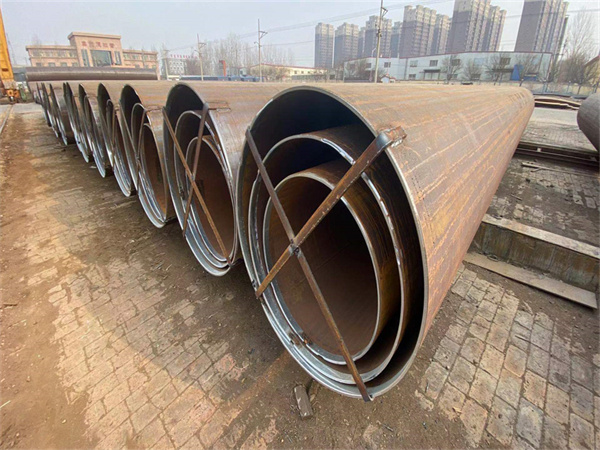

SAW (Longitudinal Submerged Arc Welded) Pipes are different from other types of welded pipes used in piping systems. They are mostly used in oil and gas transmission pipelines,and structural applications such as building bridges and tunnels.

In terms of standards, LSAW pipes conform to the standards set by the American Petroleum Institute (API), the International Organization for Standardization (ISO), and the American

Society of Mechanical Engineers (ASME). These standards define the specifications for the dimensions, chemical composition, mechanical properties, and testing requirements for LSAW pipes.

LSAW pipes are available in different grades such as ASTM A671, ASTM A672, ASTM A525, BS EN10210, BS EN10219, and API 5L Gr. B. The selection of the grade depends on the application requirements such as the pressure, temperature, and type of fluid being transported.

The usage of LSAW pipes is diverse, and they are mostly used in oil and gas transmission lines, water pipelines, and structural applications such as building bridges and tunnels. These pipes are preferred over other welded pipes as they offer better dimensional accuracy, high strength, and durability. LSAW pipes can be manufactured in large sizes and lengths, making them ideal for use in long-distance transmission pipelines.

In conclusion, LSAW pipes play a vital role in oil and gas transmission and structural applications. They conform to strict standards, come in different grades, and are durable and reliable.

Post time: May-18-2023