JIS G 3444 steel pipe is a structural carbon steel pipe made by seamless or welded process, mainly used in civil engineering and construction.

Navigation Buttons

Size Range

Grade Classification

JIS G 3444 Manufacturing Processes

Tube End Type

Chemical Composition of JIS G 3444

Mechanical Property of JIS G 3444

Flattening Resistance

Bend Test

Other Tests

Pipe Weight Table of JIS G 3444

Dimensional Tolerance of JIS G 3444

Appearances

Marking

JIS G 3444 Application

Related Standards

Our Advantages

Size Range

General purpose Outer diameter: 21.7-1016.0mm;

Foundation piles and piles for landslide suppression OD: below 318.5mm.

JIS G 3444 Manufacturing Processes

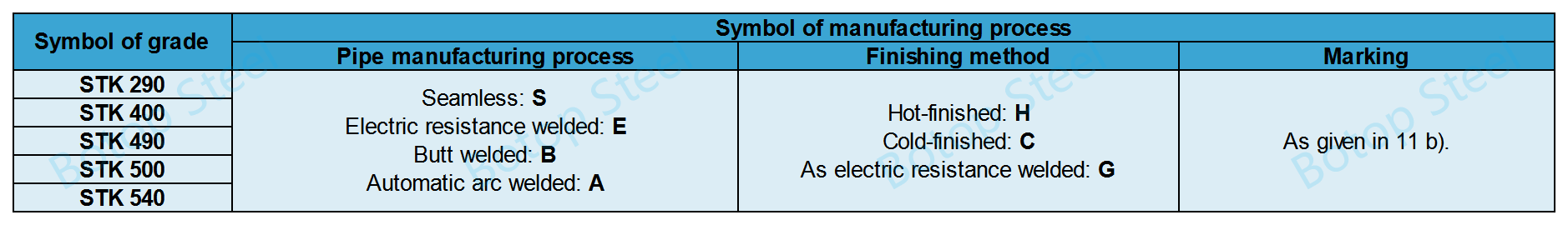

The tubes shall be manufactured by a combination of the tube manufacturing method and the finishing method which are indicated.

Tubes can be properly heat treated if desired.

If required by the Purchaser, the pipe may be fabricated from a coated steel sheet or coated steel bar. In this case, the type of coating and the quality of the coating shall conform to the requirements of JIS G 3444, Appendix A.

The types of coating that can be applied are hot-dip zinc coating, electrolytic zinc coating, hot-dip aluminum coating, hot-dip zinc-5% aluminium alloy coating, hot-dip 55% aluminium-zinc alloy coating, or hot-dip zinc-aluminium-magnesium alloy coating.

Tube End Type

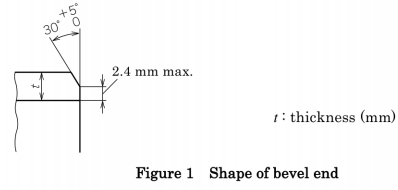

Steel pipe ends shall be flat.

If the pipe is required to be processed into a beveled end, the angle of the bevel is 30-35°, bevel width of the steel pipe edge: is max 2.4mm.

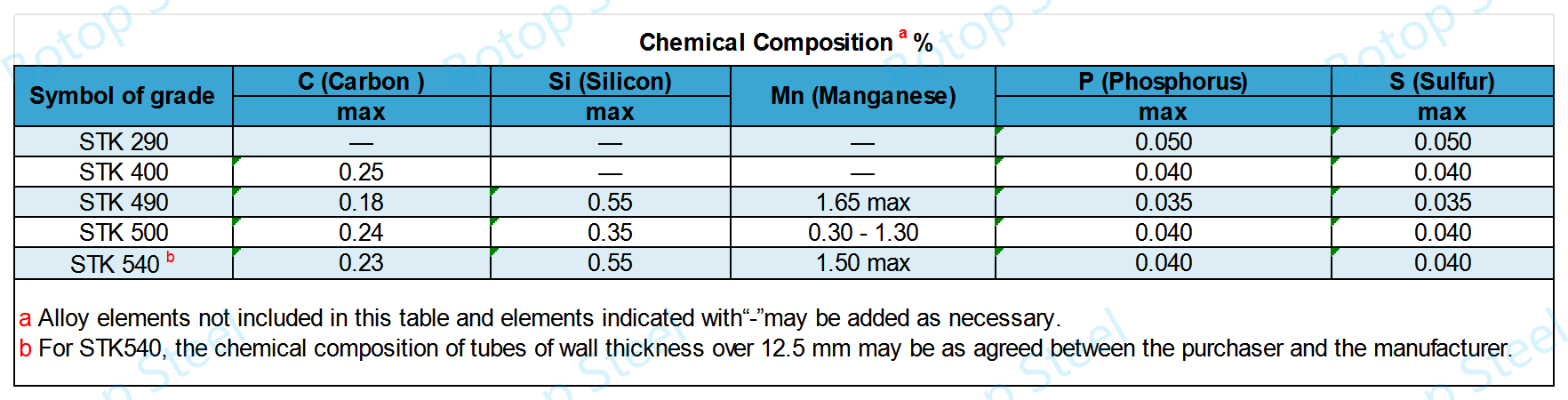

Chemical Composition of JIS G 3444

Thermal analysis methods shall be in accordance with the requirements in JIS G 0320.

The method of product analysis shall be in accordance with the requirements in JIS G 0321.

Mechanical Property of JIS G 3444

The general requirements for mechanical tests shall be in accordance with Sections 7 and 9 of JIS G 0404.

However, the sampling method for mechanical tests shall conform to the requirements of Class A provisions in Section 7.6 of JIS G 0404.

Tensile Strength and Yield Point or Proof Stress

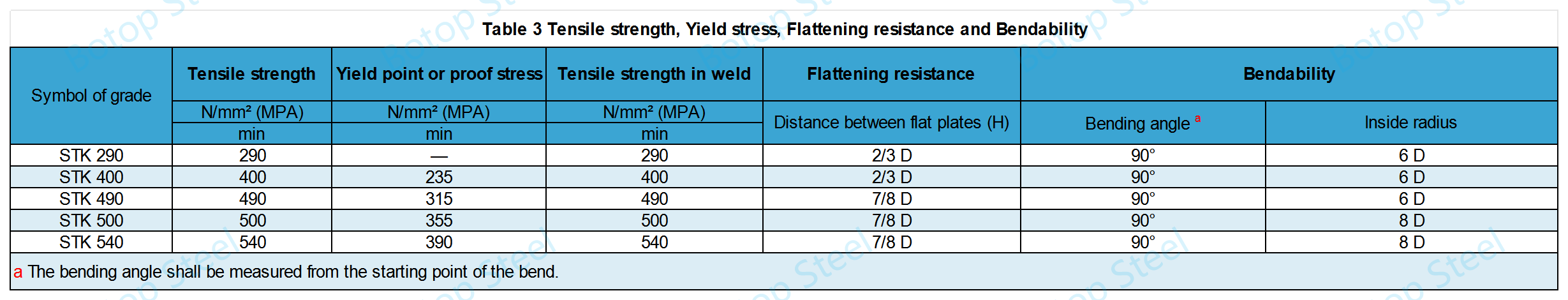

Tensile strength and yield point or proof stress as well as the tensile strength at the weld shall satisfy the values specified in Table 3.

The tensile strength of the weld is applicable to automatic arc welded tubes.

The strength of the weld is the same as that required for the pipe body. The welded part is often the weak link in the structure, so having the same tensile strength ensures the reliability of the welded structure.

Table 3 also contains the distance requirements for Flattening resistance and the requirements for bend angle and bend radius at the bendability end.

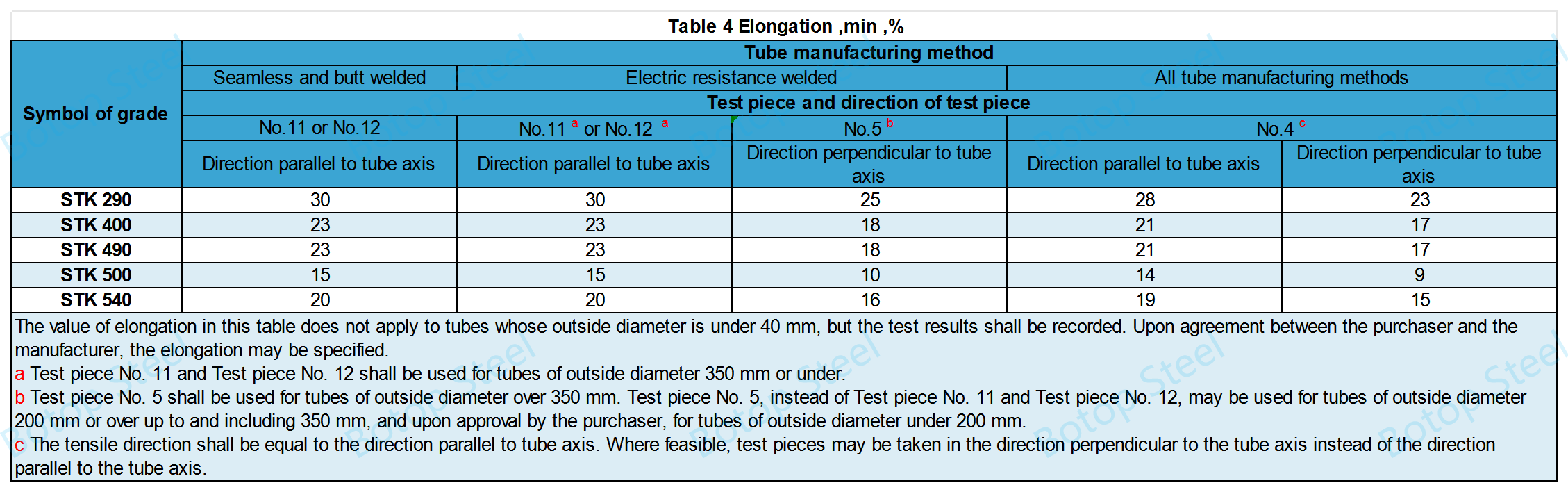

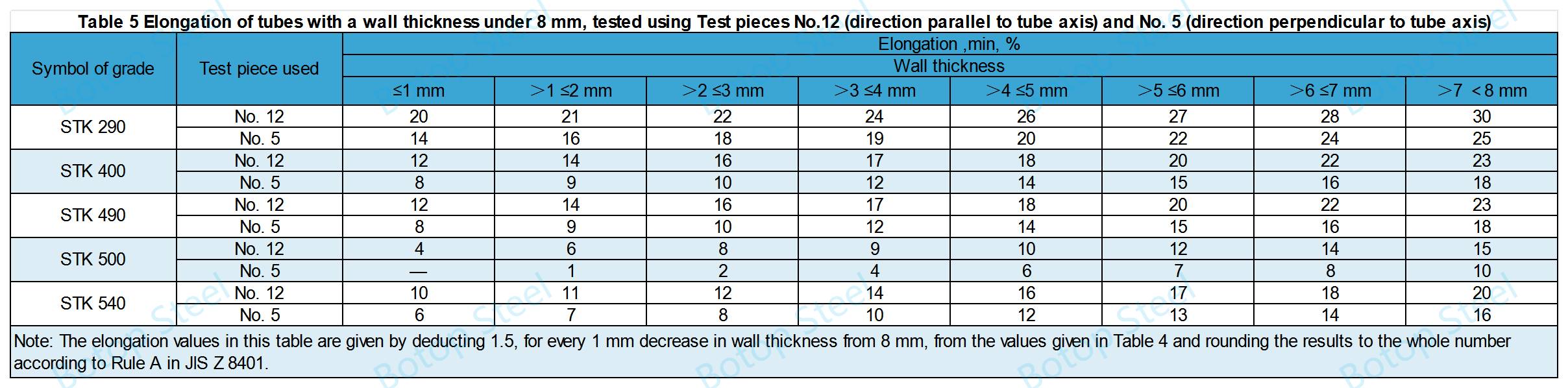

Elongation

The elongation corresponding to the tube manufacturing method is shown in Table 4.

However, when the tensile test is performed on Test Piece No. 12 or Test Piece No.5 taken from the tube under 8 mm in wall thickness, the elongation shall be in accordance with Table 5.

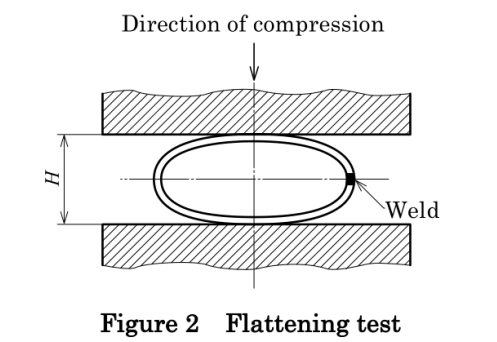

Flattening Resistance

Place the test piece at ordinary temperature (5 °C to 35 °C) between two flat plates and compress to flatten until the distance between the plates H becomes equal to or smaller than the value specified in Table 3, then examine for cracks on the test piece.

Place the welds of resistance welded steel pipe and butt welded steel pipe so that the line between the center of the pipe and the weld is perpendicular to the direction of compression.

Bend Test

Bend the test piece around a cylinder at ordinary temperature (5 °C to 35 °C) at a bending angle not less than the minimum bending angle specified in Table 3, and with an inside radius not more than the maximum inside radius specified in Table 3, and examine the test piece for cracks.

For testing the electric resistance welded steel tube and butt-welded steel tube, place the test piece such that the weld is 90 °C from the outermost position of the bend.

Other Tests

Hydrostatic tests, non-destructive tests of welds, or other tests shall be agreed in advance on the relevant requirements.

Pipe Weight Table of JIS G 3444

Steel pipe weight calculation formula

W=0.02466 t (D-t)

W: unit mass of tube (kg/m)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

0.02466: unit conversion factor for obtaining W

The formula is based on the fact that the density of steel is 7.85 g/cm³.

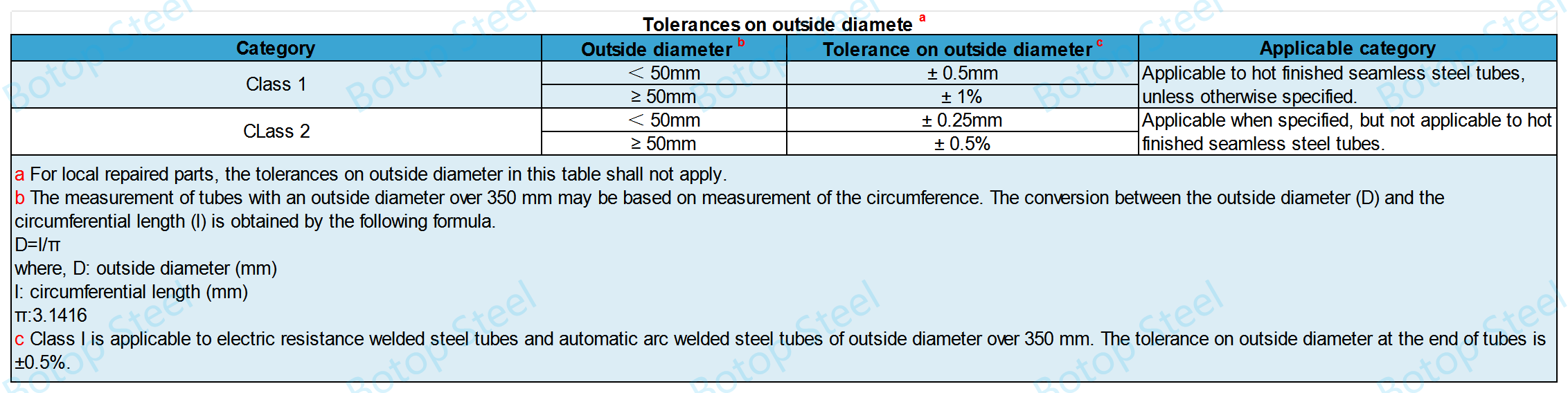

Dimensional Tolerance of JIS G 3444

Outside Diameter Tolerance

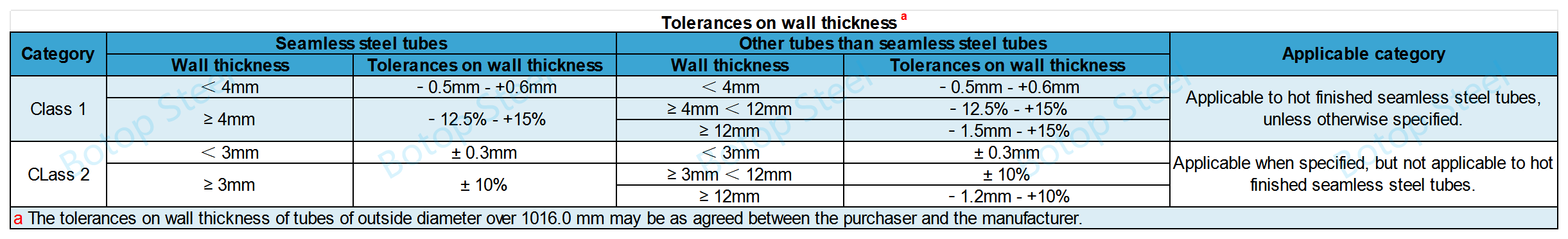

Wall Thickness Tolerance

Length Tolerance

The tolerance of the length of the steel pipe, the negative tolerance is zero, the positive tolerance is not explicitly required, the buyer and the manufacturer to decide by mutual agreement.

Appearances

The internal and external surfaces of the steel pipe shall be smooth and free from defects unfavorable to use.

Anti-corrosion coatings such as zinc-rich coatings, epoxy coatings, paint coatings, etc. can be applied to the external or internal surfaces.

Marking

Each steel pipe shall be labeled with the following information.

a) Symbol of grade.

b) Symbol for manufacturing method. The symbol for the manufacturing method shall be as follows. A dash may be replaced with a blank.

1) Hot-finished seamless steel tube: -S-H

2) Cold-finished seamless steel tube: -S-C

3) As electric resistance welded steel tube: -E-G

4) Hot-finished electric resistance welded steel tube: -E-H

5) Cold-finished electric resistance welded steel tube: -E-C

6) Butt-welded steel tubes -B

7) Automatic arc welded steel tubes -A

c) Dimensions. The outside diameter and wall thickness shall be marked.

d) Manufacturer's name or abbreviation.

When the marking on a tube is difficult because its outside diameter is small or when so requested by the purchaser, the marking may be given on each bundle of tubes by a suitable means.

Methods such as the use of labels, etc.

JIS G 3444 Application

They are used for civil engineering and architecture such as steel towers, scaffoldings, footing piles, foundation piles, and piles for landslide suppression.

Related Standards

JIS G 3452: Specifies carbon steel pipes for general purposes (different from structural purposes and more focused on the transportation of liquids or gases).

JIS G 3454: Specifies standards for carbon steel pipes for pressure piping.

ASTM A500: covers cold-formed welded and seamless carbon steel structural tubes and is similar to JIS G 3444 in some of its requirements.

EN 10219: Covers cold-formed welded hollow sections for structural purposes, including round, square, and rectangular profiles.

Our Advantages

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Tags: jis g 3444, carbon steel pipe, stk, steel tube, structure pipe.

Post time: May-10-2024