DSAW (Double Surface Arc Welding) steel pipe refers to the steel pipe manufactured by Double Submerged Arc Welded technology.

DSAW steel pipe can be straight seam steel pipe or spiral steel pipe.

DSAW Production Process

DSAW technique is usually characterized by simultaneous welding of both the inner and outer sides of the pipe, which improves the quality of the weld seam and the overall structural strength of the pipe.

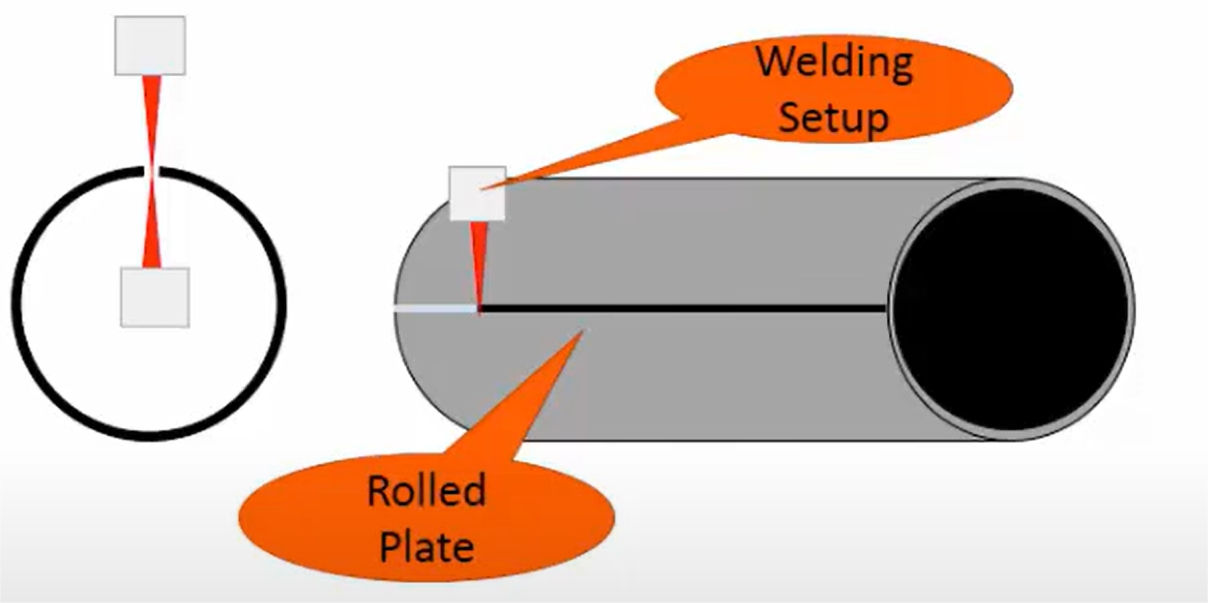

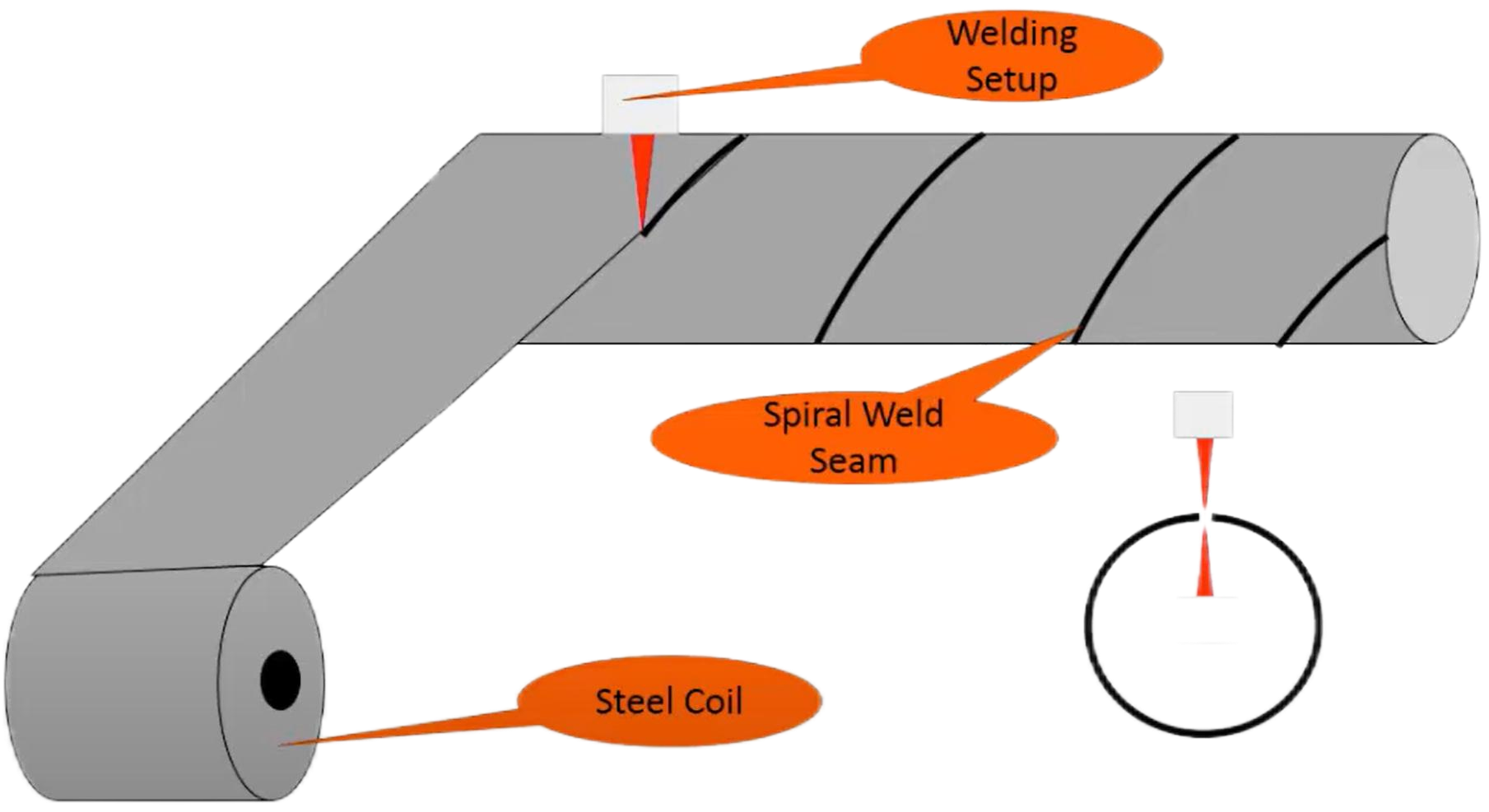

Below is a simple example of the welding process for straight and spiral weld seams:

DSAW straight seam steel pipe welding schematic

DSAW spiral steel pipe welding schematic

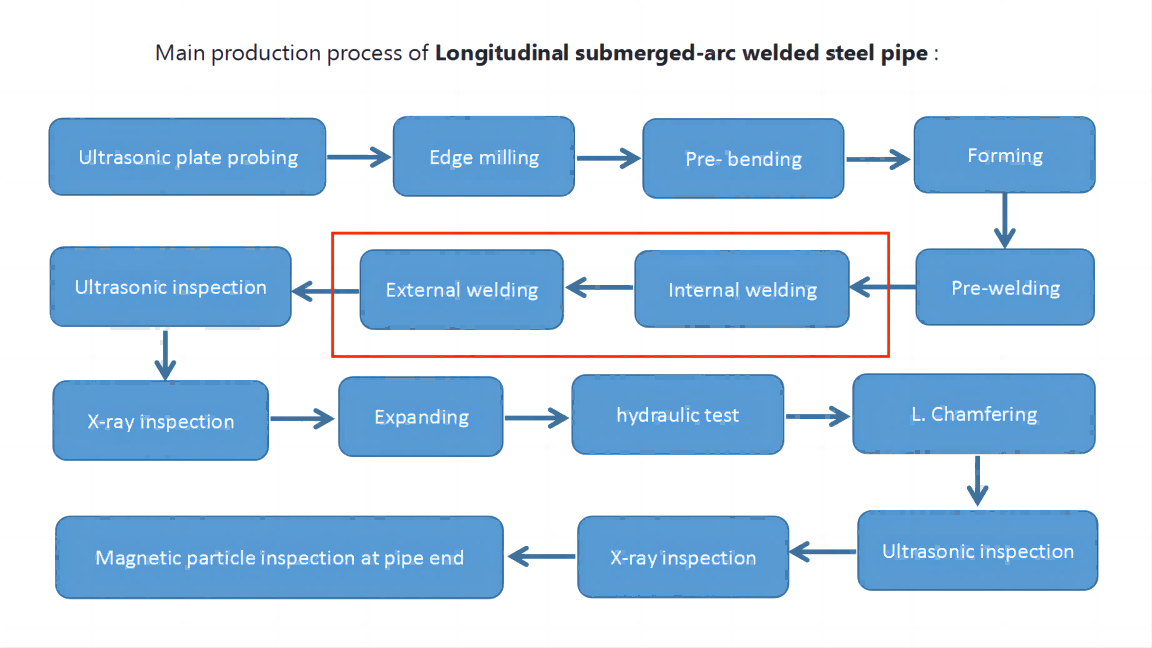

However, in actual production, the welding of internal and external welds is sometimes done separately.

Such separate operations may occur for a variety of reasons: original equipment limitations, production process optimization, quality control, etc.

The following is the process flow of DSAW steel pipe in the actual production process (straight seam example):

Differences between DSAW, LSAW and SSAW

DSAW's main feature is its welding process.

LSAW and SSAW emphasize the weld direction.

DSAW Dominance

Weld seam quality

The weak points in the strength of welded steel pipe are at the weld locations, which are better improved by the DSAW welding process.

Large Diameter and Thick Wall Applications

DSAW is used in areas where high specification strength and thick walled tubes are required, allowing the manufacture of tubes with larger diameters and thicker wall thicknesses.

Appliance

Oil and Gas Industry

Used for the transportation of crude oil, natural gas and other petroleum products. It is the material of choice for the manufacture of high pressure oil and gas pipelines, with excellent mechanical strength and pressure resistance to withstand high pressures in underground or underwater environments.

Water Conservancy

Water engineering, including water supply pipelines and drainage systems; long-distance transportation of water sources, including urban water supply and agricultural irrigation systems.The thick wall and strength of DSAW tubing ensures stable operation even under extreme pressure and environmental conditions.

Structural applications

Commonly used in bridge construction, structural columns in high-rise buildings, and other applications requiring high-strength support. Their load-bearing capacity and corrosion resistance make them an important structural material.

Energy Industry

In the construction of wind and hydroelectric power plants, DSAW tubes are used to manufacture high-strength towers and other critical structures.

Mining

Used in the mining industry for the transportation of ore slurries and in wastewater treatment systems.The abrasion and corrosion resistant properties of DSAW steel pipes make them suitable for use in environments with high levels of abrasion and chemical complexity.

How to Buy DSAW Steel Pipe

Sourcing DSAW steel pipe requires key information to be provided to the manufacturer:

Diameter

Wall thickness

Length: single length and total length

Weld direction: straight or spiral

Welding process: DSAW

Execution standard

Special requirements

About Us

Botop Steel is a high quality Welded Carbon Steel Pipe manufacturer and supplier from China, also a stockist of Seamless Steel Pipe. If you have the need of steel pipe and related products, you can contact us to provide you with good quality and low price products.

Tags:Dsaw pipe,dsaw meaning,ssaw,lsaw,Suppliers,manufacturers, factory, Stockist, companies, wholesale, buy, price, quotation, bulk, for sale,cost.

Post time: Apr-08-2024