded pipes to Saudi Arabia, highlighting the growing demand for high-quality welded carbon steel pipes in the international market. Among the various types of welded pipes, S275JRH and S355J0H welded pipes are gaining popularity due to their robust construction and versatile applications.

ERW (Electric Resistance Welding) welded pipes are known for their high dimensional accuracy and uniform wall thickness, making them suitable for a wide range of industrial and commercial applications. As compared to seamless pipes, ERW welded pipes are more cost-effective and readily available, making them a preferred choice for many projects.

Black carbon steel pipes are commonly used in the oil and gas industry, as well as in construction and structural applications. The S275JRH and S355J0H grades of welded carbon steel pipes are known for their high tensile strength and impact resistance, making them suitable for demanding environments. These pipes are manufactured in compliance with various international standards, ensuring their quality and reliability.

S275JRH welded pipes are designed for structural applications, offering good weldability and formability. These pipes are commonly used in the construction of bridges, buildings, and other structures where high strength and durability are essential. On the other hand, S355J0H welded pipes are known for their excellent impact strength and corrosion resistance, making them suitable for offshore and marine applications.

One of the key advantages of ERW welded carbon steel pipes is their uniformity and consistency. The welding process ensures that the pipes have a smooth finish and precise dimensions, making them easy to install and maintain. Additionally, ERW welded pipes can be produced in various sizes and thicknesses, allowing for greater flexibility in design and construction.

In terms of performance, S275JRH and S355J0H welded pipes offer excellent mechanical properties, making them suitable for a wide range of structural and mechanical applications. These pipes can withstand high pressure and temperature, making them ideal for conveying fluids and gases in demanding environments.

From a sustainability perspective, ERW welded carbon steel pipes are environmentally friendly, as the manufacturing process generates minimal waste and emissions. This makes them a sustainable choice for various infrastructure and construction projects, aligning with the increasing focus on green technologies and sustainable practices.

As the demand for high-quality welded carbon steel pipes continues to rise, it is essential for suppliers and manufacturers to offer a wide range of options, such as S275JRH and S355J0H welded pipes, to meet the diverse needs of their customers. With their exceptional quality and performance, these pipes are poised to play a critical role in shaping the future of various industries around the world.

Post time: Dec-18-2023