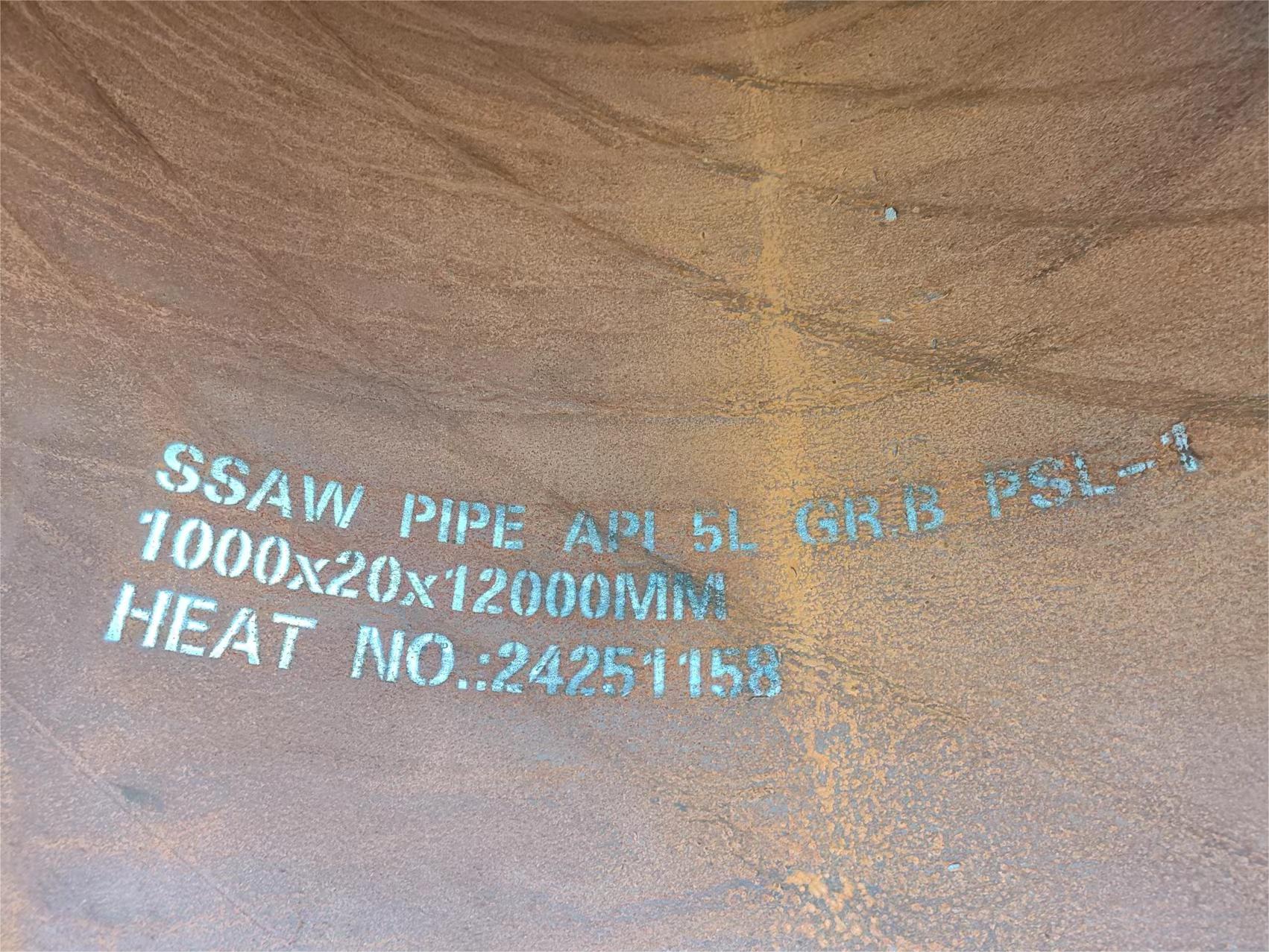

PSL1 is a product specification level in the API 5L standard and is mainly used for pipeline steel pipes in the oil and gas industry.

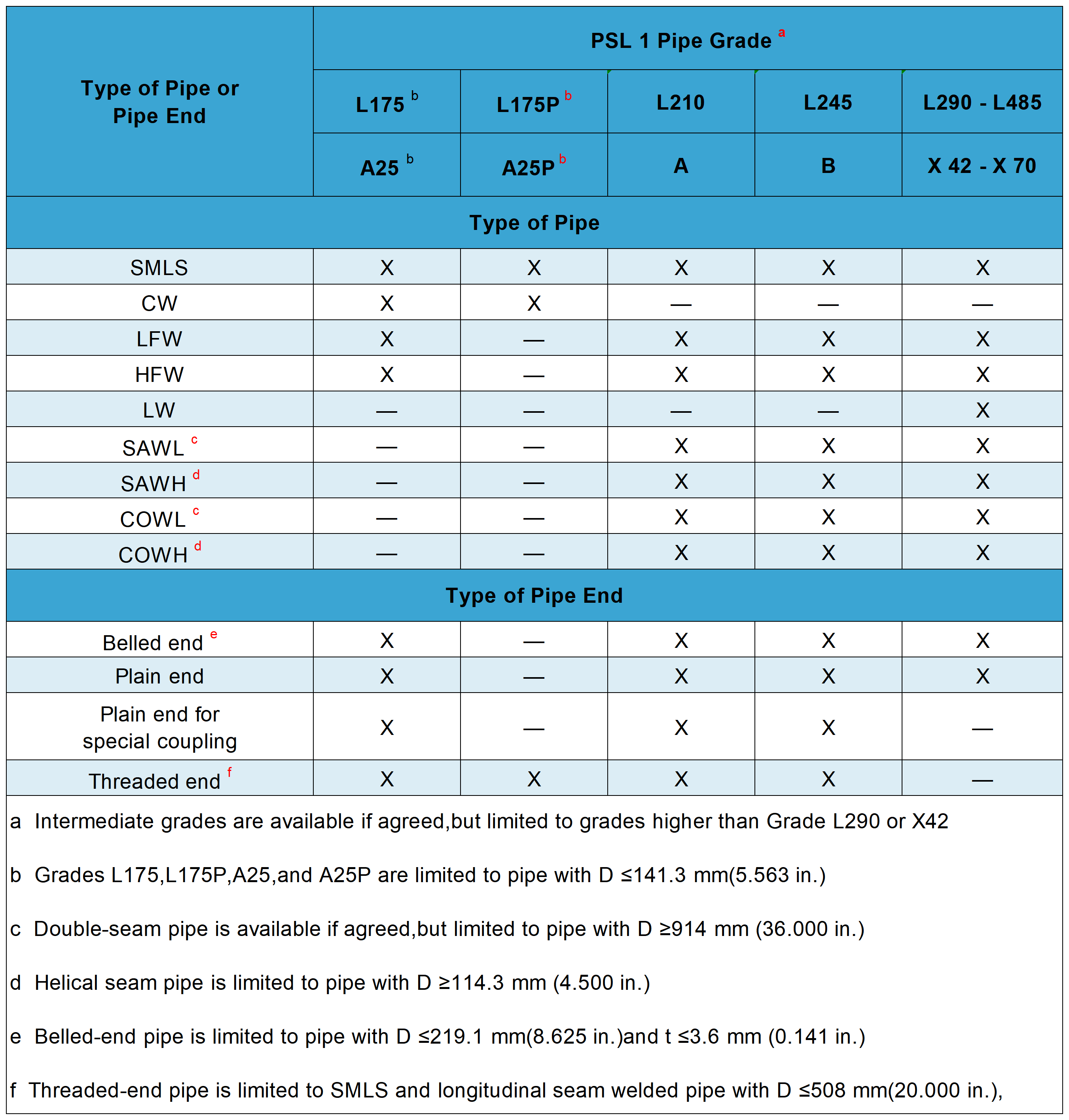

Classification

According to the type of steel pipe: seamless steel pipe and welded steel pipe.

According to the type of pipe end: flat end, threaded end, socket end, and pipe end for special clamps.

According to steel grade:

L-series (L + minimum yield strength in MPa)

L175 and L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485

X-series (X + minimum yield strength in 1000 psi)

A25 and A25P,X42,X46,X52,X56,X60,X65,X70

Common Steel Grades

Grade A and Grade B are common steel grades not defined by yield strength standards, with Grade A corresponding to L210 and Grade B corresponding to L245.

Manufacturing Process of PSL1 Steel Pipe

Raw Materials

Ingot, billet, billet, strip (coil) or plate

b) the electric furnace smelting process.

c) flat furnace steelmaking combined with ladle refining.

Delivery Conditions for PSL1

Heat treatments for PSL1 steel tubing include rolling, normalizing rolling, thermo-mechanical rolling, thermo-mechanical forming, normalizing forming, normalizing, and normalizing and tempering, which improve the mechanical properties and structural integrity of the tubing.

| PSL | Delivery Condition | Pipe Grade/Steel Grade | |

| PSL1 | As-rolled,normalizing rolled,normalized,or normalizing formed | L175 | A25 |

| L175P | A25P | ||

| L210 | A | ||

| As-rolled,normalizing rolled,thermomechanical rolled,thermomechanical formed,normalizing formed,normalized,normalized and tempered; or,if agreed,quenched and tempered for SMLS pipe only |

L245 | B | |

| As-rolled,normalizing rolled,thermomechanical rolled,thermomechanical formed,normalizing formed,normalized,normalized and tempered or quenched and tempered |

L290 | X42 | |

| L320 | X46 | ||

| L360 | X52 | ||

| L390 | X56 | ||

| L415 | X60 | ||

| L450 | X65 | ||

| L485 | X70 | ||

The letter P in L175P indicates that the steel contains a specified amount of phosphorus.

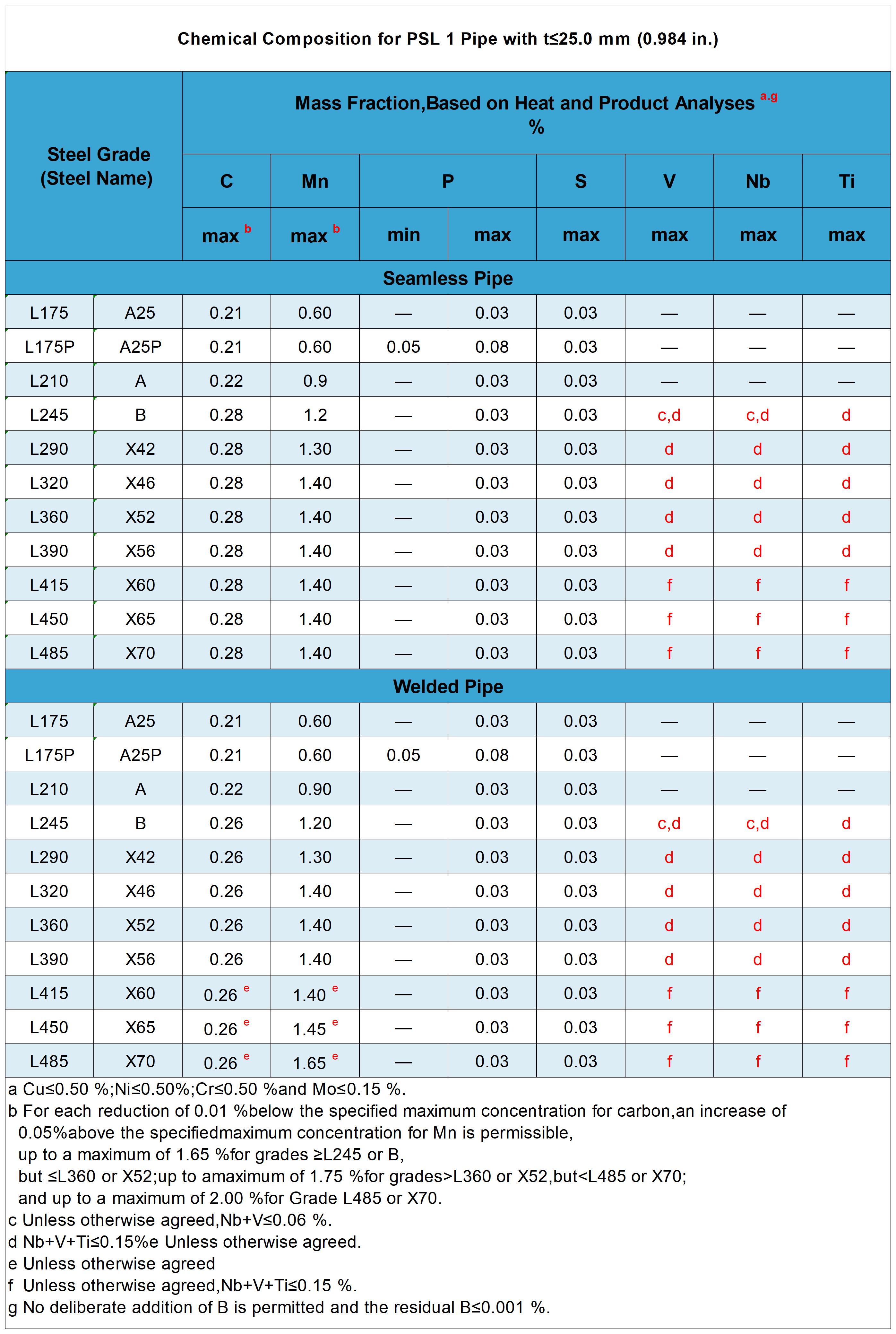

Chemical Composition of PSL1 Steel Pipe

The chemical composition of PSL1 steel pipe is strictly defined in the API 5L standard to ensure that the pipe has good mechanical properties and corrosion resistance to adapt to a variety of conveying environments.

The chemical composition of PSL1 steel pipe for t > 25.0 mm shall be determined by agreement.

Mechanical Properties of PSL1 Steel Pipe

The mechanical properties of PSL1 tubes meet the relevant requirements in API 5L, ensuring that they can withstand specific operational and environmental conditions. These mechanical property parameters mainly include yield strength, tensile strength, and elongation.

| Requirements for the Results of Tensile Tests for PSL 1 Pipe | ||||

| Pipe Grade | Pipe Body of Seamless and Welded Pipe | Weld Seam of EW, LW, SAW,and COW Pipe |

||

| Yield Strength a Rto.5 MPa(psi) |

Tensile Strength a Rm MPa(psi) |

Elongation (on 50 mm or 2 in.) Af % |

Tensile Strength b Rm MPa(psi) |

|

| min | min | min | min | |

| L175 or A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| L175P or A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 or A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 or B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 or X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 or X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 or X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 or X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 or X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 or X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 or X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Hydrostatic Test

All steel pipe shall be hydrostatically tested and there shall be no leakage from the welds or pipe body during the test.

Seamless pipes and Welded steel pipe with OD≤457mm: Voltage stabilization time ≥5s

Welded steel pipe with OD>457mm: Voltage stabilization time ≥10s

Steel pipes with threads and couplings with OD > 323.9 mm: Tests can be performed in the flat-end state.

Test methods for Experimental Items Applicable to PSL1

| Test Category | Testing Method |

| Chemical Composition | ISO 9769 or ASTM A751 |

| Mechanical Properties | ISO 6892-1 or ASTM A370 |

| Hydrostatic Test | API 5L 10.2.6 |

| Nondestructive Examination | API 5L Appendix E |

| Bending Test | ISO 8491 or ASTM A370 |

| Guided Bend Test | ISO 5173 or ASTM A370 |

| Flattening Test | ISO 8492 or ASTM A370 |

Surface Condition of PSL1 Upon Delivery

1. Light pipes

2. Temporary outer coating:

Commonly used are rust preventive oils, oil-based coatings, water-based rust preventive coatings, etc.

It can avoid rusting during storage and transportation.

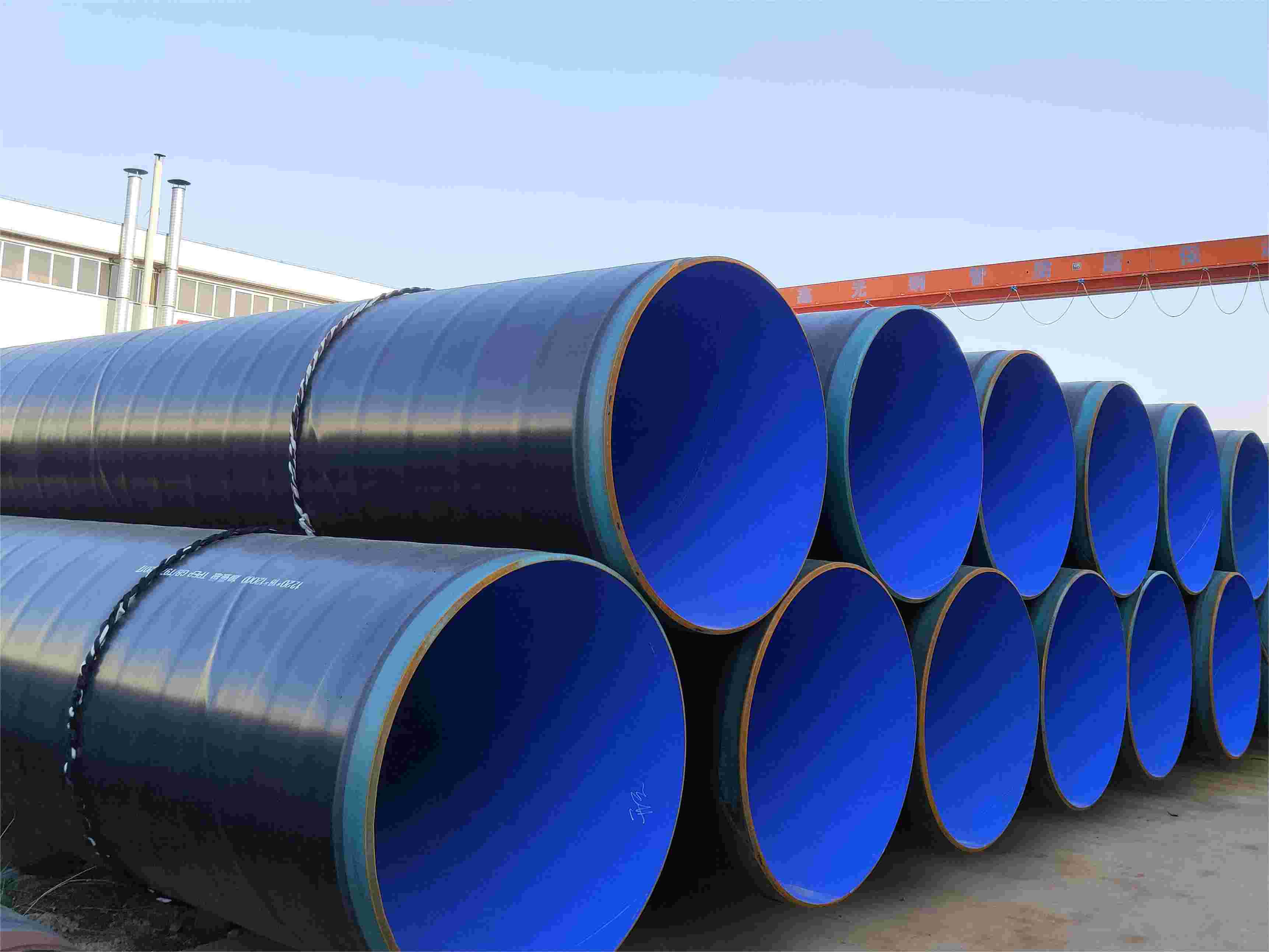

3. Special coating status:

Common ones are paint, 3LPE, 3LPP, TPEP FBE, etc.

Provides enhanced protection and improves the performance of the pipe.

Application Areas

Oil and Gas Conveyor System: for long-distance transportation of crude oil and natural gas.

Water conveyance systems: for urban water supply and irrigation systems.

Construction and Infrastructure: for bridges, road construction, and other infrastructure projects.

Plants and Processing Facilities: for the transmission of chemicals and steam in industrial facilities.

Power: for cable protection and as a component of cooling water systems.

Alternative Materials

When selecting alternative materials, the specific chemical composition and mechanical property requirements must be scrutinized to ensure that the alternative material meets the requirements of the specific project.

American Standard

ASTM A106 Grade B: For high-temperature service.

ASTM A53 Grade B: For general plumbing and structural applications.

European Standards

EN 10208-1 L245GA to L485GA: Used for pipelines carrying gas and oil.

ISO 3183 Grade L245 to L485: Very similar to the API 5L standard for use in the oil and gas industry.

DIN EN 10208-2 L245NB, L290NB: For the transportation of fuel gas and fuel oil in pressurized environments.

Japanese Standards

JIS G3454 STPG 410: Used for low-pressure fluid transportation.

JIS G3456 STPT 410: Used for high-temperature and high-pressure environments such as power plant piping.

Australian Standard

AS/NZS 1163 C350L0: Round tubes for structural and general purposes.

Chinese Standard

GB/T 9711 L245, L290, L320: Used in the oil and gas industry, similar to ISO 3183.

GB/T 8163 20#, Q345: Used for general fluid transportation pipes.

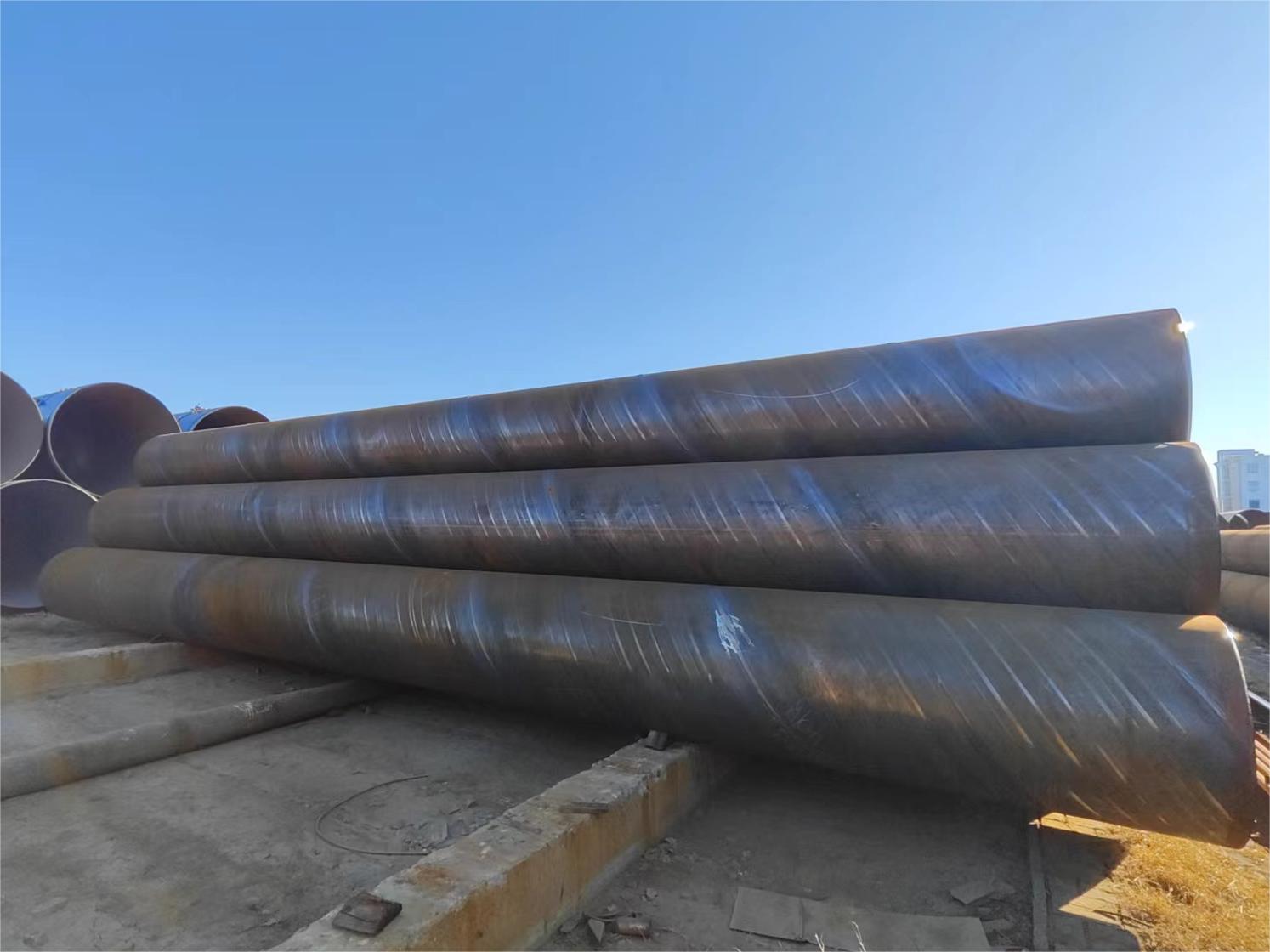

Our Related Products

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions. For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

Tags:psl1,api 5l psl1,psl1 pipe, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-13-2024