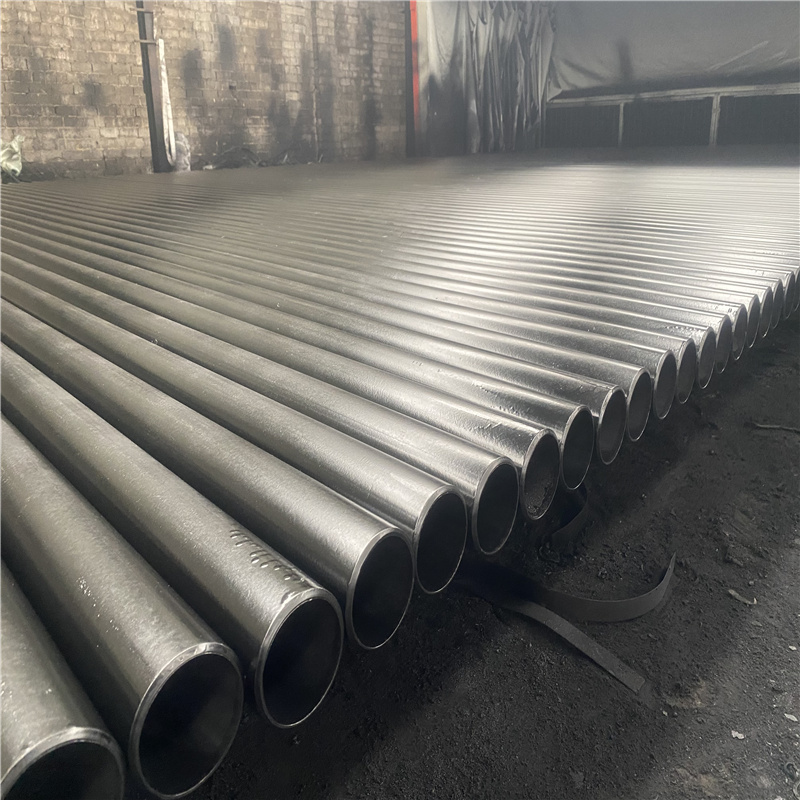

ASTM A192:Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service.

This specification covers minimum wall thickness, seamless carbon steel boiler, and superheater tubes for high-pressure service.

Navigation Buttons

ASTM A192 Size Range

Outside Diameter:12.7-177.8mm [1/2 -7 in.]

Minimum wall thickness:2.2-25.4mm [0.085 -1in.]

Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

Manufacture

Tubes shall be seamless and hot or cold worked as specified Processing.

ASTM A192 are two main manufacturing methods for seamless steel pipe: cold drawn and hot rolled.

Heat Treatment

Heat treated at 1200℉ [650℃] or above after final cold suction passage.

Dimensional Tolerances

Materials provided shall meet the applicable requirements of ASTM A450.

| Dimensional tolerances | ||

| List | sort | scope |

| Mass | DN≤38.1mm[NPS 11/2] | +12% |

| DN>38.1mm[NPS 11/2] | +13% | |

| Diameter | DN≤38.1mm[NPS 11/2] | +20% |

| DN>38.1mm[NPS 11/2] | +22% | |

| Lengths | DN<50.8mm[NPS 2] | +5mm[NPS 3/16] |

| DN≥50.8mm[NPS 2] | +3mm[NPS 1/8] | |

| Straightness and Finish | Finished tubes shall be reasonably straight and have smooth ends free of burrs. | |

| Defect Handling | Any discontinuity or irregularity found in the tube may be removed by grinding, provided that a smooth curved surface is maintained, and the wall thickness is not decreased to less than that permitted by this or the product specification. | |

ASTM A192 Pipe Weight Calculator

The weight formula is:

M=(D-T)×T×C

M is the mass per unit length;

D is the specified outside diameter, expressed in millimeters (inches);

T is the specified wall thickness, expressed in millimeters (inches);

C is 0.0246615 for calculations in SI units and 10.69 for calculations in USC units.

If you want to know more about the steel pipe weight chart and pipe schedule, click here!

ASTM A192 Test

Experimental implementation standards

| Test | Standard |

| Chemical Components | ASTM A450 Part 6 |

| Mechanical Tests | ASTM A450 Part 7 |

| Flattening test | ASTM A450 Part 19 |

| Flaring test | ASTM A450 Part 21 |

| Hardness Test | ASTM A450 Part 23 |

| Hydraulic pressure test | ASTM A450 Part 24 |

| Nondestructive Examination | ASTM A450, Part 26 |

This standard has specific requirements for chemical composition and mechanical properties: other experiments refer to ASTM A450.

Chemical Components

| Chemical Components | |

| C (Carbon) | 0.06-0.18 |

| Mn (Manganese) | 0.27-0.63 |

| P (Phosphorus) | ≤0.035 |

| S (Sulfur) | ≤0.035 |

| Si (Silicon) | ≤0.25 |

| It is not permissible to supply alloy grades that explicitly call for the addition of any element other than those listed above. | |

Tensile Properties

| Tensile Requirements | |||

| List | classification | value | |

| Tensile strength, min | ksi | 47 | |

| MPa | 325 | ||

| Yield strength, min | ksi | 26 | |

| MPa | 180 | ||

| Elongation in 50mm (2 in ), min |

% | 35 | |

Key Elements of the Marking

It shall be clearly marked:

manufacturer's name or brand

specification number, grade

the name and order number of the purchaser

hot or cold-processed.

Note: The marking need not include the year date of this specification.

For tubes less than 1 1/4 in. [31.8 mm] in diameter and tubes under 3 ft [1 m] in length, the required information may be marked on a tag securely attached to the bundle or box in which the tubes are shipped.

Additional Processing

When purchasing and using ASTM A192 pipe, the end-use environment and specific user requirements may require additional processing:

Paint or Coating

Rustproof paint or other protective coatings may be applied to the surface. These coatings provide some protection against corrosion, especially if the boiler tube is exposed to moisture.

Anti-corrosion treatments

In addition to painting, other anti-corrosion treatments such as galvanizing, aluminizing, or coating with other anti-corrosion materials may be applied to help increase the durability of the tube in harsh environments.

Heat Treatments

Although ASTM A192 specifies requirements for the manufacturing and testing of pipe, in some applications additional heat treatments (e.g., normalizing, annealing) may be required to achieve specific mechanical properties or to improve the microstructure of the pipe.

Internal and External Surface Finishes

The internal and external surfaces of boiler tubes may need to be ground, polished, or cleaned in order to improve fluid flow properties or cleanliness.

End machining

Depending on the requirements for installation and connection, the ends of boiler tubes may need to be threaded, chamfered, or otherwise machined to facilitate installation.

Additional Inspection

To ensure that tubes meet ASTM A192 and customer-specific requirements, additional inspections may be performed. For example, ultrasonic testing, X-ray testing, etc.

Specific Application

Specializing in seamless carbon steel boiler and superheater tubes. These tubes are mainly used for high-pressure services such as high-pressure boilers, ultra-high-pressure boilers, and equipment operating in high-temperature and high-pressure environments.

The following are applications of ASTM A192 steel pipe in practice:

High-pressure boilers

ASTM A192 seamless tubes are particularly suitable for manufacturing superheater tubes, hot water boiler tubes, steam conduits, large flue tubes, etc., for water tube boilers of high pressure and above. Commonly used in power stations, industrial plants and mines and chemical equipment, used to produce high temperature and high pressure steam.

Ultra-high-pressure boilers

ASTM A192 tubes are widely used in ultra-high-pressure (usually referred to as boilers with working pressures above 9.8 MPa) applications. These boilers are typically used in large power stations.

Superheaters and reheaters

These are key components of a boiler and are used to increase the temperature of the steam, which in turn increases the thermal efficiency of the entire system.

Heat exchangers

Although ASTM A192 is primarily used for boiler tubes, it can also be used in heat exchangers where good heat transfer properties are required, especially in high-temperature, high-pressure environments.

Thermal Oil Boilers

In this type of boiler, thermal energy is transferred by heating thermal oil, commonly used in the chemical, food processing, and textile industries. astm a192 tubing is suitable for the high temperature, high pressure conditions found in these applications.

Relevant Standards

ASTM A192: For seamless carbon steel boiler tubes for high-pressure boilers.

ASTM A179: Seamless cold-drawn mild steel heat exchanger and condenser tubes for low-temperature conditions.

ASTM A210: Seamless medium carbon steel boiler and superheater tubes.

ASTM A213: Seamless ferritic and austenitic alloy steel boiler, superheater, and heat exchanger tubes.

ASTM A106: Seamless carbon steel tubes for high-temperature service.

ASTM A335: Seamless ferritic and austenitic alloy steel tubes and pipes for high-temperature service, e.g. power stations.

ASTM A516: Carbon steel plate material suitable for medium and low-temperature pressure vessels.

ASTM A285: Carbon steel plate suitable for low to medium-pressure vessels.

ASTM A387: Alloy steel plate used in the manufacture of welded boilers and pressure vessels, especially where excellent heat resistance is required.

ASTM A53: Seamless and welded black and hot-dip galvanized steel tubes for general and mechanical structures.

Together, these standards cover the material properties, dimensional tolerances, mechanical properties, and chemical compositions required for use in boilers, pressure vessels, heat exchangers, etc., at various temperatures, pressures, and service conditions.

Our Related Products

Botop Steel is a China Professional Welded Carbon Steel Pipes Manufacturer& Suppliers Over 16 Years with 8000+ Tons Seamless Linepipe in Stock Each Month. If you want to know more about our steel pipe products, you can contact us to provide you with high-quality products and services!

tags:astm a192, carbon steel pipe, Boiler Tubes, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-01-2024