Correctly describing the size of a steel tube needs to include several key parameters:

Outside Diameter (OD)

The external diameter of the steel pipe, usually expressed as nominal diameter (DN) or nominal pipe size (NPS).

Nominal Pipe Size (NPS) vs. Nominal Diameter (DN)

NPS is the nominal size based on inches, while DN is the nominal diameter in millimeters. The conversion relationship is relatively simple: the value of DN is equal to the NPS value multiplied by 25.4 (mm/inch) to round the result.

In practice, the correspondence between the NPS and DN standards is based more on the standardized dimension tables that have been established.

Wall Thickness (WT)

The thickness of the pipe wall. For standard-sized pipe, the wall thickness is often associated with the Schedule of the pipe, e.g. Schedule 40 or Schedule 80, where larger values indicate thicker walls.

Length

The length of a steel pipe, which can be fixed or random, depending on production and application requirements. Common lengths are 6 meters and 12 meters.

Material

Material standards and grades for steel pipe, such as ASTM A106 Grade B, API 5L Grade B, etc. These standards specify the chemical composition and physical properties of the pipe.

Standards

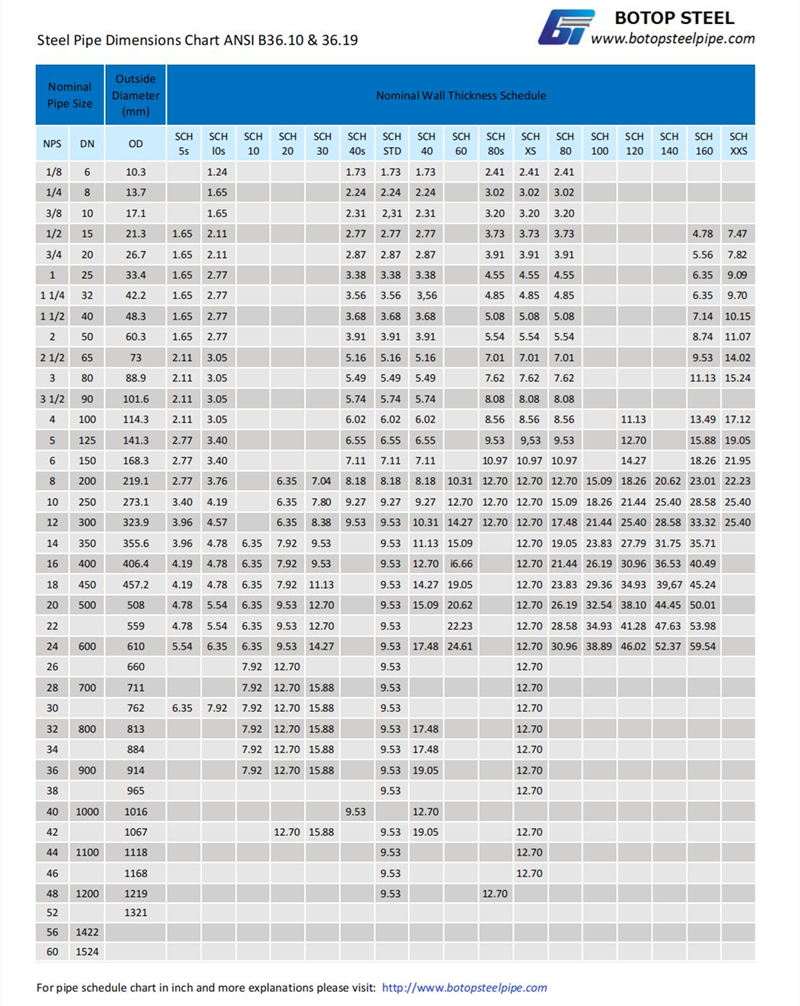

The dimensional standards for carbon and stainless steel pipe mainly follow ASME B36.10M (carbon and alloy steel) and B36.19M (stainless steel pipe).

Pipe Size Tables and Weight Grade Tables (WGT)

provide a standardized way to describe pipe wall thicknesses under different Schedules, as well as the classification of weight grades such as STD, XS, XXS, and others.

The wall thickness of a pipe directly affects the internal dimensions and weight of the pipe. Wall thickness is important because it determines the amount of internal pressure the pipe can withstand.

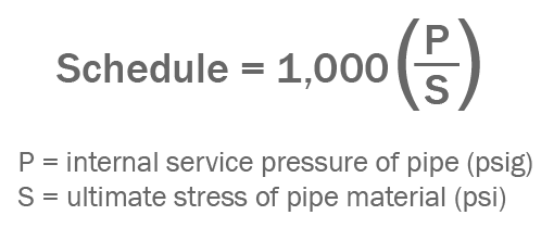

Schedule number

A way of indicating the wall thickness of a pipe, commonly such as Schedule 40 and 80, refers to the standard and reinforced wall thickness of the pipe for a given outside diameter.

The approximate calculation of a schedule number is as follows:

Because of their ability to withstand typical pressures, Schedule 40 and Schedule 80 steel pipes are commonly needed in a variety of industries. Since these pipes are designed to withstand higher pressures, they are often required in large quantities to meet the needs of various industries.

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

| 1/8 | 0.405" | 0.269" | 0.068" | 0.24 lb/ft |

| 1/4 | 0.540" | 0.364" | 0.088" | 0.42 lb/ft |

| 3/8 | 0.675" | 0.493" | 0.091" | 0.57 lb/ft |

| 1/2 | 0.840" | 0.622" | 0.109" | 0.85 lb/ft |

| 3/4 | 1.050" | 0.824" | 0.113" | 1.13 lb/ft |

| 1 | 1.315" | 1.049" | 0.133" | 1.68 lb/ft |

| 1 1/4 | 1.660" | 1.380" | 0.140" | 2.27 lb/ft |

| 1 1/2 | 1.900" | 1.610" | 0.145" | 2.72 lb/ft |

| 2 | 2.375" | 2.067" | 0.154" | 3.65 lb/ft |

| 2 1/2 | 2.875" | 2.469" | 0.203" | 5.79 lb/ft |

| 3 | 3.500" | 3.068" | 0.216" | 7.58 lb/ft |

| 3 1/2 | 4.000" | 3.548" | 0.226" | 9.11 lb/ft |

| 4 | 4.500" | 4.026" | 0.237" | 10.79 lb/ft |

| 5 | 5.563" | 5.047" | 0.258" | 14.62 lb/ft |

| 6 | 6.625" | 6.065" | 0.280" | 18.97 lb/ft |

| 8 | 8.625" | 7.981" | 0.322" | 28.55 lb/ft |

| 10 | 10.750" | 10.020" | 0.365" | 40.48 lb/ft |

| 12 | 12.75" | 11.938" | 0.406" | 53.52 lb/ft |

| 14 | 14.000" | 13.124" | 0.438" | 63.50 lb/ft |

| 16 | 16.000" | 15.000" | 0.500" | 82.77 lb/ft |

| 18 | 18.000" | 16.876" | 0.562" | 104.70 lb/ft |

| 20 | 20.000" | 18.812" | 0.594" | 123.10 lb/ft |

| 24 | 24.000" | 22.624" | 0.688" | 171.30 lb/ft |

| NPS | OUTSIDE DIAMETER (IN) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) | WEIGHT (LB/FT) |

| 1/8 | 0.405" | 0.215" | 0.095" | 0.32 lb/ft |

| 1/4 | 0.540" | 0.302" | 0.119" | 0.54 lb/ft |

| 3/8 | 0.675" | 0.423" | 0.126" | 0.74 lb/ft |

| 1/2 | 0.840" | 0.546" | 0.147" | 1.09 lb/ft |

| 3/4 | 1.050" | 0.742" | 0.154" | 1.47 lb/ft |

| 1 | 1.315" | 0.957" | 0.179" | 2.17 lb/ft |

| 1 1/4 | 1.660" | 1.278" | 0.191" | 3.00 lb/ft |

| 1 1/2 | 1.900" | 1.500" | 0.200" | 3.63 lb/ft |

| 2 | 2.375" | 1.939" | 0.218" | 5.02 lb/ft |

| 2 1/2 | 2.875" | 2.323" | 0.276" | 7.66 lb/ft |

| 3 | 3.500" | 2.900" | 0.300" | 10.25 lb/ft |

| 3 1/2 | 4.000" | 3.364" | 0.318" | 12.50 lb/ft |

| 4 | 4.500" | 3.826" | 0.337" | 14.98 lb/ft |

| 5 | 5.563" | 4.813" | 0.375" | 20.78 lb/ft |

| 6 | 6.625" | 5.761" | 0.432" | 28.57 lb/ft |

| 8 | 8.625" | 7.625" | 0.500" | 43.39 lb/ft |

| 10 | 10.750" | 9.562" | 0.594" | 64.42 lb/ft |

| 12 | 12.75" | 11.374" | 0.688" | 88.63 lb/ft |

| 14 | 14.000" | 12.500" | 0.750" | 106.10 lb/ft |

| 16 | 16.000" | 14.312" | 0.844" | 136.58 lb/ft |

| 18 | 18.000" | 16.124" | 0.938" | 170.87 lb/ft |

| 20 | 20.000" | 17.938" | 1.031" | 208.92 lb/ft |

| 24 | 24.000" | 21.562" | 1.219" | 296.58 lb/ft |

Therefore, a complete example of a steel pipe size description might be "NPS 6 inch, Schedule 40, ASTM A106 Grade B, Length 6 meters". This represents a steel pipe with a nominal diameter of 6 inches, Schedule 40, manufactured to ASTM A106 Grade B standards, and a length of 6 meters.

Post time: Feb-28-2024