In modern industry and construction, steel tubes play a vital role as a basic material. With seamless and welded steel tubes as the two main categories, understanding the differences between them is crucial to choosing the right steel tube for a specific application.

Compare and analyze the following aspects to find the differences between the two.

Appearance

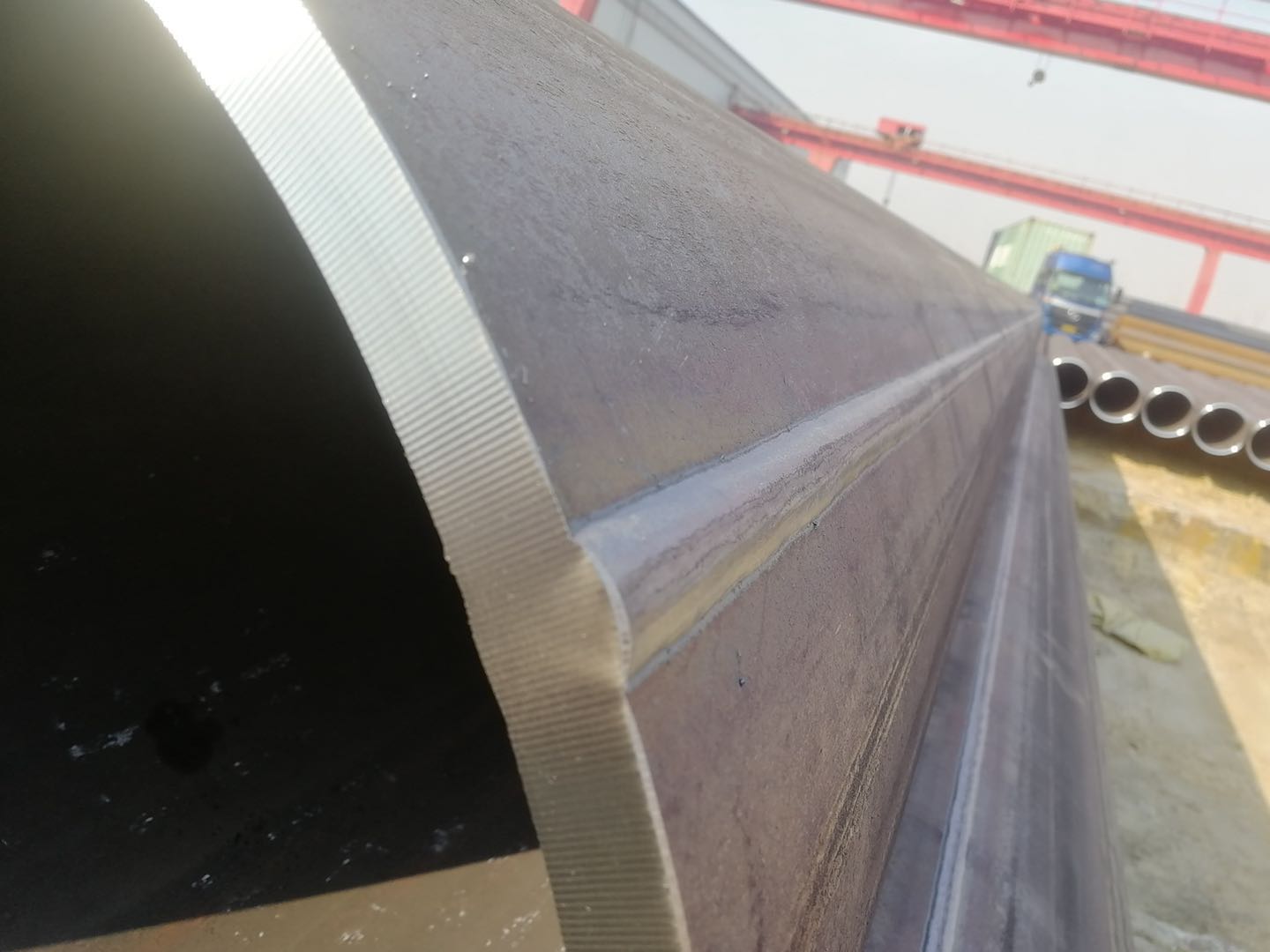

The most intuitive difference between seamless and welded steel pipe in terms of appearance is the presence or absence of welded seams.

Both seamless and welded steel pipes can undergo a variety of surface treatments to improve their appearance and performance, including sandblasting, galvanizing, and painting. These treatments can reduce the difference in appearance to a certain extent, but the basic characteristics of the welded seam is still the key factor in distinguishing the two.

Production Process

Seamless steel pipe is heated and pierced through the billet and then finished by rolling or stretching. The whole process does not involve welding, so there is no welded seam in the tube body. This production method makes seamless steel pipe have better roundness and wall thickness uniformity. The production process of seamless steel pipe includes both hot rolling and cold drawing. Hot rolling is suitable for the production of large-diameter and thick-walled steel pipes, while cold drawing is used for the production of small-diameter and thin-walled steel pipes.

Welded steel pipes are made by coiling steel plates or strips into tubes and then welding them by resistance welding or submerged arc welding, etc. The production process of welded steel pipes is relatively simple. The production process of welded steel pipe is relatively simple and low-cost, making it suitable for mass production. According to the different welding methods, welded steel pipe can be divided into straight-seam welded pipe and spiral welded pipe.

Diameter

In terms of diameter, welded steel pipe is more advantageous in the production of large-diameter steel pipe, while seamless steel pipe is more common in the small to medium-diameter range.

Wall Thickness

In terms of wall thickness, seamless tubes typically offer thicker wall options for applications subject to higher pressures, while welded tubes can more economically produce larger diameters with thinner wall thicknesses.

Corrosion Resistance

Welded steel pipe may have corrosion potential in the weld area, especially when used in corrosive environments. Seamless steel pipe because there is no welded seam, so the corrosion resistance has certain advantages.

Mechanical Properties

seamless steel pipe usually has better mechanical properties, able to work under higher pressure and more extreme environments. Welded steel pipe is sufficient for general engineering applications, but on special demanding occasions, seamless steel pipe is often a better choice.

Cost and Production Efficiency

seamless steel pipe production costs are relatively high, mainly because of its complex production process, and low material utilization. Welded steel pipe, on the other hand, is widely used in various engineering projects under non-demanding conditions due to its simple production process and lower cost.

Seamless steel pipes have an advantage in demanding application scenarios due to their excellent mechanical properties and high-pressure resistance.

Welded steel pipes, on the other hand, are widely used in many standard applications due to their cost-effectiveness and high production efficiency. The right choice of pipe type requires consideration of the specific requirements of the application scenario, the cost budget, and the performance needs.

tags: seamless, steel pipe, welded, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Feb-27-2024