JIS G 3452 Steel Pipe is the Japanese standard for carbon steel pipe applied with relatively low working pressure for transportation of steam, water, oil, gas, air, etc.

It is suitable for pipes with an outside diameter of 10.5 mm-508.0 mm.

Navigation Buttons

Symbol of Grade and Manufacturing Processes of JIS G 3452

Pipe End Type of JIS G 3452

Chemical composition of JIS G 3452

Mechanical Properties of JIS G 3452

Flattening Property

Bendability

Hydraulic Test or Nondestructive Test (NDT)

Pipe Weight Chart and Dimensional Tolerances

Steel Pipe Appearance

Galvanized of JIS G 3452

Marking of JIS G 3452

Main Applications of JIS G 3452

Relevant Standards

Our Related Products

Symbol of Grade and Manufacturing Processes of JIS G 3452

Pipes shall be manufactured with the appropriate combination of pipe manufacturing processes and finishing methods selected.

| Symbol of grade | Symbol of the manufacturing process | Classification of zinc-coating | ||

| Pipe manufacturing process | Finishing method | Marking | ||

| SGP | Electric resistance welded: E Butt welded: B |

Hot-finished: H Cold-finished: C As electric resistance welded: G |

As given in 13 b). | Black pipes: pipes not given zinc-coating White pipes: pipes given zinc-coating |

Pipes shall normally be delivered as manufactured. Cold-worked pipe shall be annealed after fabrication is completed.

If the resistance welding fabrication process is used, welds shall be removed from the inside and outside surfaces of the pipe to obtain a smooth weld along the contour of the pipe. Weld beads on the inner surface may not be removed if this is due to equipment or pipe diameter limitations.

Pipe End Type of JIS G 3452

Pipe End Selection

Type of pipe end for DN≤300A/12B: threaded or flat end.

Type of pipe end for DN≤350A/14B: flat end.

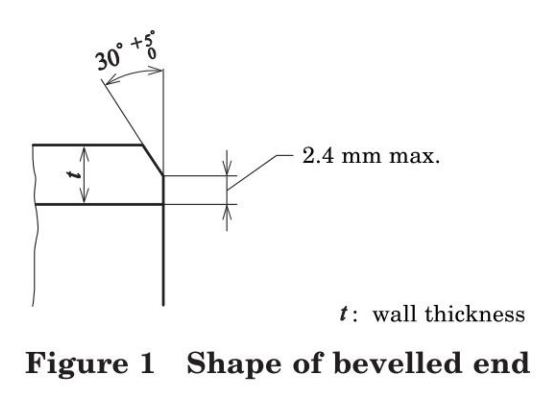

If the buyer requires beveled end, the angle of bevel is 30-35°, bevel width of steel pipe edge: max 2.4mm.

Note: In JIS G 3452, there are A series and B series of nominal diameter DN. Where A is equivalent to DN, the unit is mm; B is equivalent to NPS, the unit is in.

Requirements for Threaded Pipe Ends

Threaded pipes shall be manufactured by giving the pipe ends the taper threads as specified in JIS B 0203, and fitting one of the threaded ends with a screwed type fitting (hereafter referred to as the socket) conforming to JIS B 2301 or JIS B 2302.

The pipe end without a socket shall be protected with a thread protection ring or other suitable means.

Threaded pipes may be supplied without sockets if so specified by the purchaser. Inspection of taper threads shall be in accordance with JIS B 0253.

Chemical composition of JIS G 3452

General requirements for chemical analysis and sampling methods for thermal analysis shall be in accordance with JIS G 0404 clause 8. The method of thermal analysis shall be in accordance with the standards in JIS G 0320.

| Symbol of grade | P (Phosphorus) | S (Sulfur) |

| SGP | max 0.040% | max 0.040% |

High levels of phosphorus and sulfur reduce the workability and mechanical properties of steel and are particularly prone to brittleness during welding. Therefore, the quality and weldability of carbon steel pipes can be ensured by limiting phosphorus and sulfur content.

Other alloying elements can also be added as required.

Mechanical Properties of JIS G 3452

The general requirements for mechanical tests shall be in accordance with clauses 7 and 9 of JIS G 0404. However, of the sampling methods given in 7.6 of JIS G 0404, only sampling method A is applicable.

Tensile test: The test method shall be in accordance with the standards in JIS Z 2241.

| Symbol of grade | Tensile strength | Elongation a min, % |

||||||

| Test piece | Test direction |

Wall thickness, mm | ||||||

| N/mm² (MPA) | >3 ≤4 | >4 ≤5 | >5 ≤6 | >6 ≤7 | >7 | |||

| SGP | 290 min | No.11 | Parallel to pipe axis | 30 | 30 | 30 | 30 | 30 |

| No.12 | Parallel to pipe axis | 24 | 26 | 27 | 28 | 30 | ||

| No.5 | Perpendicular to pipe axis | 19 | 20 | 22 | 24 | 25 | ||

| a For pipes of nominal diameter 32A or under, the elongation values in this table do not apply, though their elongation test results shall be recorded. In this case, the elongation requirement agreed between the purchaser and the manufacturer may be applied. | ||||||||

Flattening Property

At room temperature (5℃~35℃), the weld is perpendicular to the compression direction. Compress the specimen between the two platforms until the distance H between the platforms reaches two-thirds of the outer diameter of the center steel pipe, and then check for cracks.

Bendability

When DN≤50A, carry out the bending test.

When bending to an inner radius of 90° of 6 times the outer diameter of the pipe, the test piece shall not produce any cracks. Before bending, measure the bending angle from the straight position.

Hydraulic Test or Nondestructive Test (NDT)

Each pipe should be a Hydraulic Test or Nondestructive Test.

Hydraulic Test

The pipe should withstand 2.5MPa for at least 5 s, without leakage.

Nondestructive Test

Nondestructive testing characteristics can be used for ultrasonic or eddy current inspection, and the pipe shall meet the following nondestructive testing characteristics.

For ultrasonic inspection, the reference samples specified in JIS G 0582 that contain UE class reference standards shall be used as the alarm level; any signal from the pipe that is equal to or greater than the alarm level shall be used as the alarm level. signal shall be used as an alarm level; any signal from the pipeline equal to or greater than the alarm level shall be cause for rejection.

For eddy current inspection, signals from reference samples containing reference standards of category EZ as specified in JIS G 0583 shall be used as alarm levels; any signal equal to or greater than the alarm level from the pipeline shall be a reason for rejection. shall serve as the alarm level; any signal from the pipeline equal to or greater than the alarm level shall be cause for rejection. At the manufacturer's discretion, a severe alarm level below the signal of the stated reference standard may be used.

Other non-destructive testing methods can also be used, e.g. for automatic flux leak detection as specified in JIS G 0586.

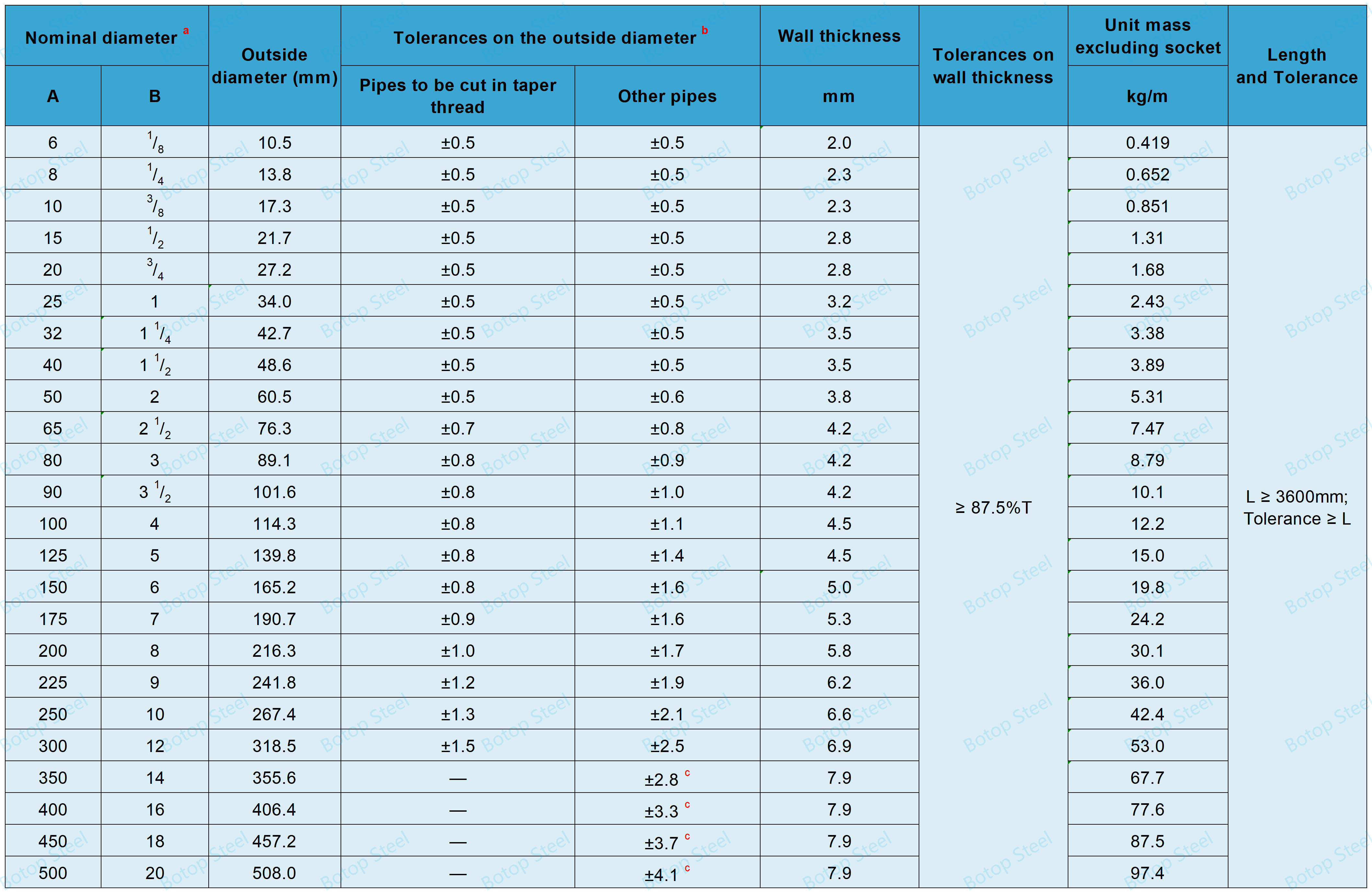

Pipe Weight Chart and Dimensional Tolerances

Steel Pipe Weight Calculation Formula

Assuming 1 cm3 of steel to be 7.85g in mass

W=0.02466t(D-t)

W: unit mass of pipe (kg/m);

t: wall thickness of pipe (mm);

D: outside diameter of pipe (mm);

0.02466: conversion factor for obtaining W;

Rounded to three significant figures in accordance with JIS Z 8401, rule A.

Pipe Weight Chart and Dimensional Tolerances

a The nominal diameter shall be according to either of the designations A or B and expressed by attaching the letter A or B, whichever designation is applied, after the numeral of the diameter.

b For locally repaired parts, tolerances in this table do not apply.

c For pipes of nominal diameter 350A or over, outside diameter measurement may be replaced by circumferential length measurement, in which case the tolerance applied shall be 0.5 %. The measured circumferential length (I) shall be converted to the outside diameter (D) using the following formula.

D=l/Π

D: outside diameter (mm);

l: circumferential length (mm);

Π: 3.1416.

Steel Pipe Appearance

Appearance

The internal and external surfaces of the pipe shall be smooth and free from defects unfavorable to use.

The pipe shall be straight, with the ends at right angles to the axis of the pipe.

Defect Repair

Black pipe (steel pipe without anti-corrosion treatment) may be repaired by grinding, machining, or other methods, and the repaired surface shall be smooth along the pipe contour.

However, the repaired wall thickness is kept within the specified tolerances.

Surface Coating

Either or both surfaces of the pipe can be coated e.g., zinc-rich coating, epoxy coating, primer coating, 3PE, FBE, etc..

Galvanized of JIS G 3452

Hot Dip Galvanizing

Steel pipes, if galvanized, threaded pipes and sockets should be coated with zinc before tightening the threads.

Thorough steel surface cleaning by sandblasting, pickling, etc., followed by hot dip galvanizing.

For zinc-coating, the distilled zinc ingot Class 1 specified in JIS H 2107 or zinc with at least equivalent quality to this shall be used.

Other general requirements for zinc coating are specified in JIS H 8641.

Galvanization Experiment

Test Method According to the test method specified in Article 6 of JISH0401, the specimen is immersed in copper sulfate solution, for 1 min 5 times, and the specimen is checked to see if it reaches the endpoint.

Marking of JIS G 3452

The content of the logo contains at least the following elements, the order of which can be freely arranged.

a) Symbol of grade(SGP)

b) Symbol of the manufacturing process

The symbol of the manufacturing process shall be as follows. The dash(es) may be replaced with blanks.

As electric resistance welded steel pipe: -E-G

Hot-finished electric resistance welded steel pipe: -E-H

Cold-finished electric resistance welded steel pipe: -E-C

Butt-welded steel pipe: -B

c) Dimensions, expressed by nominal diameter

d) Manufacturer's name or identifying brand

Example: BOTOP JIS G 3452-E-G SGP 500A*7.9*12000MM PIPE NO.001

Main Applications of JIS G 3452

JIS G 3452 steel pipes are mainly used for the transportation of water, gas, oil, steam, and other general purposes. These pipes are usually used in construction, machinery, automobiles, ships, and other fields.

Oil and gas industry: used in piping systems for transportation of oil, natural gas liquefied petroleum gas, etc.

Construction industry: used for hydraulic systems, water supply pipes, heating systems, air-conditioning systems, etc. in building structures.

Machinery manufacturing: Used in hydraulic systems, pneumatic systems, conveying pipelines of mechanical equipment, etc.

Automobile manufacturing: used in exhaust system, fuel system, hydraulic system, etc. of automobile.

Shipbuilding: used in piping systems, cabin structure of ships, etc.

Chemical industry: used in chemical plants for transportation piping, reactors, etc.

Municipal engineering: used in piping systems for urban water supply, drainage, sewage treatment, etc.

Relevant Standards

ASTM A53/A53M, DIN 2440, EN 10255, GB/T 3091, BS 1387, ISO 65, NFA 49-146, AS/NZS 1163, API 5L, ASTM A106/A106M, EN 10216-1, GB 8163.

Our Related Products

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions. For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

Tags: jis g 3452, sgp, erw, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-28-2024