Within this field of steel, there is a specific set of acronyms and terminology, and this specialized terminology is the key to communication within the industry and the basis for understanding and executing projects.

In this article, we'll introduce you to some of the most commonly used steel pipe and tubing industry acronyms and terminology, from basic ASTM standards to complex material properties, and we'll decode them one by one to help you build a framework of industry knowledge.

Navigation Buttons

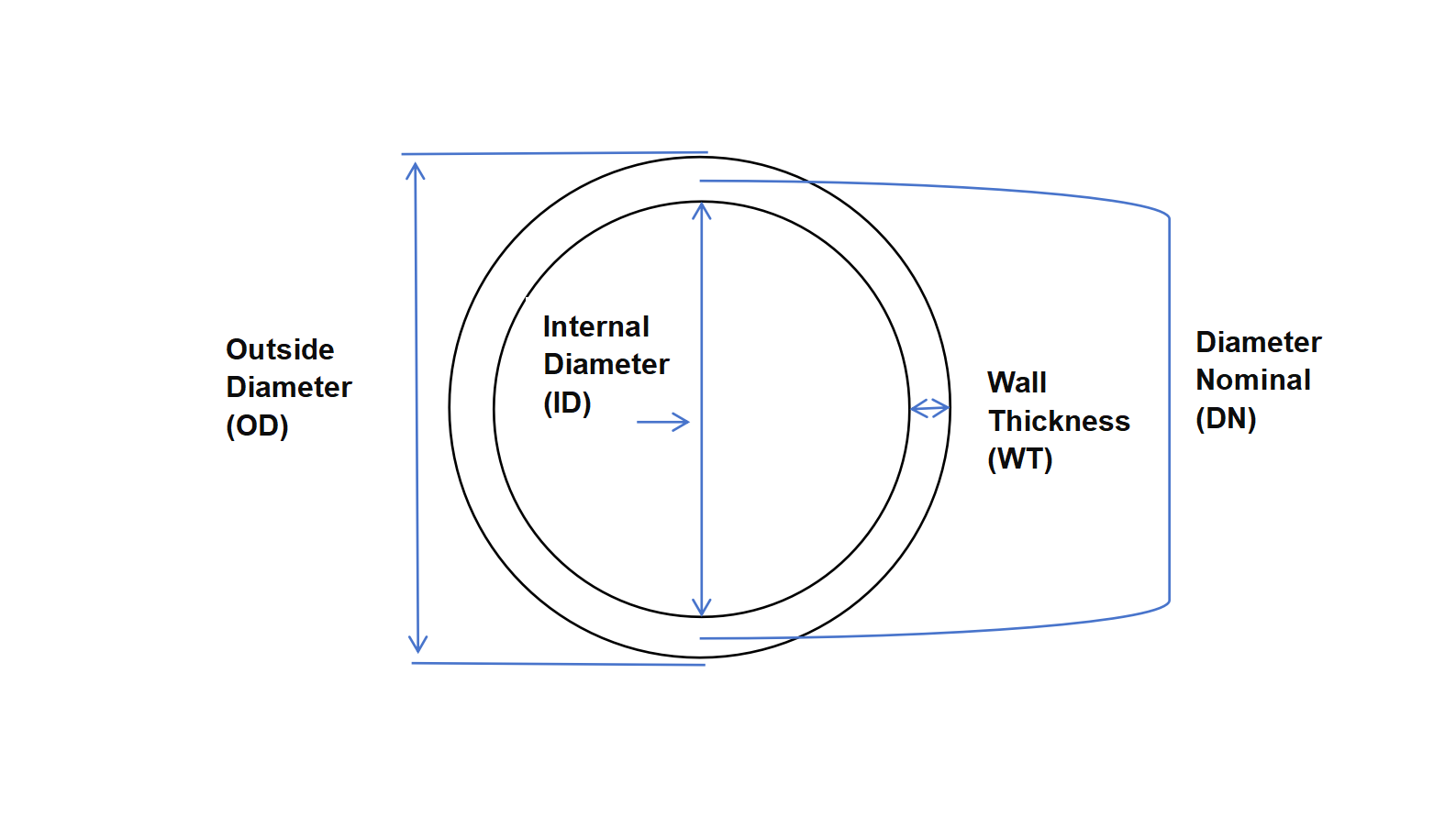

Abbreviations for Tube Sizes

NPS: Nominal Pipe Size

DN: Diameter Nominal (NPS 1 inch=DN 25 mm)

NB: Nominal Bore

OD: Outside Diameter

ID: Internal Diameter

WT or T: Wall Thickness

L: Length

SCH (Schedule Number): Describes the wall thickness grade of the tube, commonly found in SCH 40, SCH 80, etc. The larger the value, the thicker the wall thickness.

STD: Standard Wall Thickness

XS: Extra Strong

XXS: Double Extra Strong

Abbreviation for Steel Pipe Process Type

COW pipe: Products with one or two longitudinal weld seams or a spiral welded pipe manufactured by a combination of furnace gas shielding and submerged arc welding, in which the furnace gas shielded weld seam is not completely melted by the submerged arc weld channel during the welding process.

COWH pipe: A product with a spiral welded pipe manufactured using a combination of furnace gas-shielded and submerged arc welding processes, in which the furnace gas-shielded weld is not completely melted by the submerged arc weld channel during the welding process.

COWL pipe: Products with one or two straight weld seams manufactured by a combination of furnace gas shielding and submerged arc welding, in which the furnace gas shielded weld seam is not completely melted by the submerged arc weld channel during the welding process.

CW pipe (Continuous Welded pipe): A steel pipe product with a straight weld seam manufactured by the continuous furnace welding process.

EW pipe (Electrical Welded pipe): manufactured by low-frequency or high-frequency electric welding process.

ERW pipe: Electrical Resistance Welded pipe.

HFW pipe (High-Frequency pipe): Electric welded pipes welded with a frequency ≥ 70KHz welding current.

LFW pipe (Low-Frequency pipe): Frequency ≤ 70KHz welding current welded into the electric welding pipe.

LW pipe (Laser Welded pipe): Pipe products with a straight weld seam guided by the laser welding process.

LSAW pipe: Longitudinal Submerged-arc Welded Pipe.

SMLS pipe: Seamless pipe.

SAW pipe (Submerged-arc Welded pipe): Steel pipe with one or two straight welds, or a spiral weld, manufactured by the submerged arc welding process.

SAWH pipe (Submerged-arc Welded Helical pipe): Steel pipe with a spiral weld seam manufactured by submerged arc welding process

SAWL pipe (Submerged-arc Welded Longitudinal pipe): Steel pipe with one or two straight weld seams manufactured by the submerged arc welding process.

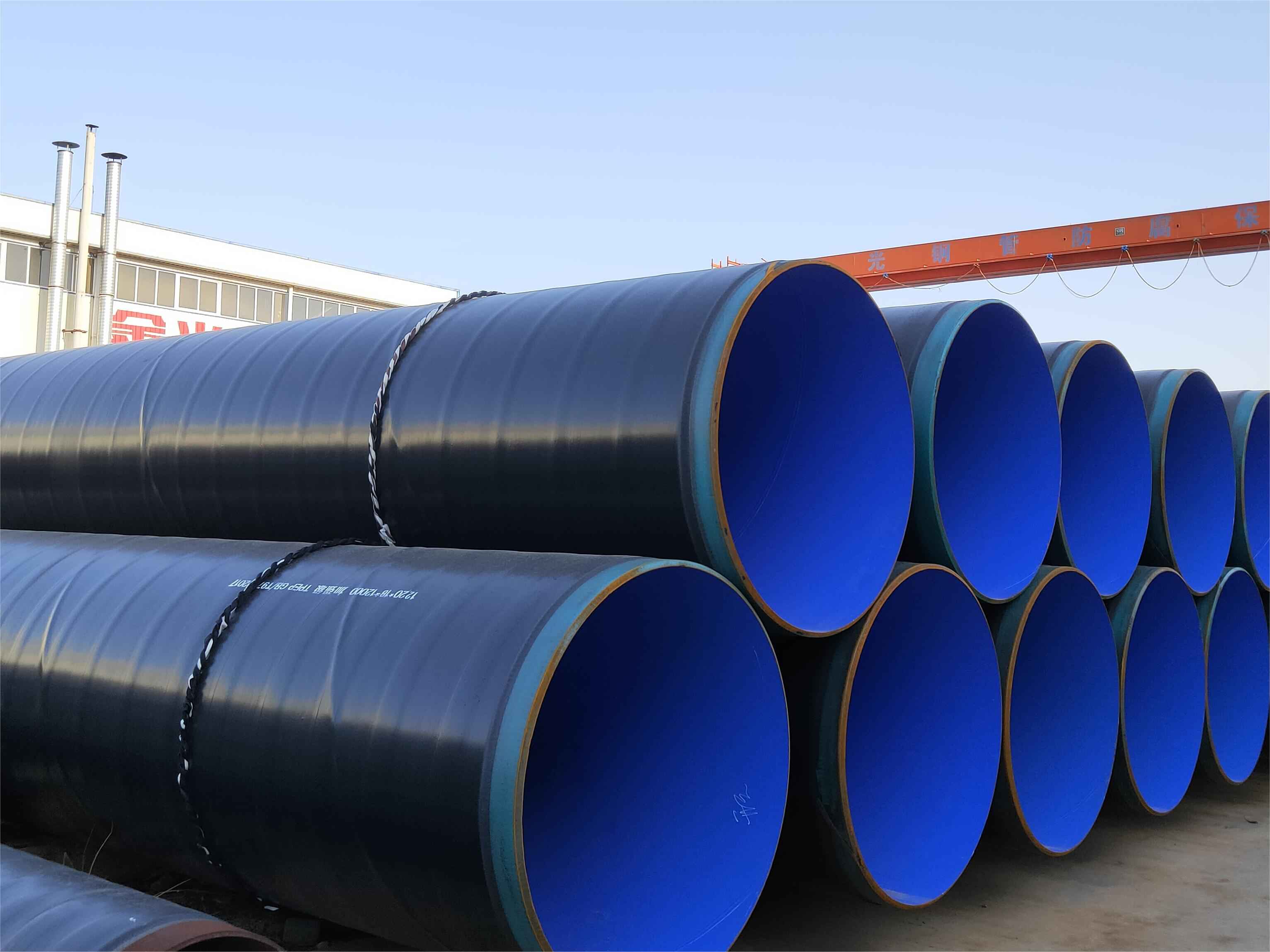

SSAW pipe: Spiral Submerged Arc Welding pipe.

RHS: Rectangular Hollow Section.

TFL: Though-the-Flow Line.

MS: Mild Steel.

Abbreviation for Anticorrosive Coating

GI (Galvanized)

3LPP

TPEP (Outer 3LPE + Inner FBE)

PU: Polyurethane Coating

GI: galvanized Steel pipe

FBE: fusion-bonded epoxy

PE: Polyethylene

HDPE: high-density polyethylene

LDPE: low-density polyethylene

MDPE: medium-density polyethylene

3LPE(Three-Layer Polyethylene): Epoxy layer, Adhesive layer and Polyethylene layer

2PE(Two-Layer Polyethylene): Adhesive layer and Polyethylene layer

PP: Polypropylene

Standard Abbreviations

API: American Petroleum Institute

ASTM: American Society for Testing Material

ASME: American Society of Mechanical Engineers

ANSI: American National Standards Institute

DNV: Det Norske Veritas

DEP: Design and Engineering Practice(SHELL Shell Standard)

EN: European Norm

BS EN: British Standards with the adoption of European Standards

DIN: German Industrial Standard

NACE: National Association of Corrosion Engineer

AS: Australian Standards

AS/NZS: Joint acronym for Australian Standards and New Zealand Standards.

GOST: Russian national standards

JIS: Japanese Industrial Standards

CSA: Canadian Standards Association

GB: Chinese national standard

UNI: Italian National Board of Unification

Abbreviations for Test Items

TT: Tensile Test

UT: Ultrasonic Test

RT: X-Ray Test

DT: Density Test

YS: Yield Strength

UTS: Ultimate Tensile Strength

DWTT: Drop-weight Tear Test

HV: Verker's Hardness

HR: Rockwell's Hardness

HB: Brinell's Hardness

HIC test: Hydrogen Induced Crack test

SSC test: Sulfide Stress Crack test

CE: Carbon Equivalent

HAZ: Heat Affected Zone

NDT: Non-Destructive Test

CVN: Charpy V-notch

CTE: Coal Tar Enamel

BE: Beveled Ends

BBE: Beveled Both Ends

MPI: Magnetic Particle Inspection

PWHT: Past Weld Heat Treatment

Abbreviation for Process Inspection Documentation

MPS: Master Production Schedule

ITP: inspection and testing plan

PPT: pre-production trial

PQT: procedure qualification trial

PQR: Procedure Qualification Record

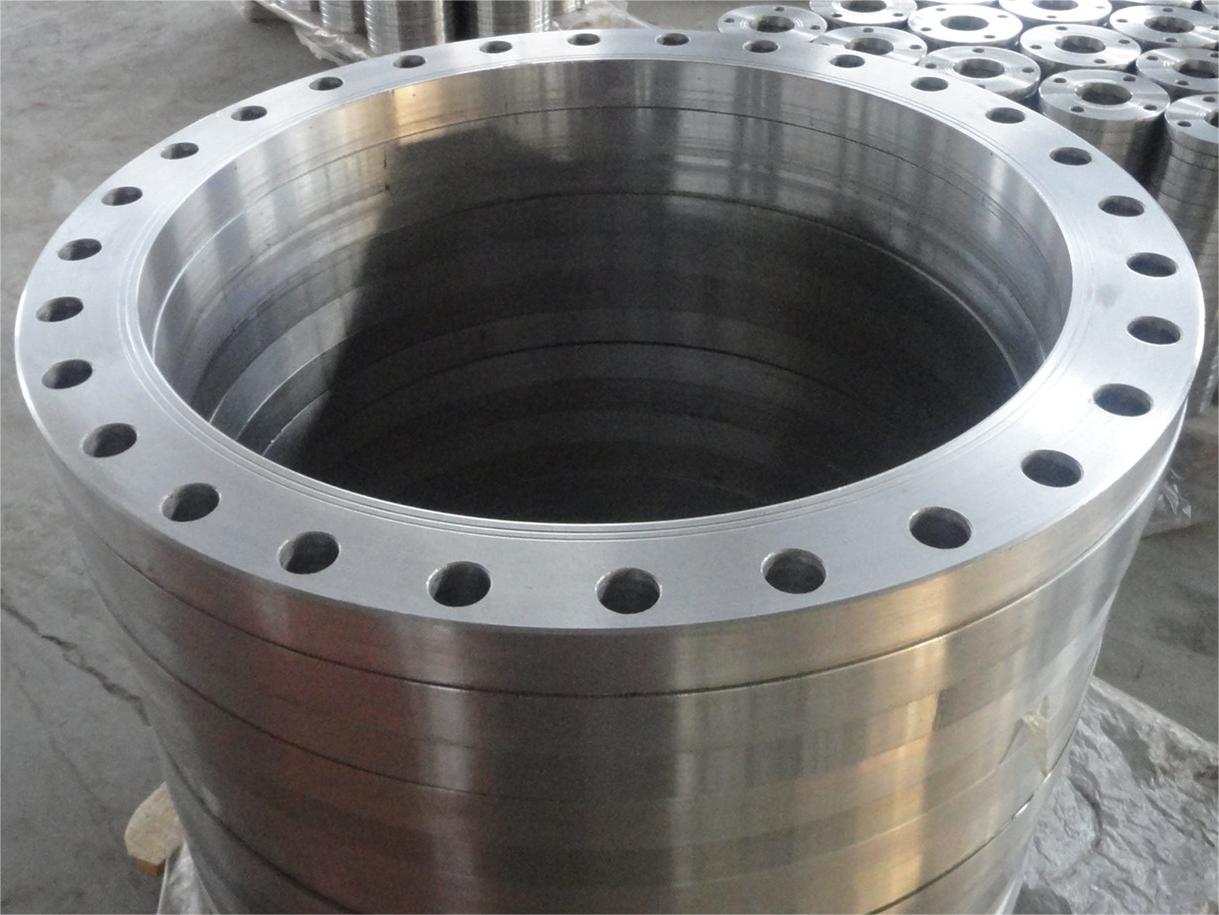

Abbreviation for Pipe Fitting Flange

Flange

Bends

FLG or FL: Flange

RF: Raised Face

FF: Flat Face

RTJ: Ring Type Joint

BW: Butt Weld

SW: Socket Weld

NPT: National Pipe Thread

LJ or LJF: Lap Joint Flange

SO: Slip-On Flange

WN: Weld Neck Flange

BL: Blind Flange

PN: Nominal Pressure

At this point, we've explored the core terms and acronyms in the steel pipe and piping industry that are key to your ability to communicate and operate effectively within the industry.

Mastering these terms is essential to accurately interpret technical documents, specifications, and design documents. Whether you are new to the industry or a seasoned professional, we hope that this guide has provided you with a solid starting point for gaining insight into a highly technical field that is full of challenges and opportunities.

tags:ssaw, erw, lsaw, smls, steel pipe, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-14-2024