Chithunzi cha ASTM A671 ndi chitoliro chachitsulo chopangidwa kuchokera ku mbale yamtengo wapatali,Electric-Fusion-Welded (EFW)kwa malo omwe ali ndi mphamvu zambiri pamalo ozungulira komanso otsika.

Ndikoyenera makamaka kwa ntchito zomwe zimafuna kukhazikika kwapamwamba komanso kutsika kwapadera.

Navigation Mabatani

Kukula kwa ASTM A671

Chizindikiro cha ASTM A671

Gulu la Maphunziro

Magulu Amagulu

Zida zogwiritsira ntchito

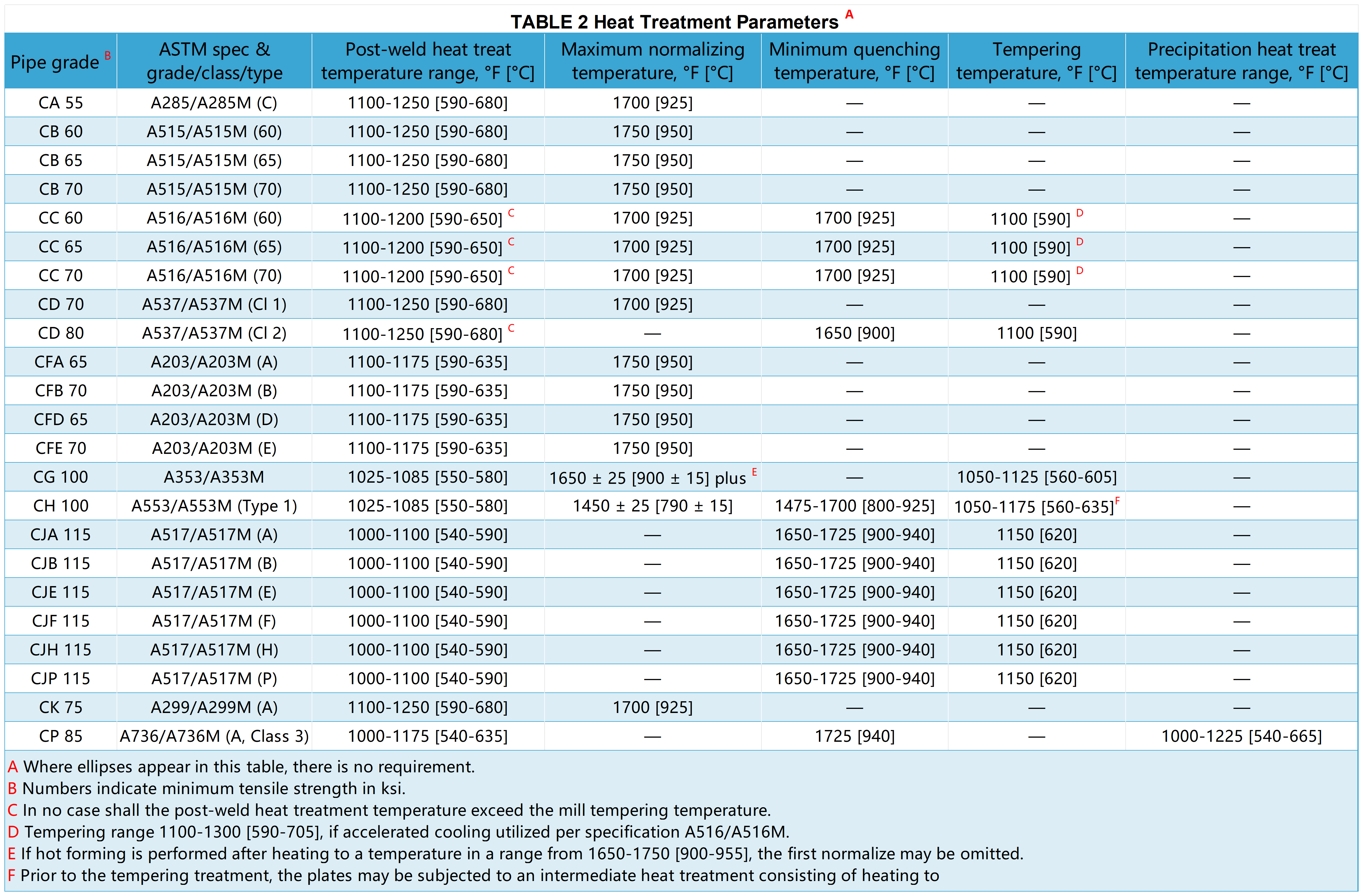

Mfundo zazikuluzikulu zowotcherera

Chithandizo cha Kutentha kwa Makalasi Osiyana

Ntchito Zoyeserera za ASTM A671

Chithunzi cha ASTM A671

Kupatuka kovomerezeka mu kukula

Mapulogalamu a ASTM A671 Steel Tubing

Zathu Zogwirizana

Kukula kwa ASTM A671

Mitundu yovomerezeka: mapaipi achitsulo ndi DN ≥ 400 mm [16 mu] ndi WT ≥ 6 mm [1/4].

Itha kugwiritsidwanso ntchito pamiyeso ina ya chitoliro, malinga ngati ikukwaniritsa zofunikira zina zamtunduwu.

Chizindikiro cha ASTM A671

Kuti timvetse bwino ASTM A671, choyamba timvetsetse zomwe zili zolembera. Izi zimathandiza kumveketsa kukula kwa kagwiritsidwe ntchito ndi mawonekedwe a muyezo uwu.

Chitsanzo cha Spray Marking:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

BOMA: Dzina la wopanga.

EFW: Njira yopangira chubu chachitsulo.

Chithunzi cha ASTM A671: Executive Standard for Steel Tubing.

Mtengo wa CC60-22: Chidule cha giredi:cc60 ndi kalasi 22.

16 "x SCH80: Diameter ndi Makulidwe a Khoma.

KUCHERA NO. 4589716: Kutentha ayi. popanga machubu achitsulo.

Uwu ndiye mtundu wamba wa ASTM A671 zolembera zopopera.

Sizovuta kupeza ASTM A671 m'kalasi ndi magulu awiri, ndiye kuti magulu awiriwa akuyimira tanthauzo lake.

Gulu la Maphunziro

Amasankhidwa molingana ndi mtundu wa mbale yomwe imagwiritsidwa ntchito popanga machubu achitsulo.

Makalasi osiyanasiyana amayimira mitundu yosiyanasiyana yamankhwala komanso makina amakina osiyanasiyana azovuta komanso kutentha.

Mwachitsanzo, magiredi ena ndi zitsulo za carbon, pamene zina ndizitsulo zokhala ndi zowonjezera zowonjezera, monga zitsulo za nickel.

| Gulu la Pipe | Mtundu wa Chitsulo | Chithunzi cha ASTM | |

| Ayi. | Gulu/kalasi/mtundu | ||

| CA 55 | mpweya wa carbon | A285/A285M | Gr C |

| CB60 | plain carbon, kuphedwa | A515/A515M | gr 60 |

| CB65 | plain carbon, kuphedwa | A515/A515M | gr65 pa |

| CB70 | plain carbon, kuphedwa | A515/A515M | gr 70 |

| CC 60 | mpweya wamba, wophedwa, njere zabwino | A516/A516M | gr 60 |

| CC 65 | mpweya wamba, wophedwa, njere zabwino | A516/A516M | gr65 pa |

| CC 70 | mpweya wamba, wophedwa, njere zabwino | A516/A516M | gr 70 |

| pa cd70 | manganese-silicon, normalized | A537/A537M | Cl 1 ndi |

| pa cd80 | manganese-silicon, kuzimitsidwa ndi kupsya mtima | A537/A537M | Cl 2 pa |

| Mtengo wa CFA65 | chitsulo cha nickel | A203/A203M | Gr A |

| Mtengo wa CFB70 | chitsulo cha nickel | A203/A203M | Gr B |

| Mtengo wa CFD65 | chitsulo cha nickel | A203/A203M | Gr D |

| Mtengo wa CFE70 | chitsulo cha nickel | A203/A203M | Gr E |

| Mtengo wa CG100 | 9% ya nickel | A353/A353M | |

| Mtengo wa CH115 | 9% ya nickel | A553/A553M | Mtundu 1 |

| Mtengo wa CJA115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr A |

| Mtengo wa CJB115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr B |

| Mtengo wa CJE115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr E |

| Mtengo wa CJF115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr F |

| Mtengo wa CJ115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr H |

| Mtengo wa CJP115 | alloy zitsulo, kuzimitsidwa ndi mkwiyo | A517/A517M | Gr P |

| ndi CK75 | carbon-manganese-silicon | A299/A299M | Gr A |

| CP85 | aloyi zitsulo, zaka kuumitsa, kuzimitsidwa ndi mpweya kutentha ankachitira | A736/A736M | Gr A, Gulu 3 |

Magulu Amagulu

Machubu amagawidwa molingana ndi mtundu wa chithandizo cha kutentha chomwe amalandira panthawi yopanga komanso ngati amawunikiridwa ndi radiographical ndikuyesedwa kukakamizidwa.

Magulu osiyanasiyana amawonetsa mitundu yosiyanasiyana ya chithandizo cha kutentha kwa machubu.

Zitsanzo zikuphatikizapo normalizing, kuchepetsa nkhawa, kuzimitsa, ndi kupsa mtima.

| Kalasi | Kutentha mankhwala pa chitoliro | Radioography, onani cholemba: | Pressure test, onani cholemba: |

| 10 | palibe | palibe | palibe |

| 11 | palibe | 9 | palibe |

| 12 | palibe | 9 | 8.3 |

| 13 | palibe | palibe | 8.3 |

| 20 | kupsinjika kumachepetsedwa, onani 5.3.1 | palibe | palibe |

| 21 | kupsinjika kumachepetsedwa, onani 5.3.1 | 9 | palibe |

| 22 | kupsinjika kumachepetsedwa, onani 5.3.1 | 9 | 8.3 |

| 23 | kupsinjika kumachepetsedwa, onani 5.3.1 | palibe | 8.3 |

| 30 | zokhazikika, onani 5.3.2 | palibe | palibe |

| 31 | zokhazikika, onani 5.3.2 | 9 | palibe |

| 32 | zokhazikika, onani 5.3.2 | 9 | 8.3 |

| 33 | zokhazikika, onani 5.3.2 | palibe | 8.3 |

| 40 | wokhazikika komanso wokwiya, onani 5.3.3 | palibe | palibe |

| 41 | wokhazikika komanso wokwiya, onani 5.3.3 | 9 | palibe |

| 42 | wokhazikika komanso wokwiya, onani 5.3.3 | 9 | 8.3 |

| 43 | wokhazikika komanso wokwiya, onani 5.3.3 | palibe | 8.3 |

| 50 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | palibe | palibe |

| 51 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | 9 | palibe |

| 52 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | 9 | 8.3 |

| 53 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | palibe | 8.3 |

| 70 | kuzimitsidwa ndi mpweya kutentha mankhwala | palibe | palibe |

| 71 | kuzimitsidwa ndi mpweya kutentha mankhwala | 9 | palibe |

| 72 | kuzimitsidwa ndi mpweya kutentha mankhwala | 9 | 8.3 |

| 73 | kuzimitsidwa ndi mpweya kutentha mankhwala | palibe | 8.3 |

Kutentha kwa ntchito kuyenera kudziwika posankha zipangizo. Zitha kufotokozedwa ku ASTM A20/A20M.

Zida zogwiritsira ntchito

Ma mbale apamwamba kwambiri a zotengera zokakamiza, tsatanetsatane wa mitundu, ndi miyeso yophatikizira angapezeke patebulo mkatiGulu la Maphunziropamwamba.

Mfundo zazikuluzikulu zowotcherera

Kuwotcherera: Mizere iyenera kukhala yowotcherera pawiri, yolowera kwathunthu.

Kuwotcherera kudzachitika motsatira njira zomwe zafotokozedwa mu Gawo IX la ASME Boiler ndi Pressure Vessel Code.

Ma welds amapangidwa pamanja kapena okha ndi njira yamagetsi yokhudzana ndi kuyika kwazitsulo zodzaza.

Chithandizo cha Kutentha kwa Makalasi Osiyana

Makalasi onse kupatula 10, 11, 12, ndi 13 azitenthedwa mu ng'anjo yoyendetsedwa mpaka ± 25 ° F [± 15 ° C].

Makalasi 20, 21, 22, ndi 23

Ayenera kutenthedwa mofanana mkati mwa kutentha kwa pambuyo pa kuwotcherera kwa kutentha komwe kwasonyezedwa mu Gulu 2 kwa osachepera 1 h/in. Kukhuthala kwa [0.4 h/cm] kapena 1 h, kukulirapo ndi chiyani.

Makalasi 30, 31, 32, ndi 33

Ayenera kutenthedwa mofanana ndi kutentha kwa austenitizing osiyanasiyana komanso osapitirira kutentha kwapamwamba komwe kukuwonetsedwa mu Table 2 ndipo kenako utakhazikika mumlengalenga kutentha kwa firiji.

Makalasi 40, 41, 42, ndi 43

Chitolirocho chiyenera kukhala chokhazikika.

Chitolirocho chiyenera kutenthedwanso ku kutentha kwa kutentha komwe kukuwonetsedwa mu Table 2 ngati kucheperachepera ndikusungidwa kutentha kwa osachepera 0.5 h / mu [0.2 h / masentimita] makulidwe kapena 0.5 h, chomwe chiri chachikulu, ndi choziziritsa mpweya.

Makalasi 50, 51, 52, ndi 53

Chitolirocho chiyenera kutenthedwa mofanana ndi kutentha mkati mwa austenitizing osiyanasiyana ndipo osapitirira kutentha kwapamwamba kozimitsa komwe kukuwonetsedwa mu Table 2.

Pambuyo pake, tsitsani madzi kapena mafuta. Pambuyo pozimitsa, chitolirocho chiyenera kutenthedwanso mpaka kutentha kochepa komwe kukuwonetsedwa mu Table 2 ndikuchitidwa pamenepo.

Kutentha kwa kutentha kosachepera 0.5 h/inchi kukhuthala kwake kapena 0.5 h, kaya ndi yaikulu iti, ndi yoziziritsidwa ndi mpweya.

Makalasi 70, 71, 72, ndi 73

Mapaipi ayenerakutenthedwa mofanana ndi kutentha kwa austenitizing osiyanasiyana, osapitirira kutentha kwakukulu kozimitsira komwe kukuwonetsedwa mu Table 2, kenako kuzimitsidwa m'madzi kapena mafuta.

Pambuyo pozimitsa chitolirocho chidzatenthedwanso mumtundu wa kutentha kwa mpweya womwe ukuwonetsedwa mu Table 2 kwa nthawi yodziwika ndi wopanga.

Ntchito Zoyeserera za ASTM A671

Chemical Composition

Malinga ndi zofunikira zofananira za kukhazikitsidwa kwa miyezo ya zida zopangira, kusanthula kwamankhwala, zotsatira za kuyesako kuti zikwaniritse zofunikira.

Tension Test

Mapaipi onse owotcherera opangidwa molingana ndi izi ayenera kukhala ndi mayeso oyeserera otenthetsera pambuyo pa kutentha komaliza, ndipo zotsatira zake ziyenera kufanana ndi zofunikira zakuthupi kuti pakhale mphamvu yomaliza yazitsulo zomwe zatchulidwa.

Kuonjezera apo, Magiredi a CD XX ndi CJ XXX, pamene awa ali a Class 3x, 4x, kapena 5x, ndi Grade CP ya 6x ndi 7x adzakhala ndi mayeso okhotakhota azitsulo opangidwa pazitsanzo zodulidwa kuchokera ku chitoliro chomalizidwa. Zotsatira za mayesowa zidzakwaniritsa zofunikira zoyeserera zamakina pamatchulidwe a mbale.

Mayeso a Transverse Guided Weld Bend

Mayeso a bend adzakhala ovomerezeka ngati palibe ming'alu kapena zolakwika zina zopitirira1/8mkati [3 mm] mbali iliyonse alipo mu chitsulo chowotcherera kapena pakati pa weld ndi chitsulo m'munsi pambuyo kupinda.

Ming'alu yomwe imayambira m'mphepete mwa chitsanzo panthawi yoyesedwa, ndipo imakhala yochepa kuposa1/4mkati. [6 mm] kuyeza mbali iliyonse sikungaganizidwe.

Mayeso a Pressure

Makalasi X2 ndi X3 chitoliro adzayesedwa malinga Specification A530/A530M, Hydrostatic Test Requirements.

Mayeso a Radiographic

Kutalika konse kwa weld iliyonse ya Makalasi X1 ndi X2 kudzawunikidwa mozama motsatira ndikukwaniritsa zofunikira za ASME Boiler ndi Pressure Vessel Code, Gawo VIII, Ndime UW-51.

The radiographic kuyezetsa akhoza kuchitidwa pamaso kutentha mankhwala.

Chithunzi cha ASTM A671

Chitoliro chomalizidwacho chizikhala chopanda zilema zovulaza ndipo chizikhala chomaliza ngati wantchito.

Kupatuka kovomerezeka mu kukula

| Masewera | Kulekerera Mtengo | Zindikirani |

| Kunja Diameter | ± 0.5% | Kutengera muyeso wozungulira |

| Kusazungulira | 1%. | Kusiyana pakati pa mainchesi akuluakulu ndi ang'onoang'ono akunja |

| Kuyanjanitsa | 1/8 mu [3 mm] | Pogwiritsa ntchito nsonga yowongoka ya mamita atatu kuti mbali zonse zigwirizane ndi chitoliro |

| Makulidwe | 0.01 mu [0.3 mm] | Kuchuluka kwa khoma kumachepera kuposa makulidwe otchulidwa mwadzina |

| Utali | 0 - +0.5 mkati [0 - +13mm] | zopanda makina |

Mapulogalamu a ASTM A671 Steel Tubing

Energy Industry

Amagwiritsidwa ntchito kunyamula madzi a cryogenic m'malo opangira gasi, malo oyeretsera, ndi malo opangira mankhwala.

Industrial Refrigeration Systems

Kuti mugwiritse ntchito mu gawo la cryogenic la firiji ndi makina owongolera mpweya kuti mutsimikizire kukhazikika kwadongosolo ndi chitetezo.

Zothandizira

Zosungirako ndi zoyendera za mpweya wa liquefied.

Kumanga ndi Kumanga

Imagwiritsidwa ntchito pama projekiti a zomangamanga pamtunda wochepa kapena malo owopsa a chilengedwe, monga kumanga kosungirako kuzizira.

Ndife mmodzi wa kutsogolera welded mpweya zitsulo chitoliro ndi zitsulo opanga msokonezo chitoliro ndi ogulitsa ku China, ndi osiyanasiyana apamwamba zitsulo chitoliro katundu, ife tadzipereka kukupatsani uthunthu wa mayankho chitoliro zitsulo. Kuti mudziwe zambiri za mankhwala, chonde omasuka kulankhula nafe, tikuyembekezera kukuthandizani kupeza bwino zitsulo chitoliro options pa zosowa zanu!

Tags: ASTM a671, efw, cc 60, kalasi 22, ogulitsa, opanga, mafakitale, ogulitsa, makampani, ogulitsa, kugula, mtengo, quotation, zambiri, zogulitsa, mtengo.

Nthawi yotumiza: Apr-19-2024