TS EN 10210 machubu achitsulondi zigawo za dzenje zotentha zazitsulo zosapangidwa ndi njere zosasunthika komanso zokongoletsedwa bwino zamitundu yosiyanasiyana yamamangidwe ndi makina omangira. Ili ndi zigawo zozungulira, masikweya, makona anayi, ndi oval.

EN 10210 ndi BS EN 10210 ndi miyezo yofanana koma ndi mabungwe osiyanasiyana.

Navigation Mabatani

Gawo la BS EN 10210

Kukula kwa BS EN 10210

Zida zogwiritsira ntchito

BS EN 10210 Dzina lachitsulo

Zoyenera Kutumizira za BS EN 10210

Mapangidwe a Chemical a BS EN 10210

Katundu wamakina a BS EN 10210

Mayeso a Impact

Weldability

Dimensional Tolerance

Maonekedwe Pamwamba

Zokhala ndi malata

Kukonza Zowonongeka Pamwamba

Chizindikiro cha BS EN 10210

Mapulogalamu

Zathu Zogwirizana

Gawo la BS EN 10210

Mwa Mtundu Wachitsulo

Zitsulo zapadera zopanda alloyed ndi alloyed

Zitsulo zosatsekedwa:S235JRH, S275JOH ,S275J2H, S355JOH, S355J2H, S355K2H , S275NH,S275NLH,S355NH,S355NLH.

Alloyed zitsulo zapaderaZithunzi za S420NH, S420NLH, S460NH, S460NLH

Njira yosavuta yozindikiritsira ndi: m'dzina lachitsulo, ngati mphamvu zokolola za index zimayamba ndi nambala '4', pazitsulo zazitsulo.

Mwa Kupanga Njira

Zigawo zamkati zamkati ziyenera kupangidwa ndinjira zopanda msoko kapena welded.

Zosasunthika zikuphatikizapo: zotentha-zomaliza komanso zozizira

Kuwotcherera wamba kumaphatikizapo Electric Resistance Welding (RW) ndi Arc Welding (SAW) pansi pamadzi: LSAW, SSAW.

Zigawo za dzenje zowotcherera ndi magetsi nthawi zambiri sizifuna kuwongolera mkati.

Mwa Mawonekedwe Opatuka

CHS: magawo ozungulira ozungulira;

RHS: magawo apakati kapena amakona anayi apakati;

EHS: elliptical dzenje zigawo;

Nkhaniyi yakonzedwa ndi circular cross-section (CHS) ya zomwe zili zoyenera.

Kukula kwa BS EN 10210

Khoma makulidwe: ≤120mm

M'mimba mwake:

Round (CHS): Akunja awiri≤2500 mm;

Square (RHS): Akunja awiri≤ 800 mm × 800 mm;

Amakona anayi (RHS): Akunja awiri≤750 mm × 500 mm;

Chowulungika (EHS): Kunja m'mimba mwake≤ 500 mm × 250 mm.

Zida zogwiritsira ntchito

Chitsulo chosasamalidwa bwino komanso chambewu.

Chitsulo chosatsekedwa mikhalidwe inayi JR, JO, J2, ndi K2 yatchulidwa.

Zitsulo zabwino zambewu: makhalidwe anayi N ndi NL amatchulidwa.

Zitsulo zambewu zabwino ndi zitsulo zokhala ndi njere zabwino, zokhala ndi njere za ferrite ≥ 6.

BS EN 10210 Dzina lachitsulo

Pazigawo zopanda alloy zitsulo zopanda kanthu zitsulo zimatchulidwa

Chitsanzo: BS EN 10210-S275J0H

lili ndi magawo anayi:S, 275, J0, ndi H.

1.S: zimasonyeza kuti structural zitsulo.

2.Nambala (275): makulidwe ≤ 16mm kwa mphamvu zokolola zochepa, mu MPa.

3.JR: imasonyeza kuti kutentha kwa chipinda chokhala ndi mphamvu zenizeni;

J0: ikuwonetsa kuti pa 0 ℃ yokhala ndi zotsatira zenizeni;

J2 kapena k2: zosonyezedwa mu -20 ℃ ndi katundu makamaka zotsatira;

4.H: ikuwonetsa magawo opanda kanthu.

Kwa zitsulo zamtengo wapatali zokhala ndi zitsulo zokhala ndi zitsulo zokhala ndi zitsulo

Chitsanzo: EN 10210-S355NLH

Lili ndi magawo asanu:S, 355, N, L, ndi H.

1. S: imasonyeza zitsulo zomangamanga.

2. Nambala (355): makulidwe ≤ 16mm osachepera otchulidwa mphamvu zokolola, unit ndi MPa.

3. N: kugudubuza kokhazikika kapena kokhazikika.

4. L: kukhudzidwa kwapadera pa -50 °C.

5.H: amatanthauza gawo lopanda kanthu.

Zoyenera Kutumizira za BS EN 10210

JR, J0, J2 ndi K2 - yatha.

N ndi NL - zokhazikika. Normalized zikuphatikizapo normalized adagulung'undisa.

JR, J0, J2 ndi K2 - ntchito yotentha

N ndi NL - Normalizing. Normalizing kumaphatikizapo normalizing kugubuduza.

Zitha kukhala zofunikira kuti magawo opanda phokoso okhala ndi makulidwe a khoma pamwamba pa 10 mm, kapena T/D ikaposa 0,1, kuti mugwiritse ntchito kuziziritsa kofulumira pambuyo pa austenitizing kuti mukwaniritse zomwe mukufuna, kapena kuzimitsa kwamadzi ndi kutentha kuti mukwaniritse zomwe zanenedwa.

Kwa magawo opanda msokonezo okhala ndi makulidwe a khoma opitilira 10 mm, kapena T / D ikaposa 0.1, kuziziritsa kofulumira pambuyo pa austenitization kungafunikire kukwaniritsa kapangidwe kake, kapena kuzimitsa kwamadzi ndi kutentha kuti mukwaniritse zomwe zidanenedwa.

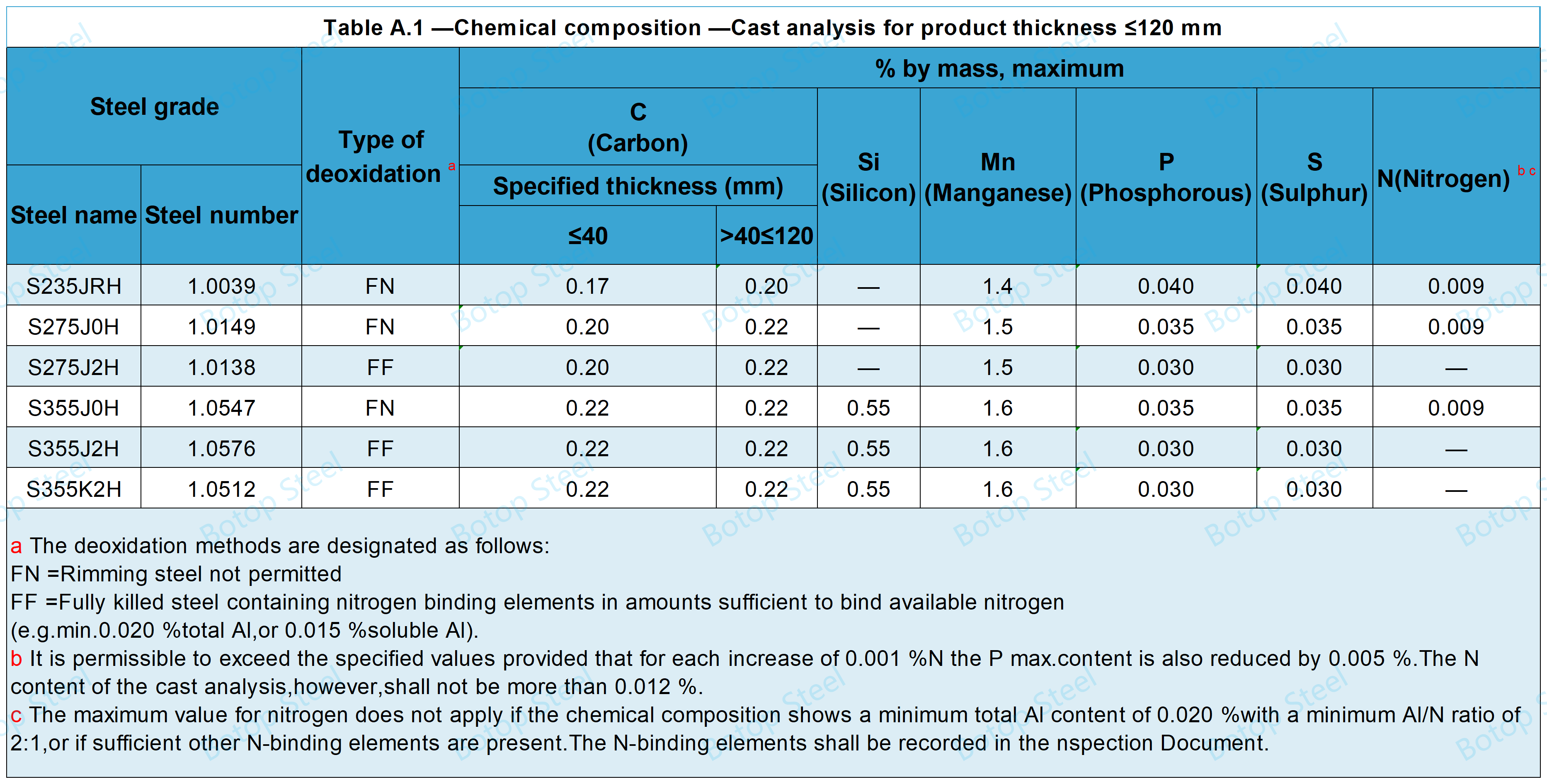

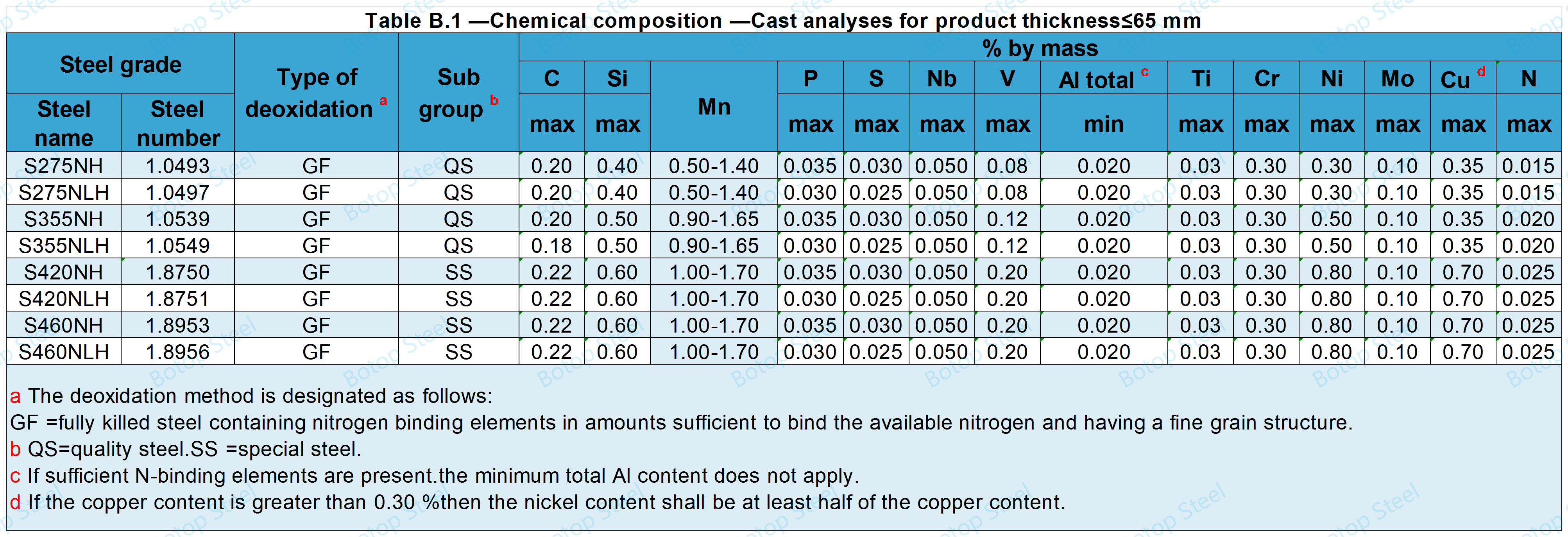

Mapangidwe a Chemical a BS EN 10210

Zitsulo Zopanda Alloy - Zopangidwa ndi Chemical

Fine Grain Steels - Chemical kapangidwe

Mukazindikira CEV njira yotsatirayi iyenera kugwiritsidwa ntchito:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

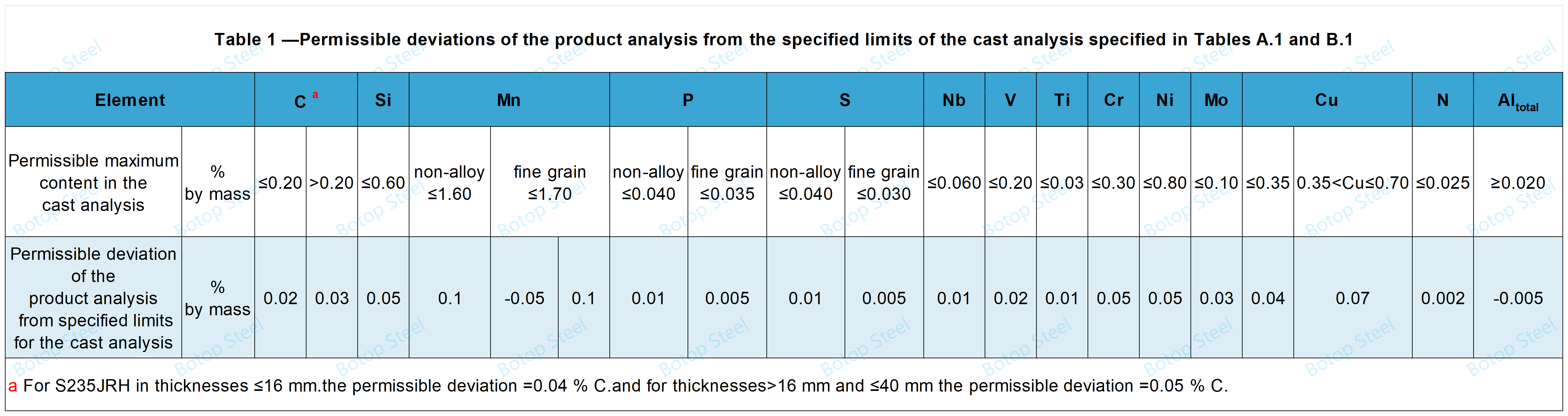

Kupatuka mu Chemical Composition

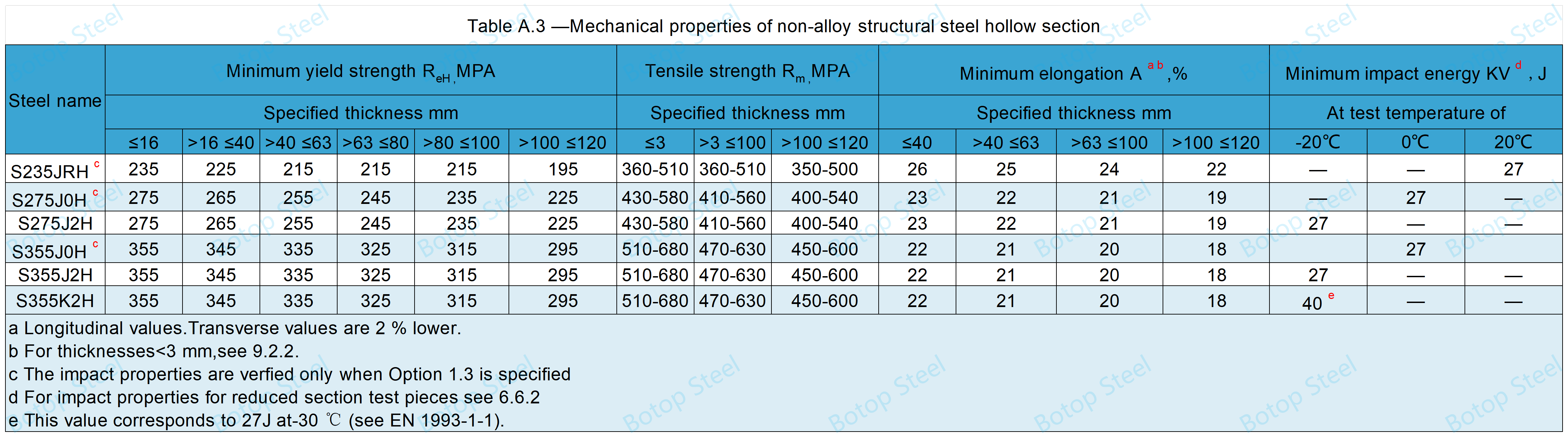

Katundu wamakina a BS EN 10210

Kuchepetsa kupsinjika kwakanthawi kopitilira 580 ° C kapena kwa ola limodzi kungayambitse kuwonongeka kwamakina.

Zitsulo Zopanda Alloy - Mechanical Properties

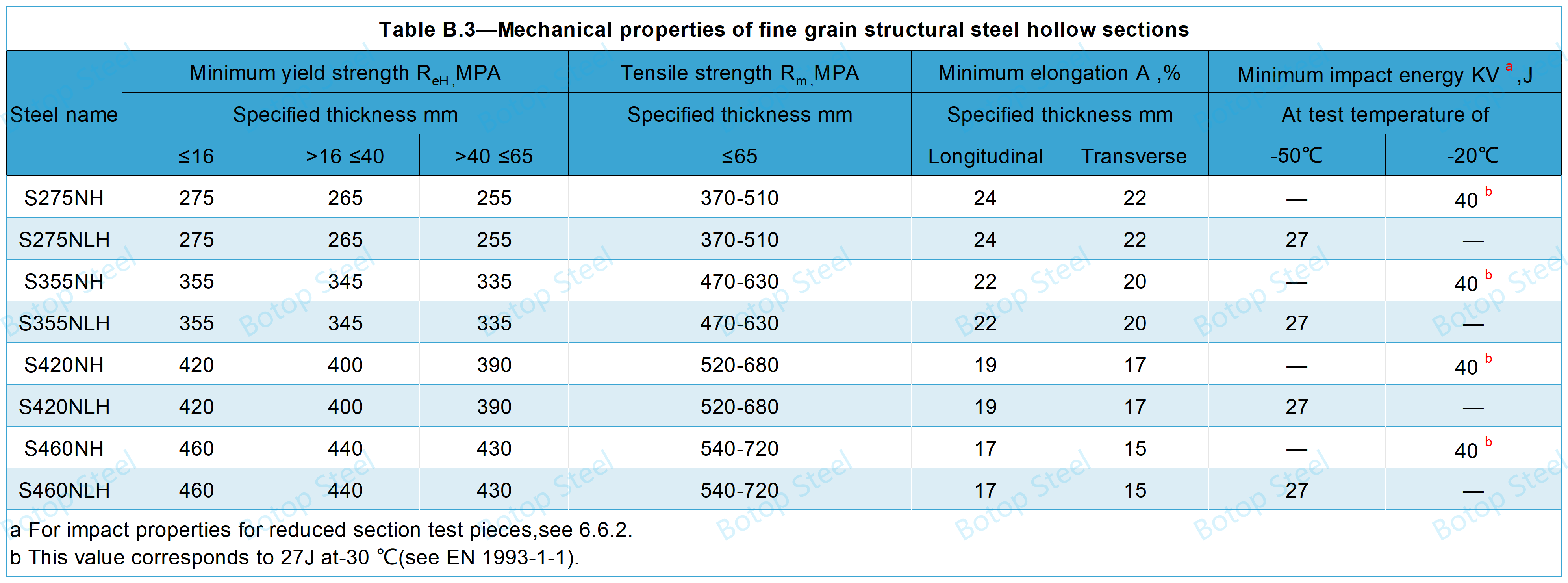

Zitsulo Zambewu Zabwino - Katundu Wamakina

Mayeso a Impact

Kuyesa kwamphamvu sikofunikira pamene makulidwe odziwika

Zitsanzo zokhazikika za V-notched malinga ndi EN 10045-1 ziyenera kugwiritsidwa ntchito.

Ngati makulidwe amtundu wamtunduwu ndi osakwanira pokonzekera zitsanzo zofananira, kuyezetsa kudzachitika pogwiritsa ntchito zitsanzo ndi m'lifupi mwake zosakwana 10 mm, koma zosachepera 5 mm.

Weldability

Zitsulo mu BS EN 10210 ndizowotcherera.

TS EN 1011-1 ndi EN 1011-2 zimafotokozera zofunikira zonse pazowotcherera.

Kuzizira kozizira m'dera la weld ndiye chiwopsezo chachikulu pomwe makulidwe azinthu, kuchuluka kwamphamvu, ndi kuchuluka kwa CEV.

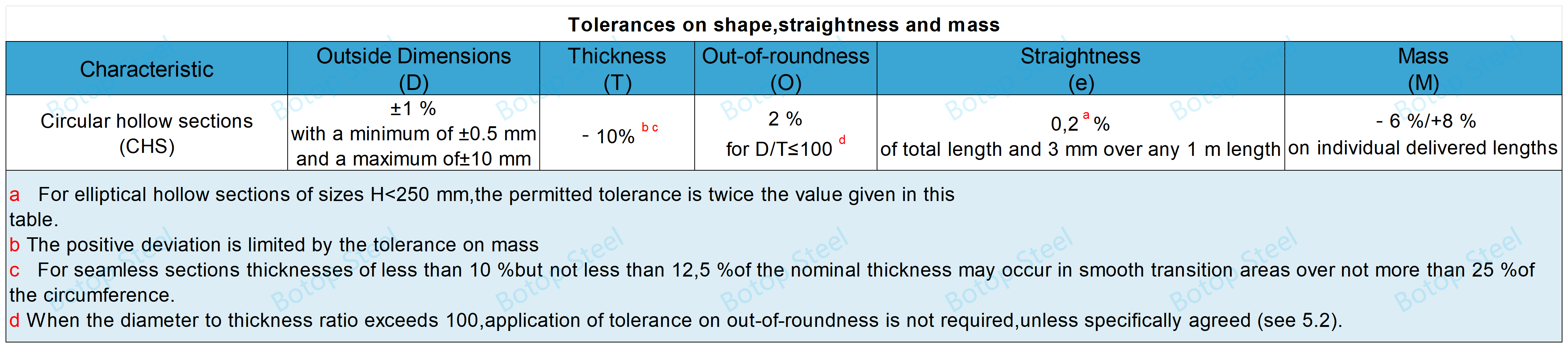

Dimensional Tolerance

Kulekerera pa Mawonekedwe, Kuwongoka ndi Misa

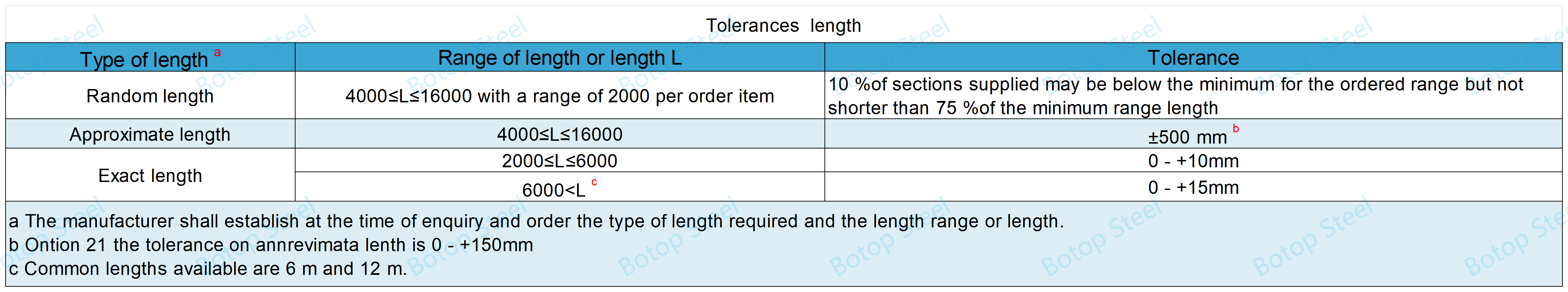

Kulekerera Utali

Seam Kutalika kwa SAW Weld

Kulekerera pa kutalika kwa mkati ndi kunja weld msoko kwa kumizidwa Arc welded dzenje zigawo.

| Makulidwe, T | Kutalika kwakukulu kwa mikanda, mm |

| ≤14,2 | 3.5 |

| > 14,2 | 4.8 |

Muyezo wa BS EN 10210 umakwirira zinthu zonse zopanda msoko komanso zowotcherera zomwe zimamalizidwa ndi dzenje. Njira zazikulu zowotcherera ndi kuwotcherera kukana (RW) ndi kuwotcherera kwa arc pansi pamadzi (SAW). Ma welds mu mapaipi achitsulo a ERW sawoneka, pomwe ma welds a SAW nthawi zambiri amakhala ovuta komanso owoneka bwino chifukwa cha SAW.

Maonekedwe Pamwamba

Pamwamba pake padzakhala ndi mapeto osalala ofanana ndi njira yopangira ntchito;

Ngati makulidwewo ali mkati mwa kulolerana, tokhala, ma grooves, kapena mikwingwirima yotalikirapo chifukwa cha kupanga amaloledwa.

Zokhala ndi malata

Zogulitsa mu BS EN 10210 ndizoyenera kuchitira galvanizing dip yotentha.

TS EN ISO 1461 iyenera kugwiritsidwa ntchito kutchula zofunikira zokutira.

Zopaka za Zinc zimagwiritsidwa ntchito pomizidwa mumtsuko wosungunuka womwe uli ndi zinc zosachepera 98%.

Kukonza Zowonongeka Pamwamba

Zowonongeka zapamtunda zitha kuchotsedwa pogayidwa ndi wopanga, malinga ngati makulidwe okonzedwawo sachepera kutsika kovomerezeka.

Ngati amapangidwa ndi njira yowotcherera, kukonza zowotcherera sikuloledwa kupatula kuwotcherera kwa arc pansi pamadzi.

Chitoliro chachitsulo chosakhala ndi aloyi chikhoza kukonzedwa ndi kuwotcherera thupi la chitoliro. Chitoliro chachitsulo cha aloyi sichingakonzedwe ndi kuwotcherera thupi.

Chizindikiro cha BS EN 10210

Zomwe zili muzitsulo zachitsulo ziyenera kukhala:

ndi dzina lachitsulo, mwachitsanzo EN 10210-S275JOH.

ndi dzina kapena chizindikiro cha wopanga.

chizindikiritso, mwachitsanzo nambala ya oda.

TS EN 10210 machubu achitsulo amatha kuzindikirika ndi njira zingapo zowonetsetsa kuti zizindikirika ndi kutsata mosavuta, kaya ndi penti, masitampu, zomatira, kapena zolemba zina zowonjezera, zomwe zitha kugwiritsidwa ntchito payekhapayekha kapena kuphatikiza.

Mapulogalamu

Chifukwa cha kulimba kwake, kulimba kwabwino, komanso kuwotcherera, BS EN 10210 imatha kupirira madera osiyanasiyana komanso kutsitsa ndipo imagwiritsidwa ntchito kwambiri pamapangidwe osiyanasiyana.

Zomangamanga: mwachitsanzo mafupa a nyumba zazitali, madenga a mabwalo amasewera, ndi zinthu zothandizira milatho.

Ukachenjede wazitsulo: mafelemu ndi zothandizira zamakina ndi zida zolemetsa.

Ukachenjede wazomanga: monga zothandizira ngalande, mizati ya mlatho, ndi zina zonyamula katundu.

Zomangamanga zamayendedwe: kuphatikiza zigawo za misewu ndi milatho ya njanji.

Gawo lamphamvu: mwachitsanzo nsanja za turbine yamphepo ndi zida zina zopangira magetsi.

Ndife apamwamba welded mpweya zitsulo chitoliro wopanga ndi katundu kuchokera China, komanso msokonezo zitsulo chitoliro stockist, kukupatsani osiyanasiyana zitsulo chitoliro njira!

Tags: bs en 10210, en 10210,s275j2h,s275j0h,s355j2h.

Nthawi yotumiza: Apr-25-2024