EN 10210 S355J2Hndi otentha-anamaliza structural dzenje gawo zitsulo malinga ndiEN 10210ndi mphamvu zochepa zokolola za 355 MPa (za makulidwe a khoma ≤ 16 mm) ndi katundu wabwino wokhudzidwa pa kutentha kochepa mpaka -20 ° C, zomwe zimapangitsa kuti zikhale bwino kuti zigwiritsidwe ntchito muzomangamanga ndi zomangamanga.

Inde, EN 10210 =Gawo la EN 10210.

TS EN 10210 ndi EN 10210 ndizofanana muukadaulo ndipo onse amayimira miyezo yaku Europe pakupanga, kupanga, ndi zofunikira pazigawo za holo za thermoformed.

BS EN 10210 ndiye mtundu womwe watengedwa ku UK, pomwe EN 10210 ndi muyeso waku Europe konse. Mabungwe osiyanasiyana oyimira mayiko akhoza kuyika patsogolo muyesowo ndi mawu achidule amtundu wina, koma zomwe zili mulingowo sizingafanane.

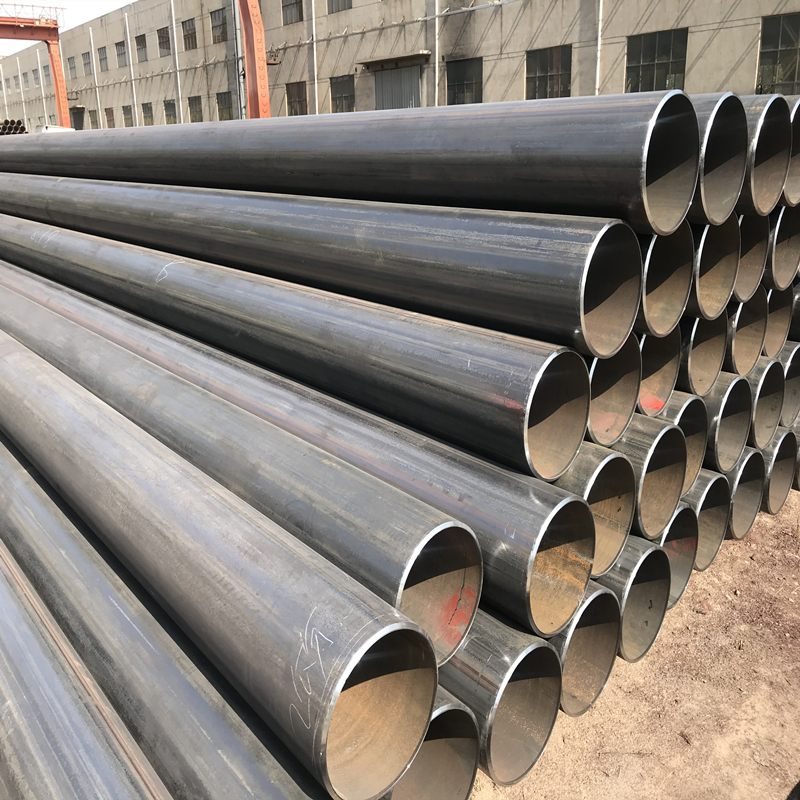

Magawo a dzenje amatha kugawidwa ngati zozungulira, masikweya kapena amakona anayi, kapena elliptical.

Komanso chifukwa ndi njira yomaliza yotentha molingana ndi EN 10210, chidule chotsatira chitha kugwiritsidwa ntchito.

Zithunzi za HFCHS= otentha omaliza zozungulira dzenje zigawo;

Mtengo wa HFRHS= magawo otentha omaliza apakati kapena amakona anayi opanda kanthu;

HFEHS= magawo otentha omaliza a elliptical hollow.

Kuzungulira: Kunja kwakunja mpaka 2500 mm;

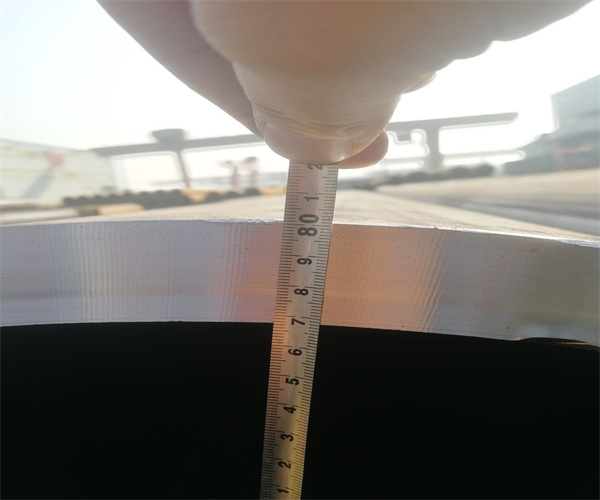

Makulidwe a khoma mpaka 120 mm.

Inde, palibe njira yopangira machubu a kukula uku ndi makulidwe a khoma ngati njira yowotcherera ya ERW ikugwiritsidwa ntchito.

ERW imatha kupanga machubu mpaka 660mm okhala ndi makulidwe a khoma la 20mm.

Chitsulo chikhoza kupangidwa kudzera mu aopanda msoko kapena kuwotchererandondomeko.

Pakati pakuwotcherera njira, njira zowotcherera wamba zikuphatikizapoERW(magetsi kukana kuwotcherera) ndiSAW(kuwotcherera kwa arc pansi pamadzi).

Mwa zina,ERWndi njira yowotcherera yomwe imalumikiza mbali zachitsulo pamodzi pogwiritsa ntchito kutentha kosasunthika komanso kupanikizika. Njirayi imagwiritsidwa ntchito pazinthu zosiyanasiyana komanso makulidwe ndipo imathandizira njira yowotcherera bwino.

SAW, Komano, ndi njira yowotcherera yomwe imagwiritsa ntchito granular flux kuphimba arc, yomwe imapereka kulowa kwakuya komanso khalidwe labwino la weld ndipo ndiloyenera kwambiri kuwotcherera mbale zakuda.

Chotsatira, ndi ndondomeko ya ERW, yomwe ndi njira yopangira kwambiri yomwe imagwiritsidwa ntchito popanga machubu ambiri achitsulo ndi mbiri.

Tiyenera kukumbukira kuti pazigawo zosagwiritsidwa ntchito komanso zosakanizidwa bwino zomwe zimapangidwa ndi njira yowotcherera, kukonza zowotcherera sikuloledwa kupatula kuwotcherera kwa arc pansi pamadzi.

Qualities JR, JO, J2 ndi K2 - yotentha yomaliza,

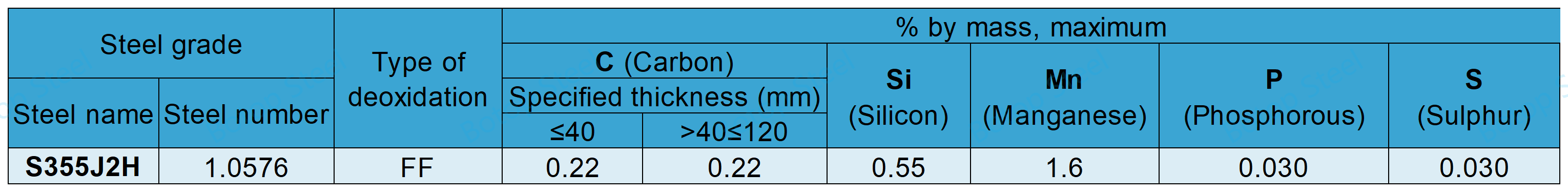

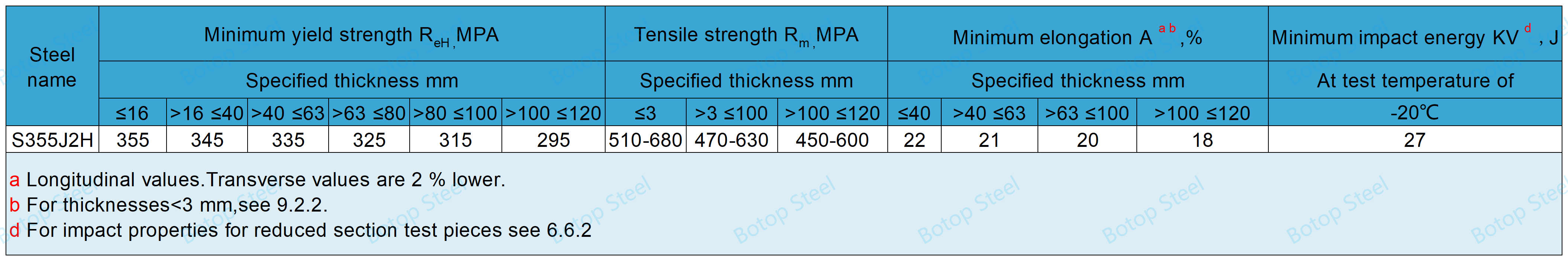

Mphamvu zochepa zokolola za chitoliro chachitsulo cha S355J2H sizinakhazikitsidwe, zidzasintha ndi makulidwe osiyanasiyana a khoma.

Mwachindunji, mphamvu zokolola za S355J2H zimayikidwa molingana ndi muyezo pamene makulidwe a khoma ndi ocheperapo kapena ofanana ndi 16mm, koma pamene makulidwe a khoma akuwonjezeka, mphamvu zokolola zidzachepetsedwa, kotero kuti si onse S355J2H chitoliro chachitsulo chingafikire mphamvu zochepa zokolola za 355MPa.

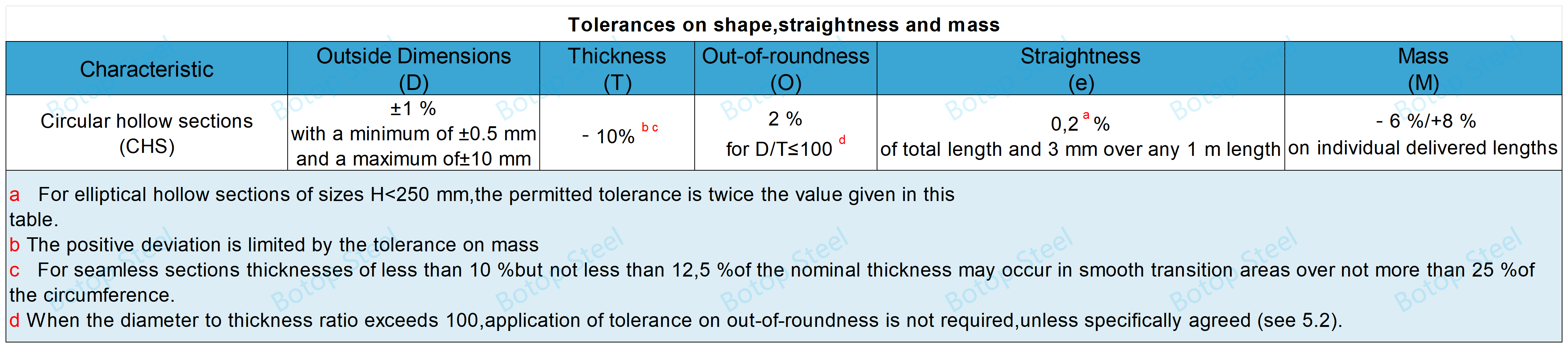

Kulekerera pa mawonekedwe, kuwongoka ndi misa

Kulekerera kutalika

| Mtundu wa kutalikaa | Kutalika kapena kutalika kwa L | Kulekerera |

| Kutalika kwachisawawa | 4000≤L≤16000 yokhala ndi 2000 pa chinthu chilichonse | 10 % ya magawo omwe aperekedwa atha kukhala ochepera pamlingo womwe walamulidwa koma osachepera 75 % ya kutalika kocheperako. |

| Pafupifupi kutalika | 4000≤L≤16000 | ± 500 mmb |

| Kutalika kwenikweni | 2000≤L≤6000 | 0 - + 10 mm |

| 6000c | 0 - + 15 mm | |

| aWopangayo adzakhazikitsa nthawi yofunsa ndikuyitanitsa mtundu wautali wofunikira komanso kutalika kapena kutalika kwake. bOntion 21 kulolerana pa annrevimata kutalika ndi 0 - +150mm cUtali wamba womwe ulipo ndi 6 m ndi 12 m. | ||

S355J2H chitsulo chitoliro ndi mkulu-mphamvu structural zitsulo chitoliro ndi ntchito kuwotcherera bwino ndi otsika kutentha zimakhudza toughness, choncho ali osiyanasiyana ntchito m'minda angapo mafakitale.

1. Zomangamanga: amagwiritsidwa ntchito m'milatho, nsanja, zomangira, zoyendera njanji, masitima apamtunda, mafelemu apadenga, mapanelo a khoma, ndi zomangira zina.

2. Dongosolo la mapaipi: Amagwiritsidwa ntchito ngati mapaipi potengera madzimadzi, makamaka nthawi zomwe zimafunikira mphamvu zambiri komanso kukana kupanikizika.

3. Umisiri wapanyanja ndi m'mphepete mwa nyanja: amagwiritsidwa ntchito popanga zombo, nsanja zakunyanja, ndi zomangamanga zina zam'madzi.

4. Makampani opanga mphamvu: amagwiritsidwa ntchito m'malo opangira magetsi monga nsanja zamphepo, pobowola mafuta, ndi mapaipi.

5. Zotengera zokakamiza: amagwiritsidwa ntchito popanga ziwiya zopondereza potsatira zofunikira za kuwotcherera ndi kutentha.

6. Makampani a migodi: amagwiritsidwa ntchito pazigawo zomangira zamagulu othandizira mgodi, makina otumizira, ndi zida zopangira ore.

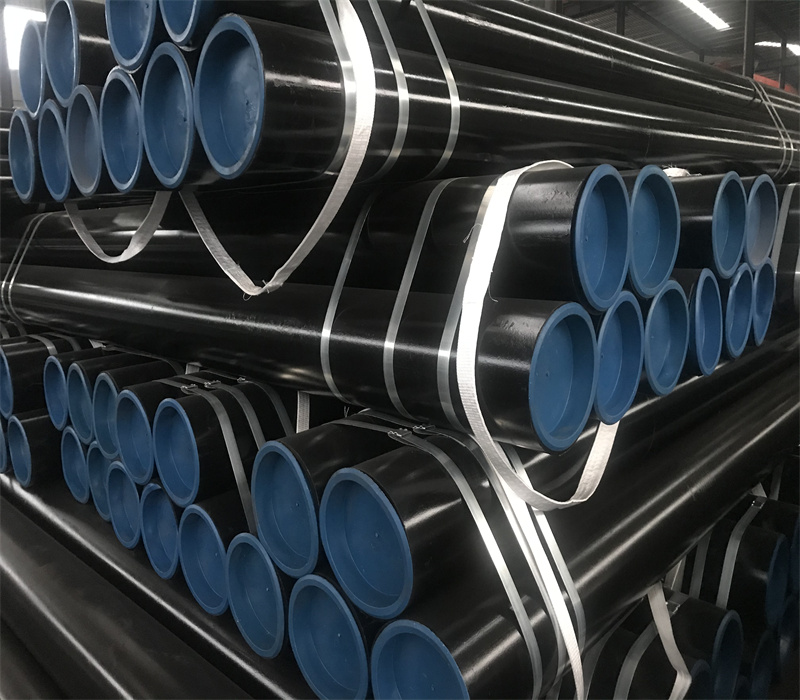

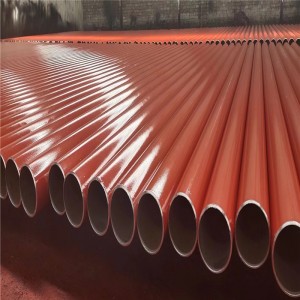

Chitoliro chopanda kanthu kapena zokutira zakuda / varnish (zosinthidwa);

m'mitolo kapena momasuka;

Zonsezi zimathera ndi otetezera mapeto;

Mapeto osavuta, malekezero a bevel (2"ndi pamwamba ndi ma bevel malekezero, digiri: 30 ~ 35 °), ulusi ndi kulumikizana;

Kuyika chizindikiro.