Large diameter steel pipe usually refers to steel pipes with an outside diameter ≥16in (406.4mm). These pipes are commonly used to transport large quantities of liquids or gases, such as oil pipelines, natural gas pipelines, water supply pipelines, etc.

Navigation Buttons

What are the Manufacturing Processes of Large Diameter Steel Pipe?

Comparison of Manufacturing Processes for Large Diameter Steel Pipes

Production Process Implementation Standards

Surface Treatment of Large Diameter Steel Tubes

Points to Consider When Buying Large Diameter Steel Pipe

Application Prospects of Large-Diameter Steel Pipes

Our Advantages

What are the Manufacturing Processes of Large Diameter Steel Pipe?

The main manufacturing processes for large-diameter steel pipes are LSAW, SSAW, and Hot-finished Seamless.

LSAW (Longitudinal Submerged Arc Welding)

LSAW is a process commonly used to manufacture large diameter steel pipe by welding.

It is used to manufacture pipes by submerged arc welding on both sides. First, steel plates are bent into a tube shape, then welded together by submerged arc welding, and finally shaped and straightened to obtain the desired diameter and length.

LSAW can now produce pipes up to 1500mm in diameter and 80mm in wall thickness.

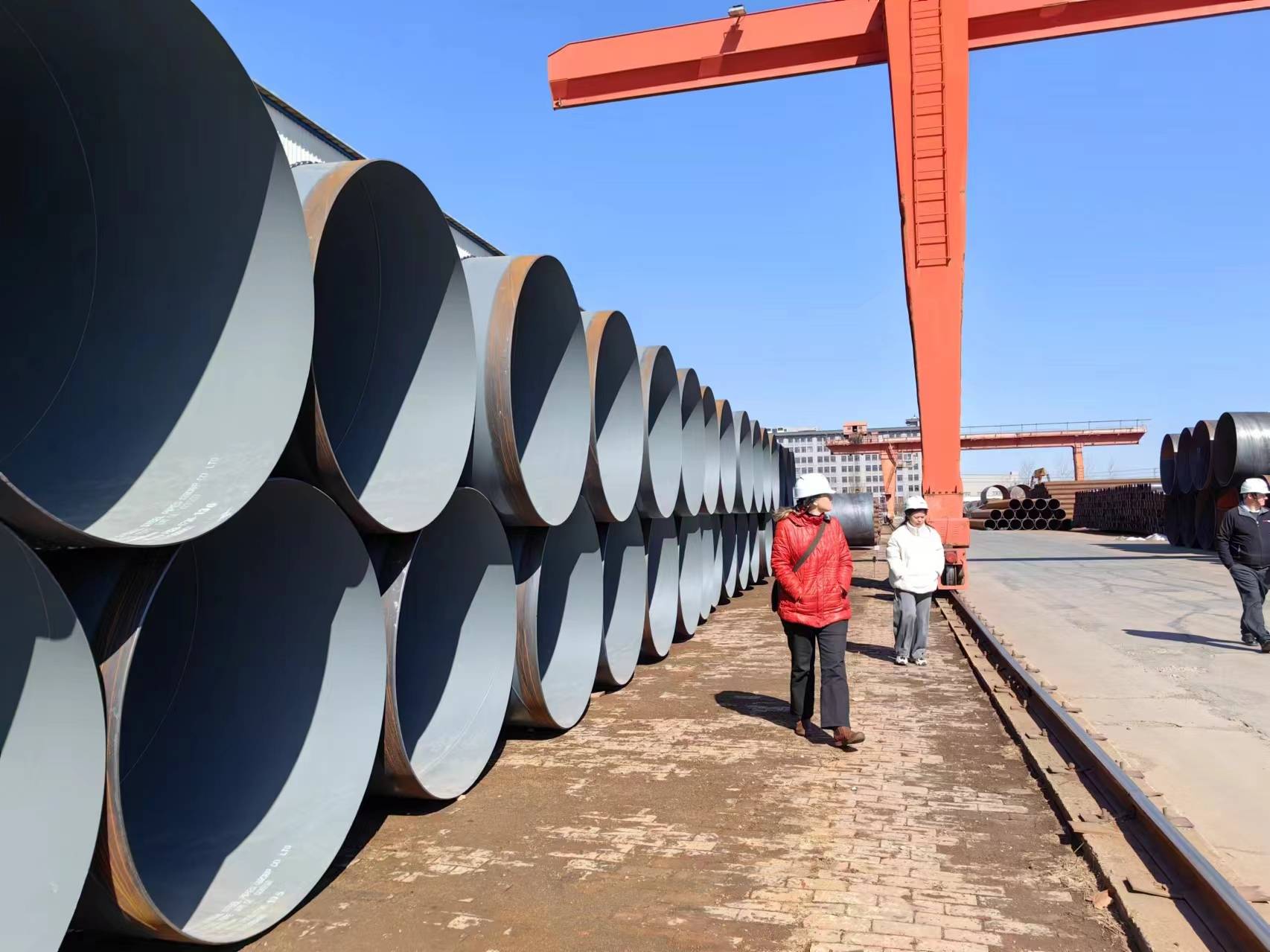

SSAW (Spiral Submerged Arc Welding)

SSAW is another process that commonly employs welding to manufacture large-diameter steel pipe.

It manufactures pipes by rotating a steel coil into a tube shape and submerged arc welding.

SSAW can now produce pipes up to a maximum diameter of 3,500mm and a maximum wall thickness of 25mm.

Hot-finished SMLS (Seamless)

It is a manufacturing process of seamless steel pipe, there are two types of seamless steel pipe generation process, hot finished and cold finished, hot finished is suitable for the production of large diameter steel pipe.

It is formed by heating and stretching the pipe from a solid round billet, maintaining the uniformity and strength of the pipe.

Hot-finished seamless pipe can now produce steel pipe with a maximum diameter of 660mm and wall thickness of 100mm.

There is another welding process, EFW, which is also suitable for the manufacture of thick-walled steel pipes over 406.4mm, but it is not as widely used as the previous three.

Comparison of Manufacturing Processes for Large Diameter Steel Pipes

LSAW steel pipe can be produced with thicker wall thicknesses due to the characteristics of its manufacturing process and therefore can withstand higher pressures than SSAW steel pipe to a certain extent. However, in high-pressure environments, weld channels can be a weak point of LSAW steel pipe, which may affect its pressure-bearing capacity and service life.

In addition, the production equipment for LSAW is more costly and the production efficiency is relatively low.

Therefore, LSAW steel pipes are mostly used in pipelines suitable for transporting oil, natural gas, and other media, as well as other engineering and construction fields that require high strength and pressure resistance.

SSAW pipes are suitable for larger diameters, especially for diameters above 1500mm, as well as for long-distance pipelines.

Compared with LSAW, SSAW is relatively cheaper but is not suitable for high-pressure working environments.

Therefore, SSAW steel pipes are mostly used for low-pressure fluid and structural purposes, such as water pipelines and bridge supports.

SMLS steel pipe is suitable for applications where high quality and strength of the pipe is required, as its seamless manufacturing process ensures the quality and strength of the pipe.

However, the price of SMLS is usually higher.

Therefore, it is mostly used in fields that require high quality and safety, such as oil and gas transportation pipelines, chemical pipelines, and so on.

Production Process Implementation Standards

Common executive standards for steel pipe production are:

LSAW and SSAW: API 5L, ASTM A252, BS EN10210, BS EN10219

Hot-finished Seamless: API 5L, ASTM A53, ASTM A106, ASTM A210, ASTM A252, BS EN10210, JIS G3454, JIS G3456, JIS G3441,ASTM A213, ASTM A519, ASTM A335, ASTM A333.

Surface Treatment of Large Diameter Steel Tubes

The surface treatment of large diameter steel pipe is important for protecting the pipe body, prolonging service life, and reducing corrosion.

The external surface treatment often adopts painting, 3PE, FBE, 3PP, etc., which effectively prevents the corrosion of the steel pipe by the external environment.

Internal surface treatment, including painting and FBE, can reduce the corrosion of the steel pipe by fluid, prolong the service life, and reduce the friction during fluid transportation.

Choosing the suitable surface treatment method can ensure that the steel pipe has good corrosion resistance and adapts to different use environments and requirements.

Points to Consider When Buying Large Diameter Steel Pipe

1. Pipe size and specification: choose the appropriate pipe size and specification according to the project requirements to ensure that it can meet the project requirements.

2. Working environment: Select the appropriate pipe material and design according to the specific environment and conditions in which the pipe will be used to ensure that it can operate stably for a long time. Considerations include temperature, pressure, medium, and so on.

3. Price: Comprehensively consider the price and performance of the pipeline and select the most suitable pipeline for your needs, while paying attention to cost-effectiveness. Consider the long-term return on investment of the pipeline.

4. Delivery time: Consider the delivery time of the supplier to ensure that the project can be completed on time.

5. Quality certification: Ensure that the purchased pipe meets the relevant quality certification standards, such as ISO, API, etc., to ensure the quality and performance of large-diameter steel pipe.

6. Supplier reputation: Choose suppliers with good reputations and rich experience to ensure that you can get high-quality products and excellent service.

7. After-sales service: Understand the supplier's after-sales service policy to ensure timely support and maintenance when needed.

8. Ease of Installation and Maintenance: Consider whether the piping is easy to install and maintain and whether additional equipment and tools are required.

9. Other factors: Consider other factors, such as transportation methods, packaging requirements, etc., according to specific circumstances.

Application Prospects of Large Diameter Steel Pipes

The rapid development of urbanization and industrialization increases the demand for infrastructure construction and energy supply, which drives the growth of the large diameter steel pipe market.

Meanwhile, with the advancement of technology, the manufacturing technology of large diameter steel pipe has been improved, the production efficiency has been increased and the cost has been reduced, which makes large diameter steel pipe more widely used in various fields.

The large diameter steel pipe market is very promising and is expected to have more opportunities and space for development in the future.

Our Advantages

Since its establishment in 2014, Botop Steel has become a leading carbon steel pipe supplier in Northern China, known for its excellent service, high-quality products, and comprehensive solutions. The company's extensive product range includes seamless, ERW, LSAW, and SSAW steel pipes, as well as pipe fittings, flanges, and specialty steels.

With a strong commitment to quality, Botop Steel implements stringent controls and tests to ensure the reliability of its products. Its experienced team provides personalized solutions and expert support, with a focus on customer satisfaction.

Tags: large diameter, steel pipe, lsaw, ssaw, smls, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: May-02-2024