BS EN 10219 Chitsulondi zitsulo zosapanga dzimbiri zosapangidwa ndi aloyi ndi zitsulo zosalala bwino kuti zigwiritsidwe ntchito mopanda kutenthetsa.

EN 10219 ndi BS EN 10219 ndi miyezo yofanana koma ndi mabungwe osiyanasiyana.

Navigation Mabatani

Gawo la BS EN 10219

Kukula kwa BS EN 10219

Zida Zopangira ndi Zoyenera Kutumizira

BS EN 10219 Dzina lachitsulo

Mapangidwe a Chemical a BS EN 10219

Katundu wamakina a BS EN 10219

Mayeso a Impact

Kuyesa kosawononga

Maonekedwe ndi Kukonza Zowonongeka

Dimensional Tolerances

Zokhala ndi malata

Chizindikiro cha BS EN 10219

Mapulogalamu

Zathu Zogwirizana

Gawo la BS EN 10219

Mwa Mtundu Wachitsulo

Zitsulo zapadera zopanda alloyed ndi alloyed.

Zitsulo zopanda madzi:

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H,S275NH, S275NLH, S355NH, S355NLH.

Alloyed zitsulo zapadera:

S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

Njira yosavuta yodziwira kusiyana kwake: mitundu yachitsulo yomwe ili ndi M kapena 4 ndi ma alloys, ndipo ma alloying azitsulo amatha kudziwika mwachangu.

Mwa Kupanga Njira

Njira zopangira zomwe zimagwiritsidwa ntchito popanga mapaipi achitsulo malinga ndi BS EN 10219 zikuphatikiza.Electric Resistance Welding (RW) ndi Submerged Arc Welding (SAW).

SAW ikhoza kugawidwanso mu Longitudinal Submerged Arc Welding (LSAW) ndi Spiral Submerged Arc Welding (SSAW) kutengera mawonekedwe a weld seam.

Mwa Mawonekedwe Opatuka

CFCHS: Kuzizira Kupanga magawo ozungulira ozungulira;

CFRHS: Kuzizira Kupanga magawo akulu akulu kapena apakati;

CFEHS: Kuzizira Anapanga zigawo za elliptical dzenje;

Pepalali likukamba za CFCHS (Cold Formed Circular Hollow Section).

Kukula kwa BS EN 10219

Khoma makulidwe: T ≤ 40mm

M'mimba mwake (D):

Kuzungulira (CHS): D ≤ 2500 mm;

Square (RHS): D ≤ 500 mm × 500 mm;

Rectangular (RHS): D ≤ 500 mm × 300 mm;

Chozungulira (EHS): D ≤ 480 mm × 240 mm.

Zida Zopangira ndi Zoyenera Kutumizira

Zitsulo zopanda aloyi

pa Zowonjezera A, Zokulungidwa kapena Zokhazikika / Zokhazikika (N) zaJR, J0, J2, ndi K2zitsulo;

Zitsulo zambewu zabwino

Pa Zowonjezera B, Kugubuduza Kokhazikika / Kokhazikika (N) kwaN ndi NLzitsulo;

Pa Appendix B.M ndi ML, zitsulo zinali thermomechanically adagulung'undisa (M).

Zigawo za dzenje ziyenera kuperekedwa mozizira popanda chithandizo cha kutentha chotsatira, kupatula kuti msoko wowotcherera ukhoza kukhala wotenthedwa kapena wotenthedwa.

Pazigawo zopanda kanthu za SAW pamwamba pa 508 mm kunja kwa m'mimba mwake, zingakhale zofunikira kuchita ntchito yotentha yopangira mawonekedwe, zomwe sizimakhudza zinthu zamakina, kuti mukwaniritse zofunikira zololera.

BS EN 10219 Dzina lachitsulo

Msonkhano wopatsa mayina wa BS EN 10219 ndi womwewoGawo la EN 10210, yomwe imagwiritsa ntchito muyezo wa EN10027-1.

Kwa zigawo zopanda alloy zitsulo zosapanga dzimbiri, chitsulo chachitsulo chimakhala

Chitsanzo: Chitsulo chaching'ono (S) chokhala ndi mphamvu zochepa zokolola zonenepa zosaposa 16 mm za 275 MPa, zokhala ndi mphamvu yochepera 27 J pa 0 ℃(J), gawo lopanda kanthu (H).

EN 10219-S275J0H

Zili ndi magawo anayi:S, 275, J0, ndi H.

1. S: zimasonyeza kuti structural zitsulo.

2. Nambala yamtengo wapatali (275): makulidwe ≤ 16mm kwa mphamvu zochepa zomwe zatchulidwa, mu MPa.

3. JR: imasonyeza kuti kutentha kwa chipinda chokhala ndi mphamvu zenizeni;

J0: ikuwonetsa kuti pa 0 ℃ yokhala ndi zotsatira zenizeni;

J2 or K2: zosonyezedwa mu -20 ℃ ndi katundu makamaka zotsatira;

4. H: ikuwonetsa magawo opanda kanthu.

Kwa zitsulo zamtengo wapatali zokhala ndi zitsulo zokhala ndi zitsulo zokhala ndi zitsulo

Chitsanzo: Chitsulo chokhazikika (S) chokhala ndi mphamvu zochepa zokolola za makulidwe osapitirira 16 mm wa 355 MPa. Normalized fine grain steel feedstock (N), yokhala ndi mphamvu yochepa ya 27 J pa -50 ℃(L), gawo lopanda kanthu (H).

EN 10219-S355NLH

Lili ndi magawo asanu:S, 355, N, L, ndi H.

1. S: imasonyeza zitsulo zomangamanga.

2. Nambala yamtengo wapatali(355): makulidwe ≤ 16mm osachepera otchulidwa mphamvu zokolola, unit ndi MPa.

3. N: kugudubuza kokhazikika kapena kokhazikika.

4. L: kukhudzidwa kwapadera pa -50 °C.

5. H: amatanthauza gawo lopanda kanthu.

Mapangidwe a Chemical a BS EN 10219

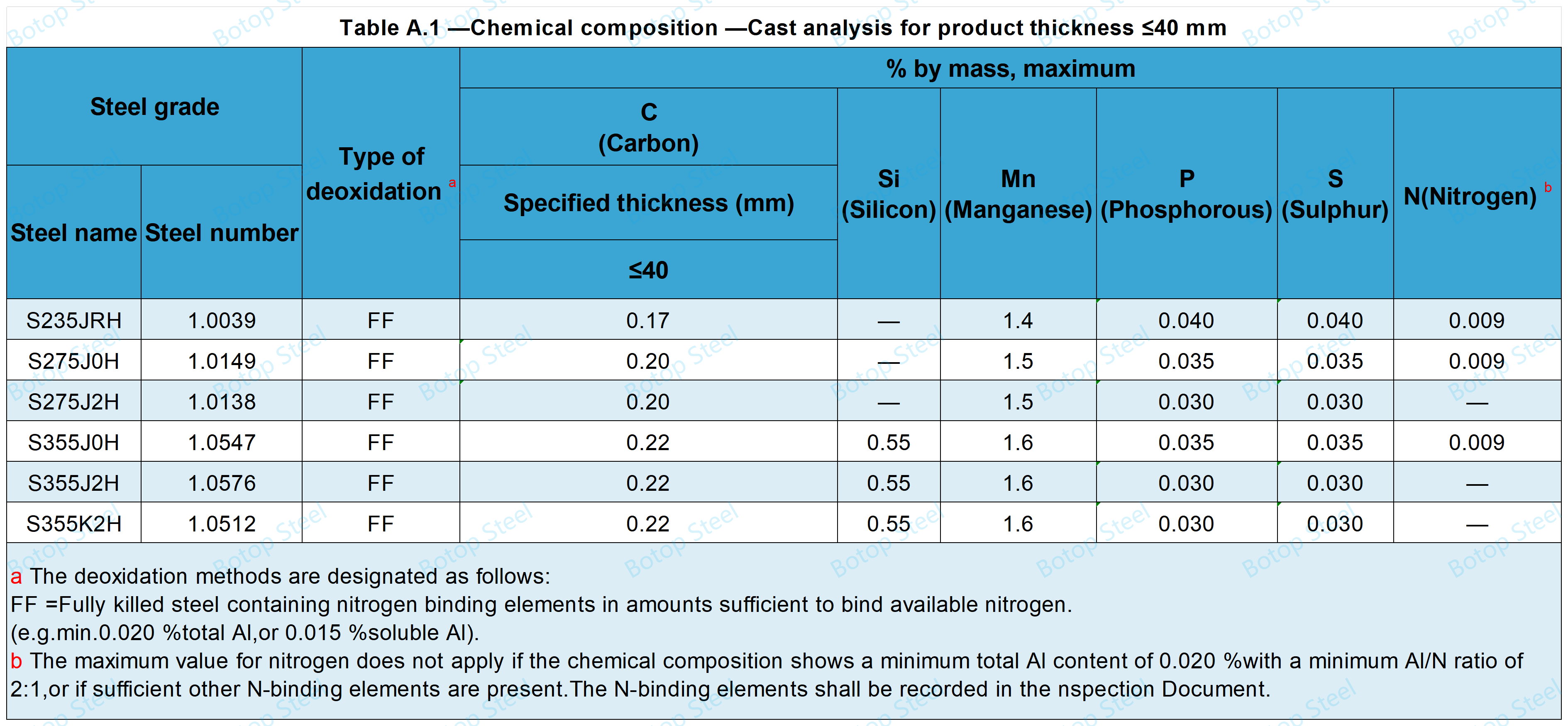

Zitsulo zopanda alloy - Chemical Composition

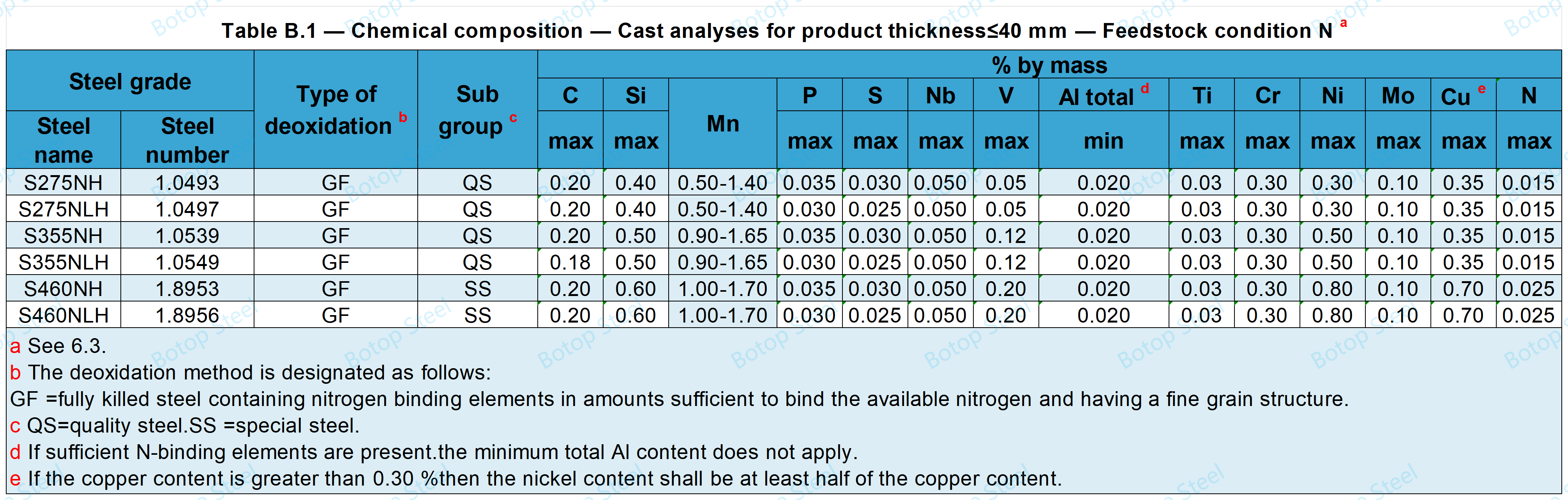

Fine Grain Steels - Chemical kapangidwe

Chitsulo chopangidwa bwino chikagwiritsidwa ntchito ngati chopangira, chimatha kugawidwa m'magulu a M ndi N malinga ndi momwe amaperekera, ndipo zofunikira zamitundu iwiriyi zimatha kusiyana.

Pozindikira CEV njira yotsatirayi idzagwiritsidwa ntchito: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Feedstock condition N

Feedstock condition M

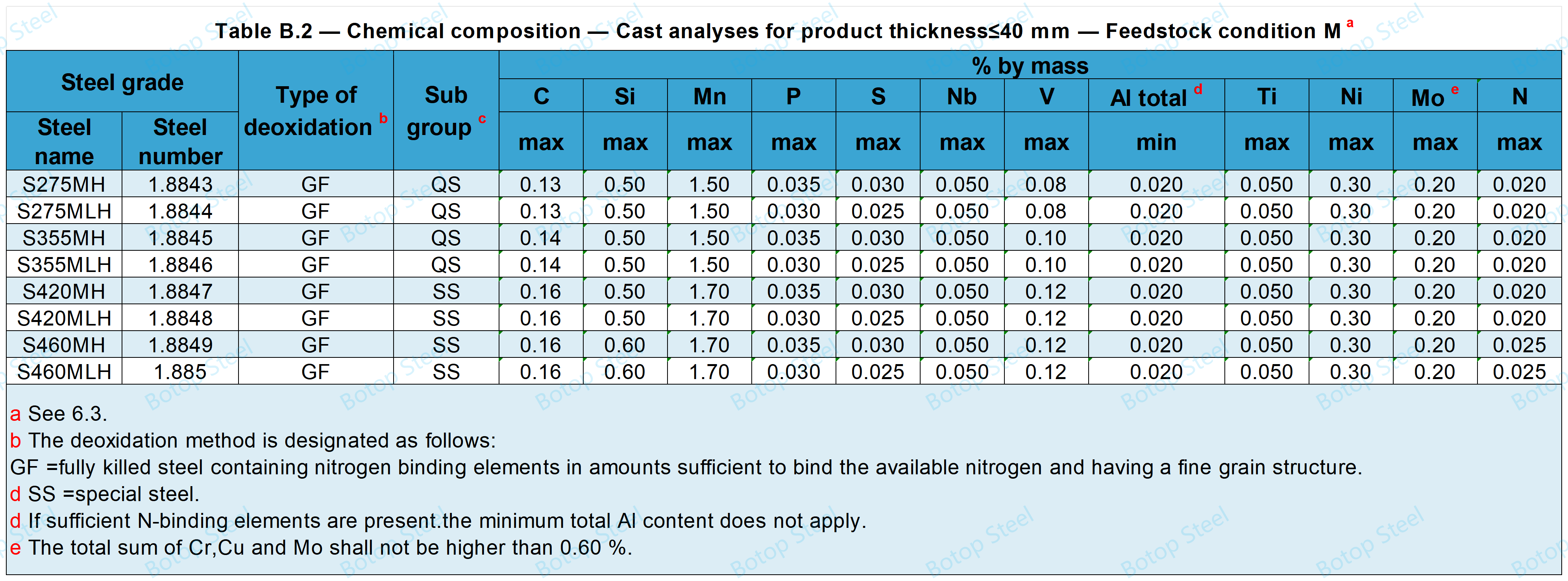

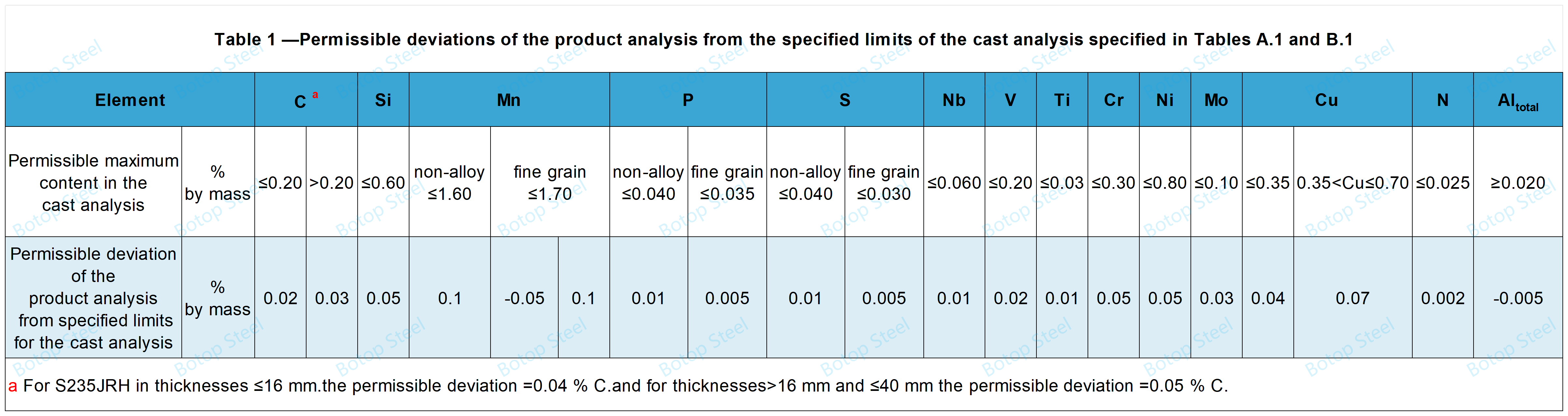

Kupatuka mu Chemical Composition

Katundu wamakina a BS EN 10219

Iyenera kuchitidwa molingana ndi EN 1000-2-1. Kuyezetsa kuyenera kuchitidwa mu kutentha kwapakati pa 10 ° C mpaka 35 ° C.

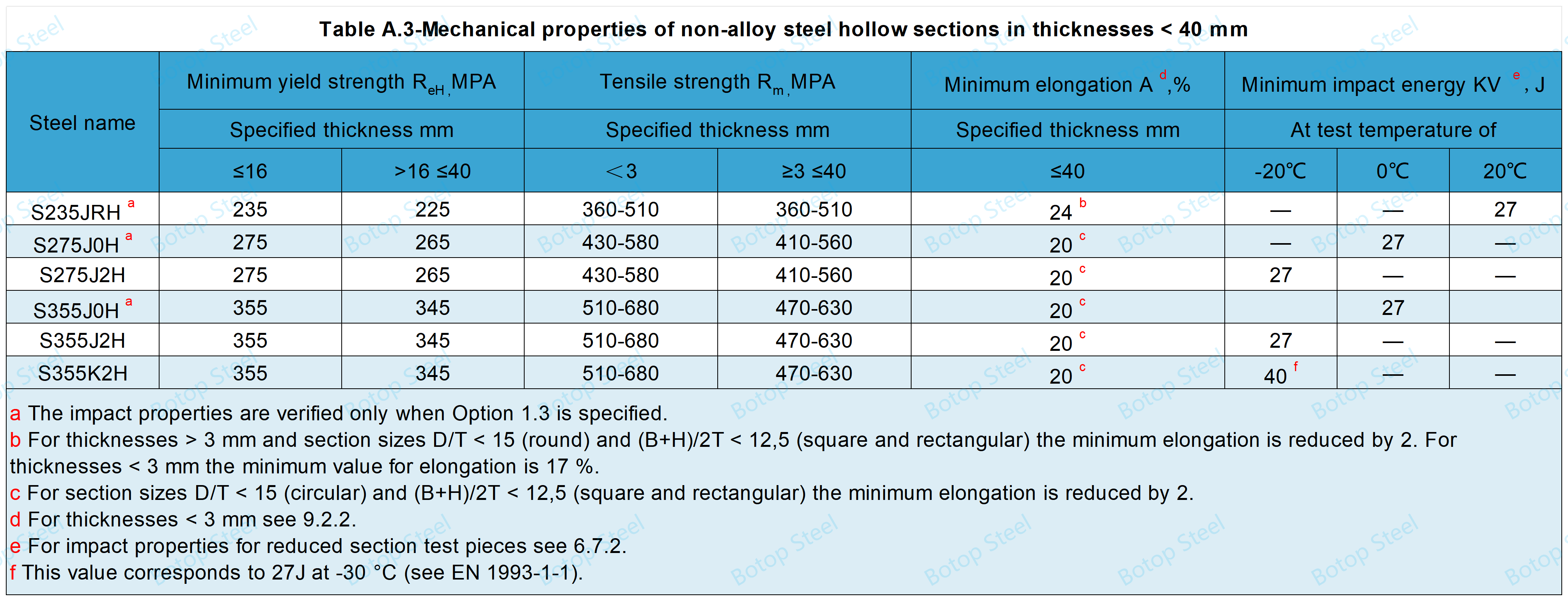

Zitsulo Zopanda Alloy - Mechanical Properties

Zitsulo Zambewu Zabwino - Katundu Wamakina

Chitsulo chopangidwa bwino chikagwiritsidwa ntchito ngati zopangira, zimatha kugawidwa m'magulu a M ndi N malinga ndi momwe amaperekera, ndipo makina amitundu iwiriyi amatha kukhala osiyana.

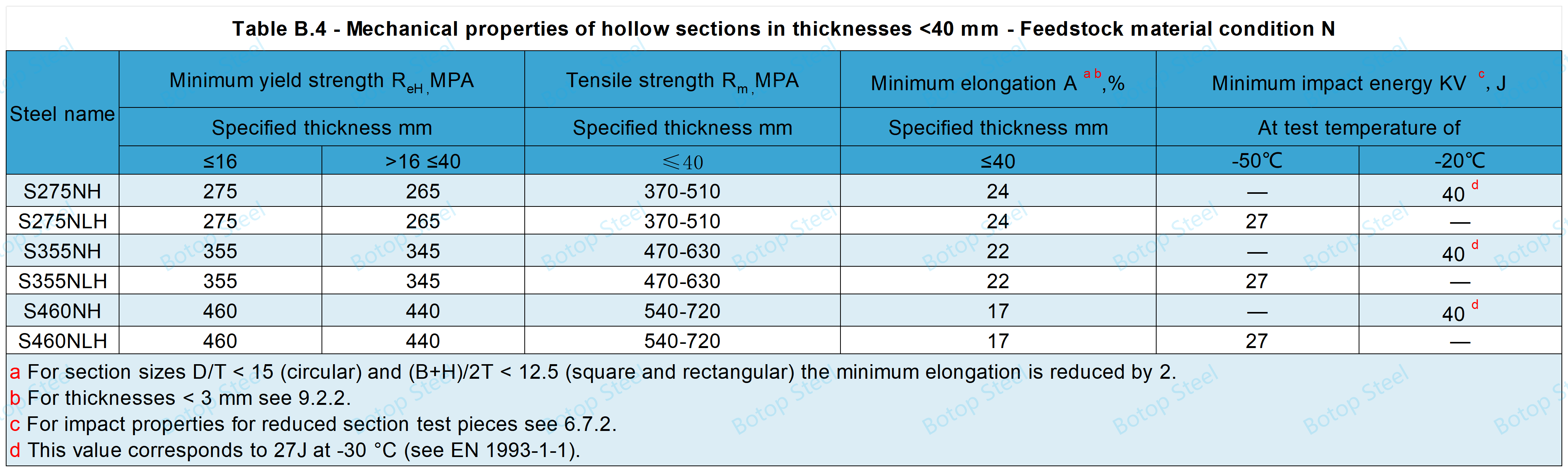

Feedstock condition N

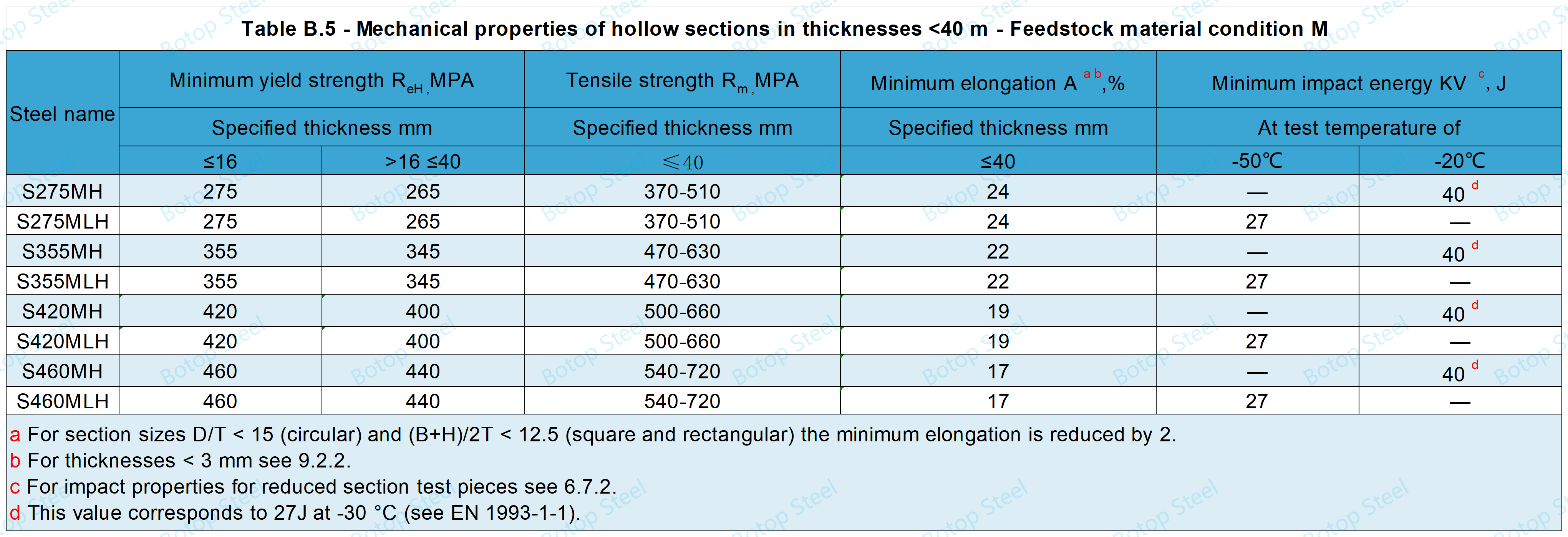

Feedstock Material condition M

Mayeso a Impact

Kuyesa kwamphamvu kudzachitika molingana ndi EN 10045-1.

Mtengo wapakati wa magulu atatu a zitsanzo udzakhala wofanana kapena wokulirapo kuposa mtengo womwe watchulidwa.

Mtengo wapayekha ukhoza kukhala wotsika kuposa mtengo womwe watchulidwa, koma siwochepera 70% ya mtengowo.

Kuyesa kosawononga

Pochita NDT pa ma welds m'magawo opanda kanthu, zofunikira zotsatirazi ziyenera kukwaniritsidwa.

Magetsi Welded Magawo

Kukwaniritsa chimodzi mwazofunikira izi:

a) TS EN 10246-3 mpaka mulingo wovomerezeka E4, kupatula kuti njira yozungulira ya chubu/pakeke sidzaloledwa;

b) EN 10246-5 ku mulingo wovomerezeka F5;

c) EN 10246-8 mpaka mulingo wovomerezeka U5.

Magawo Olowetsedwa Arc Welded

TS EN 10246-9 msoko wowotcherera wa magawo omizidwa arc welded welded ayesedwa malinga ndi EN 10246-9 kuvomereza mulingo U4 kapena ma radiography molingana ndi EN 10246-10 yokhala ndi gulu lazithunzi R2.

Maonekedwe ndi Kukonza Zowonongeka

Maonekedwe Pamwamba

Magawo opanda kanthu azikhala ndi malo osalala ogwirizana ndi njira yopangira yomwe imagwiritsidwa ntchito; tokhala, grooves kapena osaya longitudinal grooves chifukwa cha kupanga ndondomeko amaloledwa ngati yotsalira makulidwe mkati kulolerana.

Malekezero a gawo la dzenje ayenera kudulidwa mwadzina lalikulu kuti agwirizane ndi axis mankhwala.

Kukonza Zowonongeka

Zowonongeka zapamtunda zitha kuchotsedwa pogaya malinga ngati makulidwe ake ndi osachepera kutsika kovomerezeka komwe kumatchulidwa mu BS EN 10219-2 pambuyo pokonzanso.

Pazigawo za dzenje la tirigu, kukonza thupi ndi kuwotcherera sikuloledwa pokhapokha ngati atagwirizana.

Njira zokonzera weld ziyenera kutsata zofunikira za EN ISO 15607, EN ISO 15609-1, ndi EN ISO 15614-1.

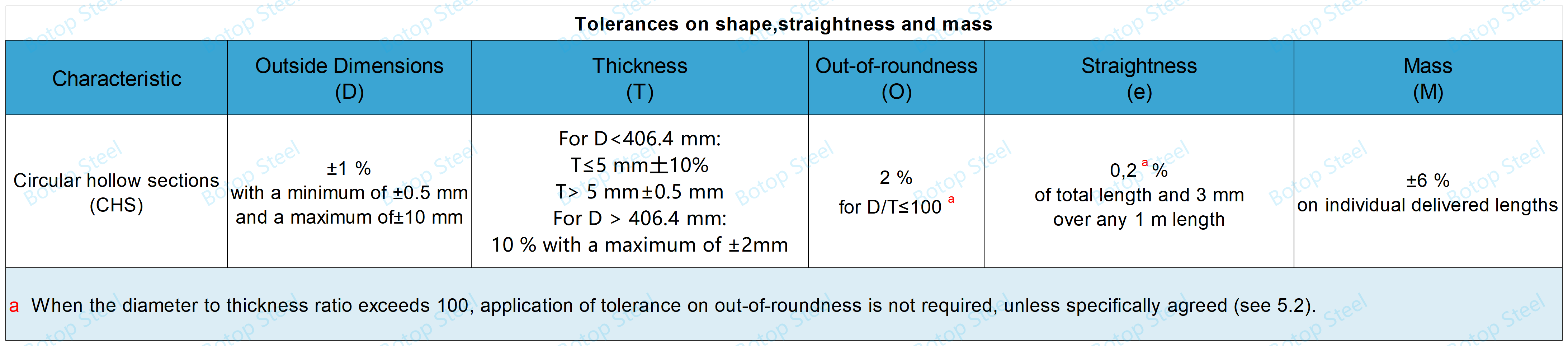

Dimensional Tolerances

Kulolera kwapang'onopang'ono kudzakhala molingana ndi zofunikira za EN 10219-2 ndipo chidwi chidzaperekedwa ku mawonekedwe a gawo la mtanda.

Kulekerera pa Mawonekedwe, Kuwongoka ndi Misa

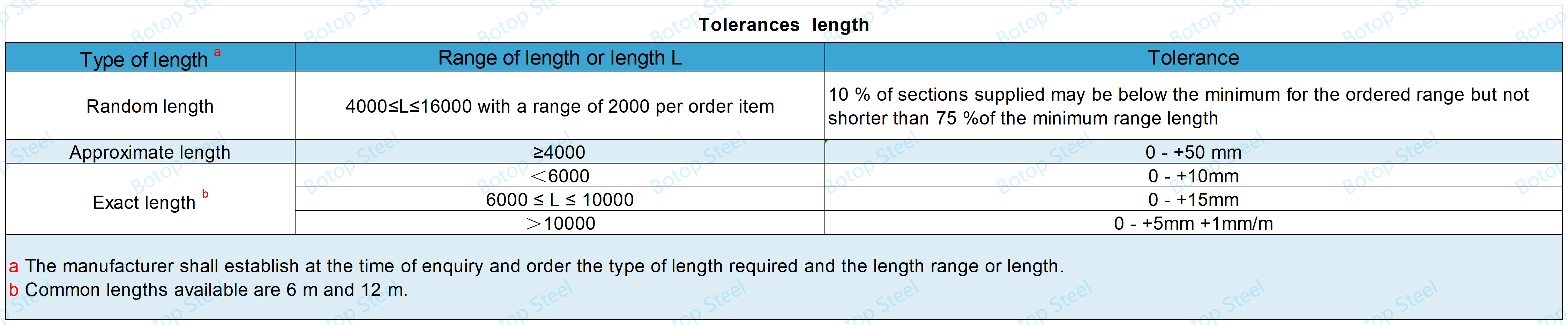

Kulekerera Utali

Seam Kutalika kwa SAW Weld

Kulekerera pa kutalika kwa mkati ndi kunja weld msoko kwa kumizidwa Arc welded dzenje zigawo.

| Makulidwe, T | Kutalika kwakukulu kwa mikanda, mm |

| ≤14,2 | 3.5 |

| > 14,2 | 4.8 |

Zokhala ndi malata

TS EN 10219 Machubu a Hollow amatha kukhala ndi malata otentha kwa moyo wautali wautumiki.

Machubu obowo amawathiridwa mu bafa lomwe lili ndi zinc zosachepera 98% kuti apange malata.

Chizindikiro cha BS EN 10219

Zomwe zili muzitsulo zachitsulo ziyenera kukhala:

Dzina lachitsulo, mwachitsanzo EN 10219-S275J0H.

Dzina kapena chizindikiro cha wopanga.

Chizindikiritso, mwachitsanzo nambala ya oda.

TS EN 10219 machubu achitsulo amatha kuzindikirika ndi njira zingapo zowonetsetsa kuti zizindikirika mosavuta komanso kutsata, kaya ndi penti, masitampu, zomatira, kapena zolemba zina zowonjezera, zomwe zitha kugwiritsidwa ntchito payekhapayekha kapena kuphatikiza.

Mapulogalamu

Kugwiritsiridwa ntchito kwa muyezo wa BS EN 0219 kumakhudza mbali zonse zofunika pakupanga zitsulo.

Zomangamanga:TS EN 10219 mapaipi achitsulo amagwiritsidwa ntchito kwambiri pantchito yomanga, monga kumanga milatho, chithandizo chanyumba, ndi zina zambiri.

Kumanga zomangamanga: amagwiritsidwa ntchito m'mapulojekiti osungira madzi, kumanga misewu, mapaipi, ndi ntchito zina zomanga zomangamanga, monga mipope ya ngalande, mapaipi amadzi, ndi zina zotero.

Kupanga: Mapaipi achitsulowa amagwiritsidwanso ntchito popanga zida zamakina, makina otumizira, ndi ntchito zina zamafakitale.

Municipal engineering: Mu engineering yama tauni yamatauni, mapaipi achitsulo a BS EN 10219 atha kugwiritsidwa ntchito kupanga zotchingira, njanji, zotchinga misewu, ndi zina zotero.

Zokongoletsera zomangamanga: Mapangidwe okongoletsera ndi mphamvu zamachubu achitsulo amawapanga kukhala zinthu zomwe zimagwiritsidwa ntchito pokongoletsa zomangamanga, monga masitepe, ma balustrade, mabatani okongoletsera, ndi zina zotero.

Chiyambireni kukhazikitsidwa mu 2014, Botop Steel yakhala chitoliro chotsogola cha carbon steel ku Northern China, chomwe chimadziwika ndi ntchito zake zabwino kwambiri, zinthu zamtengo wapatali, komanso mayankho athunthu. Zogulitsa zamakampani zimaphatikizansopoopanda msoko, mapaipi achitsulo a ERW, LSAW, ndi SSAW, komanso zopangira mapaipi, ma flanges, ndi zitsulo zapadera.

Ndi kudzipereka kwakukulu ku khalidwe, Botop Steel imagwiritsa ntchito maulamuliro okhwima ndi mayesero kuti atsimikizire kudalirika kwa zinthu zake. Gulu lake lodziwa zambiri limapereka mayankho aumwini ndi chithandizo cha akatswiri, ndikuyang'ana kukhutira kwamakasitomala.

Tags: bs en 10219, en 10219, chs, cfchs, s355j0h, s275j0h.

Nthawi yotumiza: Apr-26-2024