JIS G 3461 chitoliro chachitsulondi chitoliro chachitsulo chopanda msoko (SMLS) kapena chamagetsi-resistance-welded (RW) cha carbon steel, chomwe chimagwiritsidwa ntchito makamaka m'ma boilers ndi zotenthetsera pa ntchito monga kuzindikira kusinthana kwa kutentha pakati pa mkati ndi kunja kwa chubu.

Chithunzi cha STB340ndi mpweya zitsulo chitoliro kalasi mu JIS G 3461 muyezo. Ili ndi mphamvu yocheperako ya 340 MPa ndi mphamvu zokolola zochepa za 175 MPa.

Ndizinthu zomwe zimasankhidwa pamafakitale ambiri chifukwa cha mphamvu zake zazikulu, kukhazikika kwamafuta abwino, kusinthasintha, kukana kwa dzimbiri, kutsika mtengo, komanso kusinthika kwabwino.

Chithunzi cha JIS 3461ali ndi magiredi atatu.STB340, STB410, STB510.

Chithunzi cha STB340: Kuchepa kwamphamvu kwamphamvu: 340 MPa; Mphamvu zochepa zokolola: 175 MPa.

Chithunzi cha STB410: Mphamvu Zochepa Zochepa: 410 MPa; Mphamvu Zosachepera Zokolola: 255 MPa.

STB510:Mphamvu Zochepa Zochepa: 510 MPa; Mphamvu Zosachepera Zokolola: 295 MPa.

M'malo mwake, sizovuta kudziwa kuti kalasi ya JIS G 3461 imayikidwa molingana ndi mphamvu yocheperako ya chitoliro chachitsulo.

Pamene kalasi yazinthu ikuwonjezeka, mphamvu zake zowonongeka ndi zokolola zimawonjezeka moyenerera, zomwe zimalola kuti zinthuzo zithe kulimbana ndi katundu wambiri ndi zovuta za malo ogwirira ntchito ovuta kwambiri.

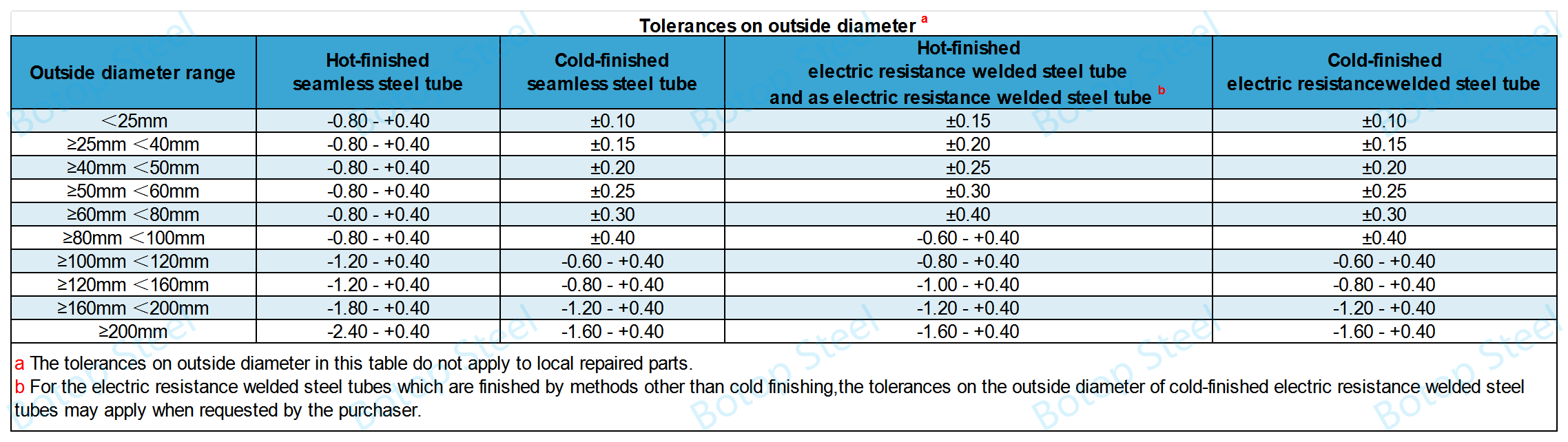

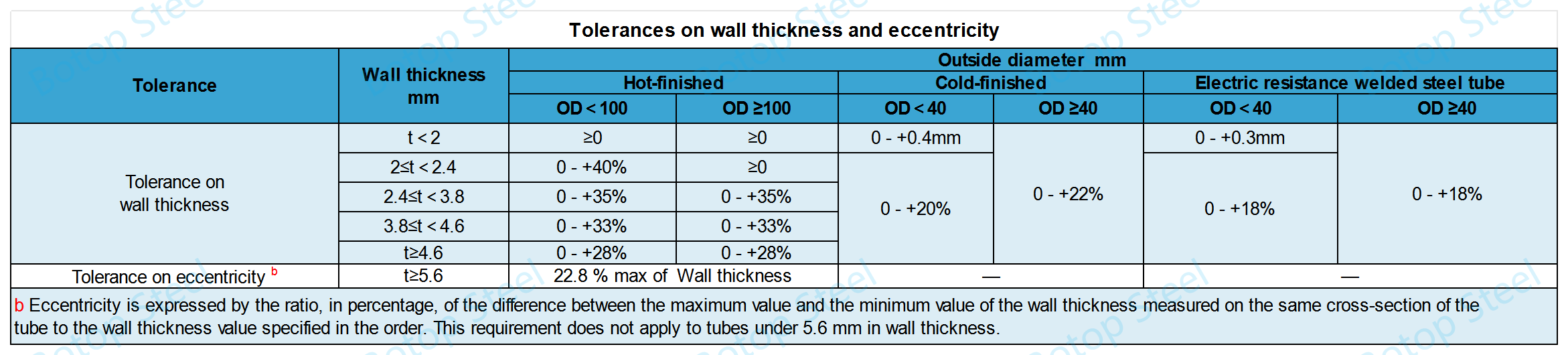

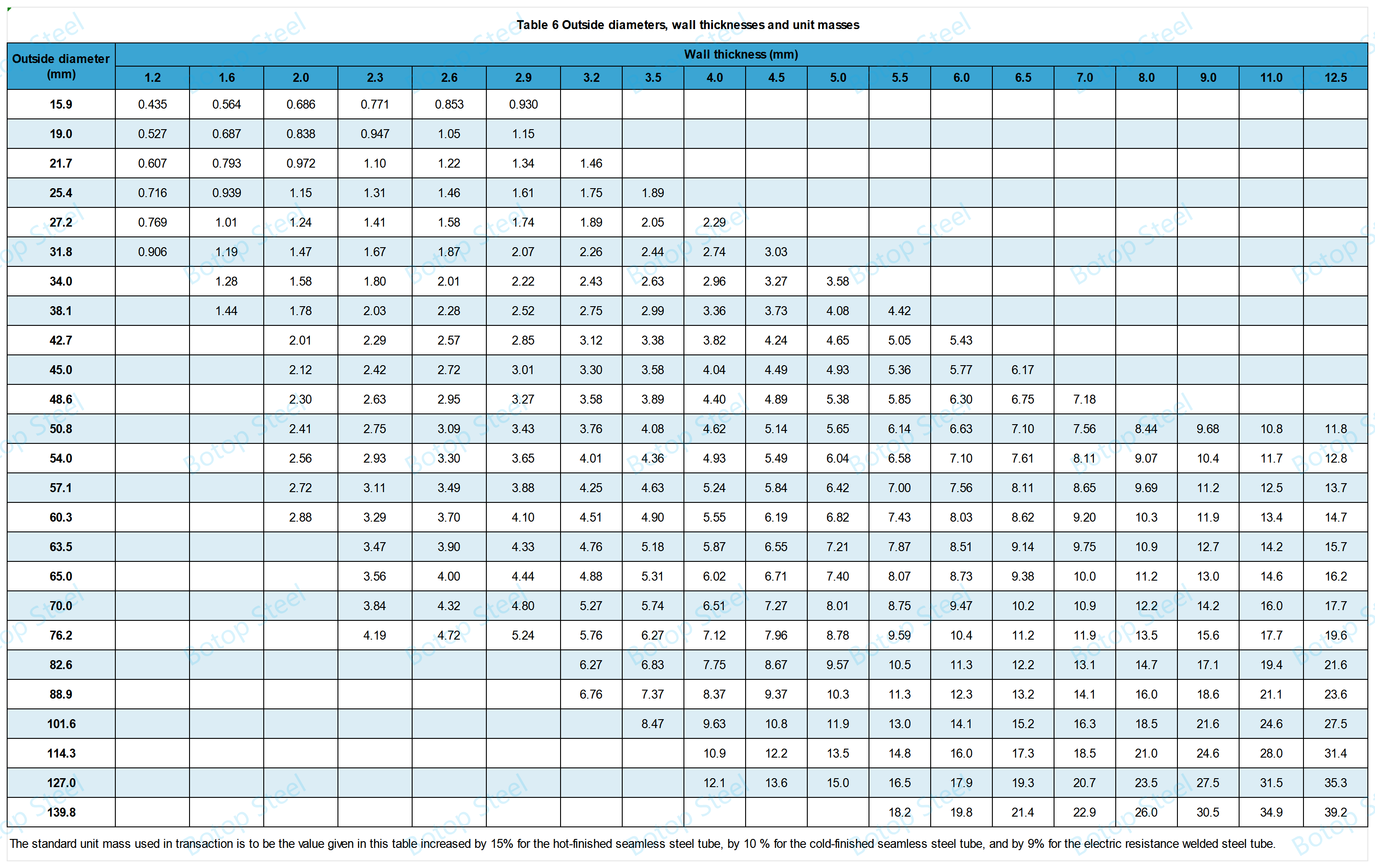

Kunja awiri 15.9-139.8mm.

Kugwiritsa ntchito ma boilers ndi zosinthira kutentha nthawi zambiri safuna ma diameter akulu kwambiri. Machubu ang'onoang'ono amawonjezera mphamvu yamafuta chifukwa kuchuluka kwa kuchuluka kwa kuchuluka kwa kutentha kumakhala kokwera. Izi zimathandiza kusamutsa mphamvu ya kutentha mofulumira komanso mogwira mtima.

Machubu adzapangidwa kuchokera kukupha chitsulo.

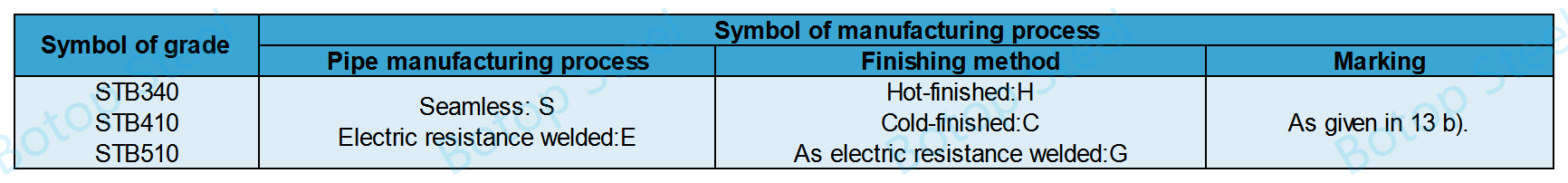

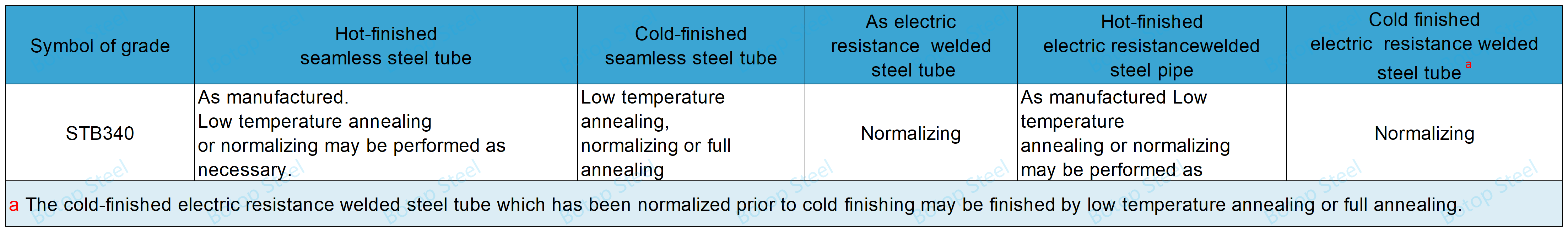

Kuphatikiza njira zopangira zitoliro ndi njira zomaliza.

Mwatsatanetsatane, iwo akhoza kugawidwa motere:

Chubu chachitsulo chosasunthika chotentha: SH

Chitsulo chozizira chomaliza chopanda msoko: SC

Monga magetsi kukana welded zitsulo chubu: EG

Kutentha komaliza kwamagetsi kukana welded steel chubu: EH

Kuzizira komaliza kwamagetsi kukana welded steel chubu: EC

Nayi kutulutsa kwa Hot-finished seamless.

Pakupanga kopanda msoko, imatha kugawidwa m'mapaipi opanda zitsulo okhala ndi mainchesi akunja opitilira 30mm pogwiritsa ntchito kumaliza kotentha, ndi 30mm pogwiritsa ntchito kumaliza kuzizira.

Njira zowunikira kutentha zizikhala molingana ndi miyezo ya JIS G 0320.

Ma alloying ena kupatula omwewo akhoza kuwonjezeredwa kuti apeze zinthu zinazake.

Pamene mankhwalawa akuwunikidwa, kusinthika kwa mankhwala a chitoliro kudzakwaniritsa zofunikira za Table 3 ya JIS G 0321 ya mipope yachitsulo yopanda msoko ndi Table 2 ya JIS G 0321 ya mapaipi achitsulo osakanizidwa.

| Chizindikiro cha kalasi | C (Kaboni) | Si (Silicon) | Mn (Manganese) | Phosphorous (P) | S (Sulphur) |

| max | max | max | max | ||

| Chithunzi cha STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Wogula atha kufotokoza kuchuluka kwa Si kukhala pakati pa 0.10 % mpaka 0.35%. | |||||

Mankhwala a STB340 adapangidwa kuti awonetsetse kuti ali ndi zida zokwanira zamakina ndi makina pomwe akupanga zinthuzo kukhala zoyenera kuwotcherera ndikugwiritsa ntchito m'malo otentha kwambiri.

| Chizindikiro cha kalasi | Mphamvu yamphamvu a | Mfundo yokolola kapena kutsindika kwa umboni | Elongation min,% | ||

| M'mimba mwake | |||||

| <10 mm | ≥10mm <20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Chigawo choyesera | |||

| No.11 | No.11 | No.11/No.12 | |||

| min | min | Njira yoyesera yolimba | |||

| Kufanana kwa chubu axis | Kufanana kwa chubu axis | Kufanana kwa chubu axis | |||

| Chithunzi cha STB340 | 340 | 175 | 27 | 30 | 35 |

Zindikirani: kokha kwa machubu osinthanitsa kutentha, wogula akhoza, ngati kuli kofunikira, kutchula mtengo wapamwamba wa mphamvu zolimba. Pachifukwa ichi, kuchuluka kwamphamvu kwamphamvu kudzakhala mtengo womwe umapezeka powonjezera 120 N/mm² pamtengo womwe uli patsamba lino.

Pamene mayeso wamakokedwe ikuchitika pa Mayeso chidutswa No. 12 kwa chubu pansi 8 mm mu makulidwe khoma.

| Chizindikiro cha kalasi | Chiyeso chogwiritsidwa ntchito | Elongation mphindi,% | ||||||

| Khoma makulidwe | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| Chithunzi cha STB340 | Nambala 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Miyezo yotalikirapo patebuloli imawerengedwa pochotsa 1.5 % pamtengo wotalikirapo womwe waperekedwa mu Gulu 4 pakutsika kulikonse kwa 1 mm mu makulidwe a khoma la chubu kuchoka pa 8 mm, ndikuzunguliza zotsatira zake kukhala nambala yathunthu malinga ndi Lamulo A la JIS Z 8401.

Njira yoyesera idzakhala yogwirizana ndi JIS Z 2245. Kuuma kwa chidutswa choyesera kudzayesedwa pamtunda wake wodutsa kapena mkati mwa malo atatu pa chidutswa choyesera.

| Chizindikiro cha kalasi | Kuuma kwa Rockwell (kutanthauza mtengo wa malo atatu) Mtengo wa HRBW |

| Chithunzi cha STB340 | 77 max. |

| Chithunzi cha STB410 | 79 max. |

| Chithunzi cha STB510 | 92 max. |

Mayesowa sayenera kuchitidwa pa machubu a khoma makulidwe 2 mm kapena pansi. Kwa machubu achitsulo okanizidwa ndi magetsi, kuyezetsa kudzachitika m'gawo lina osati madera okhudzidwa ndi kutentha.

Sichigwira ntchito ku machubu achitsulo opanda msoko.

Njira Yoyesera Ikani chitsanzocho mu makina ndikuchiphwanya mpaka mtunda wapakati pa nsanja ziwiri ufike pamtengo wotchulidwa H. Kenako yang'anani chitsanzo cha ming'alu.

Poyesa kukana zovuta welded chitoliro, mzere pakati pa weld ndi pakati pa chitoliro ndi perpendicular kwa psinjika malangizo.

H=(1+e)t/(e+t/D)

H: mtunda pakati pa mbale (mm)

t: makulidwe a chubu (mm)

D: kunja kwa chubu (mm)

е:zimatanthauzidwa nthawi zonse pa kalasi iliyonse ya chubu. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Sichigwira ntchito ku machubu achitsulo opanda msoko.

Mapeto amodzi a chitsanzocho amawotchedwa kutentha (5 ° C mpaka 35 ° C) ndi chida cha conical pa ngodya ya 60 ° mpaka m'mimba mwake akukulitsidwa ndi gawo la 1.2 ndikuwunika ming'alu.

Chofunikirachi chimagwiranso ntchito pamachubu okhala ndi m'mimba mwake kuposa 101.6 mm.

Kuyesa kwa reverse flattening kumatha kusiyidwa poyesa kuyesa kwamoto.

Dulani 100 mm kutalika kwa chidutswa choyesera kuchokera kumapeto kwa chitoliro ndikudula chidutswa choyesera mu theka la 90 ° kuchokera pamzere wowotcherera kumbali zonse za circumference, kutenga theka lomwe lili ndi weld ngati chidutswa choyesera.

Kutentha (5 °C mpaka 35 °C) phwasulani chitsanzocho kukhala mbale yokhala ndi chowotcherera pamwamba ndikuyang'ana chitsanzocho ngati ming'alu yowotcherera.

Chitoliro chilichonse chachitsulo chiyenera kuyesedwa mwa hydrostatic kapena osawonongakuonetsetsa ubwino ndi chitetezo cha chitoliro ndi kukwaniritsa mfundo ntchito.

Mayeso a Hydraulic

Gwirani mkati mwa chitoliro pang'onopang'ono kapena kuthamanga kwambiri P (P max 10 MPa) kwa masekondi osachepera 5, kenako fufuzani kuti chitolirocho chingathe kupirira kupanikizika popanda kutuluka.

P=2st/D

P: kuyesa kuthamanga (MPa)

t: makulidwe a khoma la chubu (mm)

D: kunja kwake kwa chubu (mm)

s: 60 % ya mtengo wochepera womwe watchulidwa wa zokolola kapena kutsindika kwa umboni.

Mayeso osawononga

Kuyesa kosawonongeka kwa machubu achitsulo kuyenera kuchitidwa ndikuyesa kwamakono kwa ultrasonic kapena eddy.

Zaultrasonicmawonekedwe owunikira, chizindikiritso chochokera pachitsanzo chofotokozera chomwe chili ndi muyezo wa kalasi ya UD monga momwe zafotokozedweraMtengo wa JIS 0582idzatengedwa ngati mlingo wa alamu ndipo idzakhala ndi chizindikiro chofanana kapena chachikulu kuposa mlingo wa alamu.

The muyezo kuzindikira sensitivity kwaeddy panomayeso adzakhala gulu EU, EV, EW, kapena EX otchulidwaMtengo wa JIS 0583, ndipo sipadzakhala zizindikiro zofanana kapena zazikulu kuposa zizindikiro zochokera ku chitsanzo chomwe chili ndi muyeso wamtundu womwe watchulidwawo.

Kuti mudziwe zambiriMa chart a Kulemera kwa Chitoliro ndi Madongosolo a Mapaipimkati mwa muyezo, mukhoza dinani.

Tengani njira yoyenera yolembera mfundo zotsatirazi.

a) Chizindikiro cha kalasi;

b) Chizindikiro cha njira yopangira;

c) Makulidwe: kunja awiri ndi khoma makulidwe;

d) Dzina la wopanga kapena mtundu wake.

Kuyika chizindikiro pa chubu chilichonse kumakhala kovuta chifukwa chakuchepa kwake kwakunja kapena ngati wapempha wogula, chizindikirocho chikhoza kuperekedwa pa mtolo uliwonse wa machubu ndi njira yoyenera.

STB340 imagwiritsidwa ntchito popanga mapaipi amadzi ndi mapaipi amadzi opangira ma boiler osiyanasiyana, makamaka m'malo omwe kukana kutentha ndi kupanikizika kumafunikira.

Chifukwa cha zinthu zabwino zoyendetsera kutentha, ndizoyeneranso kupanga mapaipi opangira kutentha, kuthandizira kusamutsa kutentha bwino pakati pa zofalitsa zosiyanasiyana.

Angagwiritsidwenso ntchito kunyamula madzi otentha kwambiri kapena othamanga kwambiri, monga nthunzi kapena madzi otentha, ndipo amagwiritsidwa ntchito kwambiri m'mafakitale opangira mankhwala, magetsi, ndi makina opanga makina.

ASTM A106 Gulu A

DIN 17175 St35.8

DIN 1629 St37.0

BS 3059-1 Gawo 320

EN 10216-1 P235GH

GB 3087 20 #

GB 5310 20G

Ngakhale kuti zipangizozi zikhoza kukhala zofanana ndi zomwe zimapangidwira komanso zofunikira, njira zowonongeka zowonongeka ndi makina angakhudze katundu wa mankhwala omaliza.

Chifukwa chake, kufananitsa mwatsatanetsatane ndi kuyezetsa koyenera kuyenera kuchitidwa posankha zida zofanana kuti zigwiritsidwe ntchito.

Chiyambireni kukhazikitsidwa mu 2014, Botop Steel yakhala ikugulitsa chitoliro chachitsulo cha carbon ku Northern China, chomwe chimadziwika ndi ntchito zabwino kwambiri, zinthu zamtengo wapatali, komanso zothetsera mavuto. Kampaniyi imapereka mapaipi osiyanasiyana a zitsulo za carbon ndi zinthu zomwe zimagwirizana nazo, kuphatikizapo zopanda msoko, ERW, LSAW, ndi chitoliro chachitsulo cha SSAW, komanso mzere wathunthu wazitsulo ndi flanges.

Zopangira zake zapadera zimaphatikizanso ma alloys apamwamba kwambiri ndi zitsulo zosapanga dzimbiri za austenitic, zopangidwa kuti zikwaniritse zofunikira zama projekiti osiyanasiyana a mapaipi.