WNRF (Weld Neck Raised Face) flanges, as one of the common components in piping connections, need to be rigorously dimensionally inspected prior to shipment to ensure that they meet design requirements and standards.

What are WNRF Flanges?

WNRF flange is a Weld Neck Flange with a weld neck section and a flange that is used to weld to a pipe and a flange that is used to connect to another flange or piece of equipment.

The weld neck is used to weld to the pipe and the flange is used to connect to another flange or piece of equipment. The Raised Face (RF) in WNRF flanges denotes a raised face on one side of the flange that is used to make contact with the sealing surface of the other flange, usually using packing or gaskets to ensure a tight seal.

WNRF flanges are commonly used in piping systems where high sealing performance is required, such as piping connections in high-pressure or high-temperature environments.

WNFR Test Programs

Next to our recent self-inspection of a batch of WNRF Flanges, specific material: ASNI B16.5 class 300 F52 as an example, the details of our self-inspection of internal quality control of some of the WNRF flange inspection program.

Appearances

The surface of the WNRF flange should be smooth and free from obvious oxidation, rust, oil, or other contaminants. The connecting surface of the flange is flat, without unevenness or obvious mechanical damage.

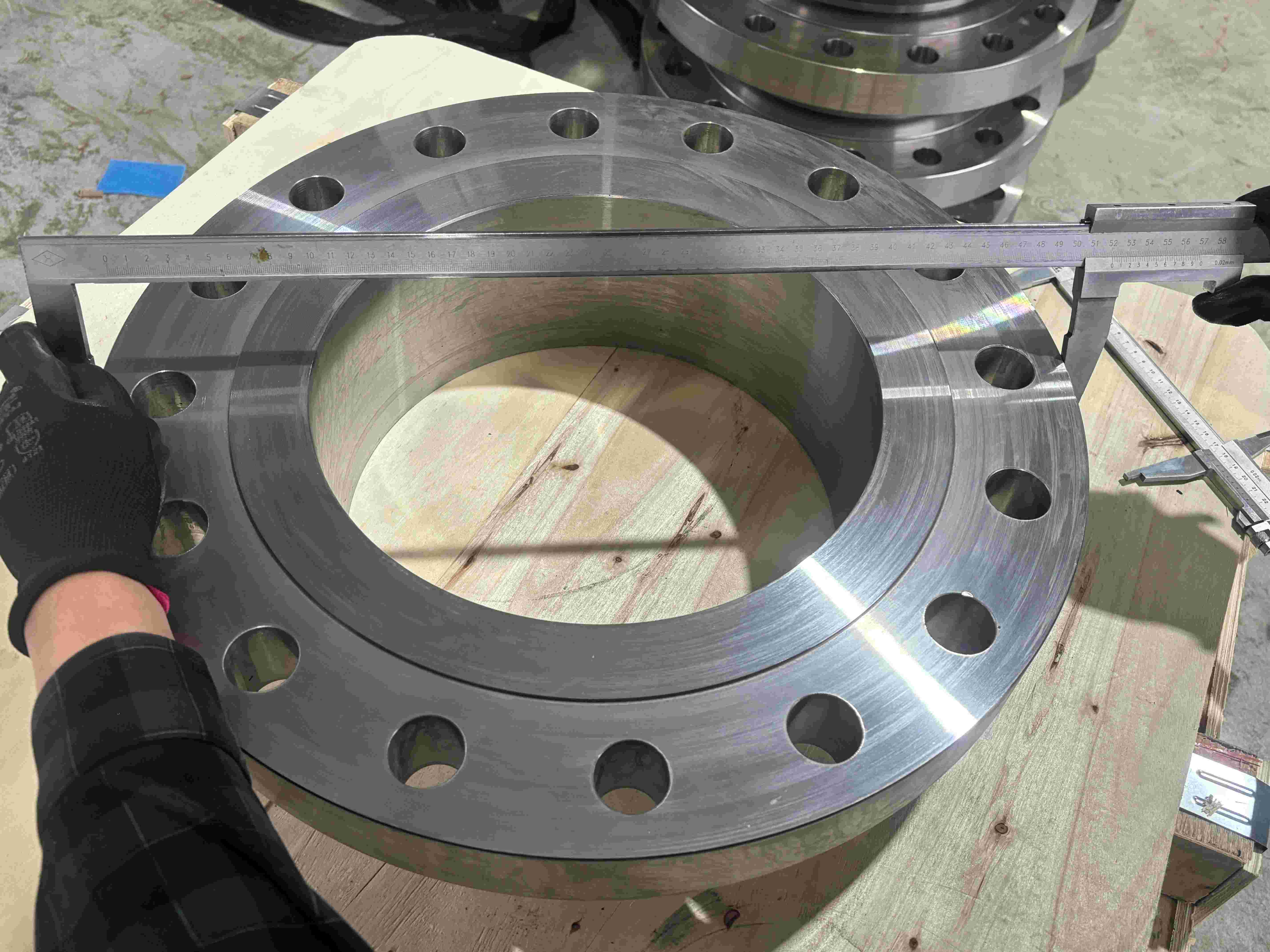

Outer Diameter of Flanges

An important dimensional parameter of weld neck flanges. The size and geometry of the flange's outside diameter directly affect the way the flange is installed and connected.

Measurement of Flange Outside Diameter Typically, a vernier caliper is placed on the outside of the flange, ensuring that the caliper is perpendicular to the surface of the flange, and then the measurement is read. Ensure that the flange can be properly installed on the pipe and connected to other flanges or pipes.

Flange Inside Diameter

The Flange Inside Diameter of a Weld Neck Flange is the diameter of the inside of the flange, often also referred to as the flange bore or pipe caliber. The size of the Flange Inside Diameter is critical to the tightness of the flange-to-pipe connection, as it needs to match the outside diameter of the pipe to ensure a tight and secure connection.

Measurement is made by placing a vernier caliper inside the flange, ensuring that the measuring portion is parallel to the inside wall of the flange and evenly positioned, and then reading the measurement. Make sure to match the pipe caliber for connection.

Weld Neck Diameter

The diameter of the welded portion on the weld neck flange is also known as the weld neck diameter. The size of the weld neck diameter depends on the outside diameter of the pipe, and it matches the outside diameter of the pipe to be welded.

Measurement of weld neck diameter is usually done using diameter calipers or a sizer on the diameter of the welded portion to ensure accuracy.

Hub Diameter

The Hub Diameter of a WNRF flange is the diameter of the protruding portion of the flange. The size of the hub diameter is the same as the diameter of the weld neck, which is the part of the flange that is used to connect to the pipe and matches the outside diameter of the pipe.

Measuring the convex diameter of a weld neck is usually done using a diameter caliper or a sizer placed over the diameter of the protruding portion of the weld neck, making sure the tool is parallel to the surface of the weld neck.

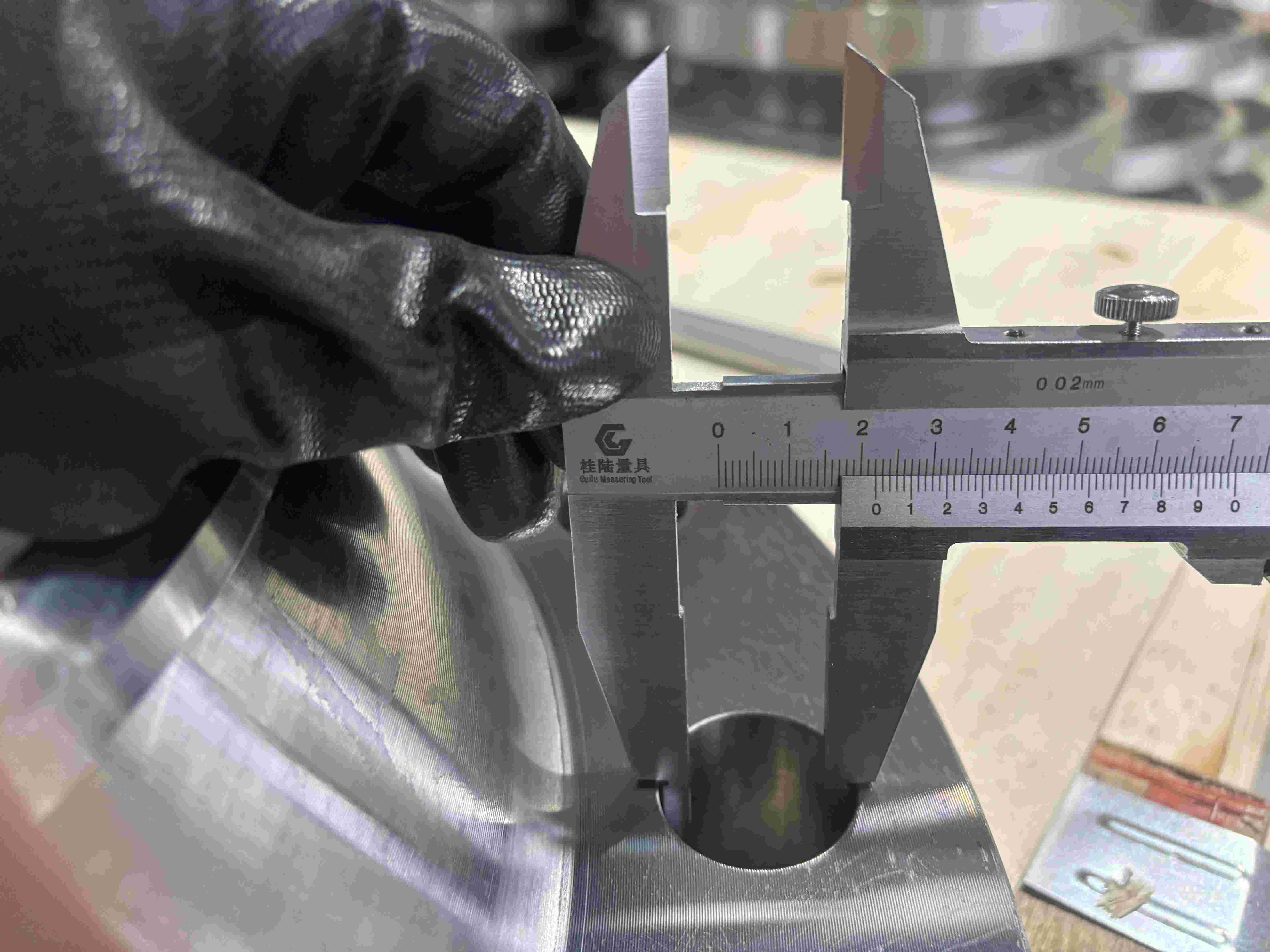

Bolt Hole Diameter

Bolt holes are the diameter of the holes in weld neck flanges used for mounting bolts. These holes pass through the thickness of the flange, usually part of the flange, and are used to join two flanges together to form a sealed pipe connection.

The diameter of the bolt holes is important to ensure that the bolts can be properly installed in the flanges. If the diameter of the hole is too small, the bolt will not fit through the hole and be secured correctly. Conversely, if the hole diameter is too large, the bolt may loosen in the hole, resulting in a weak connection.

Measure the diameter of the bolt holes in order to install the bolts.

The diameter of the hole is usually measured using an appropriate measuring tool, such as a bolt-hole gauge or vernier calipers, to ensure that it meets the standard requirements.

Flange Face Thickness

The flange thickness of WNRF refers to the thickness of the sealing surface of the flange, i.e. the thickness of the flat part of the flange.

If the flange thickness is insufficient, it may lead to deformation or rupture of the flange during installation or use, which may affect the sealing performance.

Measuring flange thickness is usually done using a thickness measuring tool such as a thickness gauge or calipers.

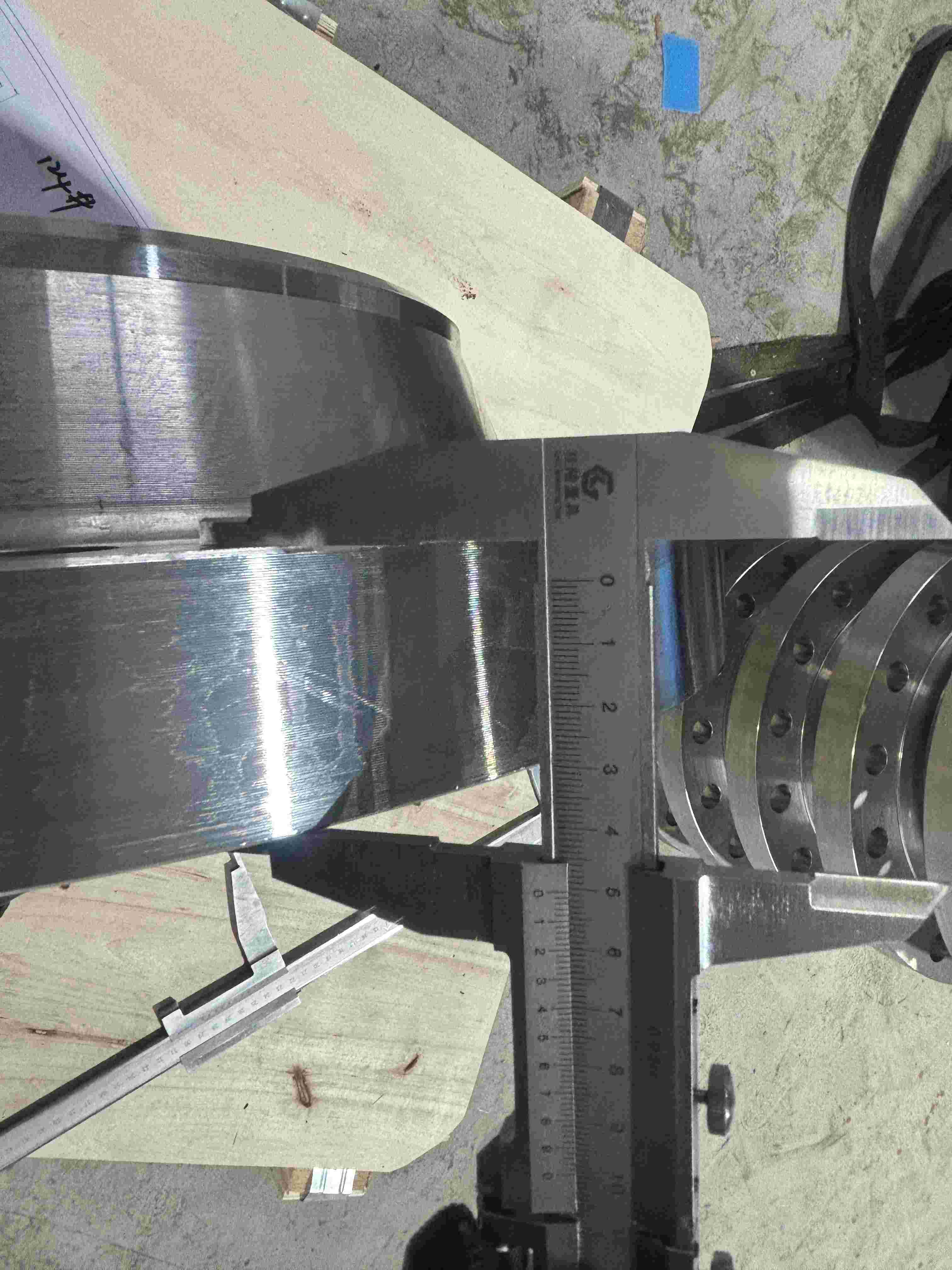

Total Height of Flange

The overall length of the flange, including the thickness of the flange disk, the length of the weld neck, and the length of the transition between the flange disk and the weld neck.

The overall flange height needs to match the height of other flanges or pipes in the piping system to ensure that the flanges are correctly connected to other components in the piping system.

Measurement of total flange height is usually done using a height measuring tool such as a height gauge, height gauge, or vernier caliper.

Significance of Dimensional Inspection

Dimensional measurements of WNRF flanges are critical for piping connections. Self-inspection ensures that the weld neck flange complies with the design and standards, improves product quality and reliability, and reduces problems that may be caused by dimensional deviations.

Dimensional measurement verifies that the dimensions of each part of the weld neck flange comply with the standard, ensures that it matches the pipeline and other components, and ensures the sealing, stability, and safety of the connection.

Our Advantages

Since its establishment in 2012, Botop Steel has become a leading supplier of carbon steel pipes in China, known for its excellent service, high-quality products and comprehensive solutions. The company's extensive product range includes seamless, ERW, LSAW and SSAW tubes, as well as pipe fittings, flanges and specialty steels.

Botop Steel has a strong commitment to quality and implements stringent controls and testing to ensure product reliability. Its experienced team provides customized solutions and expert support with a focus on customer satisfaction.

Tags: WNRF, flanges, F52, class300, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: May-01-2024