EFW Pipe (Electro Fusion Welded Pipe) is a welded steel pipe made by melting and compressing a steel plate by the electric arc welding technique.

Pipe Type

EFW steel pipe is usually straight welded seam steel pipe.

It can be carbon steel pipe or alloy steel pipe.

EFW Standards and Grades

ASTM A358

304, 304L, 316, 316L and other stainless steel grades commonly used in applications requiring good corrosion resistance.

ASTM A671

CA55, CB60, CB65, CB70, and other carbon steel grades for low-temperature environments.

ASTM A672

A45, A50, B60, B65, and B70 carbon and alloy steel grades for medium-temperature applications.

ASTM A691

CM65, CM70, CM75, and other alloy steel grades are designed for applications subject to high pressure.

API 5L

Grade B, X42, X52, X60, X65, X70, and other carbon steel pipe grades for oil and gas long-distance pipelines.

Our Products

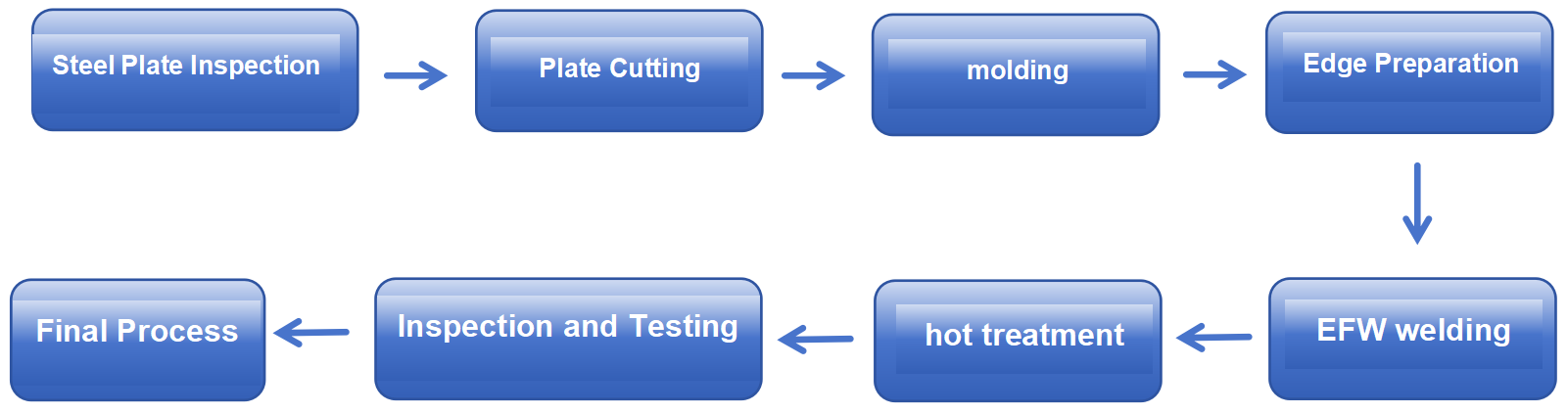

Process Flow of EFW Steel Pipe

In practice, the process is more complex, as follows:

Material selection

Select the appropriate steel plate material according to the required chemical composition and mechanical properties.

The steel plate needs to be inspected to confirm that it is free from defects and the surface cleaned to remove any impurities or oxides that may affect the quality of the weld.

Plate Cutting

The plate is cut to the required size, usually by plasma or flame-cutting methods.

Once cut, the edges of the plate may require further machining to ensure precise alignment and connection during welding.

Plate forming

Steel plates are bent into cylindrical shapes using presses or rolling mills.

Adjustments are made to the formed tube shape to ensure that the ends are perfectly aligned in preparation for the welding process that follows.

Edge preparation

The formed tubular end is ground or machined to create a beveled edge for full penetration of the weld.

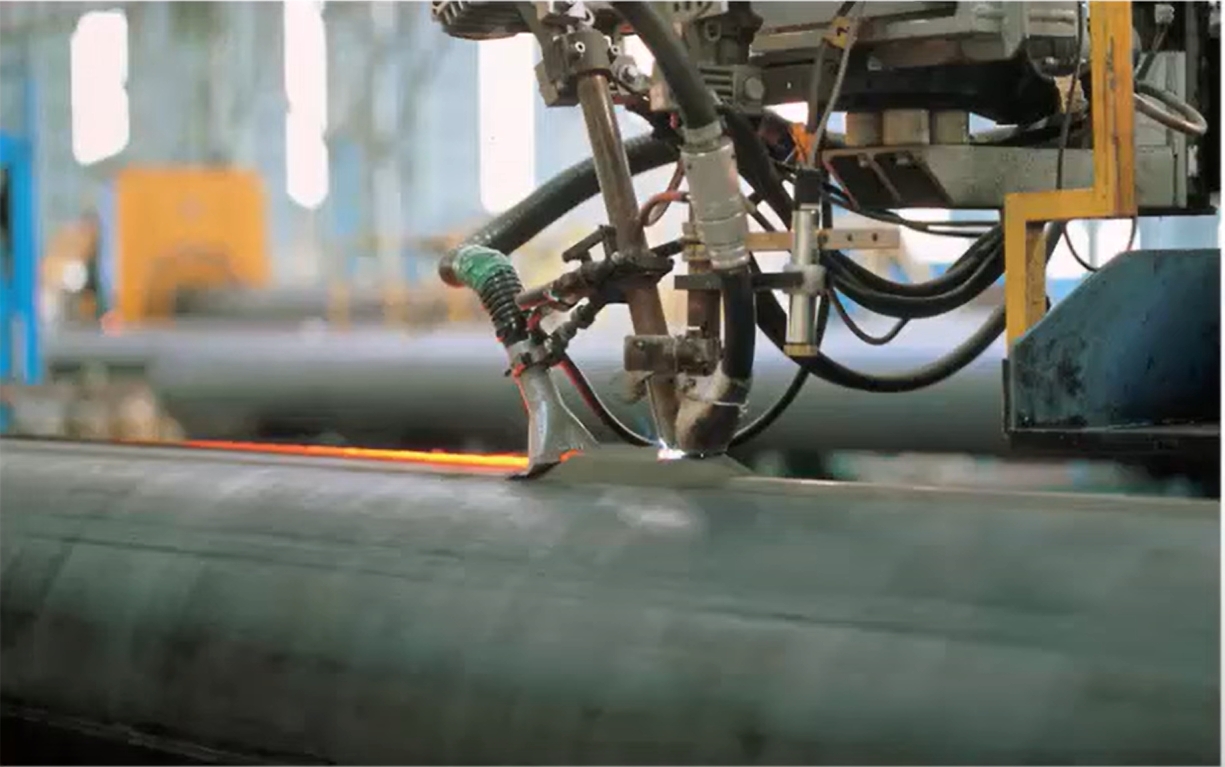

EFW Welding

Using the arc welding technique, the edges of steel plates are heated to a molten state at high temperatures.

By means of an electric arc and pressure, the edges of the molten steel are fused together to form a weld. This step may require several welds to ensure the strength and quality of the weld.

Post-weld heat treatment

After welding is completed, post-weld heat treatment is performed to relieve stresses in the weld and in the steel.

This usually involves heating the entire pipe or weld area to a specific temperature and then cooling it under controlled conditions.

Inspection and testing

Tubes are thoroughly inspected and tested after welding and heat treatment.

This includes visual inspection, dimensional inspection, non-destructive testing (e.g. ultrasonic or radiographic testing), as well as mechanical property testing (e.g. tensile and impact testing).

Final processing

Tubes are cut to specified lengths, chamfered at the ends, and possibly finished with surface treatments such as coatings.

The finished pipe is marked with pertinent information such as material grade, size, furnace number, etc. for traceability and use.

Advantages of EFW Steel Pipe

High-quality welds

The use of electrofusion welding technology allows for high quality welds with uniformity and low defect rates, enhancing structural integrity.

Large size and thick wall production

The EFW process is suitable for the production of large diameter and thick walled tubes for high pressure and heavy load requirements.

Wide range of applications

Can handle a wide range of carbon and alloy steels, suitable for high temperature, high pressure and corrosive environments.

Manufacturing Flexibility

Highly automated production line, welding parameters can be adjusted according to production size and thickness.

Economical

Long-term durability and low maintenance requirements provide good overall economics despite high initial costs.

Disadvantages of EFW Steel Pipe

Higher costs

EFW pipe is typically more expensive to produce than other types of welded pipe, such as resistance welded (ERW) pipe. This is mainly due to the high-quality materials used and the complex production process.

Lower production rates

The EFW process has a relatively slow production rate because it involves more complex welding and heat treatment processes. This can lead to longer production cycles, especially for large diameter and thick walled tubes.

Size Limitations

Although EFW is suitable for producing large diameter pipe, the technology may not be as economical or applicable for smaller pipe sizes, especially in application scenarios where higher precision and fine diameters are required.

Welding Quality

Although electrofusion welding provides high quality welds, the melting and fusion during the welding process can still introduce defects such as porosity, unfusion and inclusions, which need to be managed through stringent quality control and inspection.

High demands on operators

EFW production requires highly skilled operators and maintenance personnel to ensure that the welding process is performed correctly and the equipment operates properly. This leads to increased investment in training and skill development for employees.

Applications

Oil and gas industry

Chemical Industry

Power industry

Construction and infrastructure

Botop Steel is a high-quality welded carbon steel pipe manufacturer and supplier from China, and also a stockist of seamless steel pipe, you can contact us for your steel pipe needs!

Tags:EFW,EFW pipe,EFW piping, Suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-09-2024