Chithunzi cha JIS G3455ndi Japanese Industrial Standard (JIS) kwa utumiki wothamanga kwambiri pa kutentha kwa 350 °C kapena kutsika, makamaka kwa ziwalo zamakina.

Chitoliro chachitsulo cha STS370ndi chitoliro chachitsulo chokhala ndi mphamvu yocheperako ya 370 MPa ndi mphamvu yochepa yokolola ya 215 MPa, yokhala ndi mpweya wosapitirira 0,25% ndi silicon yokhutira pakati pa 0,10% ndi 0,35%, ndipo imagwiritsidwa ntchito makamaka pa ntchito zomwe zimafuna mphamvu zambiri komanso kutsekemera kwabwino, monga nyumba zomangira, milatho, milatho, zigawo za zombo.

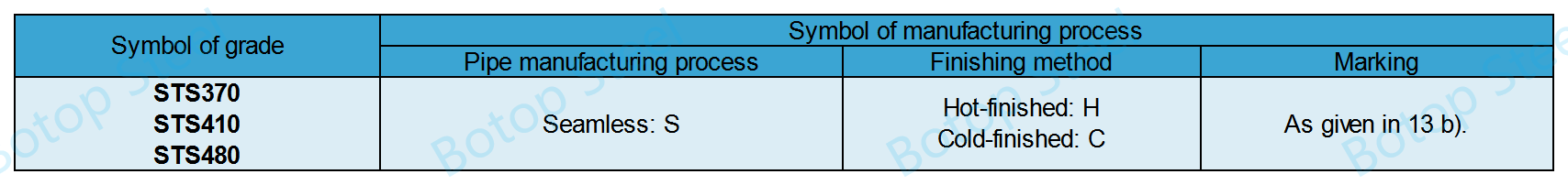

JIS G 3455 ili ndi magiredi atatu.STS370, STS410, STA480.

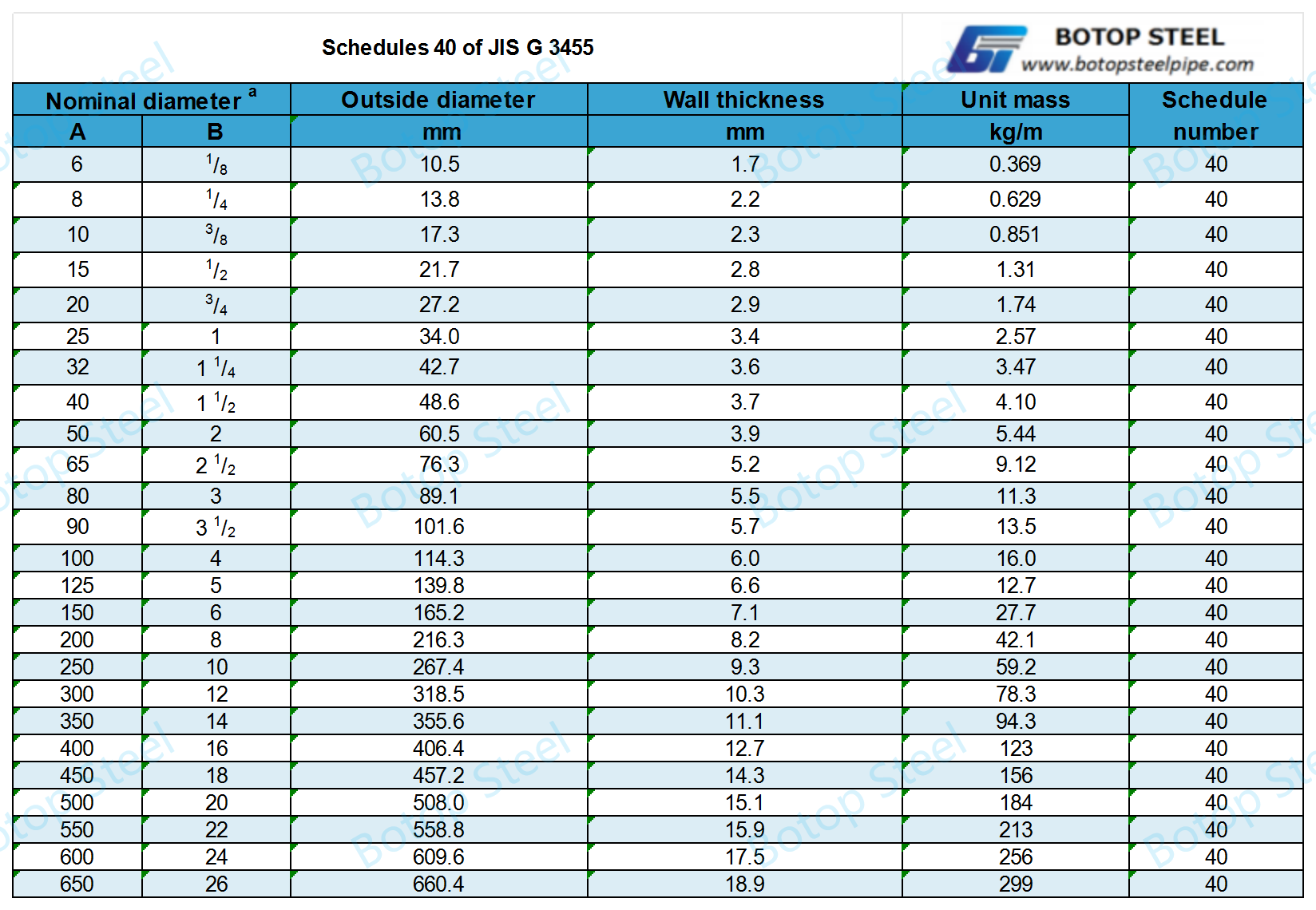

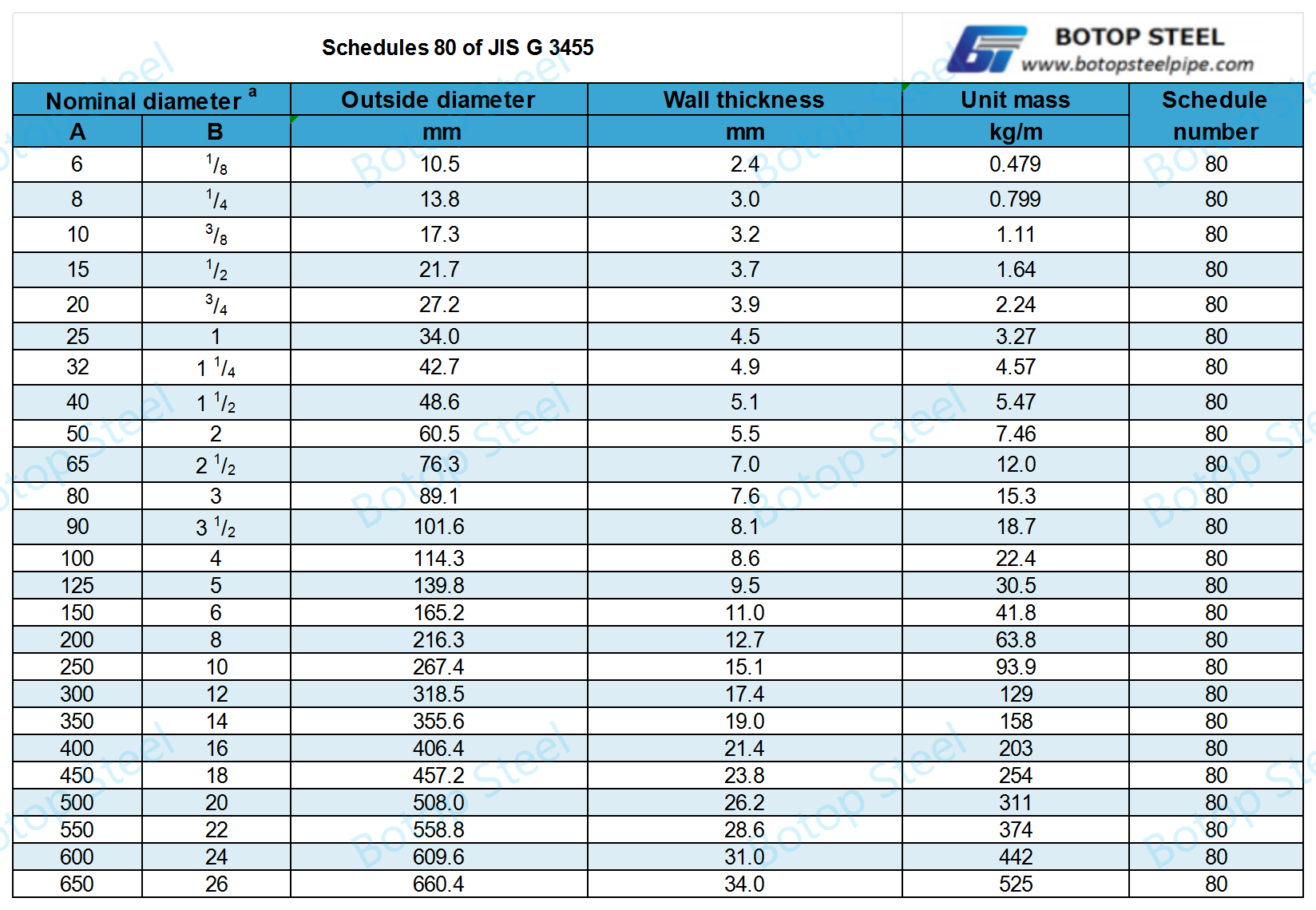

Kunja awiri a 10.5-660.4mm (6-650A) (1/8-26B).

Machubu adzapangidwa kuchokera kukupha chitsulo.

Chitsulo chophedwa ndi chitsulo chomwe chasungunuka kwathunthu chisanaponyedwe mu ingots kapena mitundu ina. Njirayi imakhala ndi kuwonjezera chinthu chochotsera ma deoxidizing monga silicon, aluminiyamu, kapena manganese kuchitsulo chisanayambe kulimba. Mawu akuti "kuphedwa" amasonyeza kuti palibe mpweya wa okosijeni umapezeka muzitsulo panthawi yolimba.

Pochotsa okosijeni, chitsulo chophedwa chimalepheretsa mapangidwe a thovu la mpweya muzitsulo zosungunuka, motero kupewa porosity ndi mpweya wa thovu pomaliza. Izi zimabweretsa chitsulo chofananira komanso chowonda kwambiri chokhala ndi zida zapamwamba zamakina komanso kukhulupirika kwamapangidwe.

Chitsulo chophedwa chimakhala choyenera kwambiri pa ntchito zomwe zimafuna khalidwe lapamwamba komanso lolimba, monga zotengera zokakamiza, nyumba zazikulu, ndi mapaipi omwe ali ndi zofunikira zapamwamba.

Pogwiritsa ntchito zitsulo zophedwa kuti mupange machubu, mutha kukhala otsimikiza kuti mukugwira ntchito bwino komanso moyo wautali wautumiki, makamaka m'malo omwe ali ndi katundu wolemetsa komanso zopanikizika.

Amapangidwa pogwiritsa ntchito njira yopangira yopanda msoko pamodzi ndi njira yomaliza.

Chitoliro chachitsulo chosasunthika chotentha chotentha: SH;

Chitoliro chachitsulo chozizira chomaliza: SC.

Pakupanga kopanda msoko, imatha kugawidwa m'mapaipi opanda zitsulo okhala ndi mainchesi akunja opitilira 30mm pogwiritsa ntchito kumaliza kotentha, ndi 30mm pogwiritsa ntchito kumaliza kuzizira.

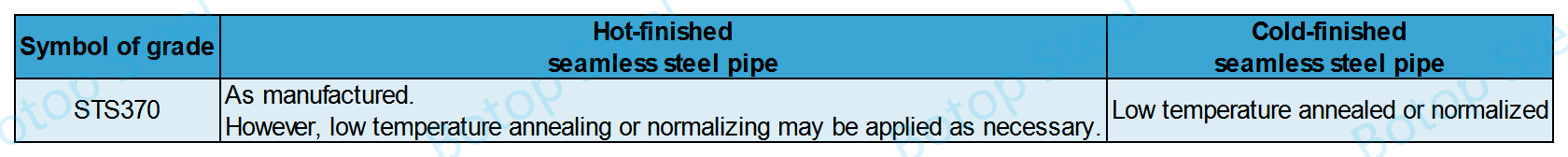

Nayi kutulutsa kwa Hot-finished seamless.

Kutentha kocheperako kumagwiritsidwa ntchito makamaka kuti zinthu ziziyenda bwino, kuchepetsa kuuma, komanso kulimba, ndipo ndizoyenera zitsulo zozizira.

Normalizing ntchito kupititsa patsogolo mphamvu ndi kulimba kwa zinthu, kotero kuti zitsulo ndi oyenera kupirira makina kupsyinjika ndi kutopa, nthawi zambiri ntchito bwino ntchito ozizira-ntchito zitsulo.

Kupyolera mu njira zochizira kutentha, mawonekedwe amkati azitsulo amakonzedwa bwino ndipo katundu wake amapangidwa bwino, zomwe zimapangitsa kuti zikhale zoyenera kuti zigwiritsidwe ntchito pofunafuna mafakitale.

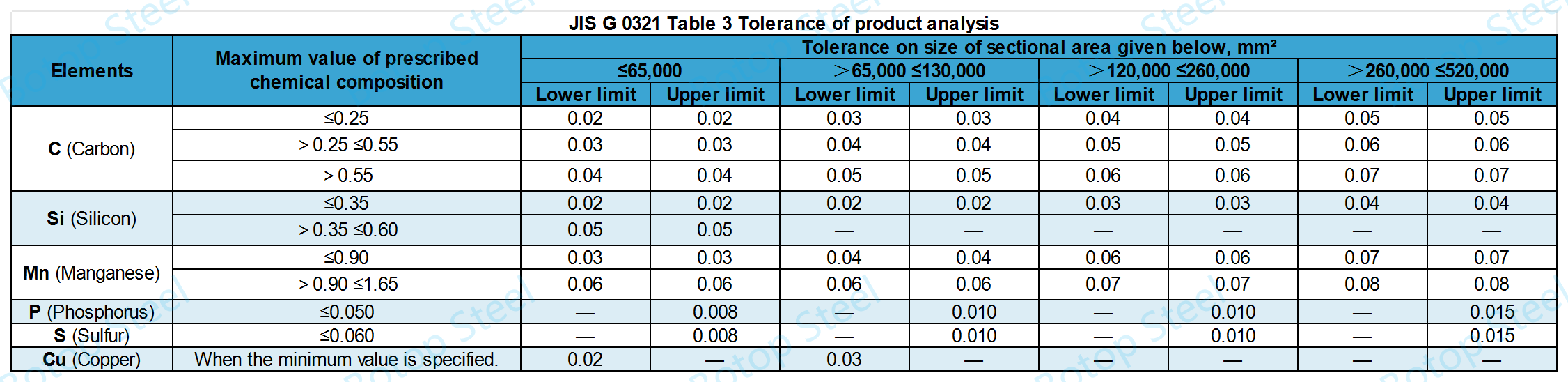

Kusanthula kutentha kudzakhala molingana ndi JIS G 0320. Kusanthula kwazinthu kudzakhala molingana ndi JIS G 0321.

| kalasi | C (Kaboni) | Si (Silicon) | Mn (Manganese) | Phosphorous (P) | S (Sulphur) |

| Zithunzi za STS370 | 0.25% kuchuluka | 0.10-0.35% | 0.30-1.10% | 0.35 peresenti | 0.35 peresenti |

Kusanthula kutenthamakamaka umalimbana kuyesa mankhwala zikuchokera ya zipangizo.

Pofufuza zamagulu azinthu zopangira, ndizotheka kulosera ndikusintha masitepe ndi mikhalidwe yomwe ingafunike popanga, monga magawo opangira kutentha komanso kuwonjezera zinthu za alloying.

Kusanthula kwazinthuamawunikidwa mankhwala a zinthu zomalizidwa kuti zitsimikizire kuti zimatsatiridwa ndi ubwino wa chinthu chomaliza.

Kusanthula kwazinthu kumawonetsetsa kuti zosintha zonse, zowonjezera kapena zodetsa zilizonse zomwe zingachitike panthawi yopanga zikuwongolera komanso kuti chomaliza chikukwaniritsa zofunikira zaukadaulo ndi zofunikira pakugwiritsa ntchito.

JIS G 3455 mfundo za kusanthula kwazinthu sizimangotsatira zofunikira za zinthu zomwe zili pamwambapa, komanso kulekerera kumayenera kutsatira zofunikira za JIS G 3021 Table 3.

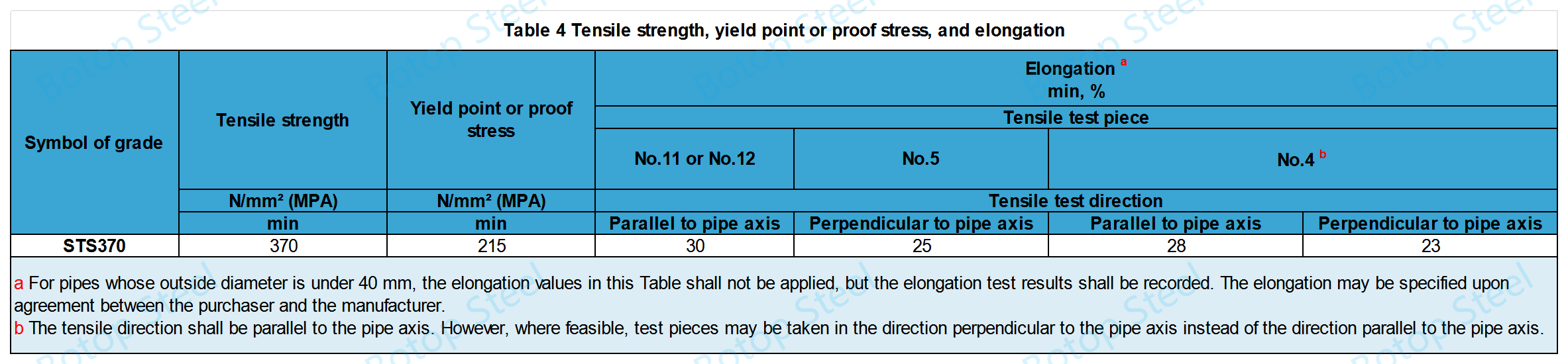

Elongation mfundo za Test chidutswa No. 12 (kufanana chitoliro olamulira) ndi Mayeso chidutswa No. 5 (perpendicular kuti chitoliro axis) chotengedwa mipope pansi 8 mm makulidwe khoma.

| Chizindikiro cha kalasi | Chiyeso chogwiritsidwa ntchito | Elongation mphindi,% | ||||||

| Khoma makulidwe | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| Zithunzi za STS370 | Nambala 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Nambala 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Makhalidwe otalikirapo patebuloli amapezedwa pochotsa 1.5 % pamtengo wotalikirapo womwe waperekedwa mu Gulu 4 pakutsika kulikonse kwa 1 mm mu makulidwe a khoma kuchokera pa 8 mm, ndikuzunguliza zotsatira zake kukhala nambala imodzi molingana ndi Lamulo A la JIS Z 8401. | ||||||||

Kuyesa kwa flattening kungasiyidwe pokhapokha atanenedwa ndi wogula.

Ikani chitsanzocho mu makina ndikuchiphwanya mpaka mtunda wa pakati pa nsanja ziwiri ufike pamtengo wotchulidwa H. Kenaka yang'anani chitsanzo cha ming'alu.

Poyesa kukana zovuta welded chitoliro, mzere pakati pa weld ndi pakati pa chitoliro ndi perpendicular kwa psinjika malangizo.

H=(1+e)t/(e+t/D)

H: mtunda pakati pa mbale (mm)

t: makulidwe a chubu (mm)

D: kunja kwa chubu (mm)

е:zimatanthauzidwa nthawi zonse pa kalasi iliyonse ya chubu.0.08 ya STS370: 0.07 ya STS410 ndi STS480.

Oyenera mapaipi ndi m'mimba mwake kunja kwa ≤ 50 mm.

Chitsanzocho chizikhala chopanda ming'alu pamene chikupindika pa 90 ° ndi m'mimba mwake 6 kuwirikiza kunja kwa chitoliro.

Ngongole yopindika iyenera kuyezedwa kumayambiriro kwa bend.

Chitoliro chilichonse chachitsulo chiyenera kuyesedwa mwa hydrostatic kapena osawonongakuonetsetsa ubwino ndi chitetezo cha chitoliro ndi kukwaniritsa mfundo ntchito.

Mayeso a Hydraulic

Ngati palibe kukakamizidwa kwa mayeso komwe kutchulidwa, kupanikizika kocheperako kwa hydro test kudzatsimikiziridwa molingana ndi Ndondomeko ya Pipe.

| Mwadzina khoma makulidwe | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Kuthamanga kocheperako kwa hydraulic test, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Pamene makulidwe a khoma la m'mimba mwake akunja chitoliro zitsulo si mtengo muyezo mu tebulo kulemera kwa chitoliro zitsulo, m'pofunika kugwiritsa ntchito chilinganizo kuwerengera kuthamanga mtengo.

P=2st/D

P: kuyesa kuthamanga (MPa)

t: makulidwe a chitoliro (mm)

D: kunja kwake kwa chitoliro (mm)

s: 60 % ya mtengo wochepera wa mfundo zokolola kapena kutsindika kwa umboni woperekedwa.

Pamene kupanikizika kocheperako kwa hydrostatic kuyesa kwa nambala yosankhidwa kupitilira kukakamiza koyesa P komwe kumapezeka ndi formula, kukakamiza P kudzagwiritsidwa ntchito ngati kuyesa kocheperako kwa hydrostatic m'malo mosankha kutsika kocheperako kwa hydrostatic test patebulo pamwambapa.

Mayeso osawononga

Kuyesa kosawonongeka kwa machubu achitsulo kuyenera kuchitidwa ndikuyesa kwamakono kwa ultrasonic kapena eddy.

Zaultrasonicmawonekedwe owunikira, chizindikiritso chochokera pachitsanzo chofotokozera chomwe chili ndi muyezo wa kalasi ya UD monga momwe zafotokozedweraMtengo wa JIS 0582idzatengedwa ngati mlingo wa alamu ndipo idzakhala ndi chizindikiro chofanana kapena chachikulu kuposa mlingo wa alamu.

The muyezo kuzindikira sensitivity kwaeddy panomayeso adzakhala gulu EU, EV, EW, kapena EX otchulidwaMtengo wa JIS 0583, ndipo sipadzakhala zizindikiro zofanana kapena zazikulu kuposa zizindikiro zochokera ku chitsanzo chomwe chili ndi muyeso wamtundu womwe watchulidwawo.

Kuti mudziwe zambiriMa chart a Kulemera kwa Chitoliro ndi Madongosolo a Mapaipimkati mwa muyezo, mukhoza dinani.

Dongosolo la 40 chitoliro ndi loyenera kugwiritsa ntchito kutsika kwapakatikati chifukwa limapereka makulidwe olimba a khoma omwe amapewa kulemera kwambiri komanso mtengo wake ndikuwonetsetsa kuti ali ndi mphamvu zokwanira.

Dongosolo la 80 mapaipi amagwiritsidwa ntchito kwambiri m'mafakitale omwe amafunikira kuwongolera kwambiri, monga makina opangira mankhwala ndi mapaipi opatsira mafuta ndi gasi, chifukwa chotha kupirira kupsinjika kwapamwamba komanso kukhudzidwa kwamphamvu kwamakina chifukwa cha makulidwe ake a khoma, kupereka chitetezo chowonjezera, chitetezo, komanso kulimba.

Chubu chilichonse chidzalembedwa ndi mfundo zotsatirazi.

a)Chizindikiro cha kalasi;

b)Chizindikiro cha njira yopangira;

c)MakulidweChitsanzo 50AxSch80 kapena 60.5x5.5;

d)Dzina la wopanga kapena mtundu wake.

Pamene kukula kwa kunja kwa chubu chilichonse kuli kochepa ndipo kumakhala kovuta kuika chizindikiro chubu chirichonse, kapena pamene wogula akufuna kuti mtolo uliwonse wa machubu ulembedwe, mtolo uliwonse ukhoza kulembedwa ndi njira yoyenera.

STS370 ndiyoyenera kutengera kachitidwe kocheperako koma kotentha kwambiri.

Machitidwe otenthetsera: Pakutentha kwa mzinda kapena makina otenthetsera nyumba zazikulu, STS370 ingagwiritsidwe ntchito kunyamula madzi otentha kapena nthunzi chifukwa imatha kupirira kupsinjika ndi kusintha kwa kutentha kwadongosolo.

Zomera zamagetsi: Popanga magetsi, mapaipi ambiri othamanga kwambiri amafunikira, ndipo STS370 ndizinthu zabwino zopangira mapaipi awa chifukwa zimatha kupirira kutentha kwanthawi yayitali komanso malo ogwirira ntchito.

Makina oponderezedwa a mpweya: Popanga ndi kupanga makina opangira makina, mpweya woponderezedwa ndi gwero lofunikira la mphamvu, ndipo chitoliro chachitsulo cha STS370 chimagwiritsidwa ntchito popanga mapaipi a machitidwewa kuti atsimikizire kuti mpweya wabwino ndi wotetezeka.

Kugwiritsiridwa ntchito kwa zomangamanga ndi makina onse: Chifukwa cha makina ake abwino, STS370 itha kugwiritsidwanso ntchito popanga zida zosiyanasiyana zamakina komanso zamakina, makamaka pamakina omwe amafunikira mphamvu yopondereza.

JIS G 3455 STS370 ndi zida za kaboni zomwe zimagwiritsidwa ntchito popanikiza kwambiri. Zinthu zotsatirazi zitha kuonedwa ngati zofanana kapena pafupifupi zofanana:

1. ASTM A53 Gulu B: Yoyenera pamakina ndi makina ogwiritsira ntchito komanso mayendedwe amadzimadzi.

2. API 5L Gulu B: Kwa mapaipi oyendetsa mafuta ndi gasi othamanga kwambiri.

3. DIN 1629 St37.0: Kwa uinjiniya wamakina wamba komanso kupanga zombo.

4. EN 10216-1 P235TR1: Chitoliro chosasunthika chachitsulo cha kutentha kwambiri ndi chilengedwe chapamwamba kwambiri.

5. ASTM A106 Gawo B: Wopanda mpweya zitsulo chitoliro ntchito mkulu-kutentha.

6.ASTM A179: Machubu achitsulo osasunthika osakokedwa ndi kuzizira komanso mapaipi a ntchito yotsika kutentha.

7. DIN 17175 St35.8: Zida zopanda chubu zama boilers ndi zotengera zokakamiza.

8. EN 10216-2 P235GH: Machubu osasunthika ndi mapaipi azitsulo zopanda aloyi ndi aloyi pazigawo zotentha kwambiri komanso zopanikizika kwambiri.

Chiyambireni kukhazikitsidwa mu 2014, Botop Steel yakhala ikugulitsa chitoliro chachitsulo cha carbon ku Northern China, chomwe chimadziwika ndi ntchito zabwino kwambiri, zinthu zamtengo wapatali, komanso zothetsera mavuto. Kampaniyi imapereka mapaipi osiyanasiyana a zitsulo za carbon ndi zinthu zomwe zimagwirizana nazo, kuphatikizapo zopanda msoko, ERW, LSAW, ndi chitoliro chachitsulo cha SSAW, komanso mzere wathunthu wazitsulo ndi flanges.

Zopangira zake zapadera zimaphatikizanso ma alloys apamwamba kwambiri ndi zitsulo zosapanga dzimbiri za austenitic, zopangidwa kuti zikwaniritse zofunikira zama projekiti osiyanasiyana a mapaipi.