JIS G 3461 steel pipe is a seamless (SMLS) or electric-resistance-welded (ERW) carbon steel pipe, mainly used in boilers and heat exchangers for applications such as realizing heat exchange between inside and outside the tube.

Navigation Buttons

Size Range

Grade Classification

Raw Materials

Manufacturing Processes of JIS G 3461

Pipe End Type

Heat Treatment

Chemical Composition of JIS G 3461

Mechanical Performance of JIS G 3461

Hardness Test

Hydraulic Test or Non-destructive Test

Pipe Weight Chart of JIS G 3461

Dimensional Tolerance of JIS G 3461

Appearance

Marking

Applications for JIS G 3461

JIS G 3461 Equivalent Standard

Our Related Products

Size Range

Suitable for steel pipes with an outside diameter of 15.9-139.8mm.

Raw Materials

Tubes shall be manufactured from the killed steel.

Killed steel is a type of steel in which oxygen is removed from the steel by the addition of a deoxidizer such as silicon, aluminum, or manganese during the melting process.

This treatment results in a steel that is virtually free of air bubbles or other gaseous inclusions, which enhances the uniformity and overall properties of the steel.

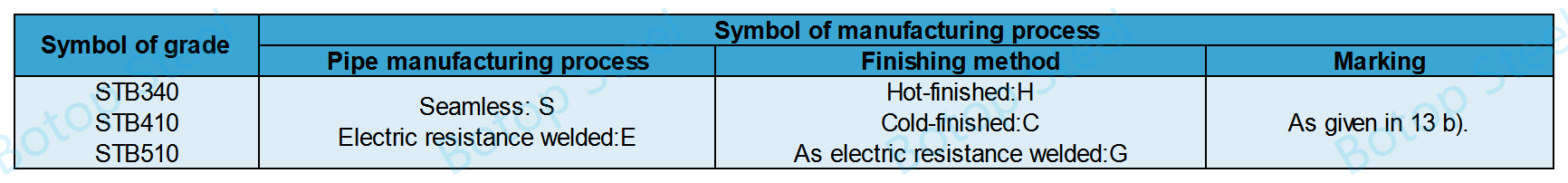

Manufacturing Processes of JIS G 3461

Combination of pipe manufacturing methods and finishing methods.

Hot-finished seamless steel tube: S-H

Cold-finished seamless steel tube: S-C

As electric resistance welded steel tube: E-G

Hot-finished electric resistance welded steel tube: E-H

Cold-finished electric resistance welded steel tube: E-C

When a steel pipe is fabricated by resistance welding, weld beads shall be removed from the inner and outer surfaces so that the surface of the pipe is smooth along the contour.

Weld beads on the inner surface may not be removed if the purchaser and manufacturer agree.

Pipe End Type

Steel pipe should be flat-ended.

Heat Treatment

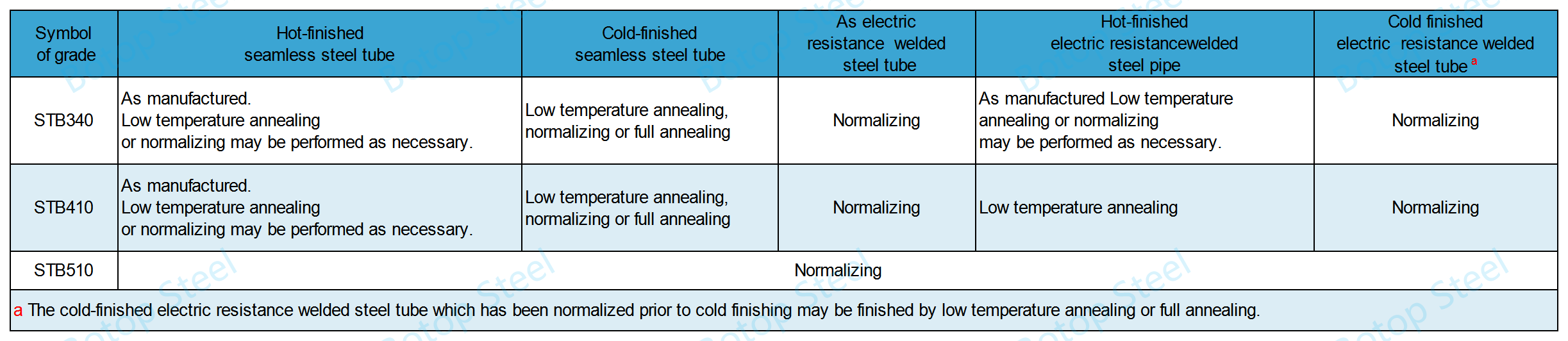

The manufacturing process of the steel pipe and its corresponding material grade need to be considered when selecting the appropriate heat treatment.

Different manufacturing processes and material grades may require different heat treatment methods to achieve the desired mechanical properties and microstructure.

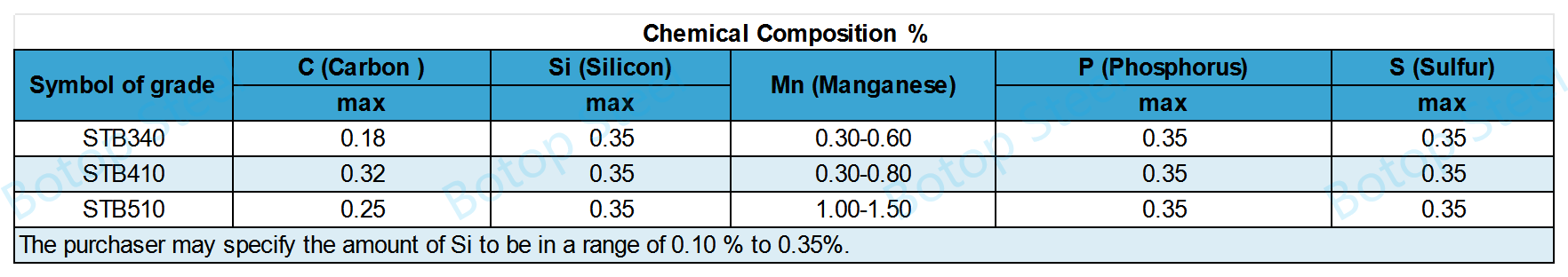

Chemical Composition of JIS G 3461

Thermal analysis methods shall be in accordance with the standards in JIS G 0320.

Alloying elements other than those may be added to obtain specific properties.

The method of product analysis shall be in accordance with the standards in JIS G 0321.

When the product is analyzed, the deviation values of the chemical composition of the pipe shall meet the requirements of Table 3 of JIS G 0321 for seamless steel pipes and Table 2 of JIS G 0321 for resistance-welded steel pipes.

Mechanical Performance of JIS G 3461

The general requirements for mechanical tests shall be in accordance with Sections 7 and 9 of JIS G 0404.

However, the sampling method for mechanical tests shall conform to the requirements of Class A provisions in Section 7.6 of JIS G 0404.

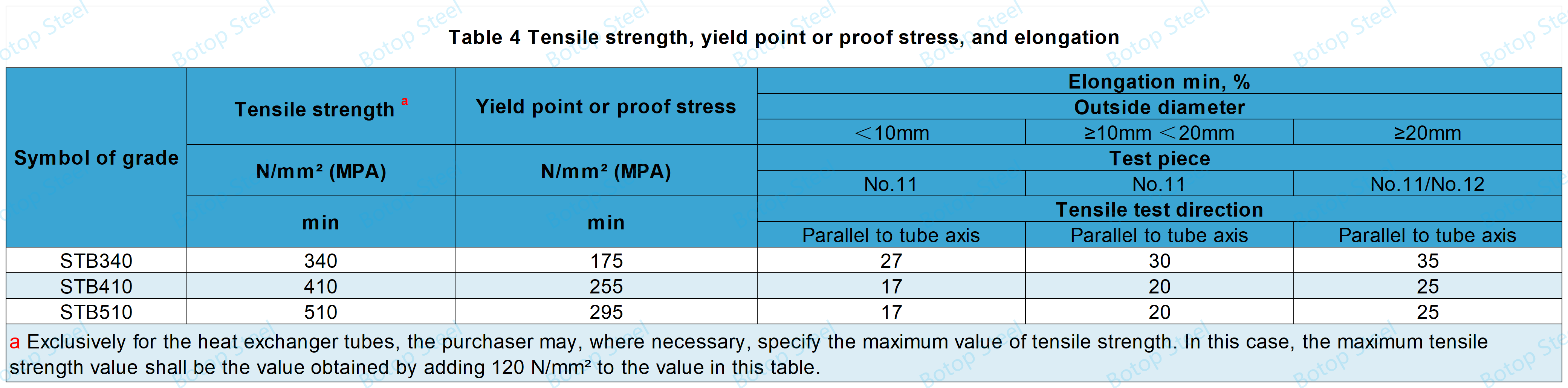

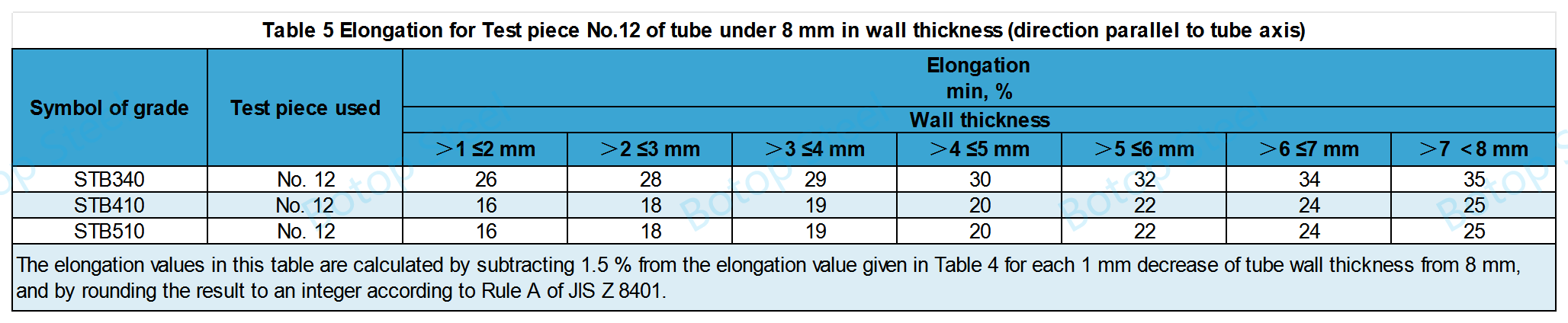

Tensile Strength, Yield Point or Proof Stress, and Elongation

When the tensile test is carried out on Test piece No. 12 for the tube under 8 mm in wall thickness, the elongation shall be in accordance with Table 5.

Flattening Resistance

A flattening Resistance test is not required for seamless steel pipe.

Test Method Place the specimen in the machine and flatten it until the distance between the two platforms reaches the specified value H. Then check the specimen for cracks.

When testing critical resistance welded pipe, the line between the weld and the center of the pipe is perpendicular to the compression direction.

H=(1+e)t/(e+t/D)

H: distance between platens (mm)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

е: constant defined for each grade of the tube. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Flaring Property

The Flaring Property test is not required for seamless tubes.

One end of the specimen is flared at room temperature (5°C to 35°C) with a conical tool at an angle of 60° until the outside diameter is enlarged by a factor of 1.2 and inspected for cracks.

This requirement also applies to tubes with an outside diameter of more than 101.6 mm.

Reverse Flattening Resistance

The reverse flattening test piece and the test method shall be as follows.

Cut a 100 mm length of test piece from one end of the pipe and cut the test piece in half 90° from the weld line on both sides of the circumference, taking the half containing the weld as the test piece.

At room temperature (5 °C to 35 °C) flatten the specimen into a plate with the weld at the top and inspect the specimen for cracks in the weld.

Hardness Test

| Symbol of grade | Rockwell hardness (mean value of three positions) HRBW |

| STB340 | 77 max. |

| STB410 | 79 max. |

| STB510 | 92 max. |

Hydraulic Test or Non-destructive Test

A Hydraulic or non-destructive test shall be performed on each pipe.

Hydraulic Test

Hold the inside of the pipe at minimum or higher pressure P for at least 5 seconds, then check that the pipe can withstand the pressure without leaks.

P=2st/D

P: test pressure (MPa)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

s: 60 % of the specified minimum value of yield point or proof stress.

P max. 10 MPa.

If the Buyer specifies a pressure, greater than the calculated test pressure P or 10 MPa, the applied test pressure shall be agreed upon by the Buyer and the manufacturer.

It shall be specified in 0.5 MPa increments if less than 10 MPa and in 1 MPa increments if 10 MPa or higher.

Non-destructive Test

Non-destructive testing of steel tubes should be performed by ultrasonic or eddy current testing.

For ultrasonic inspection characteristics, the signal from a reference sample containing a reference standard of class UD as specified in JIS G 0582 shall be considered as an alarm level and shall have a basic signal equal to or greater than the alarm level.

For eddy current inspection characteristics, the signal from the reference standard specified in JIS G 0583 with EY category shall be considered as the alarm level, and there shall be no signal equal to or greater than the alarm level.

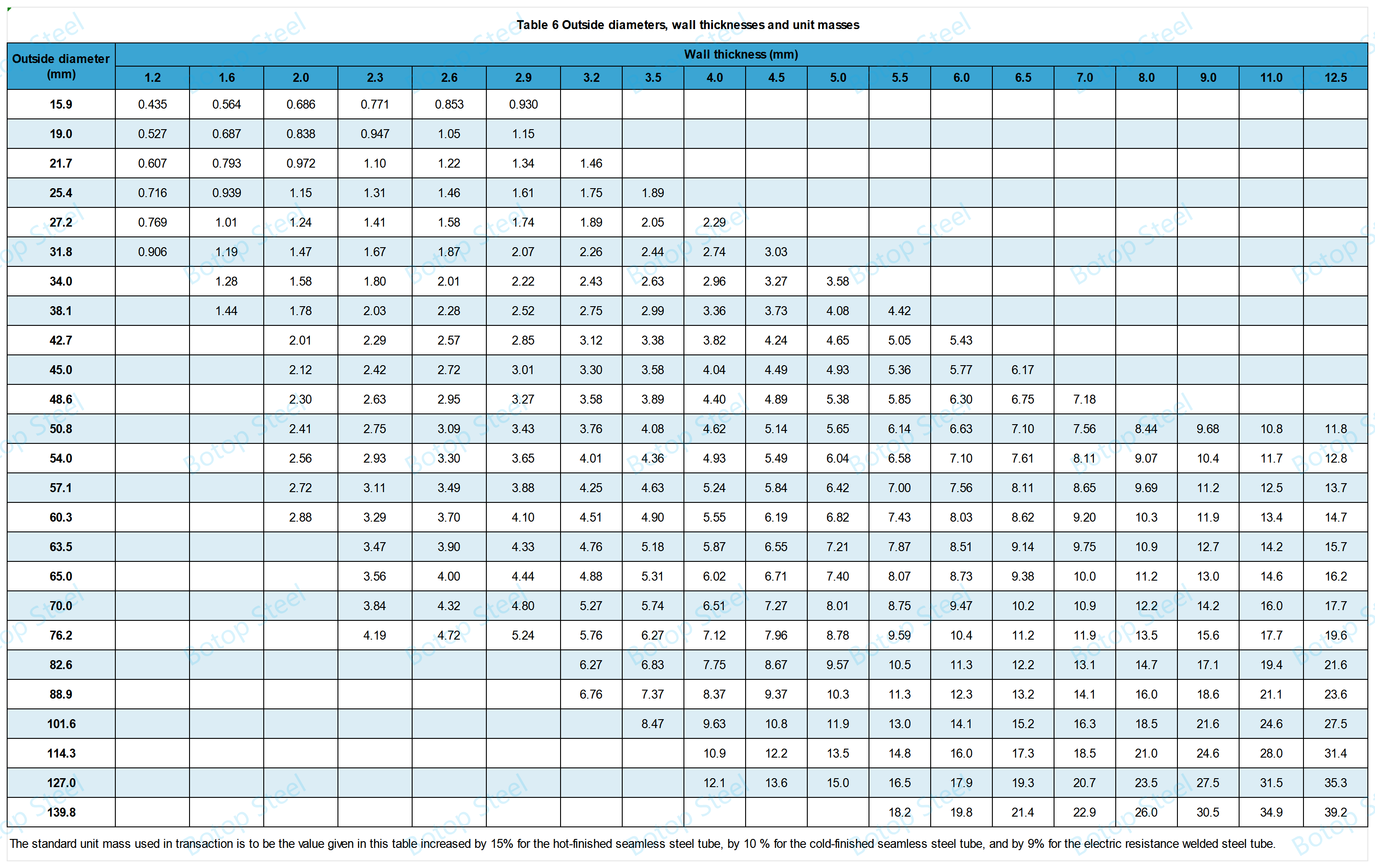

Pipe Weight Chart of JIS G 3461

The data in the weight chart is based on the formula below.

W=0.02466t(D-t)

W: unit mass of pipe (kg/m)

t: wall thickness of pipe (mm)

D: outside diameter of the pipe (mm)

0.02466: conversion factor for obtaining W

The above formula is a conversion based on the density of steel tubes of 7.85 g/cm³ and the results are rounded to three significant figures.

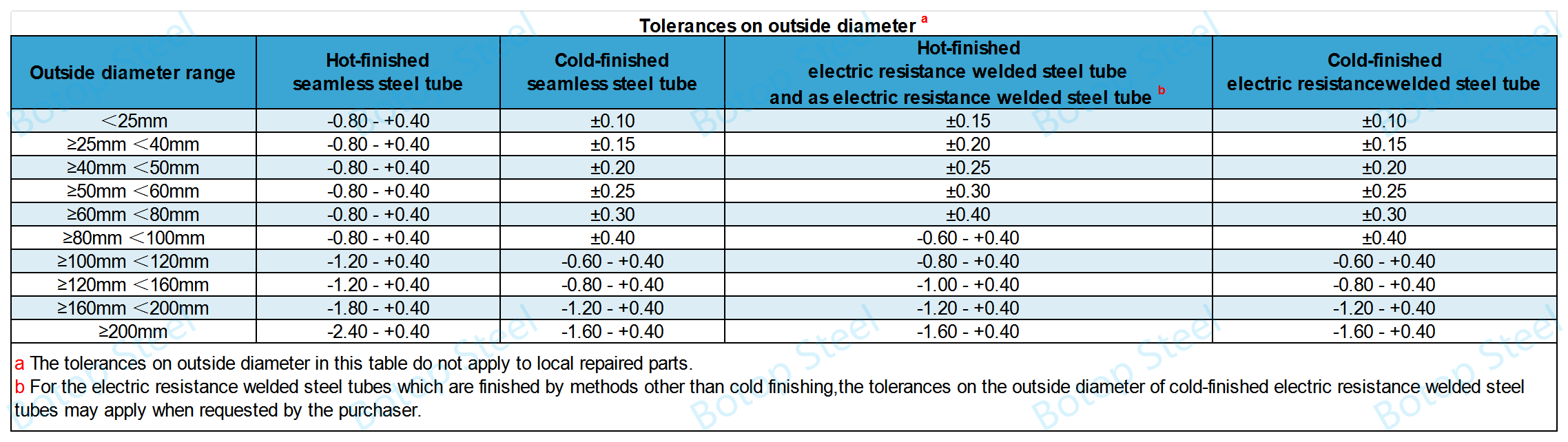

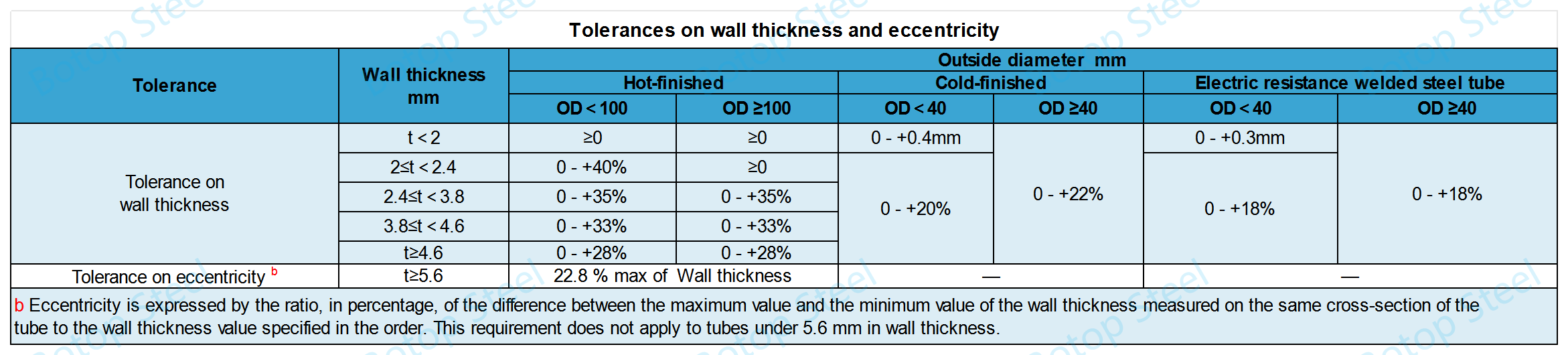

Dimensional Tolerance of JIS G 3461

Tolerances on Outside Diameter

Tolerances on Wall Thickness and Eccentricity

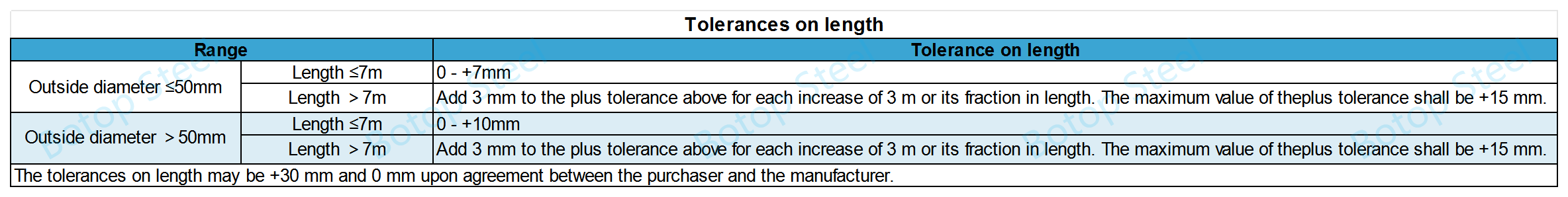

Tolerances on Length

Appearance

The internal and external surfaces of the steel pipe should be smooth and free from defects unfavorable to use. For resistance welding steel pipe, the height of the inside weld ≤ 0.25mm.

For steel pipes with OD ≤ 50.8mm or wall thickness ≤ 3.5mm, INSIDE CAMPS ≤ 0.15mm can be required.

The surface of the steel pipe can be repaired by grinding and chipping, machining, or other methods. As long as the repaired wall thickness

is within the specified wall thickness tolerance, and the surface of the repaired part shall be smooth.

Marking

Take an appropriate approach to labeling the following information.

a) Symbol of grade;

b) Symbol for the manufacturing method;

c) Dimensions: outside diameter and wall thickness;

d) Manufacturer's name or identifying brand.

Applications for JIS G 3461

Mainly used for water pipes, flue pipes, superheater pipes, and air preheater pipes in boilers, these carbon steel tubes are used to realize heat exchange inside and outside the tube.

In addition, these tubes are widely used in the chemical and petroleum industries for heat exchanger tubes, condenser tubes and catalyst tubes.

However, they are not suitable for combustion heater tubes and heat exchanger tubes for low temperatures.

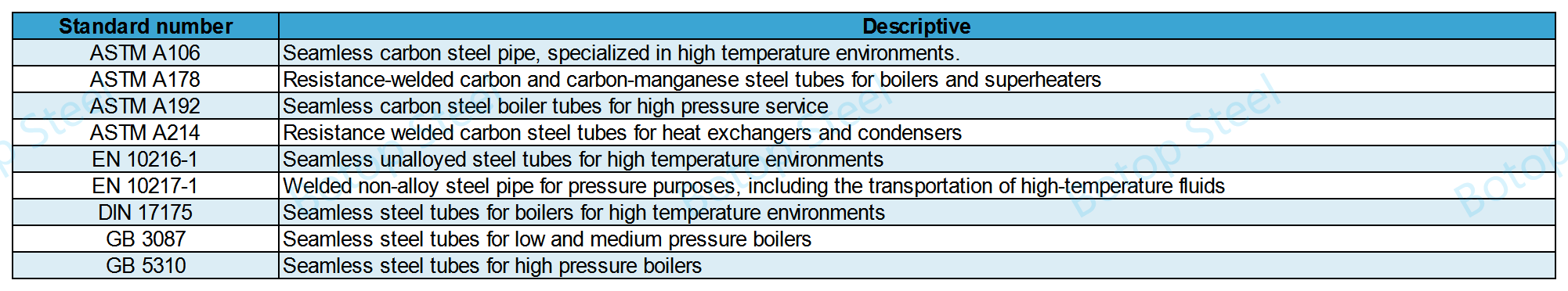

JIS G 3461 Equivalent Standard

Our Related Products

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Tags: jis g 3461, stb310, stb410, stb510, carbon steel pipe, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: May-11-2024