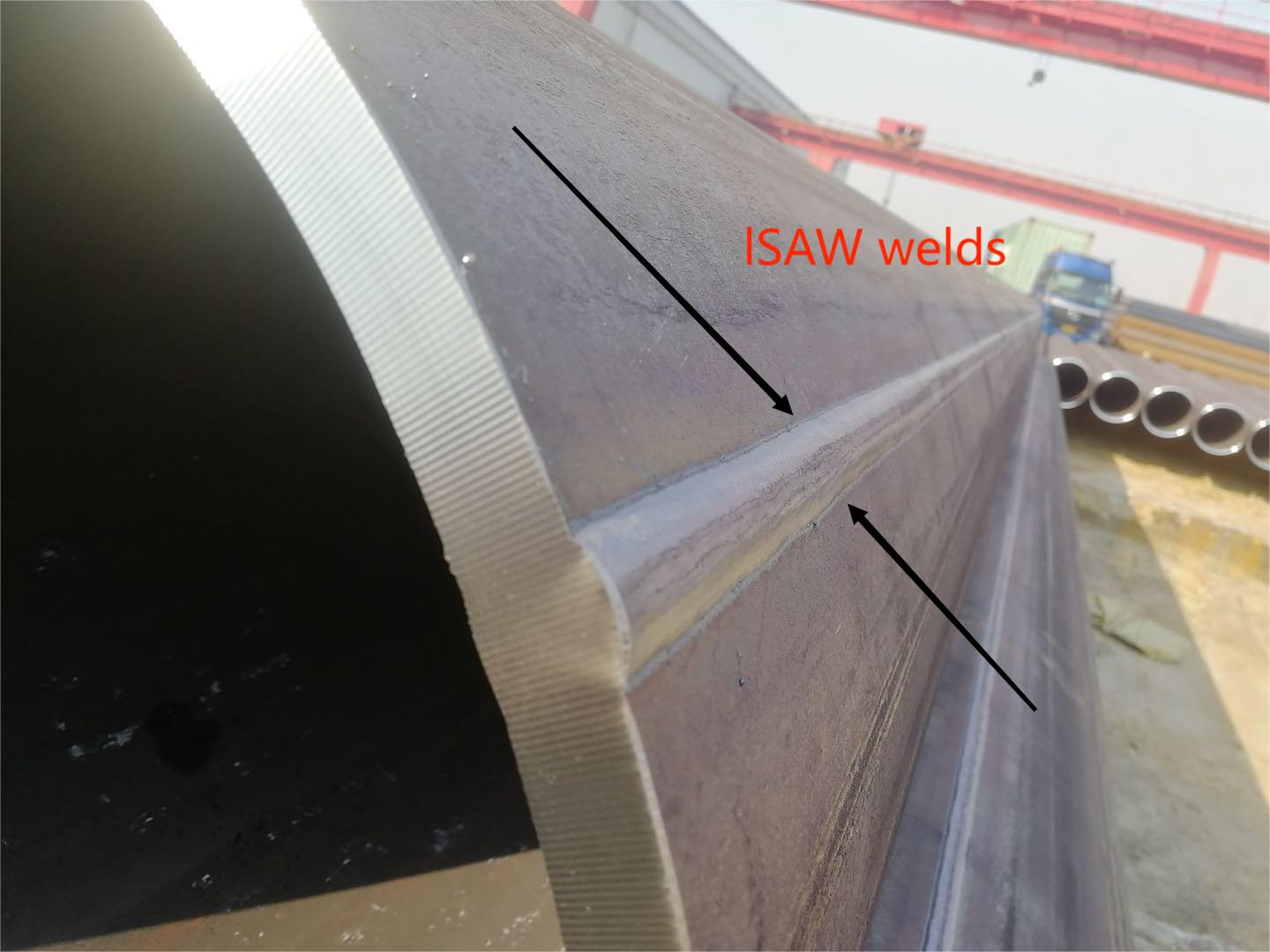

LSAW pipes are made by bending a steel plate into a tube and then welding it on both sides along its length using submerged arc welding technology, with both internal and external welding seams.

LSAW Molding Methods:JCOE, UOE, RBE

JCOE Molding Method

JCOE forming method is one of the most commonly used techniques in the production of LSAW tubes, which is mainly used for the production of large-diameter and thick-walled tubes. The method can be divided into four main steps according to the process:

J-forming: First, the ends of the steel plate are pre-bent into a "J" shape, which ensures that the weld seams at both ends can be matched smoothly.

C-forming: Next, the J-shaped steel plate is further pressed into a "C" shape.

O-forming: The C-shaped steel plate is further pressed to close it into a round or nearly round tubular structure.

E (Expansion): Finally, the diameter and roundness of the tube are adjusted through the expansion process to ensure that the tube dimensions meet the standard requirements.

UOE Molding Method

UOE forming method is similar to JCOE, but differs in the process, which is divided into three main steps:

U forming: First, the steel plate is pressed into a "U" shape.

O-forming: The U-shaped steel plate is further pressed to close it into a round or nearly round tube-like structure.

E (Expansion): The diameter and roundness of the tube body are adjusted through the expansion process to ensure that the dimensions of the tube body meet the standard requirements.

RBE Molding Method

RBE (Roll Bending and Expanding) forming method is another technique used to produce LSAW tubing, primarily for relatively small-diameter LSAW tubing. In this method, steel plates are bent by rollers to form an open tubular structure, and then the openings are closed by welding. Finally, an expansion process may be performed to ensure that the tube body is dimensionally accurate.

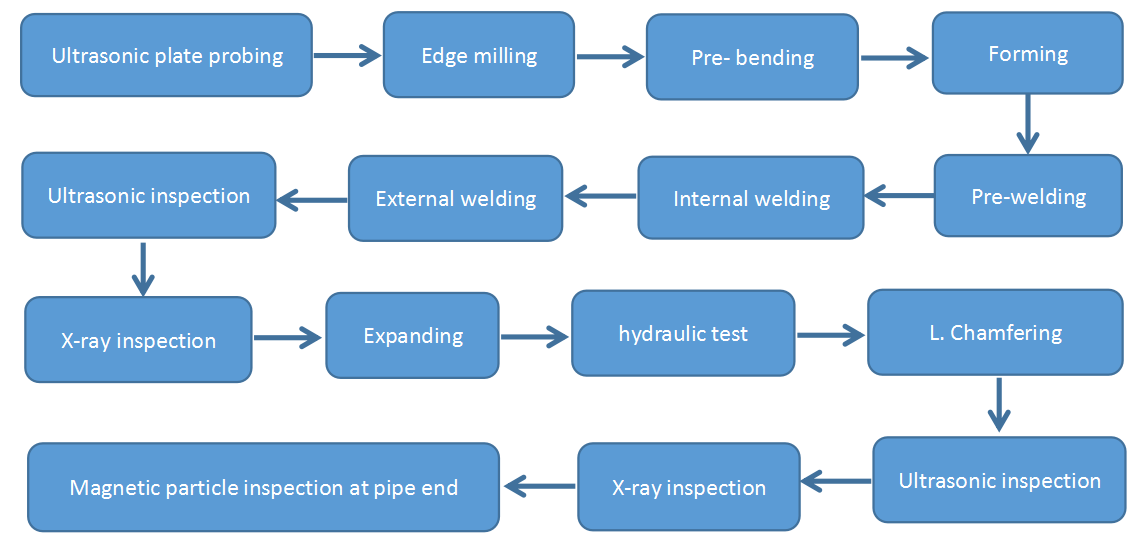

LSAW Steel Pipe Production Process

The molding process is only one of the more important aspects of the LSAW steel pipe production process, which is as follows:

Diameter Wall Thickness Length Range

Diameter Range

LSAW tubing is typically available in diameters starting at approximately 406 mm and can be 1829mm or larger.

Wall Thickness Range

LSAW tubes are available in a wide range of wall thicknesses, from about 5 mm to 60 mm.

Length Range

The length of LSAW steel pipe is usually customized to meet the needs of the project, with a range of lengths typically between 6 m and 12 m.

LSAW Implementation Standards

API 5L - long-distance pipelines for the oil and gas industry.

ASTM A53 - welded and seamless steel tubes and pipes for the transportation of fluids under pressure.

EN 10219 - Cold-formed welded round, square and rectangular section steel pipes.

GB/T 3091 - Welded Steel Pipes and Tubes for Low Pressure Fluid Transportation.

JIS G3456 - Carbon Steel Pipe for High Temperature Conditions.

ISO 3183 - Pipeline Conveyance Systems for the Oil and Gas Industry.

DIN EN 10217-1 - Welded Steel Tubes and Pipes for the Transportation of Liquids under Pressure.

CSA Z245.1 - Steel pipes for pipeline transportation systems.

GOST 20295-85 - Welded Steel Pipes for the Oil and Gas Industry.

ISO 3834 - Quality requirements for welded metals.

LSAW Pipe Applications

Major applications include oil and gas transportation, urban construction, structural engineering, and a variety of industrial uses.

Whether it is for long-distance transportation of crude oil and natural gas, water and drainage systems in cities, important building structures and bridges, or gas and steam transportation under high pressure and temperature environments.

Advantages of LSAW Steel Pipe

HIGH STRENGTH AND DURABILITY

LSAW steel pipe has high strength and toughness due to the fact that it is manufactured from a single piece of steel plate. The ability to withstand high internal and external pressures makes it ideal for high-pressure, high-strength applications.

Dimensional versatility

Compared to other types of welded pipe, such as ERW, LSAW pipe can be produced in larger diameters and thicker wall thicknesses.

High welding quality

Submerged Arc Welding (SAW) technology allows for automation and mechanization of the weld seam, ensuring continuity and uniformity of the weld seam and improving the quality of the weld.

Suitable for complex geological conditions

Due to its good mechanical properties and strength, LSAW steel pipe is suitable for complex geological conditions, such as mountainous areas, river bottoms, urban construction, and so on.

Reduction of welded joints

The fabrication process of LSAW steel pipe allows for the production of longer pipes, which reduces the number of welded joints during pipelaying, which contributes to the overall strength and safety of the pipeline.

Advantages of LSAW Steel Pipe

BotopSteel is a China Professional Welded Carbon Steel Pipes Manufacturer& Suppliers Over 16 Years with 8000+ Tons of Seamless Line pipe in Stock Each Month. Provide you with high-quality and low-price steel pipe products, if you need please contact us, we will provide you with a wide range of steel pipe solutions.

tags:lsaw,jcoe,lsaw steel pipe,lsaw Production Process, Suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-02-2024