Chithunzi cha JIS G3454ndi muyeso wamafakitale waku Japan wamapaipi achitsulo cha kaboni pamakina okakamiza omwe ali ndi kutentha kwambiri kwa 350 ° C. Mulingo uli ndi magiredi awiri:Mtengo wa 370ndiMtengo wa 410. Zimagwira ntchito pamagetsi osakanizidwa ndi welded (RW) kapena mapaipi opanda msoko okhala ndi m'mimba mwake mwadzina wa 10.5 mm mpaka 660.4 mm (ie 6A mpaka 650A, kapena 1/8B mpaka 26B).

Mapaipi achitsulo a JIS G 3454 adzapangidwa pogwiritsa ntchito njira zoyenera zopangira zitoliro zachitsulo ndi njira zomaliza zomwe zili m'munsimu.

| Chizindikiro cha kalasi | Chizindikiro cha kupanga | ||

| Njira yopanga mapaipi | Njira yomaliza | Gulu la zokutira zinc | |

| Chithunzi cha STPG370 Chithunzi cha STPG410 | Zopanda malire: S Kukana kwamagetsi welded: E | Zomaliza: H Zomaliza: C Momwe kukana kwamagetsi kumawotcherera: G | Mapaipi akuda: mapaipi osapatsidwa zokutira zinki Mipope yoyera: mapaipi opaka zinki |

Makamaka, pali njira zisanu zopangira:

SH: Chitoliro chachitsulo chosasunthika chotentha chamoto;

SC: Chitoliro chozizira chozizira chosasunthika;

EH: Hot-anamaliza kukana magetsi welded zitsulo chitoliro;

EC: Cold-anamaliza kukana magetsi welded zitsulo chitoliro;

EG: Kukana kwamagetsi kumawotcherera chitoliro chachitsulo kupatulapo kutentha komaliza komanso kuzizira.

Botop Steelndi wopanga ndi katundu wa apamwamba welded mpweya zitsulo mipope ku China, komanso stockist wa mipope zitsulo zitsulo. Ngati muli ndi zosowa zilizonse, chonde omasuka kulankhula nafe ndipo tidzakupatsani chithandizo chaulere chaukadaulo.

| Chizindikiro cha kalasi | C | Si | Mn | P | S |

| max | max | - | max | max | |

| Mtengo wa 370 | 0.25% | 0.35 % | 0.30-0.90% | 0.040 % | 0.040% |

| Mtengo wa 410 | 0.30% | 0.35 % | 0.30-1.00% | 0.040 % | 0.040% |

Amalola kuwonjezera zinthu zina alloying.

Kulimba Kwamphamvu, Kutulutsa Pansi kapena Kupanikizika Kwaumboni, ndi Kutalikira

| Chizindikiro wa kalasi | Kulimba kwamakokedwe | Zokolola kapena umboni kupsinjika | Elongation mphindi,% | |||

| Tensile test chidutswa | ||||||

| No.11 kapena No.12 | No.5 | No.4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Njira yoyesera yolimba | ||||

| min | min | Kufanana ndi nsonga ya chitoliro | Perpendicular to pipe axis | Kufanana ndi nsonga ya chitoliro | Perpendicular to pipe axis | |

| Chithunzi cha STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| Chithunzi cha STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Mayeso a Flattening

Pamene mtunda pakati pa mbale ziwiri ukufikira mtunda wotchulidwa H, sipadzakhala chilema kapena ming'alu pamwamba pa chitoliro chachitsulo.

Kwa machubu opanda zitsulo: H = (1 + e) t / (e + t / D);

Kwa mipope yachitsulo ya ERW: H = 1/3 D (ya weld) kapena H = 2/3 D (kwa gawo popanda weld);

H: mtunda pakati pa mbale za flattening (mm);

е: nthawi zonse amatanthauzidwa payekha pa giredi iliyonse ya chitoliro, 0.08 kwa STPG 370, 0.07 kwa STPG 410;

t: khoma makulidwe a chitoliro (mm);

D: kunja kwake kwa chitoliro (mm);

Kuyesa kwa Flattening kumagwiritsidwa ntchito pamapaipi achitsulo okhala ndi mainchesi akulu kuposa 40A (48.6mm).

Kukhazikika

Bendability imagwira ntchito pamapaipi okhala ndi mainchesi 40 A (48.6) kapena ocheperako.

Chitolirocho chiyenera kupindika 90 ° pamtunda wa 6 kuwirikiza kwake kunja. Khoma la chitoliro liyenera kukhala lopanda chilema kapena ming'alu.

Chitoliro chilichonse chachitsulo chiyenera kuyesedwa kwa hydrostatic pressure kapena kuyesa kosawononga.

Kuyesedwa kwa Hydrostatic

Pitirizani kuthamanga kwina kwa masekondi osachepera 5 popanda kutayikira.

Kupanikizika kwamtengo kumakhudzana ndi ndondomeko No. ya chitoliro chachitsulo.

| Mwadzina khoma makulidwe | Nambala ya Ndandanda: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Kuthamanga kocheperako kwa hydraulic test, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Mayeso osawononga

Ngati kuyang'ana kwa akupanga kukugwiritsidwa ntchito, kuyenera kukhazikitsidwa pamlingo wokhwima kuposa chizindikiro cha UD kalasi mu JIS G 0582.

Ngati kuyesa kwamakono kwa eddy kukugwiritsidwa ntchito, kuyenera kutengera muyeso womwe ndi wolimba kwambiri kuposa chizindikiro cha gulu la EY mu JIS G 0583.

| M'mimba mwake mwadzina | M'mimba mwake | Khoma makulidwe | Unit mass | Nambala ya ndondomeko (Sch No.) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

JIS G 3454 imaphatikizapondondomeko 10, ndondomeko 20, ndondomeko 30, ndondomeko 40, ndondomeko 60,ndindondomeko 80.

Mutha kudina pa ndandanda No. mukufuna kuwona; takonza mitundu yofananira ya PDF kuti muthandizire.

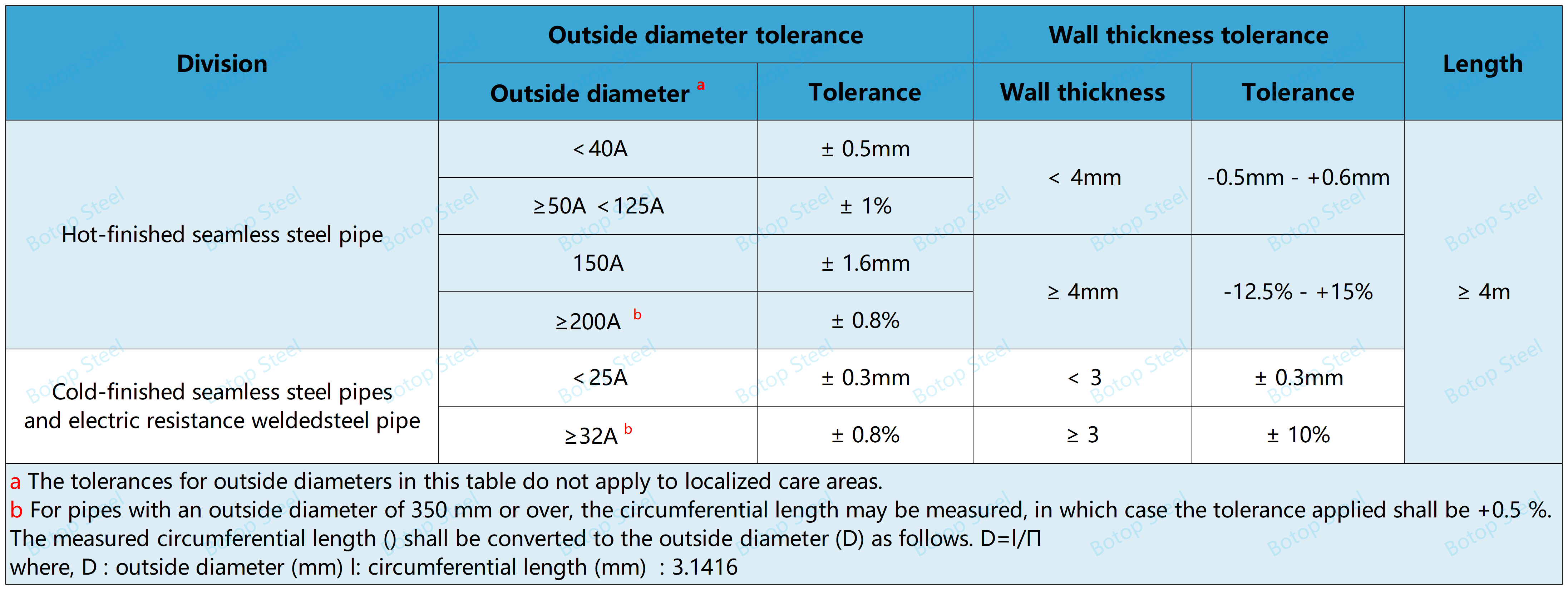

JIS G 3454 kulolerana kwa mainchesi akunja, makulidwe a khoma, eccentricity, ndi kutalika zikwaniritsa izi.

Chiyambireni kukhazikitsidwa mu 2014, Botop Steel yakhala ikugulitsa chitoliro chachitsulo cha carbon ku Northern China, chomwe chimadziwika ndi ntchito zabwino kwambiri, zinthu zamtengo wapatali, komanso zothetsera mavuto.

Kampaniyi imapereka mapaipi osiyanasiyana a zitsulo za carbon ndi zinthu zomwe zimagwirizana nazo, kuphatikizapo zopanda msoko, ERW, LSAW, ndi chitoliro chachitsulo cha SSAW, komanso mzere wathunthu wazitsulo ndi flanges.

Zopangira zake zapadera zimaphatikizanso ma alloys apamwamba kwambiri ndi zitsulo zosapanga dzimbiri za austenitic, zopangidwa kuti zikwaniritse zofunikira zama projekiti osiyanasiyana a mapaipi.

Chonde titumizireni, tidzakupatsirani mapaipi apamwamba kwambiri, okhazikika achitsulo omwe ali ndi ntchito yabwino komanso yothandiza. Botop akuyembekezera kukutumikirani.