Chithunzi cha ASTM A519machubu amapangidwa ndi njira yopanda msoko ndipo azikhala otentha kapena oziziritsa monga momwe tafotokozera.

Kwa machubu ozungulira okhala ndi m'mimba mwake osapitirira 12 3/4 in (325 mm).

Machubu achitsulo amathanso kupanga masikweya, makona anayi, kapena mawonekedwe ena ngati pakufunika.

ASTM A519 akhoza m'gulu malinga ndi zitsulo:Chitsulo cha Carbonndi Alloy Steel.

Chitsulo cha carbonyagawidwa muLow Carbon MT(Mechanical Tubing),High Carbon SteelndiDesulfurized kapena Rephosphorized, kapena zonse ziwiriChitsulo cha Carbon, kuti zigwirizane ndi zosowa zosiyanasiyana zamafakitale ndi zochitika zogwiritsira ntchito.

Ngati palibe kalasi yomwe yatchulidwa, opanga ali ndi mwayi woperekaMT1015 kapena MTX1020magiredi.

M'mimba mwake: 13.7 - 325 mm;

Khoma makulidwe: 2-100mm.

Chitsulo chikhoza kupangidwa ndi ndondomeko iliyonse.

Chitsulo chikhoza kuponyedwa mu ingots kapena kuponyedwa chingwe.

Machubu adzapangidwa ndi andondomeko yopanda msokondipo idzakhala yotsirizidwa yotentha kapena yozizira, monga momwe zafotokozedwera.

Machubu achitsulo opanda msoko ndi machubu opanda nsonga zowotcherera ponseponse.

Machubu oziziritsa oziziraamalimbikitsidwa kuti azifuna kwambiri kulondola kwa dimensional ndi mawonekedwe apamwamba.

Chodetsa nkhawa kwambiri ndi kutsika mtengo komanso kulimba kwa zinthu,chitoliro chachitsulo chotentha chomalizakungakhale kusankha koyenera.

Chotsatira ndi kupanga ndondomeko ya chitoliro chachitsulo chosasunthika chotentha.

Wopanga zitsulo azisanthula kutentha kwa chitsulo chilichonse kuti adziwe kuchuluka kwa zinthu zomwe zafotokozedwa.

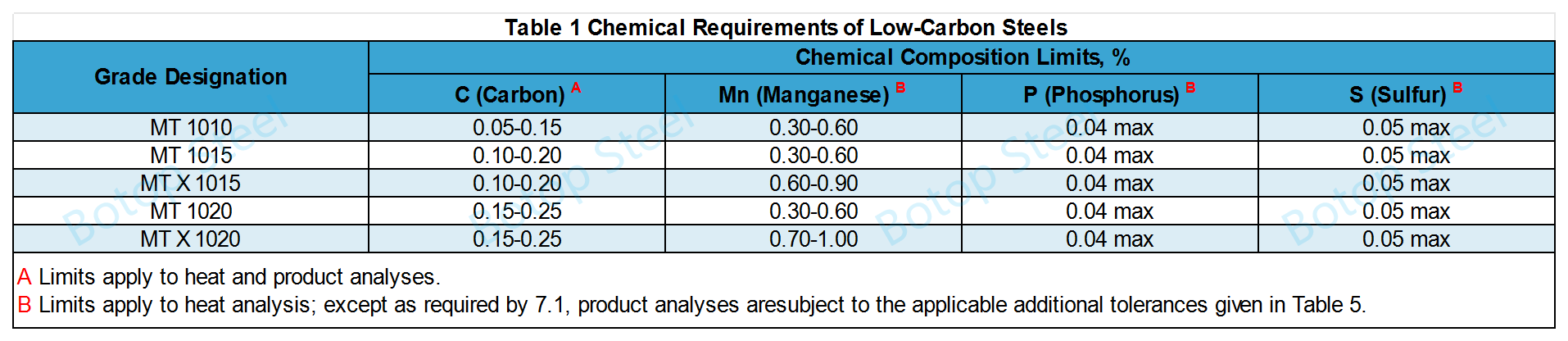

Table 1 Zofunikira za Chemical pazitsulo za Carbon Low

Chitsulo chofewa ndi chitsulo chokhala ndi mpweya wa carbon nthawi zambiri sichidutsa 0.25%. Chifukwa chokhala ndi mpweya wochepa kwambiri, chitsulochi chimakhala ndi ductility bwino ndi malleability ndipo sichikhala cholimba komanso champhamvu poyerekeza ndi chitsulo cha carbon high.

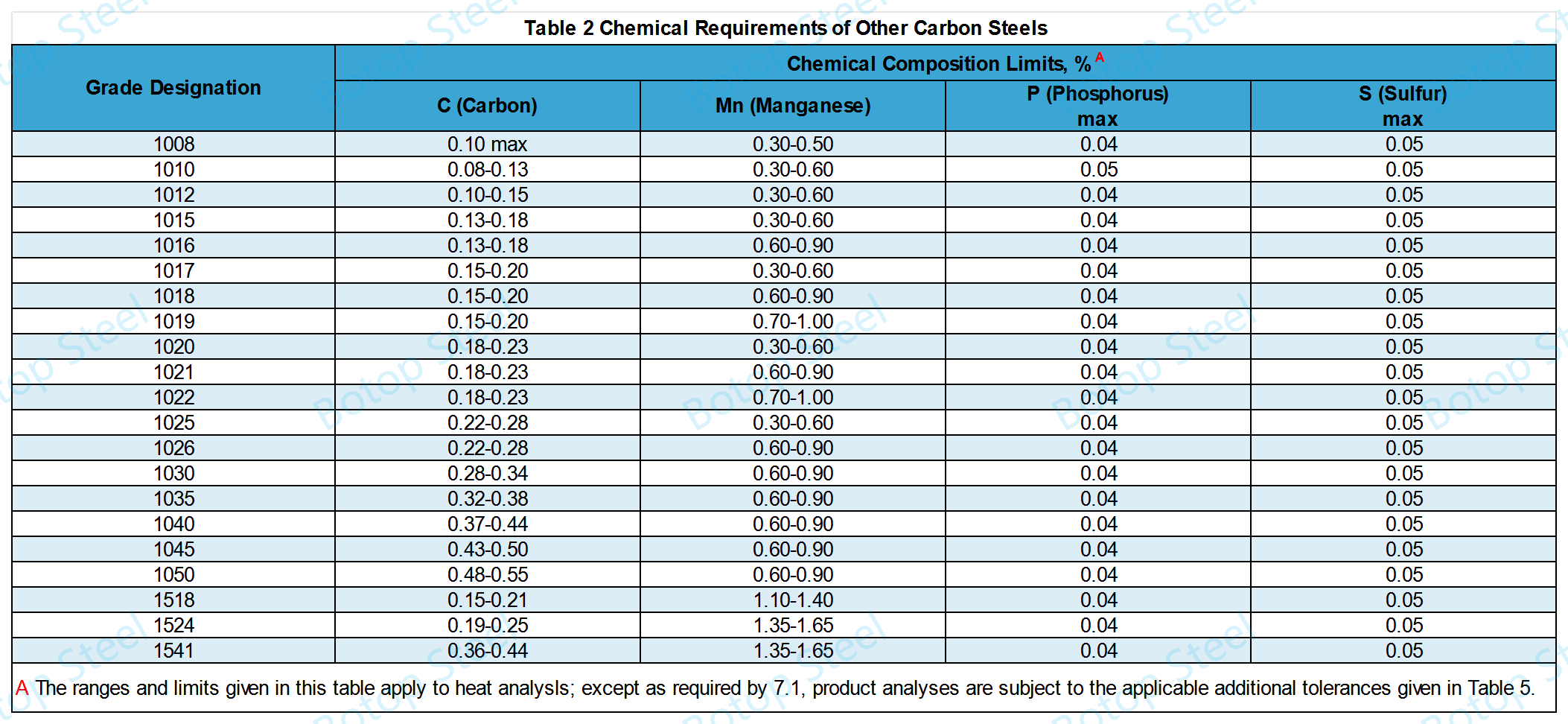

Table 2 Zofunikira Zamankhwala Pazitsulo Zina Za Carbon

Zitsulo zapakati za carbon: Ili ndi pakati pa 0.25% ndi 0.60% carbon, imapereka kuuma kwakukulu ndi mphamvu ndipo imafuna chithandizo cha kutentha kuti chiwongolere katundu.

High carbon steel: Muli pakati pa 0.60% ndi 1.0% kapena kupitilira apo, ndipo imapereka kuuma kwakukulu ndi mphamvu, koma kutsika kolimba.

Table 3 Zofunikira Zamankhwala Pazitsulo za Aloyi

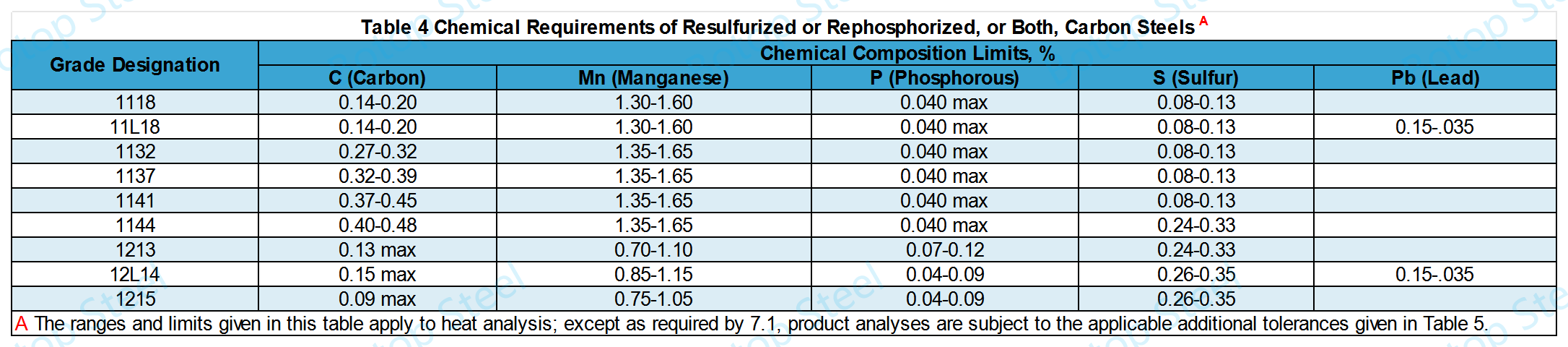

Table 4 Zofunika Zamankhwala Zopangira Resulfurized kapena Rephosphorized, kapena Onse, Zitsulo za Carbon

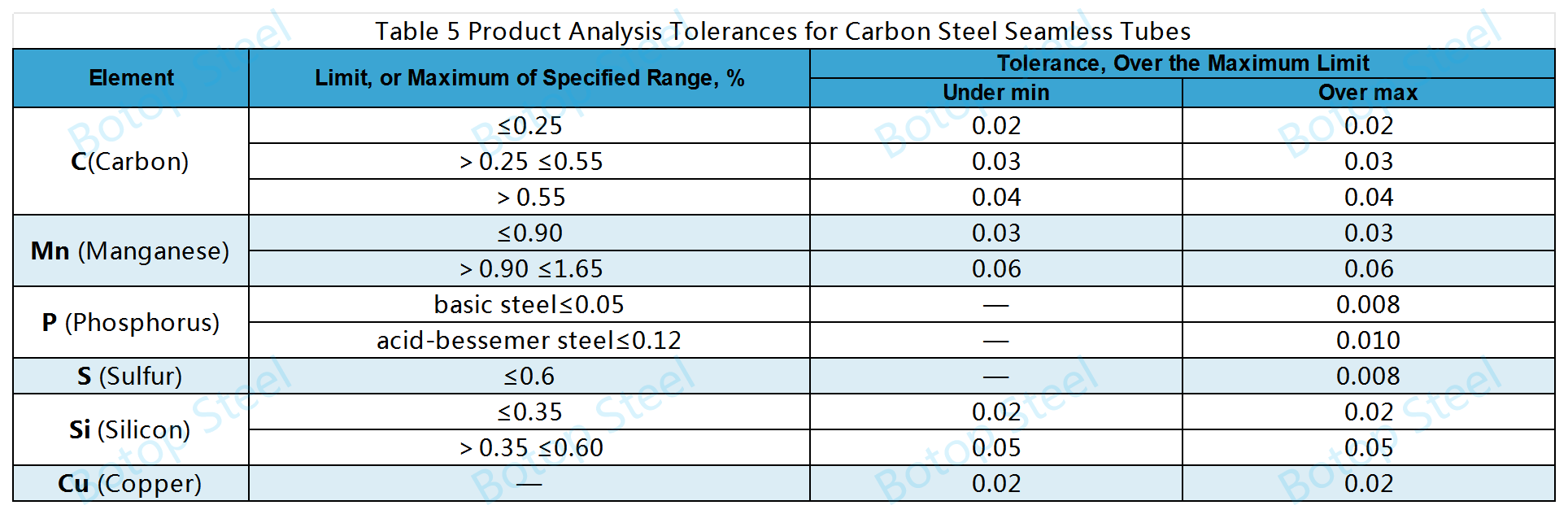

TABLE 5 Product Analysis Tolerances Over or Under Specified Range or Limit

Wopangayo ayenera kungofunsidwa kuti aunike malondawo ngati akufunika ndi dongosolo.

ASTM A519 imakhala ndi zinthu zotsatirazi:

Mayeso Olimba; Mayesero azovuta; Mayeso Osawononga; Kuyesa kwa Flaring; Chitsulo Ukhondo ndi Kuuma.

| Kusankhidwa kwa Maphunziro | Mtundu wa Chitoliro | Mkhalidwe | Uitimate Mphamvu | Zokolola Mphamvu | Kutalikira mu 2in.[50mm],% | Rockwell, Kulimba B Scale | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Chitsulo cha Carbon | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Chitsulo cha Carbon | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Chitsulo cha Carbon | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Chitsulo cha Carbon | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Chitsulo cha Carbon | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized kapena Rephosphorized, kapena onse awiri, Zitsulo za Carbon | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized kapena Rephosphorized, kapena onse awiri, Zitsulo za Carbon | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Aloyi Zitsulo | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Aloyi Zitsulo | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-Cold Worked, SR-Stress Relied, A-Annealed ndi N-Normalized.

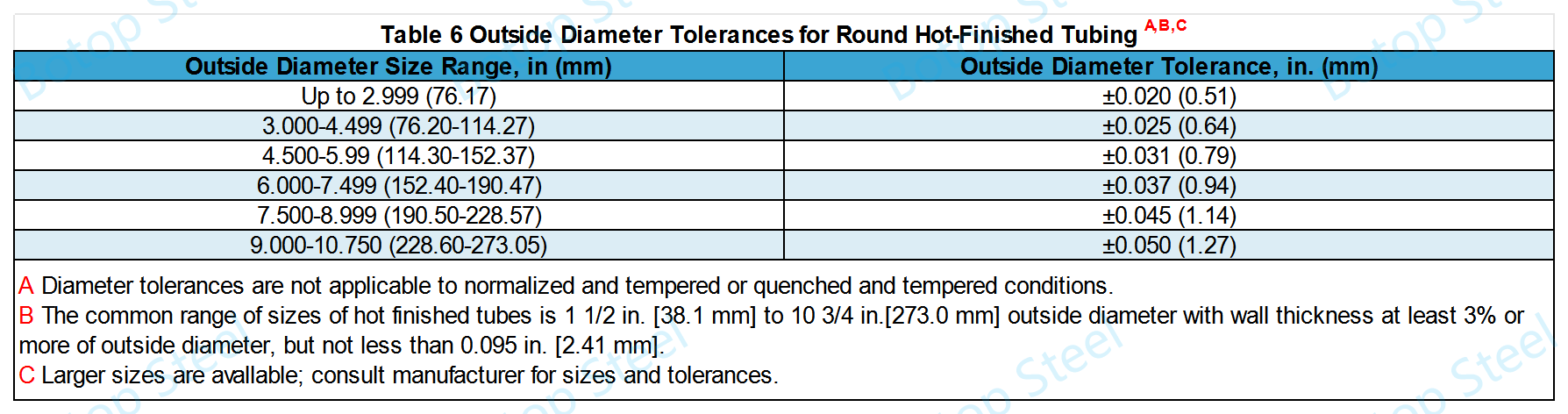

Kulekerera Kwa Diameter Kunja

Table 6 Kulekerera Diameter Kunjakwa Round Hot-Finished Tubing

Table 12 Kulekerera Diameter Kunja kwaGround Seamless Tubing

| Kukula Kunja Diameter, mu.[mm] | Kulekerera Kunja Kwa Diameter Kwa Makulidwe ndi Utali Woperekedwa, mkati [mm] | |||

| Zatha | Pansi | Zatha | Pansi | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] pamene L≤16ft[4.9m] | 0.000 | 0.004 [0.10] pamene L>16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] pamene L≤16ft[4.9m] | 0.000 | 0.006 [0.15] pamene L>16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] pamene L≤12ft[3.7m] | 0.000 | 0.006 [0.15] pamene L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] pamene L≤12ft[3.7m] | 0.000 | 0.006 [0.15] pamene L≤16ft[4.9m] | 0.000 |

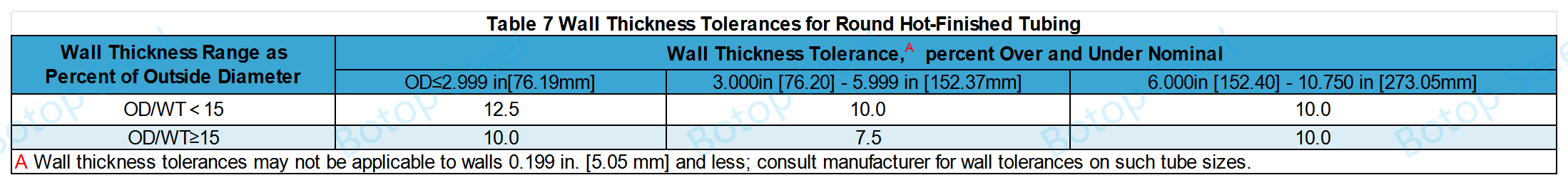

Kulekerera kwa Wall Makulidwe

Table 7 Kulekerera Makulidwe a Khomakwa Round Hot-Finished Tubing

Table 10 Kulekerera Makulidwe a Khomakwa Round Cold-Worked Tubing

| Makulidwe a Khoma Amakhala ngati Maperesenti Akunja Diameter | Kulolera kwa Khoma Kupitirira ndi Pansi Mwadzina,% | |

| OD≤1.499in[38.07mm] | OD≥1.500 mu [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

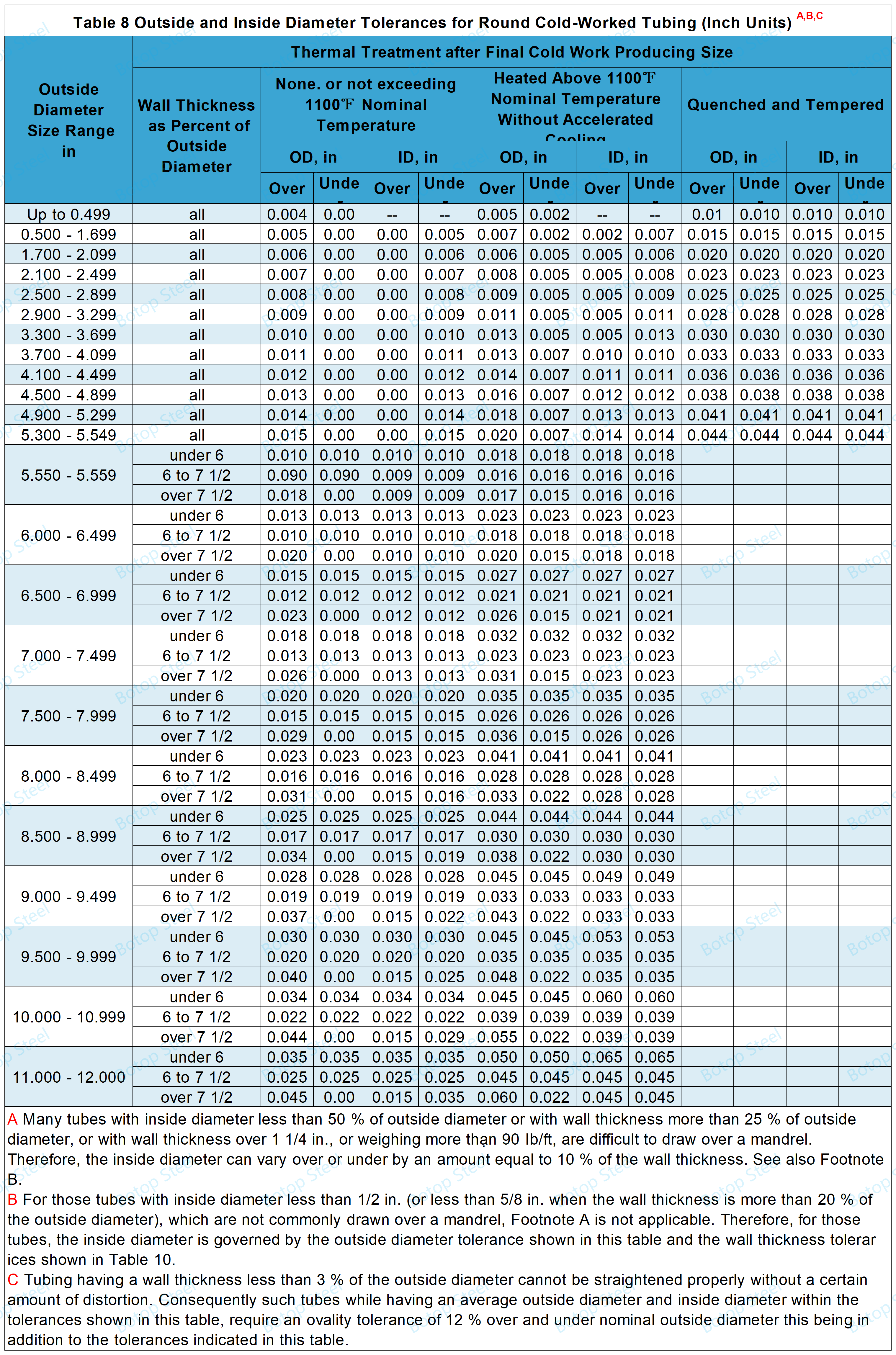

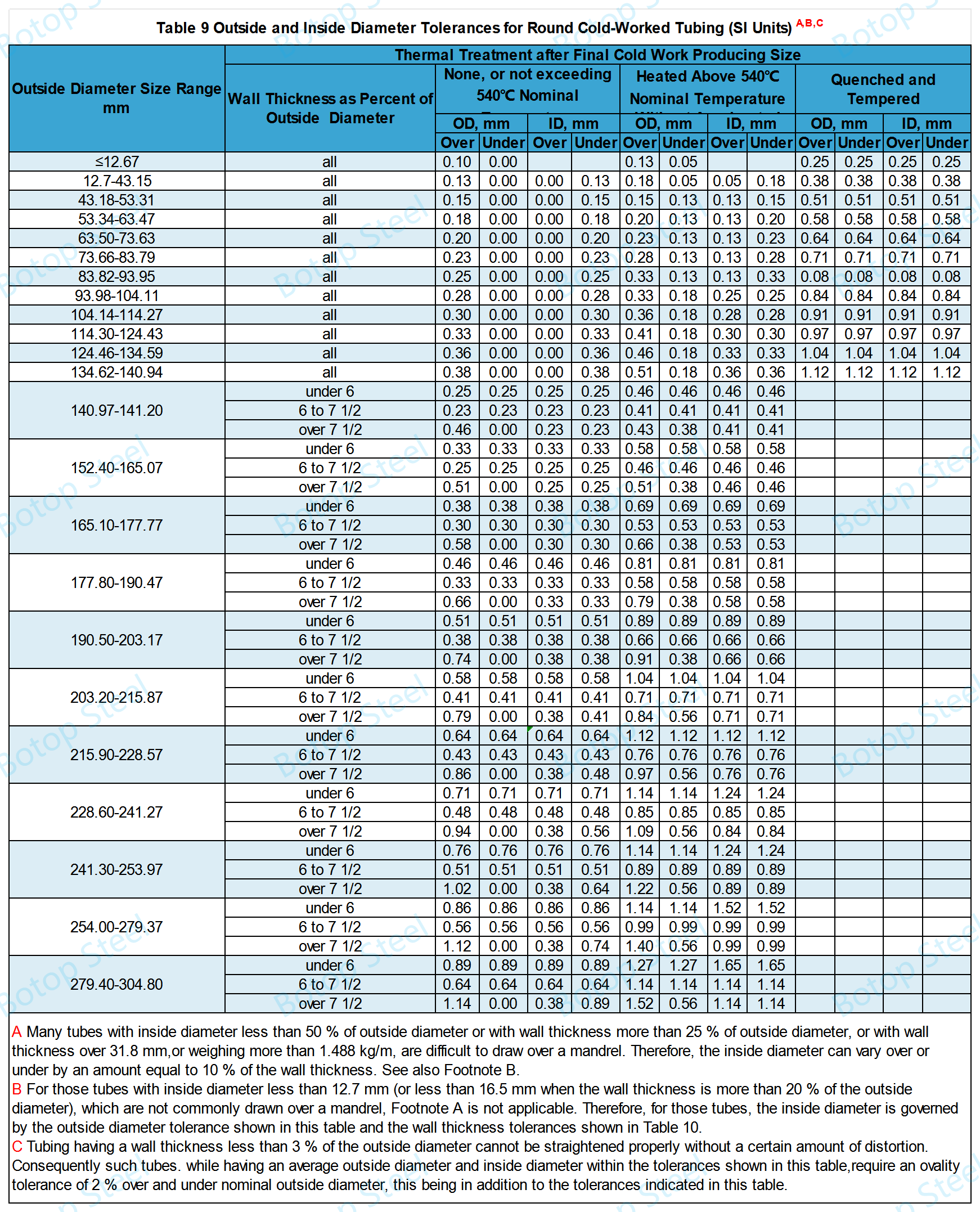

Kulekerera Kwakunja ndi Mkati mwa Diameter

Table 8 Kulekerera Kunja ndi Mkati mwa Diameter kwaMachubu Ozungulira Ozizira (Mayunitsi a Inchi)

Table 9 Kulekerera Kunja ndi Mkati mwa Diameterkwa Round Cold-Worked Tubing (ma SI Units)

Kulekerera kwa Diameter Yakunja ndi Makulidwe a Khoma

Tebulo 11 Kunja Kwa Diameter ndi Kulekerera Kwakhomakwa Rough-Turned Seamless Steel Tubing

| Kukula kwake Kunja Diameter, mkati [mm] | Kunja Diameter, mkati [mm] | Makulidwe a khoma, % |

| <6 3/4 [171.4] | ± 0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ± 0.010 [0.25] | ± 12.5 |

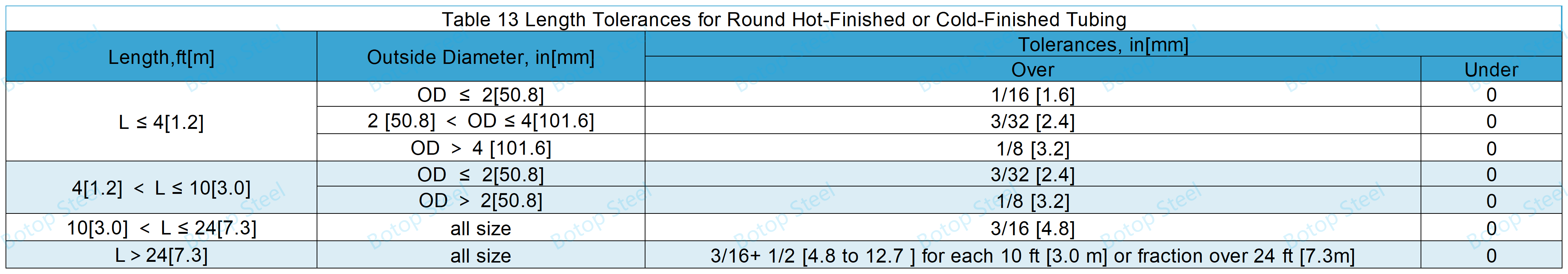

Kulekerera Kwautali

Table 13 Kulekerera Kwautalikwa Round Hot-Finished kapena Cold-Finished Tubing

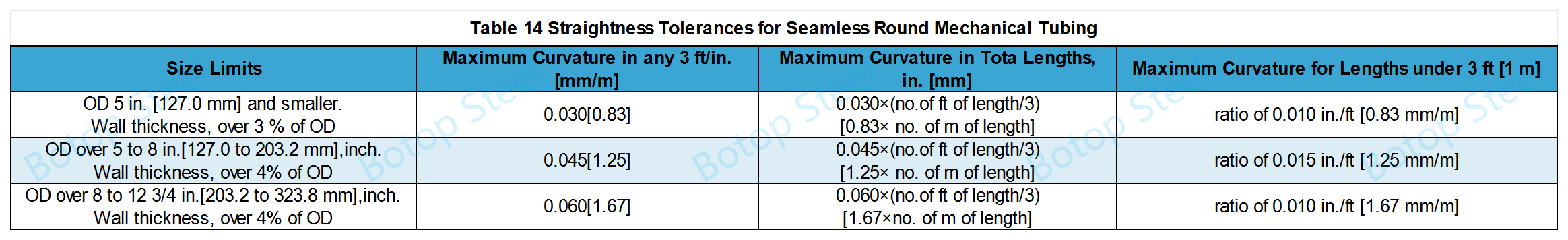

Kulekerera Kuwongoka

Table 14 Kulekerera Kuwongokaza Seamless Round Mechanical Tubing

Chitolirocho chiyenera kuphimbidwa ndi filimu yamafuta musanawumbe kuti zisachite dzimbiri.

Mafuta oteteza dzimbiri angagwiritsidwenso ntchito mkati ndi kunja kwa chitoliro.

Ndege ndi ndege: kupanga zinthu zofunika kwambiri monga injini za ndege ndi makina othandizira ndege.

Makampani opanga mphamvu: zida zobowolera komanso kupanga mapaipi othamanga kwambiri.

Kupanga makina ndi zida: Zigawo zapakati zomwe zimapanga makina osiyanasiyana a mafakitale ndi zida.

Zida zamasewera: Kupanga mafelemu apanjinga ochita bwino kwambiri ndi malo ena amasewera.

Kumanga ndi kumanga: Zothandizira zomangira zomanga ndi ntchito m'malo opanikizika kwambiri.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, ndi zina zotero. Zidazi zikhoza kuwonedwa ngati zofanana ndi zitsulo za carbon ndi alloy mu ASTM A519.

2. DIN 1629: St52, St37.4, etc. Kawirikawiri amagwiritsidwa ntchito pazinthu zamakina ndi zomangamanga, izi ndizofanana ndi zitsulo zofatsa za ASTM A519.

3. JIS G3445: STKM13A, STKM13B, etc. Awa ndi machubu a carbon steel omwe amagwiritsidwa ntchito pazinthu zamakina ndi zomangamanga.

4. BS 6323: CFS 3, CFS 4, CFS 8, ndi zina zotero. Awa ndi machubu achitsulo opanda msoko ndi otsekemera a magalimoto, makina, ndi zomangamanga.

5. GB / T 8162: 20 #, 45 #, 40Cr, 20CrMo, etc. Machubu osasunthika azitsulo ndi mapaipi amtundu wambiri komanso makina opangira.

6. ISO 683-17: 100Cr6, ndi zina zotero, zomwe zimagwiritsidwa ntchito popanga katundu, zimathanso kupeza ntchito mu makina opanga makina ndipo zimakhala ndi ntchito zofanana ndi zitsulo zina za ASTM A519.

Posankha chinthu chofanana, ndikofunikira kutchula mwatsatanetsatane kapangidwe kake kake ndi mafotokozedwe azinthu zamakina kuti muwonetsetse kuti zomwe zasankhidwa zikwaniritsa zofunikira pakugwiritsa ntchito.

Chiyambireni kukhazikitsidwa mu 2014, Botop Steel yakhala ikugulitsa chitoliro chachitsulo cha carbon ku Northern China, chomwe chimadziwika ndi ntchito zabwino kwambiri, zinthu zamtengo wapatali, komanso zothetsera mavuto. Kampaniyi imapereka mapaipi osiyanasiyana a zitsulo za carbon ndi zinthu zomwe zimagwirizana nazo, kuphatikizapo zopanda msoko, ERW, LSAW, ndi chitoliro chachitsulo cha SSAW, komanso mzere wathunthu wazitsulo ndi flanges.

Zopangira zake zapadera zimaphatikizanso ma alloys apamwamba kwambiri ndi zitsulo zosapanga dzimbiri za austenitic, zopangidwa kuti zikwaniritse zofunikira zama projekiti osiyanasiyana a mapaipi.