API (American Petroleum Institute Standard) 5L ndiye muyeso wapadziko lonse lapansi wamapaipi achitsulo omwe amagwiritsidwa ntchito pamapaipi oyendera.

API 5L imakwirira chitoliro chachitsulo pazinthu zosiyanasiyana zoyendetsera gasi, mafuta, ndi zakumwa zina.Tsiku logwira ntchito la kope la 46: likugwira ntchito pa Novembara 1, 2018.

Ngati mukungofuna kudziwa zambiri za API 5L, chonde dinaniAPI 5L Chitsogozo Chofotokozera Chitoliro.

Navigation Mabatani

Zomwe Zasinthidwa mu API 5L 46th

Chiyambi cha API 5L PSL

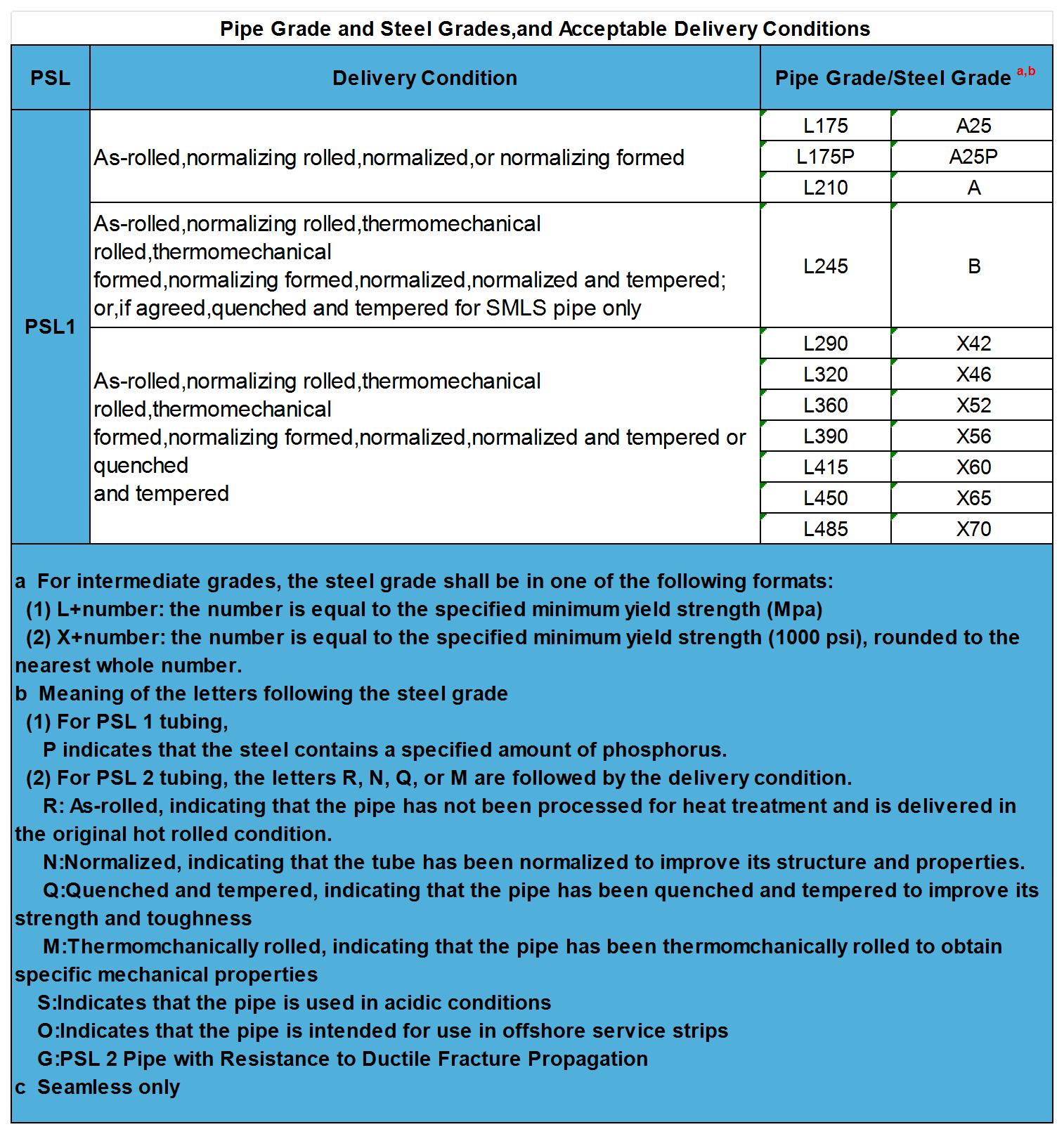

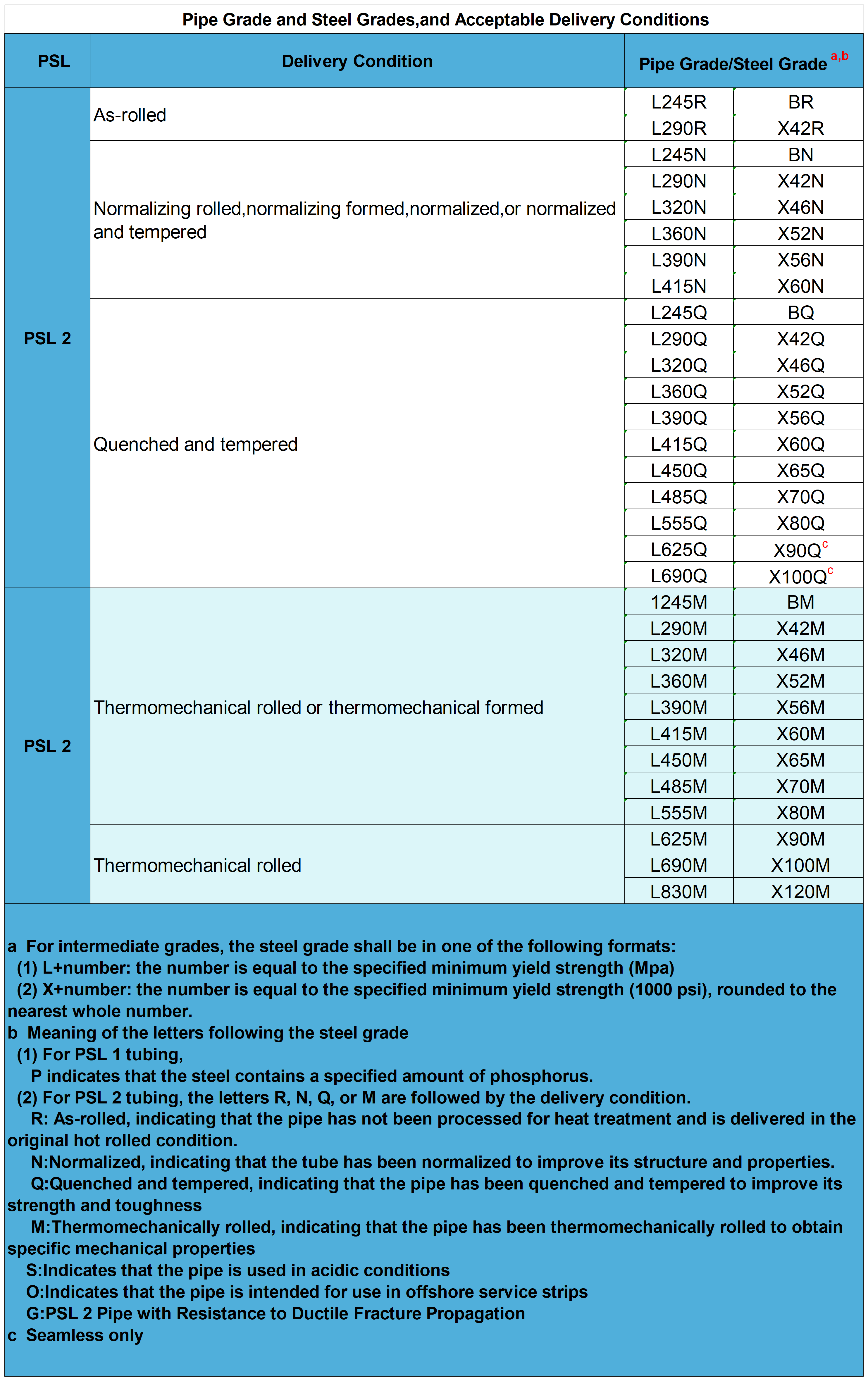

Kugawika kwa Magiredi a Chitsulo ndi Makalasi a Chitoliro

Maiko Ovomerezeka Otumizira

Zida Zopangira Mapaipi Azitsulo

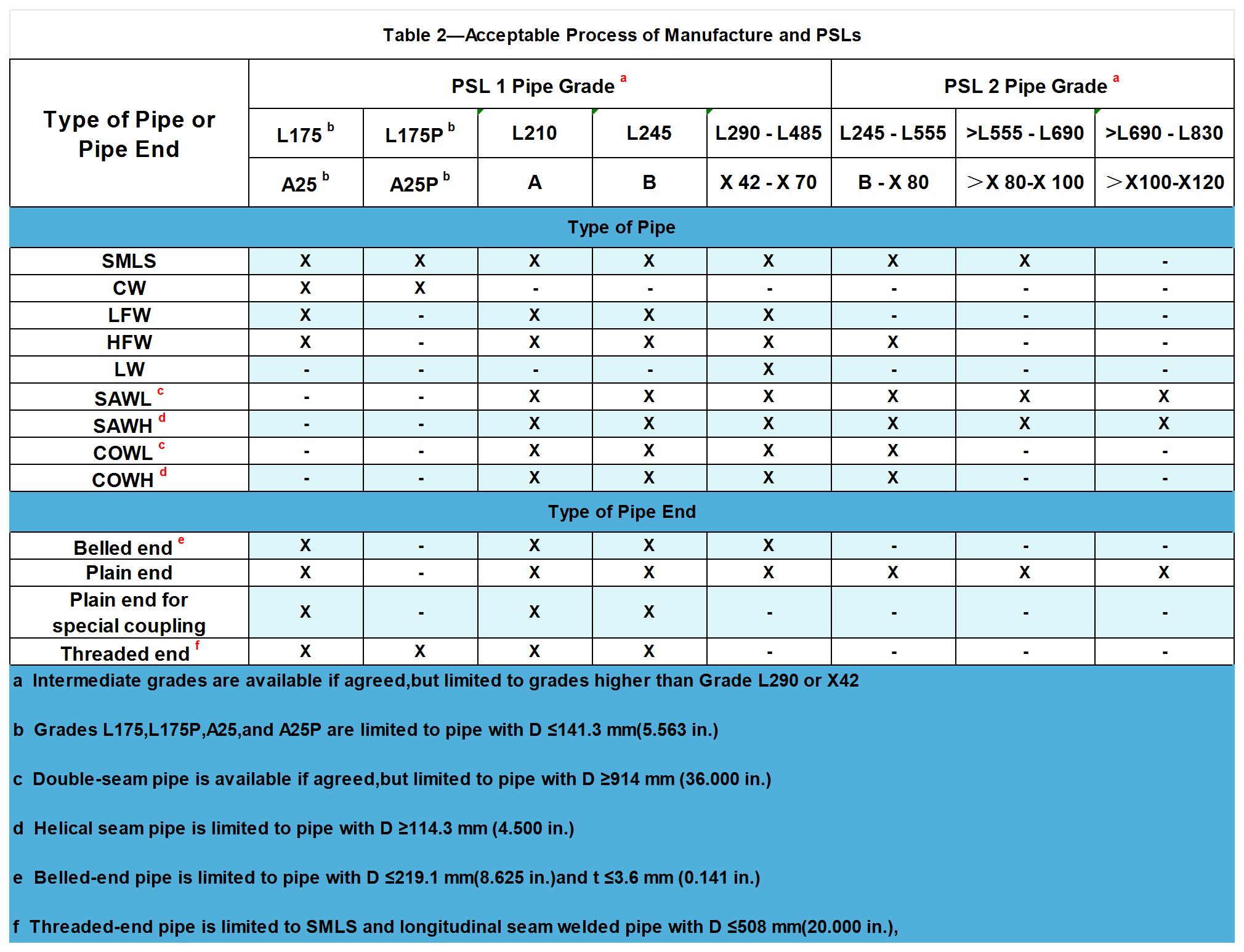

Mitundu ya Chitoliro Chachitsulo ndi Tube Ends Yophimbidwa ndi API 5L

Njira Zovomerezeka Zopanga za PSL2 Steel Tubing

Kuyang'anira maonekedwe ndi zolakwika za API 5L

Dimensional Inspection (Dimensional Deviations)

Zinthu Zoyesa za API 5L

Kuyika Chitoliro ndi Malo

Equivalence Standard

Zathu Zogwirizana

Zomwe Zasinthidwa mu API 5L 46th

Zosintha

Zofunikira zosinthidwa ndikukulitsidwa kwa olumikizirana milled;

Kusinthidwa zofunika kwa chitoliro mapeto perpendicularity;

Zofunikira pakuyesa kuuma kwa API 5LPSL 2 mapaipi am'malo owawa ndi mapaipi a API 5L PSL 2 am'madera akunyanja;

Chatsopano

API 5L PSL 2 chitoliro ntchito amafuna longitudinal pulasitiki mavuto mphamvu.

Chiyambi cha API 5L PSL

PSL: Chidule cha Mulingo wa Pipeline Specification;

Amagawidwa mu: API 5L PSL 1 ndi API 5L PSL 2.

Kugawika kwa Magiredi a Chitsulo ndi Makalasi a Chitoliro

L + nambala(chilembo L chimatsatiridwa ndi mphamvu zochepa zokolola mu MPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + nambala(chiwerengero chotsatira chilembo X chimatchula mphamvu zochepa zokolola mu 1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Ndipo giredi A ndi giredi b.Gulu A=L210 Gulu B=L 2459

Mayiko ovomerezeka otumizira

Chidziwitso: L415/X60 kapena magiredi apamwamba sayenera kugwiritsidwa ntchito m'malo mwa L360/X52 kapena magiredi otsika popanda chilolezo cha wogula.

Zida Zopangira Mapaipi Azitsulo

Ingot, billet, billet, strip (coil) kapena mbale.

Zindikirani:

1. The zopangira kwaAPI 5L PSL2Chitoliro chachitsulo chiyenera kukhala chitsulo chosungunuka.

2. Mzere wachitsulo (koyilo) kapena mbale yomwe imagwiritsidwa ntchito popanga API 5L PSL2 chitoliro chachitsulo sichidzanyamula ma welds aliwonse.

Mitundu ya Chitoliro Chachitsulo ndi Tube Ends Yophimbidwa ndi API 5L

Welded Steel Pipe

CW Pipe:Njira yopangira msoko potenthetsa chingwecho mu ng'anjo ndi kukanikiza m'mphepete mwake pamodzi, momwe mizere yotsatizana ya mzerewo imalumikizidwa pamodzi kuti mphero yowotcherayo iziyenda mosalekeza.

Mtengo wa COWHPipe:Tubular mankhwala okhala ndi helical msoko opangidwa ndi osakaniza mpweya zitsulo arc ndi kumizidwa arc kuwotcherera, mmene mpweya zitsulo arc kuwotcherera mkanda si kwathunthu kuchotsedwa ndi kumizidwa arc kuwotcherera akudutsa.

NKHANI Chitoliro:Tubular mankhwala okhala ndi seams limodzi kapena awiri kotenga nthawi opangidwa ndi osakaniza mpweya zitsulo arc ndi kumizidwa arc kuwotcherera, mmene mpweya zitsulo arc kuwotcherera mkanda si kwathunthu kuchotsedwa ndi kumizidwa arc kuwotcherera akudutsa.

EW Pipe:Chopangidwa ndi tubular chokhala ndi msoko umodzi wautali wopangidwa ndi kuwotcherera kwamagetsi otsika kapena okwera kwambiri.

Chitoliro cha HFW:EWpipe opangidwa ndi kuwotcherera mafupipafupi panopa ofanana kapena kuposa 70 kHz.

LFW Pipe:EW chitoliro amapangidwa ndi kuwotcherera panopa pafupipafupi zosakwana 70 kHz.

LW Pipe:Chopangidwa ndi tubular chokhala ndi msoko umodzi wautali wopangidwa ndi kuwotcherera kwa laser.

Chitoliro cha SAWH:Chopangidwa ndi tubular chokhala ndi msoko umodzi wa helical wopangidwa ndi njira yowotcherera ya arc.

Mtengo wa SAWLChitoliro:Chopangidwa ndi tubular chokhala ndi seam imodzi kapena ziwiri zazitali zomwe zimapangidwa ndi kuwotcherera kwamadzi.

Chitoliro Chachitsulo Chopanda Seam

Chitoliro cha SMLS:Hot adagulung'undisa mopanda chitsulo chitoliro ndi ozizira adagulung'undisa mopanda chitsulo chitoliro, pali njira zina processing, monga kujambula ozizira, kujambula ozizira, forging, etc.

Mitundu ya API 5L PSL2 ya mapulogalamu apadera

Kukaniza Kufalikira kwa Ductile Fracture (G)

Chitoliro cha Sour Service Condition Pipe (S)

Offshore Service Condition Pipe (O)

Kufunika kwa Longitudinal Plastic Strain Capacity Pipe

Mitundu Yamapeto a Pipe

Socket End, Flat End, Special Clamp Flat End, Threaded End.

Zindikirani:

1. Malekezero a socket, mapeto a chitoliro cha zitoliro zapadera, ndi mapeto a mapaipi a API 5L PSL1 okha.

2. L175 P / A25 P kalasi yachitsulo API 5L PSL1 chitoliro chachitsulo chidzapangidwa ndi nsonga za ulusi, ndipo API 5L PSL1 chitoliro chachitsulo chamagulu ena achitsulo chidzapangidwa ndi malekezero athyathyathya.

3. Machubu a API 5L PSL 2 adzaperekedwa ndi mapeto athyathyathya.

Njira Zovomerezeka Zopanga za PSL2 Steel Tubing

| Gulu 3-Njira Zovomerezeka Zopanga za PSL 2 Pipe | ||||

| Mtundu wa Chitoliro | Kuyambira Materia | Kupanga Mapaipi | Kutentha kwa Pipe Chithandizo | Kutumiza Mkhalidwe |

| SMLS | Ingot, bloom, kapena billet | Monga-wogudubuza | - | R |

| Normalizing kupanga | - | N | ||

| Kutentha kupanga | Normalizing | N | ||

| Kutentha ndi kuzizira | Q | |||

| Kutentha kupanga ndi kuzizira kumaliza | Normalizing | N | ||

| Kutentha ndi kuzizira | Q | |||

| Mtengo wa HFW | Normalizing-anagulung'undisa koyilo | Kuzizira kupanga | Kutentha mankhwalaa wa weld area okha | N |

| Thermomechanical-anagulung'undisa kolala | Kuzizira kupanga | Kutentha mankhwalaa wa weld area okha | M | |

| Kutentha mankhwalaa wa weld area komanso kupsinjika kwa chitoliro chonse | M | |||

| Monga-adagubuduza kapena koyilo ya thermomechanical | Kuzizira kupanga | Normalizing | N | |

| Kuzimitsa ndi kukwiya | Q | |||

| Kuzizira kupanga kenako ndi kutentha kuchepetsa molamulidwa kutentha chifukwa chikhalidwe chokhazikika | - | N | ||

| Kuzizira kupanga kenako kupanga thermomechanical cha pipi | - | M | ||

| SAW kapena NG'OMBE | Normalized kapena normalizing- adagulung'undisa koyilo kapena mbale | Kuzizira kupanga | - | N |

| Monga-wogudubuza Thermomechanical-anagulung'undisa normalizing-anagulung'undisa, kapena normalized | Kuzizira kupanga | Normalizing | N | |

| Thermomechanical-anagulung'undisa coil kapena mbale | Kuzizira kupanga | - | M | |

| Kuzimitsidwa ndi kupsya mtima mbale | Kuzizira kupanga | - | Q | |

| Monga-wogudubuza Thermomechanical-anagulung'undisa normalizing-anagulung'undisa, kapena koyilo yokhazikika kapena mbale | Kuzizira kupanga | Kuzimitsa ndi kukwiya | Q | |

| Monga-wogudubuza Thermomechanical-anagulung'undisa normalizing-anagulung'undisa, kapena koyilo yokhazikika kapena mbale | Normalizing kupanga | - | N | |

| aOnani ISO 5L 8.8 pazamankhwala oyenera kutentha | ||||

Kuyang'anira maonekedwe ndi zolakwika za API 5L

Mawonekedwe

Kunja kwa chitoliro kudzakhala kosalala komanso kopanda zilema zomwe zingakhudze mphamvu ndi kusindikiza katundu wa chitoliro.

Zolakwika Zazikulu

M'mphepete mwa nibbled:Mphepete za nibbled zitha kupezeka bwino poyang'ana mawonekedwe.

Kuwotcha kwa Arc:Kuwotcha kwa Arc kudzaweruzidwa ngati cholakwika.

Kuwotcha kwa Arc ndi zolakwika zingapo zomwe zimapangidwira chifukwa cha kusungunuka kwa zitsulo zomwe zimayambitsidwa ndi arc pakati pa electrode kapena electrode yoyambira ndi pamwamba pa chitoliro chachitsulo.

Malo olumikizirana ndi mawanga apakati pafupi ndi mzere wowotcherera wa chitoliro cha EW, chifukwa cha kulumikizana pakati pa ma elekitirodi omwe amapereka kuwotcherera pano komanso pamwamba pa chitoliro.

Delamination:Delamination kapena kuphatikizika kulikonse komwe kumapitilira pamwamba pa chitoliro kapena nkhope yopindika ndipo ndi> 6.4 mm (0.250 mkati) muutali wozungulira pakuwunika kowoneka kudzawonedwa ngati cholakwika.

Zopatuka pa geometric:Kupatuka kwa geometric (mwachitsanzo, chipika chathyathyathya kapena pout, etc.), kupatula dzenje ladontho, lomwe limayambitsidwa ndi njira yopangira chubu kapena kupanga ntchito.Mtunda pakati pa nsonga yowopsya ndi kutambasula kwa mawonekedwe abwino a chubu, mwachitsanzo, kuya kwakukulu kuposa 3.2 mm (0.125 mkati), idzatengedwa ngati chilema.

Maenje otsitsa azikhala ≤ 0.5 D mbali iliyonse.

Kuuma: Kuyang'ana kowoneka kukuwonetsa kuuma kokayikiridwa, choyesa cholimba chonyamula chidzagwiritsidwa ntchito poyesa kuuma, ndipo cholozera pamfundo imodzi chokhala ndi kuuma kwamtengo wopitilira 35 HRC, 345 HV10, kapena 327 HBW chidzatengedwa kukhala cholakwika ngati kukula kwake kuli kolimba. wa indentation ndi wamkulu kuposa 50 mm (2.0 mu) mbali iliyonse.

Kusamalira Chilema

Chonde onani zofunikira mu API 5L Zowonjezera C kuti mugwire.

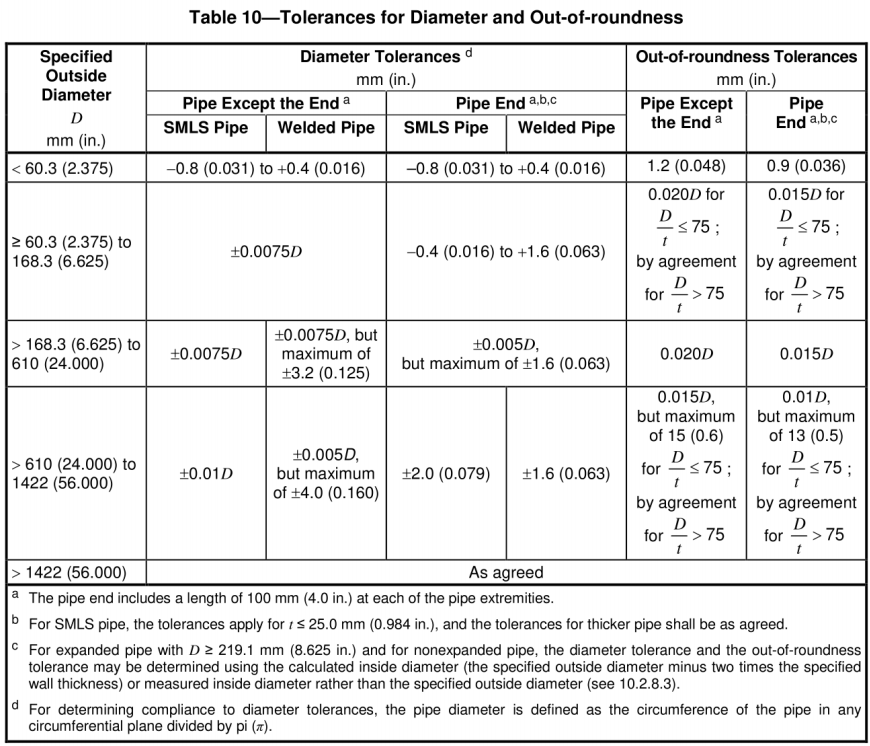

Dimensional Inspection (Dimensional Deviations)

Tchati cha Kulemera kwa Chitoliro ndi Kupatuka kwa Kunenepa

Kulemera formula

M=(DT)×T×C

M ndi kulemera kwa unit kutalika;

D ndi m'mimba mwake wotchulidwa kunja, wowonetsedwa mu millimeters ( mainchesi);

T ndi makulidwe otchulidwa khoma, owonetsedwa mu millimeters ( mainchesi);

C ndi 0.02466 powerengera mu mayunitsi a SI ndi 10.69 powerengera mayunitsi a USC.

PIPE WIGHT CHART NDI NDONDOMEKO

matebulo kulemera kwa chitoliro mu API 5L amatchulidwaISO 4200ndiASME B36.10M, zomwe zimapereka milingo yofananira ya chitoliro chokhala ndi mainchesi akunja ndi makulidwe ake odziwika.

Ndandanda 40 ndi Ndandanda 80zaphatikizidwa pansipa, ngati mukufuna kuwona dongosolo lonse la chitoliro,chonde dinani apa!

Kupatuka Kunenepa

Ubwino wa chitoliro chilichonse wachibale ndi chiphunzitso: kulemera: 95% ≤ kulemera kwamalingaliro ≤ 110;

Kupatuka ndi machubu owonjezera-oonda kwambiri: 5% ≤ 110% ya kulemera kwamalingaliro;

L175, L175P, A25, ndi A25P zitsulo kalasi: 95% ≤ 110% ya kulemera chiphunzitso.

Kunja Diameter ndi Wall Makulidwe Range

| Table 9-Zovomerezeka Zodziwika Kunja Kwa Diameter ndi Makulidwe Odziwika Pakhoma | ||

| Kutchulidwa Kunja Diameter D mm (m.) | Kunenepa Kwamakoma t mm (m.) | |

| Kuwala Kwapadera Kwapaderaa | Makulidwe Okhazikika | |

| ≥10.3 (0.405) ku<13.7 (0.540) | - | ≥1.7 (0.068)mpaka≤2.4 (0.094) |

| ≥13.7 (0.540) ku<17.1 (0.675) | - | ≥2.2 (0.088)mpaka≤3.0 (0.118) |

| ≥17.1 (0.675) ku<21.3 (0.840) | - | ≥2.3 (0.091)mpaka≤3.2 (0.125 |

| ≥21.3 (0.840) ku<26.7 (1.050) | - | ≥2.1 (0.083)mpaka≤7.5(0.294) |

| ≥26.7(1.050)mpaka<33.4(1.315) | - | ≥2.1 (0.083)mpaka≤7.8 (0.308) |

| ≥33.4(1311}5)mpaka<48.3 (1.900) | - | ≥2.1 (0.083)mpaka≤10.0 (0.394) |

| ≥48.3 (1.900) mpaka<60.3 (2.375) | - | ≥2.1 (0.083)mpaka≤12.5 (0.492) |

| ≥60.3 (2.375) ku<73.0 (2.875) | ≥2.1 (0.083)mpaka≤3.6 (0.141) | >3.6 (0.141)mpaka≤14.2 (0.559) |

| ≥73.0 (2.875) mpaka<88.9(3.500) | ≥2.1 (0.083)mpaka≤3.6 (0.141) | >3.6 (0.141)mpaka≤20.0 (0.787) |

| ≥88.9 (3.500) mpaka<101.6(4.000) | ≥2.1 (0.083)mpaka≤4.0 (0.156) | >4.0 (0.156)mpaka≤22.0 (0.866) |

| ≥101.6(4.000)mpaka<168.3 (6.625) | ≥2.1 (0.083)mpaka≤4.0 (0.156) | >4.0(0.156)mpaka≤25.0 (0.984) |

| ≥168.3 (6.625)to<219.1 (8.625) | ≥2.1 (0.083)mpaka≤4.0 (0.156 | >4.0 (0.156)mpaka≤40.0(1.575) |

| ≥219.1 (8.625) ku<273.1 (10.750) | ≥3.2 (0.125) mpaka≤4.0 (0.156 | >4.0 (0.156)mpaka≤40.0 (1.575 |

| ≥273.1 (10.750) ku<323.9 (12.750) | ≥3.6 (0.141)mpaka≤5.2 (0.203) | >5.2 (0.203)mpaka≤45.0 (1.771) |

| ≥323.9(12.750) ku<355.6(14.000) | ≥4.0 (0.156)mpaka≤5.6 (0.219) | >5.6 (0.219)mpaka≤45.0(1.771 |

| ≥355.6(14.000)mpaka<457(18.000) | ≥4.5 (0.177)mpaka≤7.1 (0.281) | >7.1 (0.281)mpaka≤45.0(1.771 |

| ≥457 (18.000) ku<559 (22.000) | ≥4.8 (0.188)mpaka≤7.1 (0.281) | >7.1 (0.281)mpaka≤45.0(1.771) |

| ≥559 (22.000) mpaka<711(28.000) | ≥5.6 (0.219)mpaka≤7.1 (0.281) | >7.1 (0.281)mpaka≤45.0(1.771) |

| ≥711 (28.000) ku<864(34.000) | ≥5.6(0.219)mpaka≤7.1 (0.281) | >7.1 (0.281)mpaka≤52.0 (2.050) |

| ≥864 (34.000) mpaka<965(38.000) | - | ≥5.6 (0.219)mpaka≤52.0 (2.050) |

| ≥965(38.000) ku<1422 (56.000) | - | ≥6.4 (0.250)mpaka≤52.0 (2.050) |

| ≥1422(56.000) ku<1829 (72.000) | - | ≥9.5 (0.375)mpaka≤52.0 (2.050 |

| ≥1829(72.000)mpaka<2134(84.000) | - | ≥10.3 (0.406)mpaka≤52.0 (2.050) |

| aChitoliro chokhala ndi kuphatikizika kwa m'mimba mwake komwe kumatchulidwa kunja ndi makulidwe a khoma kumatanthauzidwa ngati chitoliro chapadera cha kuwala;Zosakaniza zina zomwe zaperekedwa mu tebulo ili zimatanthauzidwa ngati chitoliro chokhazikika. | ||

Kupatuka kwa Diameter ndi Roundness

Kupatuka kwa Wall Makulidwe

| Table 11-Kulolera kwa Makulidwe a Khoma | |

| Makulidwe a Khoma t mm (mu.) | Kulekereraa mm (mu.) |

| Mtengo wa SMLSb | |

| ≤4.0 (0.157) | + 0.6 (0.024) -0.5 (0.020) |

| >4.0 (0.157) mpaka<25.0 (0.984) | + 0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146) kapena +0.1t, chomwe chili chachikulu -3.0 (0.120) kapena-0.1t, chomwe chili chachikulu |

| Welded Chitolirocd | |

| ≤5.0 (0.197) | ± 0.5 (0.020) |

| > 5.0 (0.197) ku<15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aNgati zogulira zikuwonetsa kulekerera kwa minus kwa makulidwe a khoma kucheperako mtengo womwe waperekedwa patebuloli, kupirira kophatikizana kwa makulidwe a khoma kudzawonjezedwa ndi kuchuluka kokwanira kuti mupitirizebe kupirira. bPakuti chitoliro ndi D2 355.6 mamilimita (14.000 mu.) ndi 1 2 25.0 mamilimita (0.984 mu.), khoma makulidwe kulolerana kwanuko akhoza upambana kuphatikiza kulolerana kwa khoma makulidwe ndi zina 0.05t, malinga ngati kuphatikiza kulolerana misa (onani 9.14) sichinapitirire. cThe kuphatikiza kulolerana kwa khoma makulidwe si ntchito ku weld dera. dOnani 9.13.2 zoletsa zina. | |

Kutalika Kwapatuka

Kulekerera kwa machubu okhazikika: Kutalika kwake kuyenera kukhala 500 mm ( mainchesi 20).

Kulekerera kwa mapaipi akutali:

| Table 12-Kulolera kwa Chitoliro Chautali Wachisawawa | |||

| Utali Wachisawawa Kusankhidwa m(ft) | Utali Wochepa m (ft) | Utali Wochepa Wapakati Pa Chida chilichonse cha Order m (ft) | Kutalika Kwambiri m (ft) |

| Chitoliro-ndi-zophatikizana | |||

| 6 (20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72 (45.0 |

| Chitoliro Chosavuta | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91(85.0) |

Kuwongoka Kupatuka

Kupatuka kwathunthu kuchokera pamzere wowongoka pamtunda wonse wa chitoliro kudzakhala <0.2% ya kutalika kwa chitoliro;

Kupatuka kokhazikika kuchokera pamzere wowongoka kudzakhala <3.2 mm (0.125 mu) kupitirira 1.5 m (5.0 ft) kutalika kwa chitoliro chilichonse.

Kupatuka kwa Bevel Angle

Chubu chokhala ndi t> 3.2 mm (0.125 mu) kumapeto kwa lathyathyathya chidzapangidwa ndi bevel wowotcherera wokhala ndi ngodya ya 30 ° -35 °.

Kukula kwa Mizu Yotukuka Pamwamba

1.6 mm (0.063 mkati) ndi kupatuka kwa ± 0.8 mm (0.031 mkati).

Mitundu ya Inner Cone Angle (yokha ya chitoliro chopanda chitsulo)

| Table 13-Maximum Angle of Internal Taper for SMLS Pipe | |

| Kunenepa Kwamakoma t mm (m.) | Maximum Angle of Taper madigiri |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413) ku<14.0 (0.551) | 9.5 |

| 14.0 (0.551) ku<17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

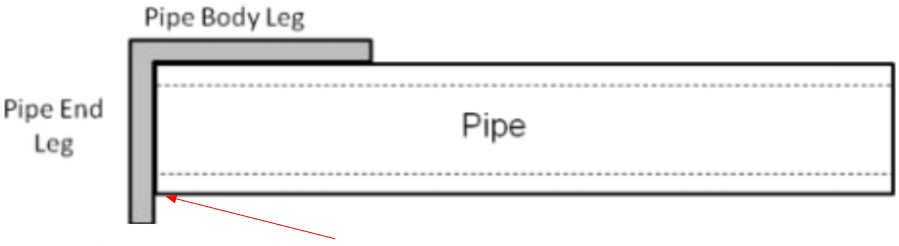

Pipe End Squareness (kunja kwa masikweya)

Kutuluka kwa-squareness kumayesedwa ngati kusiyana pakati pa mapeto a chitoliro ndi mwendo wotsiriza wa chitoliro, womwe udzakhala 1.6 mm (0.063 mkati).

Kupatuka kwa Welding Seam

Kusalongosoka kwa Mzere/Mapepala:

Kwa chitoliro cha electro-welded (EW) ndi laser-welded (LW) chitoliro, kusanja bwino sikuyenera kuchititsa kuti makulidwe otsala a khoma pa weld omwe ndi ocheperapo kusiyana ndi makulidwe ovomerezeka a khoma.

Kwa chitoliro cha Submerged Arc Welded (SAW) ndi Combination Welded (COW) chitoliro, kusalongosoka sikuyenera kupitirira zomwe zimaperekedwa mu Table 14 ya API 5L.

Burrs (Electro-welded (EW) ndi laser-welded (LW) machubu):

Ma burrs akunja amachotsedwa kuti akhale otsika kwambiri (ndi maziko).

Mabotolo amkati sayenera kupitirira 1.5 mm (0.060 mu) kupitirira mzere wa chubu, ndipo makulidwe a khoma pamtunda wa kuchotsa burr sikuyenera kukhala osachepera makulidwe ovomerezeka a khoma.

Weld Kutalika(Submerged Arc Welding (SAW) ndi Combination Welding (COW) Pipe):

Chotsani kutalika kotsalira kwa chowotcherera chamkati mkati mwa osachepera 100 mm (4.0 mu) kumapeto kwa chitoliro kumapeto kwa chitoliro, ndikupera chowotcherera kuti chisawuke kuposa 0,5 mm (0.020 mu) pamwamba pake. wa chitoliro choyandikana.

Zinthu Zoyesa za API 5L

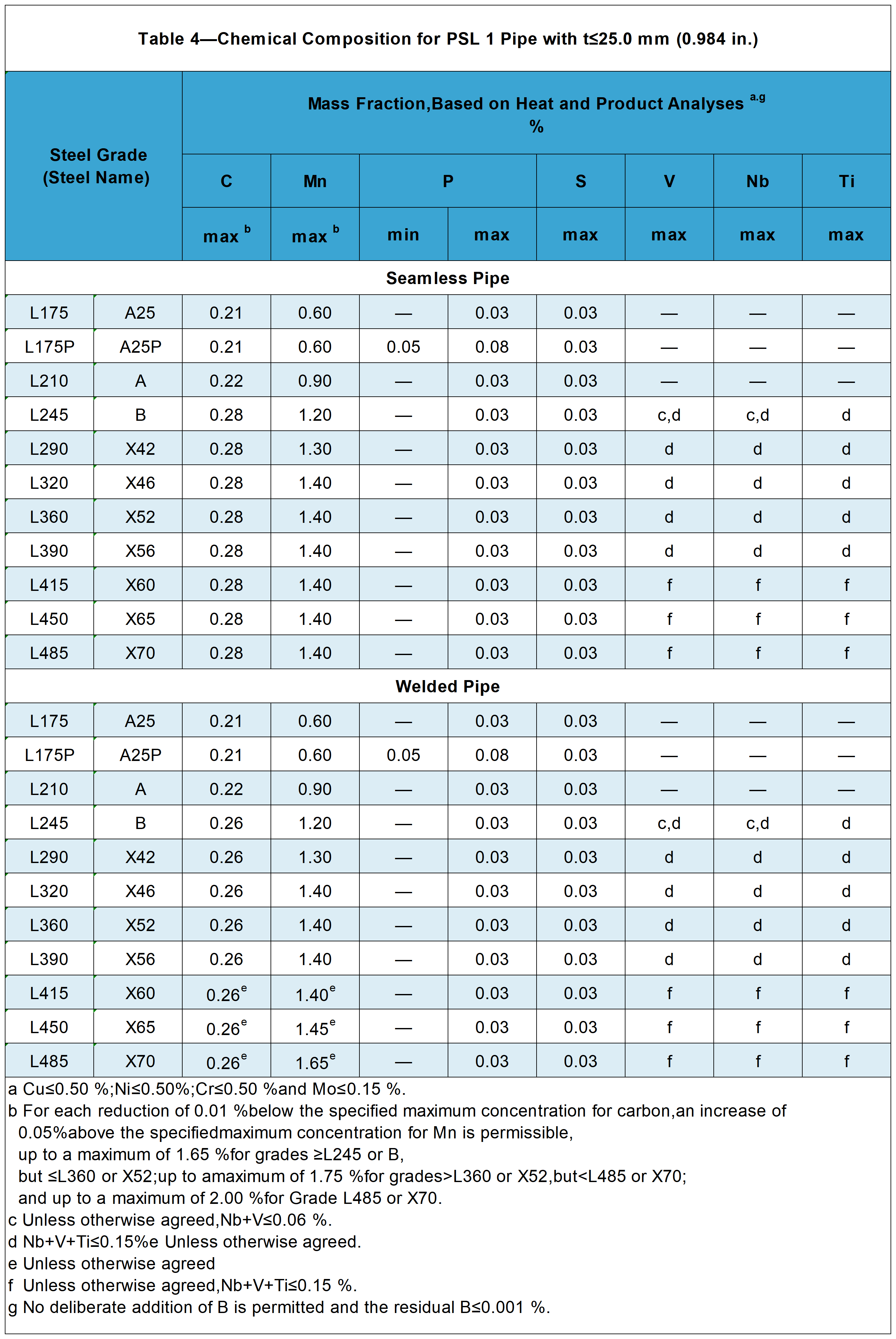

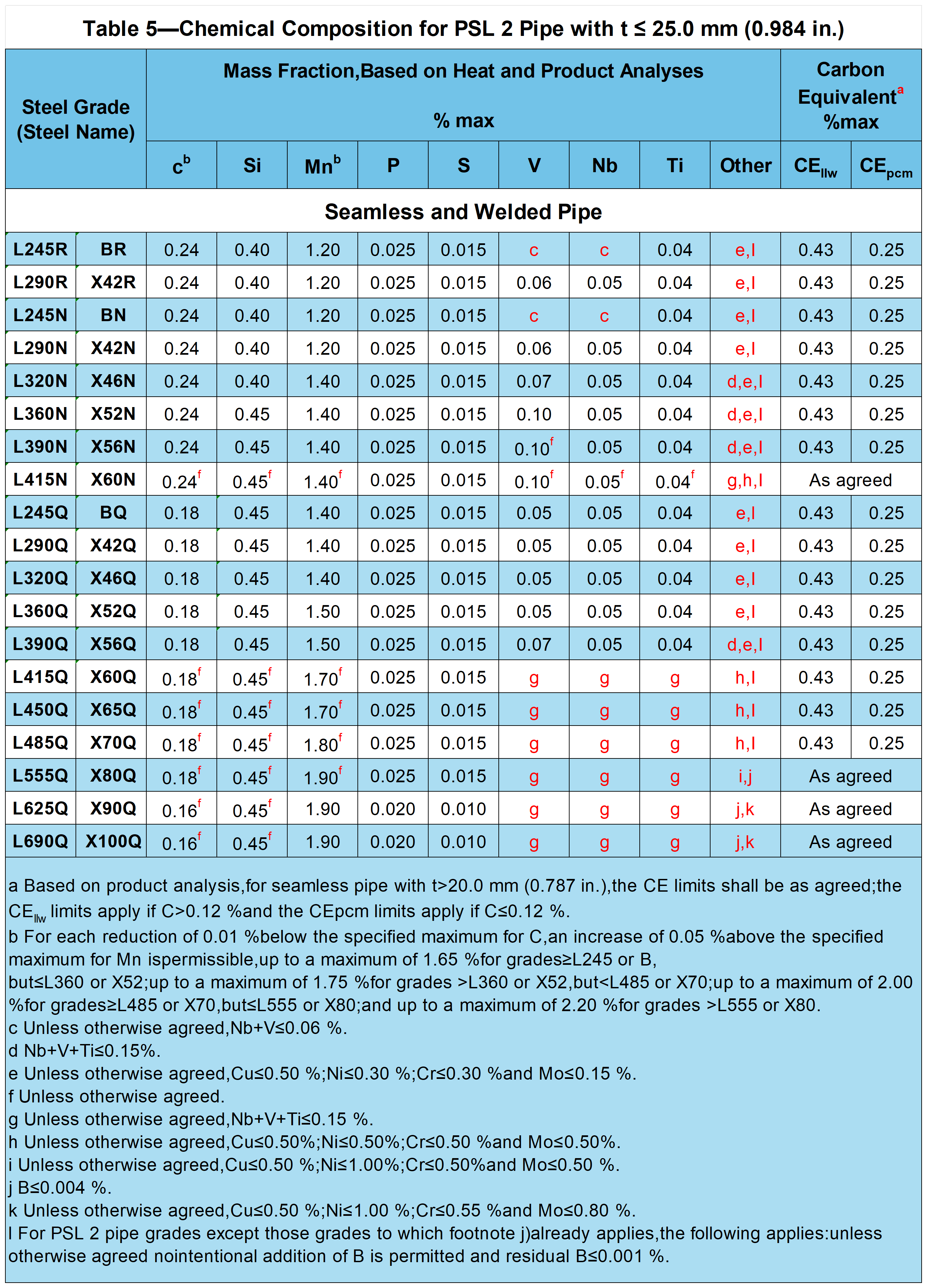

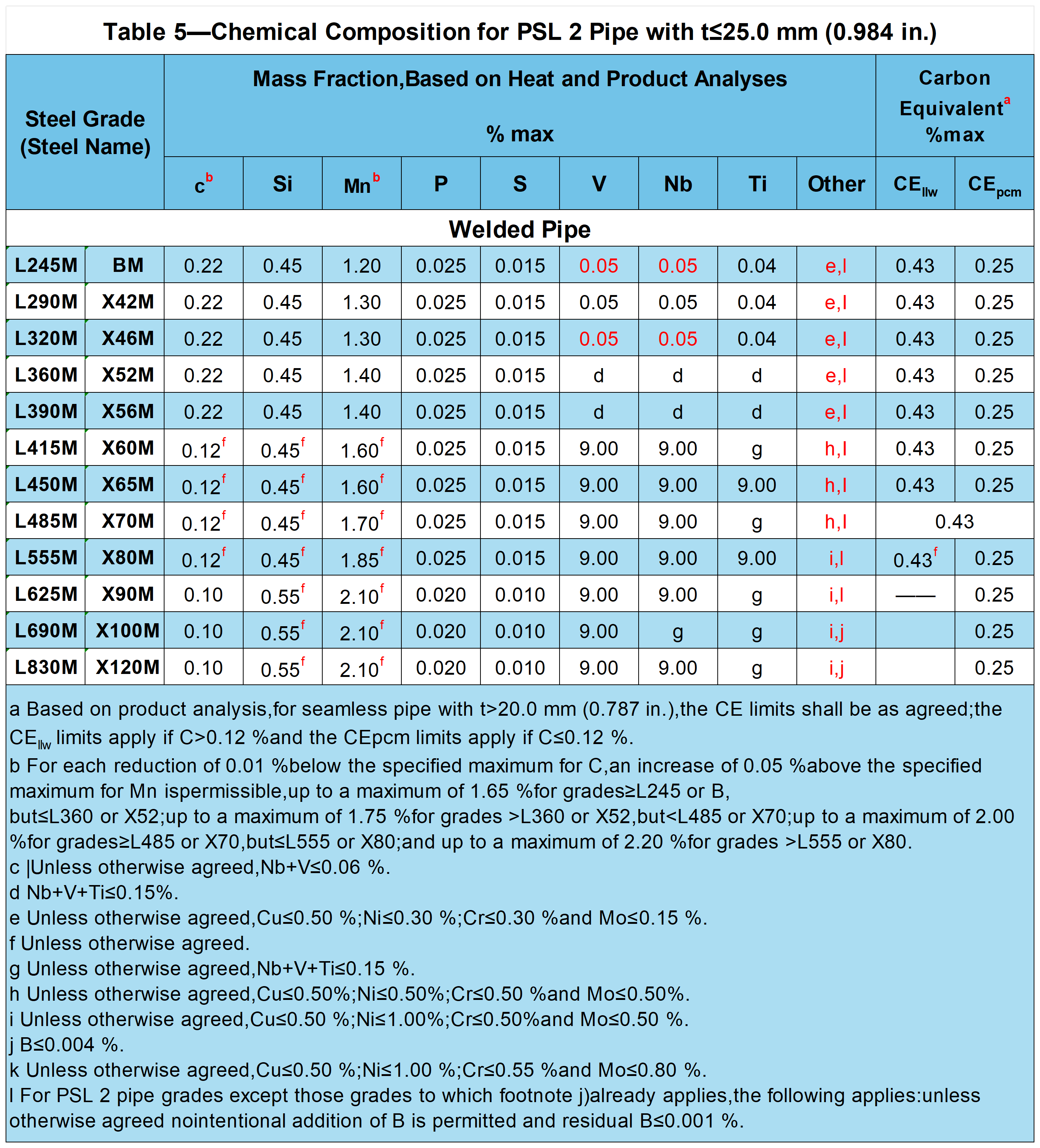

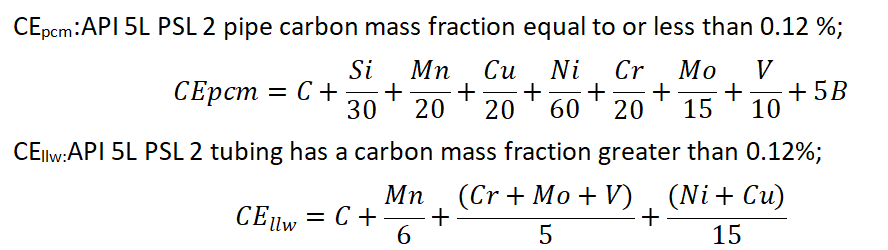

Chemical Composition

Njira Yoyesera: Onani ISO 9769 kapena ASTM A751.

Kapangidwe ka mankhwala a API 5L PSL1 ndi API 5L PSL2 chitoliro chachitsulo t> 25.0 mm (0.984 mu) chidzatsimikiziridwa ndi kukambirana motengera zolemba za mankhwala mu matebulo ofanana.

Mapangidwe a Chemical a PSL 1 Pipe yokhala ndi t≤25.0 mm (0.984 in.)

Mapangidwe a Chemical a PSL 2 Pipe yokhala ndi t≤25.0 mm (0.984 in.)

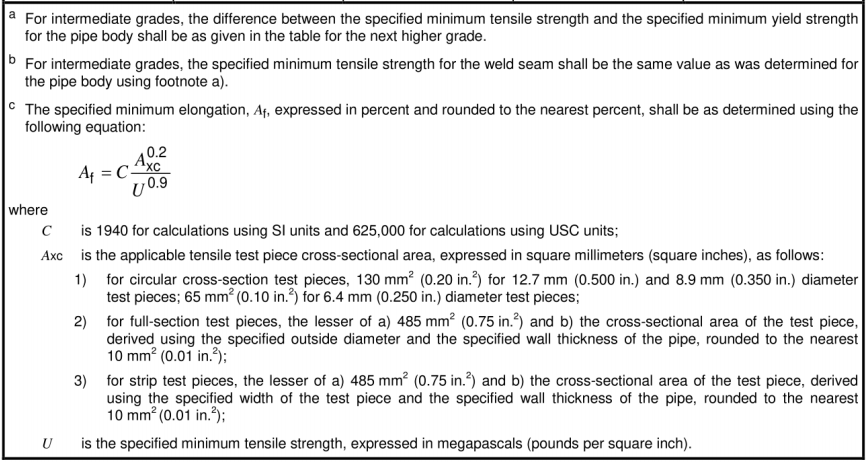

Tensile Properties

Njira Zoyesera: Ziyenera kuchitidwa molingana ndi ISO 6892-1 kapena ASTM A370.

Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 1 Pipe

| Table 6-Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 1 Pipe | ||||

| Gulu la Pipe | Chitoliro cha Chitoliro cha Chitoliro Chopanda Msoko ndi Chowotcherera | Weld Seam ya EW, LW, SAW, ndi COW Pipe | ||

| Zokolola Mphamvua Rku.5 MPa (psi) | Kulimba kwamakokedwea Rm MPa (psi) | Elongation (pa 50 mm kapena 2 in.) Af % | Kulimba kwamakokedweb Rm MPa (psi) | |

| min | min | min | min | |

| L175 kapena A25 | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L175P kapena A25P | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L210 kapena A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 kapena B | 245 (35,500) | 415 (60,200) | c | 415 (60,200) |

| L290 kapena X42 | 290(42,100) | 415 (60,200) | c | 415 (60,200) |

| L320 kapena X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 kapena X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| L390 kapena X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 kapena X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| L450 kapena X65 | 450 (65,300) | 535 (77,600) | c | 535 (77,600) |

| L485 kapena X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

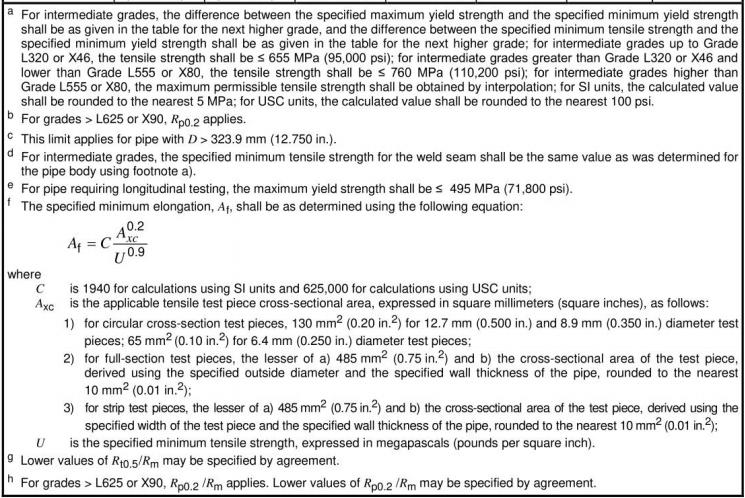

Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 2 Pipe

| Gulu 7-Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 2 Pipe | |||||||

| Gulu la Pipe | Chitoliro cha Chitoliro cha Chitoliro Chopanda Msoko ndi Chowotcherera | Weld Seam pa HFW SAW ndi Mtengo wa CoW | |||||

| Zokolola Mphamvua Rto.5 MPa (psi) | Kulimba kwamakokedwea Rm MPa (psi) | Chiŵerengeroac Rt0.5/Rm | Elongation (pa 50 mm kapena 2 mu.) Af % | Tensile Mphamvud Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R kapena BR L245N kapena BN L245Q kapena BQ L245M kapena BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R kapena X42R L290N kapena X42N L290Q kapena X42Q L290M kapena X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N kapena X46N L320Q kapena X46Q L320M kapena X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N kapena X52N L360Q kapena X52Q L360M kapena X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N kapena X56N L390Q kapena X56Q L390M kapena X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N kapena X56N L390Q kapena X56Q L390M kapena X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N kapena X60N L415Q kapena X60Q L415M kapena X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q kapena X65Q L450M kapena X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q kapena X70Q L485M kapena X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q kapena X80Q L555M kapena X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M kapena X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q kapena X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M kapena X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q kapena X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M kapena X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Kutalika kwaperesenti panthawi yopuma kumayenera kufotokozedwa kwa zitsanzo zomwe zimakhala ndi kutalika kwa 50 mm (2 in).

Kwa zitsanzo zokhala ndi kutalika kwa geji zosakwana 50 mm (2 mu), elongation panthawi yopuma idzasinthidwa kukhala elongation pa 50 mm (2 mu) malinga ndi ISO 2566-1 kapena ASTM A370.

Mayeso a Hydrostatic Pressure

Njira yoyesera: API 5L 10.2.6.

Miyeso yonse ya chitoliro chopanda msoko (SMLS) ndi chitoliro chowotcherera ndi D ≤ 457 mm (18.000 mu) chidzakhala ndi nthawi yokhazikika yosachepera masekondi 5.welded chitoliro ndi D> 457 mm (18.000 mu) adzakhala ndi okhazikika nthawi zosachepera 10 masekondi.

Bend Test

Njira Zoyesera: Mayeso opindika adzagwirizana ndi zofunikira za ISO 8491 kapena ASTM A370.

Palibe gawo lachitsanzo lomwe lidzaphwanyike ndipo chowotcherera sichidzasweka.

Gulu la L175P/A25P ndi chitsulo chowonjezera cha phosphorous chomwe chimapereka ulusi wabwino kuposa L175/A25 chitsulo koma chimakhala chovuta kupindika.

Mayeso a Flattening

Njira Zoyesera: Mayeso opondereza amayenera kutsatira zofunikira za ISO 8492 kapena ASTM A370.

Mtunda pakati pa mbale ziwirizi udzakhala woti palibe kusweka kwa weld kudzachitika mpaka mtunda wotchulidwawo wafika.

Mayeso Opindika Motsogozedwa

Njira Zoyesera: Mayeso opindika motsogozedwa adzagwirizana ndi zofunikira za ISO 5173 kapena ASTM A370.

Mayeso Olimba

Njira yoyesera: Mayeso a kuuma molingana ndi ISO 6506, ISO 6507, ISO 6508, kapena ASTM A370.

Zikawoneka zolimba zokayikitsa zikapezeka pakuwunika kwa mawonekedwe, choyezera kuuma chimayenera kugwiritsidwa ntchito poyesa kuuma.

CVN Impact Test for API 5L PSL2 Steel Pipe

Njira Zoyesera: Mayeso a charpy impact adzakwaniritsa zofunikira za ASTM A370.

Mayeso a DWT a API 5L PSL2 Welded Pipe

Njira yoyesera: Mayeso a DWT azikhala molingana ndi API5L3.

Macro-Inspection ndi Metallographic Test

Kupatuka kwa weld mkati ndi kunja kwa mipope ya arc welded (SAW) ndi combi-welded (COW) iyenera kufufuzidwa ndi kuyang'ana kwakukulu.

Kwa machubu omwe amafunikira chithandizo cha kutentha kwa weld, kuyezetsa kwachitsulo kudzachitidwa kuti muwonetsetse kuti HAZ yonse yatenthedwa bwino munjira ya makulidwe a khoma.

Kwa machubu omwe safuna chithandizo cha kutentha kwa weld, kuyezetsa kwazitsulo kudzachitidwa kuti zitsimikizire kuti palibe chotsalira cha untempered martensite.

Mayeso Osawononga (mapaipi atatu a API 5L PSL2 a zolinga zapadera)

Njira yoyesera: API 5L Annex E.

Kuyika Chitoliro ndi Malo

Zinthu zodziwika bwino zamachubu achitsulo:

Dzina la wopanga mapaipi kapena chizindikiro;

Kulemba "API Spec 5L".(Kawirikawiri amafupikitsidwa kukhala API 5L.) Zogulitsa zomwe zimagwirizana ndi mulingo wopitilira umodzi zitha kuzindikirika ndi dzina la mulingo uliwonse.

Kutchulidwa Kunja Diameter

Kunenepa khoma

Chitoliro (dzina lachitsulo)

Mtundu wa chitoliro

Utali (m'litali wa chitoliro mu m kufika pafupi ndi 0.01 m (mu ft kufika pafupi gawo lakhumi la phazi))

Malo azitsulo zachitsulo zolembera

D ≤ 48.3 mm (1.900 mu) chitoliro chachitsulo: Ma tabu omwe amapangidwa mosalekeza motsatira utali wa chitoliro chachitsulo kapena otetezedwa ku mtolo wachitsulo.

Chitoliro chokhala ndi D > 48.3 mm (1.900 mkati):

Kunja: Kuyambira pamtunda wakunja kwa chitoliro pakati pa 450 mm ndi 760 mm (1.5 ft ndi 2.5 ft) kuchokera kumapeto kwa chitoliro.

Mkati pamwamba: Yambani chizindikiro mkati mwa chitoliro osachepera 150 mm (6.0 mu) kuchokera kumapeto kwa chitoliro.

Equivalence Standard

Miyezo yapadziko lonse lapansi komanso yachigawo ndi machubu omwe API 5L ndiyofanana kapena, nthawi zina, njira ina, komanso milingo yokhudzana ndi kugwiritsa ntchito:

Miyezo yapadziko lonse ndi yachigawo

1. ISO 3183 - Mulingo wapaipi wapadziko lonse wamakampani amafuta ndi gasi wofalitsidwa ndi International Organisation for Standardization komanso wogwirizana kwambiri ndi API 5L.

TS EN 10208 - European Standard ya mapaipi achitsulo onyamula mpweya wamafuta ndi zakumwa.

3. GB/T 9711 - Muyezo wa dziko la China wa machitidwe oyendetsa mapaipi mumakampani amafuta ndi gasi.

4. CSA Z245.1 - Canadian Standard yophimba chitoliro chonyamula mafuta ndi gasi.

5. GOST 20295 - Muyezo wa Russian wa chitoliro chachitsulo chonyamula katundu wamafuta ndi mafuta.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards for line pipe for the oil and gas industry.

7. JIS G3454, G3455, G3456 - Japanese Industrial Standards kwa mapaipi opatsirana a magulu osiyanasiyana opanikizika.

8. DIN EN ISO 3183 - German Industrial Standard yochokera ku ISO 3183 ya chitoliro cha mzere.

9. AS 2885 - Muyezo wa Australia wa machitidwe a mapaipi amtundu wamayendedwe amafuta ndi gasi.

Miyezo Yeniyeni Yogwiritsa Ntchito

1. API 5CT - American Petroleum Institute muyezo wa chitsime cha mafuta ndi chubu, zomwe, ngakhale zimagwiritsidwa ntchito makamaka m'zitsime zamafuta, ndizofunikanso pamakampani amafuta ndi gasi.

2. ASTM A106 - American Society for Testing and Equipment muyezo wa chitoliro chachitsulo chosasunthika komanso chowotcherera cha carbon chitsulo chothandizira kutentha kwambiri.

3. ASTM A53 - National Institute for Testing and Equipment muyezo wa chitoliro chachitsulo chosasunthika komanso chokokedwa, chomwe chimagwiritsidwa ntchito poyendetsa madzimadzi kutentha kapena kutentha pang'ono.

4. ISO 3834 - International Organisation for Standardization standard for quality, poyang'ana machitidwe otsimikizira zazitsulo zowotcherera.

5. dnv-os-f101 - Muyezo wa gulu la anthu aku Norway pamapaipi apamadzi apamadzi am'mphepete mwa nyanja ndi mapaipi otumizira mafuta ndi gasi.

6. MSS SP-75 - Muyezo wa Manufacturers Standards Society womwe umayang'ana kwambiri mphamvu zazikulu, zozungulira zazikulu zozungulira zozungulira zowotcherera zitsulo.

Kasamalidwe Kabwino ndi Miyezo Yakuyenerera Kwachilengedwe

1. NACE MR0175/ISO 15156 - Zofunikira pazida zomwe zimagwiritsidwa ntchito pochotsa mafuta ndi gasi m'malo okhala ndi hydrocarbon okhala ndi sulfure, zomwe, makamaka zokhudzana ndi kusankha kwazinthu, ndizofunikira pakuwonetsetsa kuti zinthu zomwe zimagwiritsidwa ntchito pamafuta ndi gasi sizingawonongeke.

Zathu Zogwirizana

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Welded Pipe

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Chitoliro Chachitsulo cha Carbon

API 5L GR.B Kukhuthala Kwa Khoma Lolemera Chitoliro Chopanda Chitsulo Chopangira Makina

API 5L Gr.X52N PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 for sour service

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Mafuta ndi Gasi Carbon Seamless Steel Pipe

API 5L GR.B Chitoliro Chopanda Mzere cha Kupanikizika ndi Kapangidwe

API 5L/ASTM A106/ASTM A53 Gr.B Chitoliro Chachitsulo Chopanda Kaboni

BotopSteel ndi Katswiri waku ChinaWopanga & Otsatsa Mapaipi a Zitsulo za CarbonKupitilira Zaka 16 ndi 8000+ Matani a Seamless Linepipe mu Stock Mwezi uliwonse.Ndife okonzeka kukuyankhani pasanathe maola 24 titangolandira pempho limodzi komanso kupanga zabwino zonse komanso madongosolo azinthu zomwe zingatheke.

Tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,ogulitsa, opanga, mafakitale, ogulitsa, makampani, ogulitsa, kugula, mtengo, quotation, zambiri, zogulitsa, mtengo.

Nthawi yotumiza: Mar-22-2024