API 5L X42 steel pipe, also known as L290, is named for its minimum yield strength of 42,100 psi (290 MPa). X42 has a minimum tensile strength of 60,200 psi (415 MPa).

X42/L290 grade steel pipe belongs to the lower grade and is mainly used for applications with low pressure. Such as city gas transmission, water transmission systems, and other piping systems that do not require high-pressure carrying capacity.

Levels

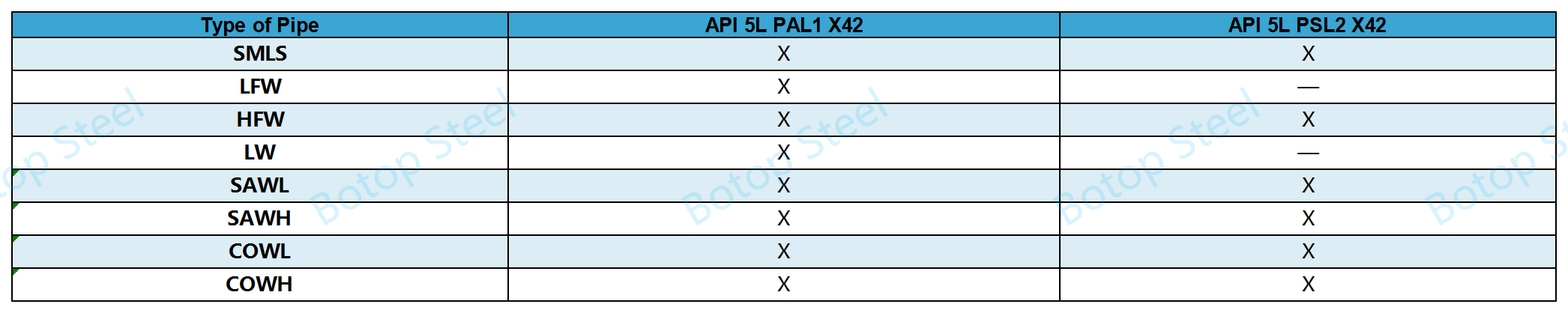

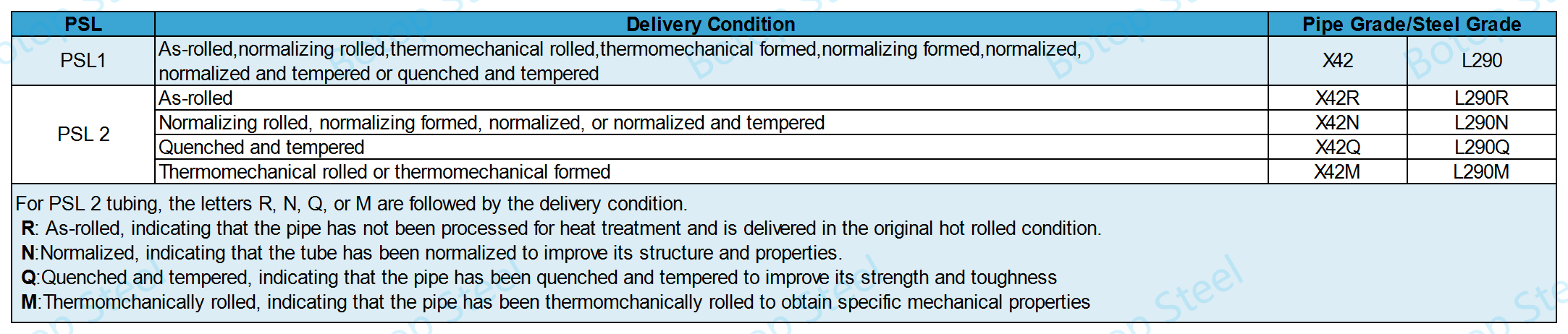

Depending on the performance requirements, X42 tubes are divided into two product specification levels, PSL1 and PSL2.

PSL1 is a basic grade line pipe specification. It is typically used in standard transportation systems where environmental conditions are less extreme.

PSL2 is a more advanced grade. It is designed for more demanding conditions, such as higher-pressure environments, and more complex or corrosive applications.

The choice of which grade of steel pipe to use depends on the specific requirements of the project, including the intended service environment and durability needs.

Steel Pipe Manufacturing Process

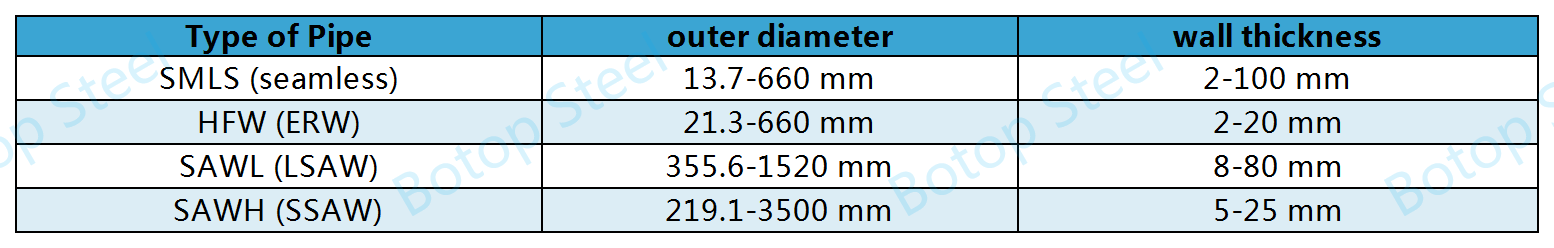

The production of X42 steel tubes covers a wide range of manufacturing techniques to meet different engineering and environmental needs. From seamless to various types of welding techniques, each method offers its own unique advantages and areas of application.

Size Range

Tube End Type

| Type of Pipe End | API 5L PAL1 X42 | API 5L PSL2 X42 |

| Belled end | X | — |

| Plain end | X | X |

Acceptable Delivery Conditions

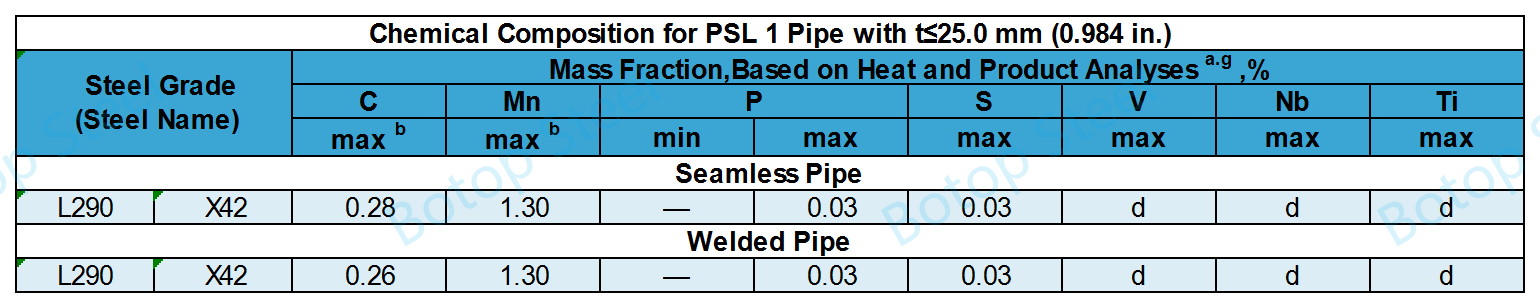

Chemical Components

API 5L X42 PSL1 Chemical Composition

The chemical composition requirements for PSL1 are relatively relaxed, with the aim of ensuring the weldability and toughness of the material.

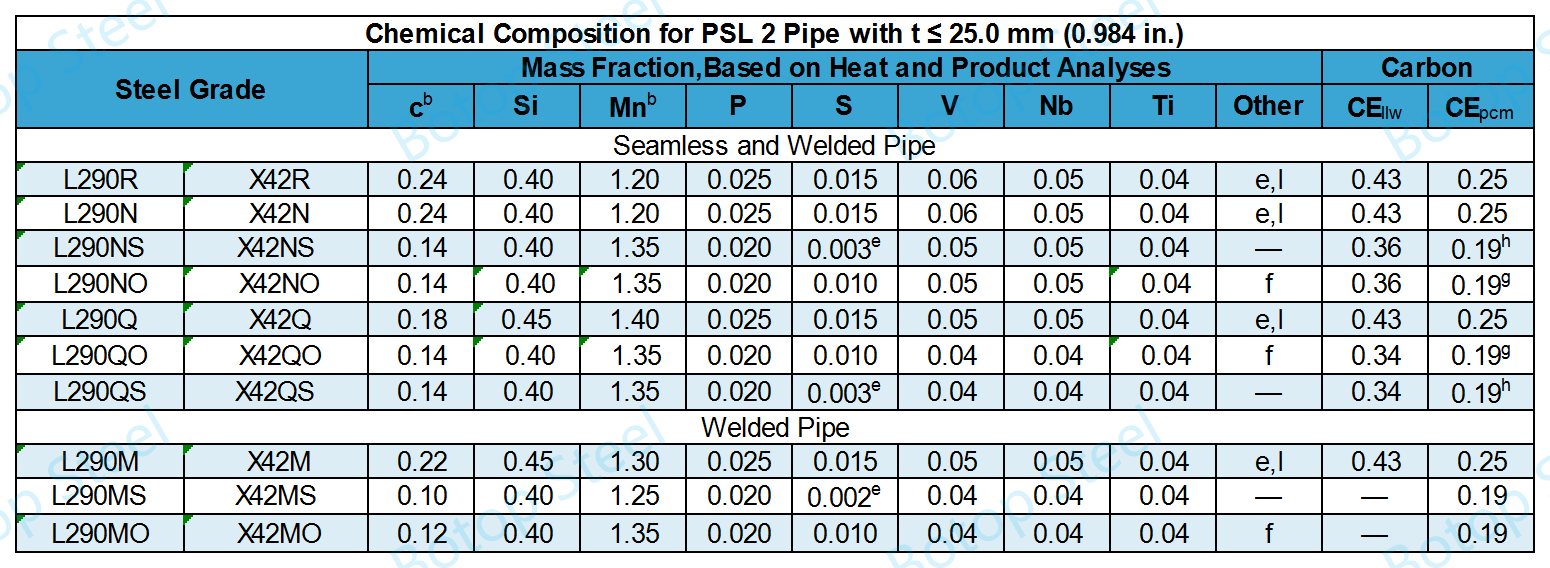

API 5L X42 PSL2 Chemical Composition

PSL2 has tighter control of the chemical composition to ensure higher quality and performance for more demanding environments and applications.

Certain grades of PSL2 tubing are specifically designed for special applications, including the material suffixes "S" and "O". The "S" suffix indicates that the pipe is designed for sour environments, while pipes with the "O" suffix are designed for offshore platform environments.

Because these environments are particularly corrosive, the corrosion resistance of steel pipe is improved by changing the chemical composition.

Mechanical Properties

API 5L X42 PSL1 Mechanical Properties

| Pipe Grade | Pipe Body of Seamless and Welded Pipe | Weld Seam of EW, LW, SAW, and COW Pipe |

||

| Yield Strength Rto.5 MPa(psi) |

Tensile Strength Rm MPa(psi) |

Elongation (on 50 mm or 2 in.) Af % |

Tensile Strengthb Rm MPa(psi) |

|

| min | min | min | min | |

| X42 or L290 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

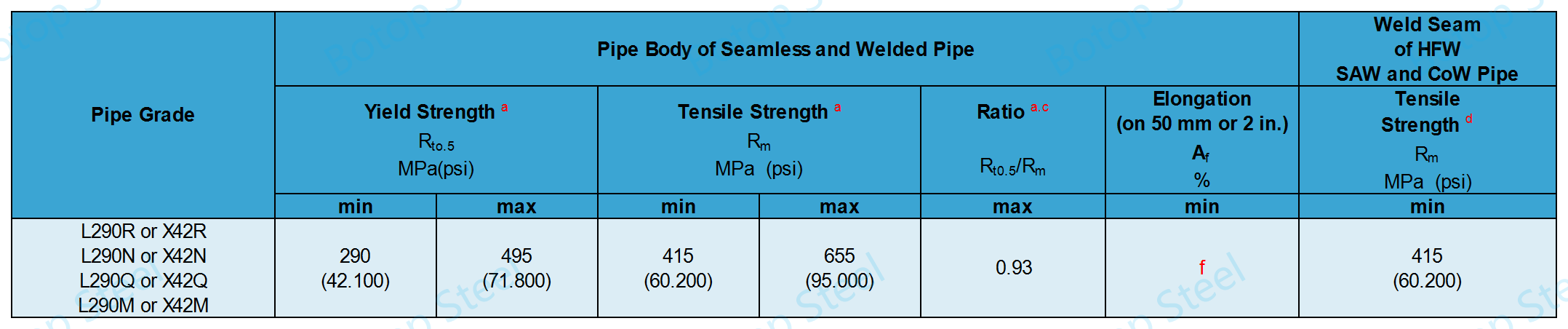

API 5L X42 PSL2 Mechanical Properties

For tubes in acidic and marine environments, the basic mechanical property requirements remain the same, and the corrosion resistance is improved by adjusting the chemical composition.

Dimensional Tolerance

Click to view API 5L dimensional requirements.

Advantages of X42 Grade Steel Tubing

1. Moderate strength and toughness: X42 steel pipe has a minimum yield strength of 42,100 psi (290 MPa), which provides good mechanical strength while maintaining sufficient toughness to withstand a certain amount of internal and external stresses without fracture.

2. Good weldability: X42 pipe usually has good weldability, which makes it easier and more economical to install and repair. This feature is especially important for long-distance pipeline projects, which usually require a lot of welding work.

3. Suitable for low and medium-pressure applications: Due to its moderate yield strength, it is particularly suitable for low and medium-pressure applications such as municipal gas transmission, low-pressure water distribution systems, etc. This makes it ideal for many municipal and industrial infrastructure projects.

4. Cost-effectiveness: Compared with higher grades (e.g. X65, X70, etc.), X42 steel pipe is often more advantageous in terms of manufacturing and procurement costs.

5. Wide range of applicability: Provides a wide range of options for different project requirements, with PSL1 being suitable for general quality requirements and PSL2 being suitable for applications where higher performance is required.

6. Standardized production: As part of the API 5L standard, the production and quality control of X42 steel pipe follows strict industry standards, which guarantees its quality consistency and reliability.

X42 Steel Pipe Application

1. Oil and gas transportation: commonly used in the construction of oil and gas pipelines for oil and gas fields. This kind of steel pipe can safely and effectively transport crude oil, natural gas and other petrochemical products, especially suitable for medium and low-pressure transportation systems.

2. Water pipeline: It is also used in water transportation and sewage treatment systems. Due to its good corrosion resistance and structural strength, it can be used in main and branch transmission pipelines, suitable for urban water supply and industrial water systems.

3. Building and structural uses: In the construction industry, it can be used as part of structural supports and frames. Its strength and weldability make it an ideal material for building bridges, road supports, and other infrastructure.

4. Power stations: In the power industry, especially in cogeneration and geothermal power stations, X42 steel pipe is used to transport steam and hot water, helping to maintain efficient energy transfer in these environments.

X42 Pipe Equivalent Material

1. EN 102082 L290NB: L290 refers to a minimum yield strength of 290 MPa. NB stands for normalized or normalized rolled and is suitable for similar applications such as oil and gas transmission.

2. ISO 3183 L290: The L290 grade of ISO 3183 is very similar to API 5L X42 in terms of chemical composition and mechanical properties.

3. GB/T 9711 L290: This is the Chinese standard for pipeline steel pipe, and L290 is equivalent to API 5L X42 in terms of minimum yield strength.

4. ASTM A106 Grade B: Although typically used for seamless carbon steel pipe, ASTM A106 Grade B can be used as an alternative to welded steel pipe in some cases, especially in non-pressurized environments.

When selecting an equivalent material, it is important to ensure that the selected material meets the chemical composition requirements, mechanical properties, and other relevant standards for the particular application. In addition, manufacturing processes, quality assurance measures, and cost-effectiveness may need to be considered.

About Us

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products,

including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels,tailored to meet the demands of various pipeline projects.

Tags:x42, API 5L, PSL1, PSL2, line pipe.

Post time: May-15-2024