Type E steel pipe is manufactured in accordance with ASTM A53 and is produced using the Electric-Resistance-Welding (ERW) process.

This pipe is primarily used for mechanical and pressure applications but is also suitable for use as general piping for the transportation of steam, water, gas, and air.

The size range of ASYM A53 is DN 6-650.

The production range of Type E is DN 20-650 DN.

Pipe diameters below DN 20 are too small for Type E. For technical reasons there is no way to produce them, so Type S, which is a seamless manufacturing process, is commonly used.

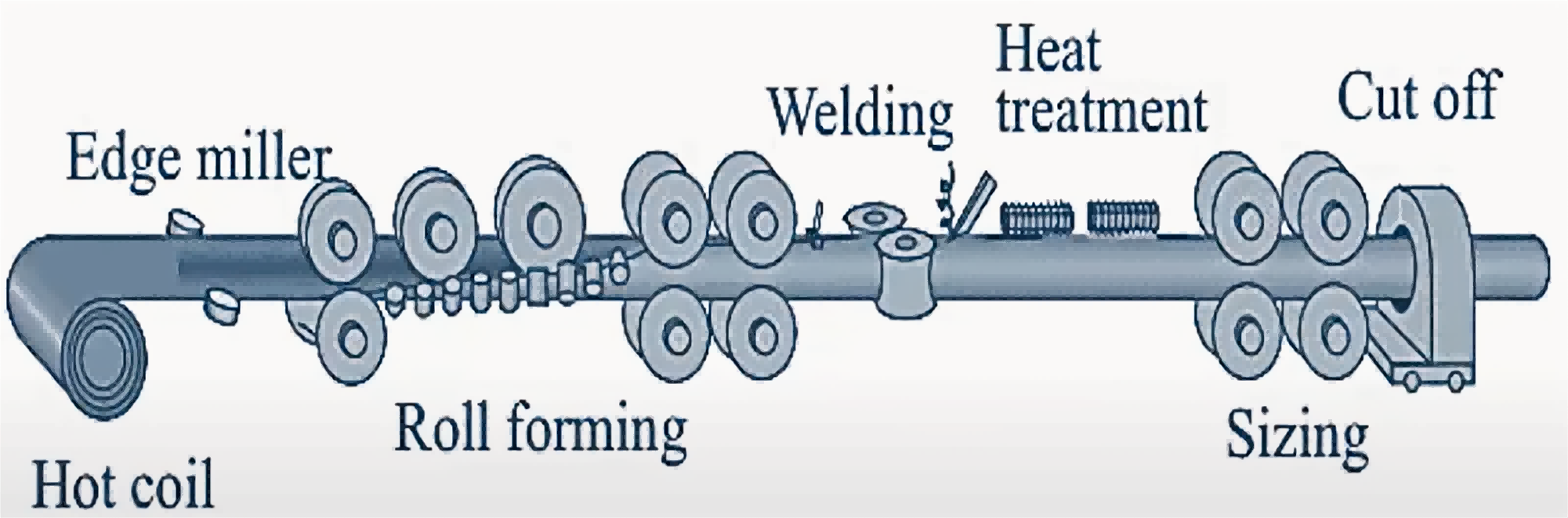

Manufacturing Process for ASTM A53 Type E

The production process involves forming steel coils through rolls, welding edges by resistance heating, deburring welds, and sizing and straightening to make tubes.

Characteristics of ASTM A53 Type E Steel Pipe

Has two longitudinal butt welds inside and outside. The edges of the steel plates are welded on both the inside and outside of the pipe during the production process to ensure strength and sealing.

The inner and outer welds are not visible. The internal and external welds are cleaned to about the same height as the pipe surface during production, which contributes to the overall appearance and possible hydrodynamic properties of the pipe.

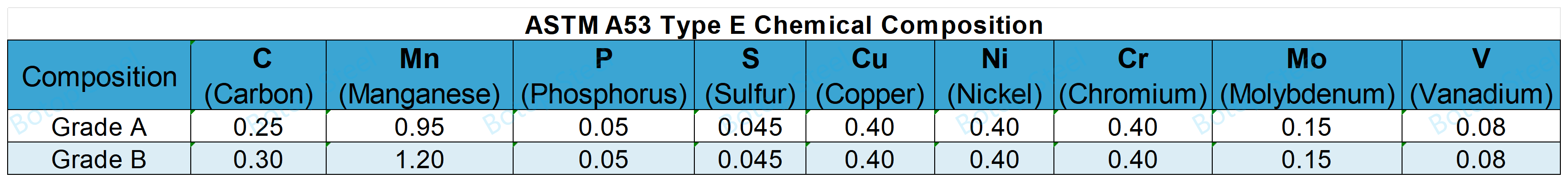

ASTM A53 Type E Chemical Components

For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % of manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

Cu, Ni, Cr, Mo, and V, are the five elements together not exceeding 1.00%.

ASTM A53 Type E Mechanical Properties

Tension Test

Resistance welded pipes DN ≥ 200 shall be tested using two transverse specimens, one across the weld and the other opposite the weld.

| List | classification | Grade A | Grade B |

| Tensile strength, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Yield strength, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation in 50 mm (2 in ) | Note | A, B | A, B |

Note A: The minimum elongation in 2 in[50 mm] shall be that determined by the following equation:

e = 625000 [1940] A0.2/U0.9

e = minimum elongation in 2 in or 50 mm in percent, rounded to the nearest percent

A = the lesser of 0.75 in2 [500 mm2] and the cross-sectional area of the tension test specimen, calculated using the specified outside diameter of the pipe, or the nominal width of the tension test specimen and the specified wall thickness of the pipe, with the calculated value rounded to the nearest 0.01 in2 [1 mm2].

U=specified minimum tensile strength, psi [MPa].

Note B: See Table X4.1 or Table X4.2, whichever is applicable, for the minimum elongation values that are required for various combinations of tension test specimen size and specified minimum tensile strength.

Bend Test

For pipe, DN ≤50, a sufficient length of pipe shall be capable of being bent cold through 90° around a cylindrical mandrel, the diameter of which is twelve times the specified outside diameter of the pipe, without developing cracks at any portion and without opening the weld.

Double-extra-strong pipe over DN 32 need not be subjected to the bend test.

"Double-extra-strong", often referred to as XXS is a pipe with a specially reinforced wall thickness, commonly used in industrial applications to withstand higher pressures and harsher environments. The wall thickness of this pipe is much thicker than normal pipe, so it provides more strength and better durability.

Flattening Test

The flattening test shall be made on welded pipe over DN 50 in extra-strong weight (XS) or lighter.

The following experimental procedure applies to Type E, Grades A and B.

During flat pressing, the weld should be positioned at 0° or 90° to the line of force direction, depending on the specific requirements.

Step 1: Test the ductility of the weld. There should be no cracks or breaks in the inner or outer surfaces of the weld until the distance between the flat plates is less than two-thirds of the outside diameter of the pipe.

Step 2: Continue to press flat and test for ductility in the area outside the weld. There should be no cracks or breaks on the inside or outside surfaces of the pipe beyond the weld until the distance between the flat plates is less than one-third of the outside diameter of the pipe, but not less than five times the thickness of the pipe wall.

Step 3: Test the integrity of the material by continuing to press flat until the test specimen breaks or the pipe walls come into contact. This is used to test the material for problems such as cracked layers, unsoundness, or incomplete welds.

Hydrostatic Test

The hydrostatic test shall be applied, without leakage through the weld seam or the pipe body.

Plain-end pipe shall be hydrostatically tested to the applicable pressure given in Table X2.2,

threaded-and-coupled pipe shall be hydrostatically tested to the applicable pressure given in Table X2.3.

For steel pipes with DN ≤ 80, the test pressure shall not exceed 17.2MPa;

For steel pipes with DN >80, the test pressure shall not exceed 19.3MPa;

Nondestructive Electric Test

For Type E and Type F Class B pipes DN ≥ 50, the welds must be subjected to non-destructive electrical testing.

Non-destructive electrical testing shall be performed in accordance with Specifications E213, E273, E309 or E570.

If non-destructive electrical testing has been performed, the pipe shall be marked "NDE".

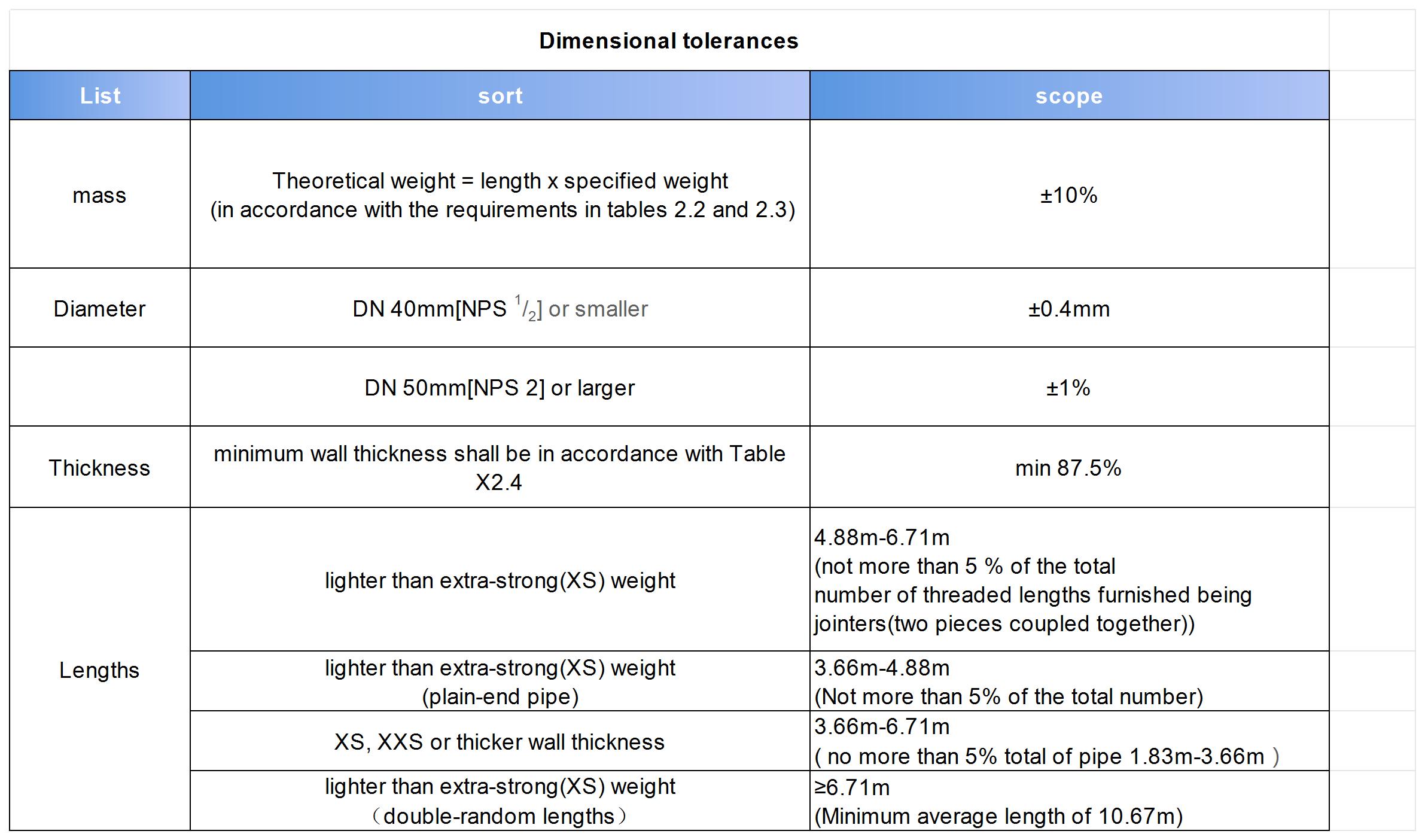

ASTM A53 Dimensional Tolerances

Pipe Weight Charts and Pipe Schedules

Advantages of ASTM A53 Type E Pipe

Resistance welding is a relatively low-cost welding method, making Type E tubes relatively inexpensive to produce and suitable for mass production.

The resistance welding process is fast and can be produced continuously, which increases productivity and reduces lead times.

Due to its good mechanical properties and corrosion resistance, this type of pipe is widely used in a variety of applications for transporting fluids, such as water, gas, and steam.

The welds can be made virtually invisible through fine treatment of the welds, which not only improves the appearance of the pipe but may also reduce the resistance to fluid flow caused by the welds.

Applications of ASTM A53 Type E Steel Pipe

Structural use: In construction, A53 Type E steel pipe is used as structural components such as building supports and truss systems.

Water piping: Used in water supply systems for buildings, including fire sprinkler systems.

Steam systems: In industrial facilities, this steel pipe is commonly used in steam delivery systems, especially in low-pressure applications.

Gas transmission: Used for the transportation of natural or other gases, especially in municipal and residential gas supply systems.

Chemical plants: for conveying low-pressure steam, water, and other chemicals.

Paper and sugar mills: to convey raw materials and finished products, as well as to dispose of process wastes.

Heating and cooling systems: Widely used for piping in heating, ventilation, and air conditioning (HVAC) systems.

Wastewater treatment: For conveying wastewater or treated water.

Irrigation systems: Water pipes used for irrigation of agricultural land.

Mining: Used for water and gas transportation in mines.

Our Related Products

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products,

including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels,tailored to meet the demands of various pipeline projects.

Tags: ASTM a53, type e, grade a, grade b, erw.

Post time: May-12-2024