ASTM A501 steel is black and hot dipped galvanized hot-formed welded and seamless carbon steel structural tubing for bridges, buildings, and other general structural purposes.

Navigation Buttons

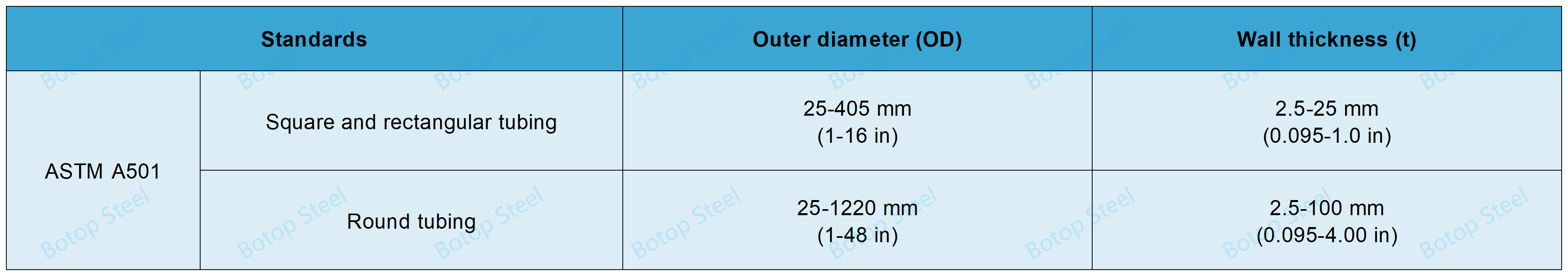

ASTM A501 Size Range

Classification of Grades

ASTM A501 is classified into three grades, Grade A, Grade B, and Grade C.

Hollow Section Shapes

Square, round, rectangular, or special shapes.

Raw Materials

The steel shall be made by basic-oxygen or electric-arc-furnace steel-making process.

Steel may be cast in ingots or may be strand cast.

Manufacturing Processes

The tubing shall be made by one of the following processes: seamless; furnace-butt-welding (continuous welding); electric resistance welding (ERW) or submerged arc welding (SAW) followed by reheating throughout the cross-section and hot forming by a reducing or shaping process, or both.

The final shape formation shall be made by a hot forming process.

It shall be permissible to add a normalizing heat treatment for tubing with a wall thickness greater than 13mm [1/2 in].

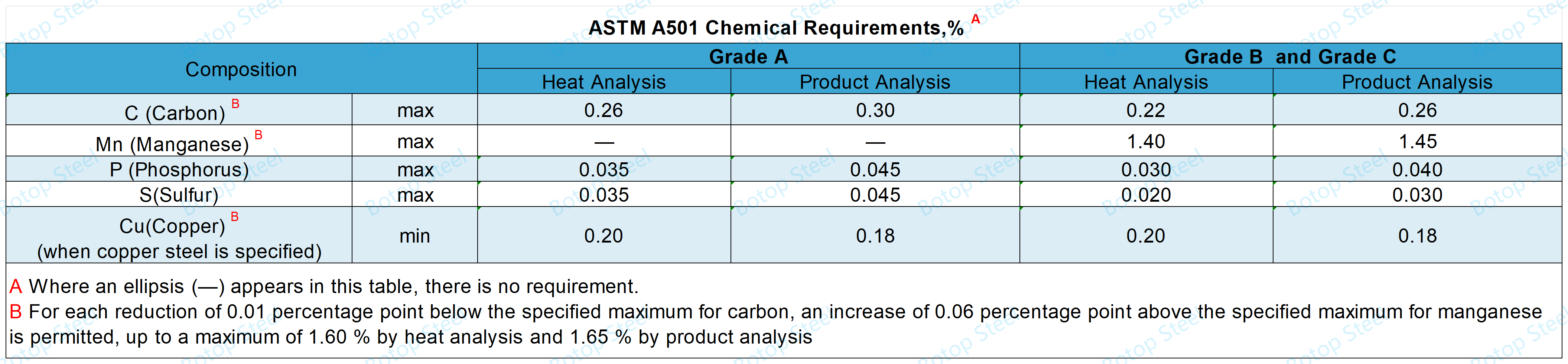

Chemical Composition of ASTM A501

Test Method: ASTM A751.

In the ASTM A501 standard, there are two methods of analysis for the chemical composition of steel: thermal analysis and product analysis.

Thermal analysis is performed during the melting process of the steel. Its purpose is to ensure that the chemical composition of the steel meets the requirements of a specific standard.

Product analysis, on the other hand, is performed after the steel has already been made into a product. This method of analysis is used to verify that the chemical composition of the final product meets the specified requirements.

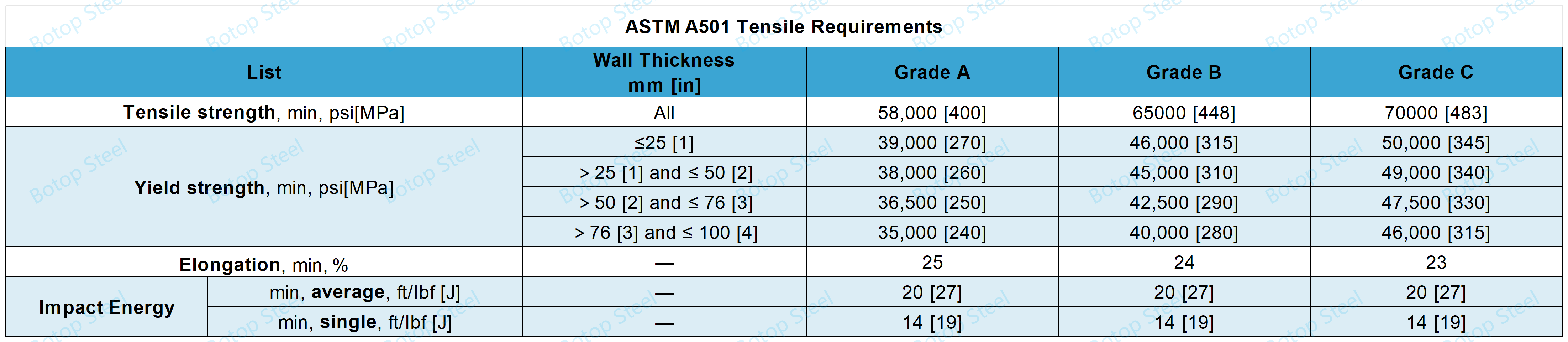

Mechanical Properties of ASTM A501

Test methods and definitions are in accordance with the relevant requirements of ASTM A370.

Wall thicknesses ≤ 6.3mm [0.25in] do not require impact testing.

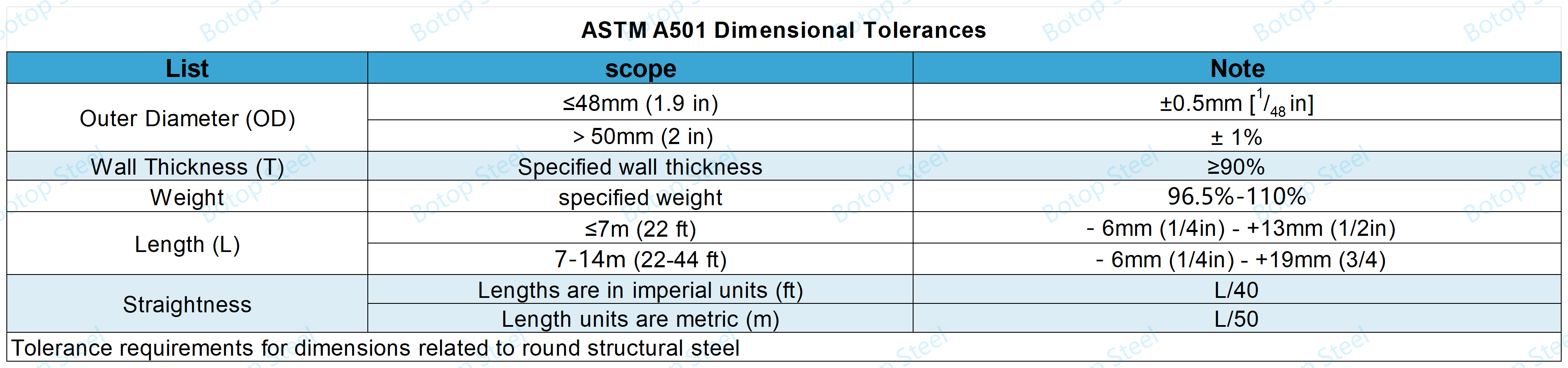

Dimensional Tolerance of ASTM A501

Galvanizing

For structural tubes to be hot-dip galvanized, this coating shall meet the requirements of Specification A53/A53M.

Measure the value of the coating on the outer surface of the pipe to determine the coating weight/thickness.

Appearance

Structural tubes shall be free of defects and have a smooth surface during hot rolling manufacturing.

Surface defects shall be classified as such when the depth of the surface defect exceeds 10% of the nominal wall thickness.

Defects requiring repair shall be completely eliminated by cutting or grinding prior to welding.

Marking

The ASTM A501 marking should have the following information as a minimum:

Manufacturer's name

Brand or trademark

Size

Name of the standard (year of publication is not required)

Grade

Each length of structural tubing should be marked by a suitable method, such as rolling, stamping, stamping, or painting.

For structural tubes <50 mm [2 in] OD, it is permissible to mark the steel information on a label attached to each bundle.

Relevant Standards

ASTM A53/A53M: Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded, and Seamless.

ASTM A370: Test Methods and Definitions for Mechanical Testing of Steel Products.

ASTM A700: Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment.

ASTM A751: Test Methods and Practices for Chemical Analysis of Steel Products.

ASTM A941: Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys.

Applications

Mainly used in construction and civil engineering.

Bridge construction: due to its good mechanical properties and strength, it is suitable for important parts of bridge structures, including load-bearing girders, bridge decks, and supporting structures.

Building construction: it can be used in the skeleton structure of buildings, including columns, beams, framing systems, and roof and floor supports.

General Structural Applications: In addition to bridges and buildings, it is also suitable for other projects that require structural support, such as the construction of sports stadiums, parking lots, schools, and other large public facilities.

Industrial applications: In some industrial facilities, such as factories and warehouses, this steel may also be used to build support architectures, roof frames, and other load-bearing structures.

Infrastructure: This steel may also be used in infrastructure such as traffic signs, lighting, and communication towers, for example.

Our Advantages

Since its establishment in 2014, Botop Steel has become a leading carbon steel pipe supplier in Northern China, known for its excellent service, high-quality products, and comprehensive solutions. The company's extensive product range includes seamless, ERW, LSAW, and SSAW steel pipes, as well as pipe fittings, flanges, and specialty steels.

With a strong commitment to quality, Botop Steel implements stringent controls and tests to ensure the reliability of its products. Its experienced team provides personalized solutions and expert support, with a focus on customer satisfaction.

Tags: ASTM a501, grade a, grade b, grade c, steel tube, structural steel tubing.

Post time: May-06-2024