API 5L X70 ndi API 5L zakuthupi kalasi kwa mzere chitoliro ndi osachepera zokolola mphamvu 70,000 psi.Amagwiritsidwa ntchito kwambiri poyendetsa gasi, mafuta, ndi madzi.

Kuti mudziwe zambiri za API 5L-46th, muthaDinani apa!

Zinthu za API 5L X70

Mphamvu zokolola zambiri: Mphamvu zochepa zokolola za 70,000 psi (pafupifupi 485 MPa), zoyenera kupanikizika kwambiri mkati.

Kulimba kwabwino: kumasunga magwiridwe antchito pamatenthedwe otsika kumadera ozizira komanso kunyanja yakuzama.

Kuwotcherera kwabwino kwambiri: Mphamvu yayikulu ndikusunga kutenthetsa bwino, ndi ma welds ofanana ndi zitsulo zoyambira.

Kulimbana ndi dzimbiri: kutha kupitilizidwa ndi kuwongolera kapangidwe ka mankhwala ndi kuchiritsa pambuyo pake (monga zokutira), zoyenera kumadera akunyanja ndi kuwononga.

Kukwanira kwa chilengedwe: Itha kupangidwa kuti igwiritsidwe ntchito pamtunda wanthawi zonse, m'mphepete mwa nyanja, komanso m'malo a acid.

Kusasunthika: Kuchepetsa kuwononga chilengedwe komanso kupititsa patsogolo kufalitsa kachilomboka ngati chinthu chobwezerezedwanso.

API 5L X70 Magulu

Mtundu wa Chitoliro: Chitoliro chachitsulo chowotcherera komanso chosasunthika

Gawo lazogulitsa: API 5L X70 PSL1 ndi API 5L X70 PSL2

Kupanga mapaipi: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

Mtundu wotsiriza wa chitoliro: Mapeto a belu, Mapeto osavuta

Zida zogwiritsira ntchito

Ingots, billets, billets, strips (coils), kapena mbale monga zopangira popanga mapaipi achitsulo.

Zopangira za PSL2 zitsulo chitoliro zidzakhala zabwino-mbewu sedimented zitsulo.

Kuphatikiza apo, chingwe chachitsulo (koyilo) kapena mbale yomwe imagwiritsidwa ntchito popanga chitoliro chachitsulo cha PSL2 sichikhala ndi ma welds aliwonse.

API 5L X70 Pipe Manufacturing Process

| Mtundu wa Chitoliro | SMLS | LFW | Mtengo wa HFW | LW | Mtengo wa SAWLc | SAWHd | NKHANIc | Mtengo wa COWHd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | - | X | - | X | X | X | X |

cChitoliro chamsoko wapawiri chimapezeka ngati chikugwirizana, koma chitoliro chochepa ndi D ≥ 914 mm.

dChitoliro chamsokonezo cha helical chimakhala ndi chitoliro chokhala ndi D ≥ 114.3 mm.

Mitundu Yotsiriza ya Pipe ya API 5L X70

| Pipe End | Belled mapetoe | Mapeto osavuta |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | - | X |

eBelled-mapeto chitoliro ndi malire chitoliro ndi D ≤219.1 mm ndi t≤ 3.6 mm.

Mkhalidwe Womaliza Wopereka

API 5L X70 yomaliza yobereka boma (chomaliza kutentha mankhwala omalizidwa zitsulo chitoliro) akhoza kugawidwa mu: kugudubuza, normalizing kugudubuza, thermo-makina kugudubuza, thermo-makina kupanga, normalizing kupanga, normalizing, normalizing ndi tempering kapena quenching ndi kutentha.

| PSL | Mkhalidwe Wotumizira | Gulu la Pipe / Steel Giredi | |

| PSL1 | Monga-adagulung'undisa, normalizing adagulung'undisa, thermomechanical atagulung'undisa, thermomechanical kupangika, kukhazikika kupangidwa, kukhazikika, kukhazikika komanso kupsya mtima kapena kuzimitsidwa ndi kupsya mtima | X70 | L485 |

| Chithunzi cha PSL2 | Kuzimitsidwa ndi kupsya mtima | X70Q | L485Q |

| Thermomechanical adagulung'undisa kapena thermomechanical anapanga | X70M | L485M | |

Maiko operekera awa amawonetsetsa kuti machubu a API 5L X70 amagwira bwino ntchito zosiyanasiyana, monga kugwiritsidwa ntchito m'malo opanikizika kwambiri, otsika kwambiri, kapena owononga.

Chemical Composition

API 5L X70 PSL1 Chemical Composition

Chitoliro chachitsulo cha API 5L X70 PSL1 chimaphatikizapo mpweya wochepa, manganese ochepa, ndi phosphorous, sulfure, ndi silicon.Kuphatikiza apo, zinthu zophatikizira monga chromium, faifi tambala ndi mkuwa zimawonjezeredwa kuti ziwonjezere mphamvu komanso kukana dzimbiri.Ma Micro-alloying monga vanadium, molybdenum ndi titaniyamu amakulitsa kulimba komanso zokolola, ndikuwonetsetsa kuti magwiridwe antchito akuyenda bwino m'malo ovuta.

| Mapangidwe a Chemical a PSL 1 Pipe yokhala ndi t≤25.0 mm (0.984 in.) | |||||||||

| Kalasi yachitsulo (Dzina lachitsulo) | Misa Fraction, Kutengera Kutentha ndi Kuwunika Kwazinthuag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | min | max | max | max | max | max | ||

| Chitoliro Chopanda Msoko | |||||||||

| L485 | X70 | 0.28 | 1.40 | - | 0.03 | 0.03 | f | f | f |

| Welded Chitoliro | |||||||||

| L485 | X70 | 0.26e | 1.65e | - | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50%ndi Mo≤0.15%. b Pakuchepetsa kulikonse kwa 0,01 % pansi pa ndende yodziwika bwino ya kaboni, kuwonjezeka kwa 0.05% pamwamba pa ndende yodziwika bwino ya Mn ndiyololedwa, mpaka 1.65% pamlingo wopitilira ≥L245 kapena B, koma ≤L360 kapena X52;mpaka pazipita 1.75 % kwa magiredi> L360 kapena X52, koma ndi kufika pa 2.00 % pa Giredi L485 kapena X70. e Pokhapokha atagwirizana f Pokhapokha atagwirizana mwanjira ina, Nb+V+Ti≤0.15 %. g Palibe kuwonjezera dala kwa B ndikololedwa ndipo yotsalira B≤0.001%. | |||||||||

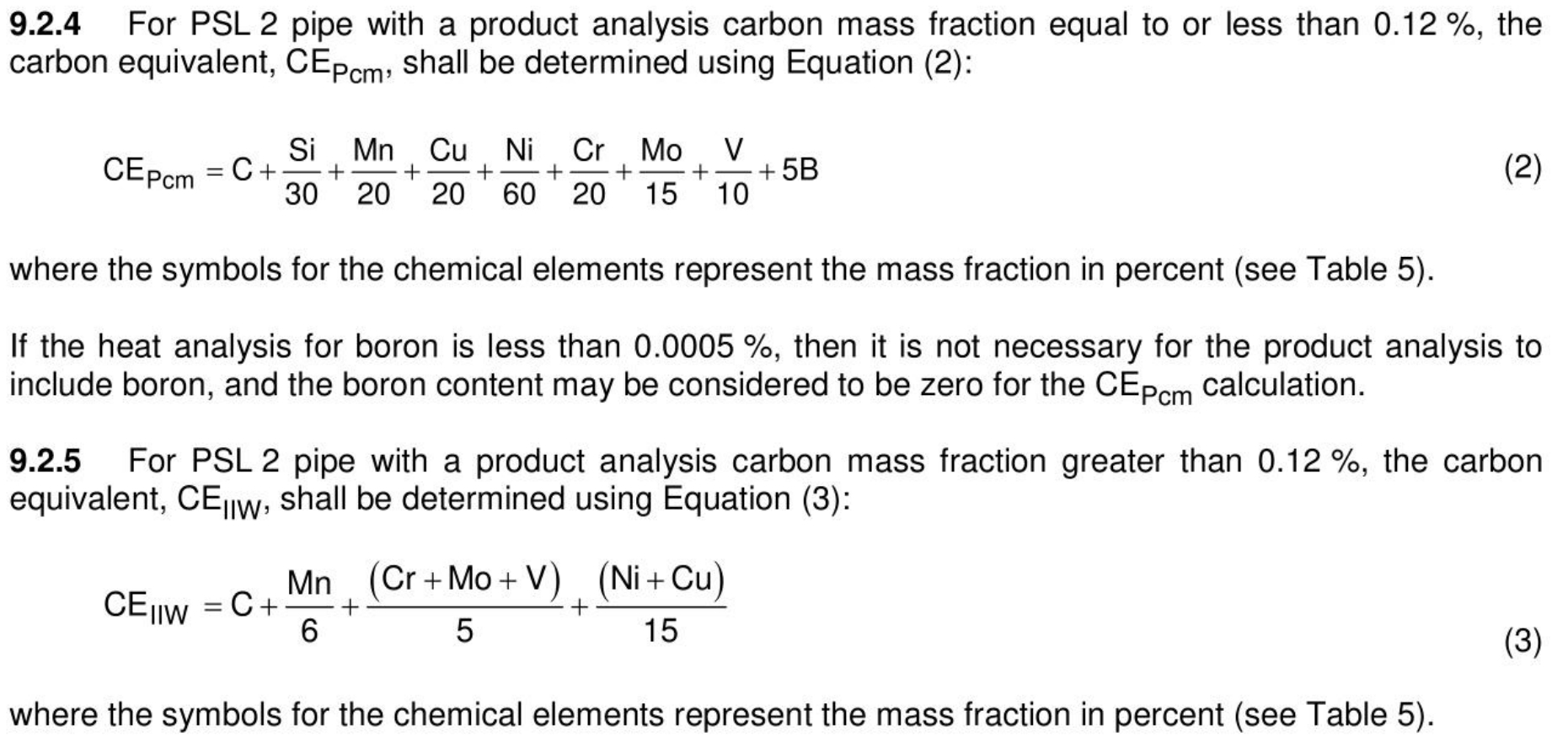

API 5L X70 PSL2 Chemical Composition

Kapangidwe kakemidwe ka API 5L X70 PSL2 kumaphatikizapo mpweya woyendetsedwa bwino, manganese, sulfure, ndi phosphorous, komanso kuchuluka kwa silicon, chromium, faifi tambala, ndi mkuwa.Kuwongolera kokhazikika kwazinthu sikumangowonjezera mphamvu zokolola komanso kulimba kwa chitoliro komanso kumathandizira kukana kwa dzimbiri pansi pamikhalidwe yovuta kwambiri.Kuphatikiza apo, kufufuza zinthu monga vanadium, molybdenum, ndi titaniyamu zasinthidwa kuti zipititse patsogolo magwiridwe antchito, ndikupangitsa X70 PSL2 kukhala yabwino kuthana ndi malo omwe ali pachiwopsezo chachikulu.

| Mapangidwe a Chemical a PSL 2 Pipe yokhala ndi t ≤ 25.0 mm (0.984 mu.) | ||||||||||||

| Kalasi yachitsulo (Dzina lachitsulo) | Misa Fraction, Kutengera Kutentha ndi Kuwunika Kwazinthu % max | Mpweya Zofananaa %max | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Zina | CEllw | CEpcm | ||

| Chitoliro Chopanda Msoko ndi Chowotcherera | ||||||||||||

| L485Q | X70Q | 0.18f | 0.45 f | 1.80f | 0.025 | 0.015 | g | g | g | h, ndi | 0.43 | 0.25 |

| Welded Chitoliro | ||||||||||||

| L485M | X70M | 0.12 f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h, ndi | 0.43 | |

| a Kutengera kusanthula kwazinthu, kwa chitoliro chopanda msoko chokhala ndi t>20.0 mm (0.787 in.), malire a CE azikhala monga momwe adavomerezera;malire a CEllw amagwira ntchito ngati C>0.12 %, ndipo malire a CEpcm akugwira ntchito ngati C≤0.12 %. b Pakuchepetsa kulikonse kwa 0.01% pansi pamlingo womwe wafotokozedwa wa C, chiwonjezeko cha 0.05% pamwamba pamlingo womwe waperekedwa kwa Mn wosaloledwa, mpaka 1.65% pamlingo wa giredi≥L245 kapena B, koma≤L360 kapena X52;mpaka 1.75% pamlingo wapamwamba> L360 kapena X52, komaL555 kapena X80. c Pokhapokha atagwirizana mwanjira ina, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Pokhapokha atagwirizana mwanjira ina, Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 %ndi Mo≤0.15 %. f Pokhapokha atagwirizana. g Pokhapokha atagwirizana mwanjira ina, Nb+V+Ti≤0.15 %. h Pokhapokha ngati atagwirizana mwanjira ina, Cu≤0.50%;Ni≤0.50%;Cr≤0.50%ndi Mo≤0.50%. i Pokhapokha atagwirizana mwanjira ina, Cu≤0.50 %;Ni≤1.00%;Cr≤0.50%ndi Mo≤0.50%. j B≤0.004 %. k Pokhapokha atagwirizana mwanjira ina, Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 %ndi Mo≤0.80 %. l Kwa magiredi a mapaipi a PSL 2 kupatula magiredi omwe mawu am'munsi j) akugwira kale ntchito, zotsatirazi zikugwira ntchito: pokhapokha ngati kuvomerezana kwina kowonjezera kwa B ndikololedwa ndi kutsalira B≤0.001 %. | ||||||||||||

Chemical Composition for Sour Service Conditions API 5L X70 PSL2

Mikhalidwe yautumiki wowawasa imatchula makamaka kugwiritsa ntchito mapaipi m'malo okhala ndi hydrogen sulfide (H₂S), zomwe zimatha kupangitsa kuti hydrogen sulfide stress corrosion cracking (HIC) ndi sulfide stress corrosion cracking (SSCC).

Kusintha kwa mankhwala: Pazifukwa izi, kapangidwe kake kazitsulo ka mapaipi amayenera kusinthidwa moyenera kuti azitha kudwala.Nthawi zambiri, izi zikuphatikizapo kuchepetsa mpweya wa zinthu ndi kuwonjezera zinthu alloying monga molybdenum (Mo) ndi faifi tambala (Ni), zomwe zimawonjezera kukana dzimbiri ndi kuuma kwa zinthu.

| Table H.1—Mapangidwe Amankhwala a Chitoliro ndi t≤25.0 mm (0.984 in.) | |||||||||||

| Kalasi yachitsulo | Chigawo Chachikulu Chotengera Kutentha ndi Kuwunika Kwazinthu% max | Mpweya Zofananaa % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Zinac,d | CEllw | CEpcm | |

| SMLS ndi Welded Pipe | |||||||||||

| L485QS kapena X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.003e | 0.09 | 0.05 | 0.06 | g, ine, k | 0.42 | 0.22h |

| Welded Chitoliro | |||||||||||

| L485MS kapena X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002e | 0.10 | 0.08 | 0.06 | g, ine,j | - | 0.22 |

Zambiri zitha kupezeka mu API 5L Appendix H.

Chemical Composition of API 5L X70 PSL2 for Offshore Service Conditions

Ntchito zam'mphepete mwa nyanja zimaphatikizapo malo am'madzi, kuphatikiza madzi amchere komanso nyengo yoipa.Izi zimafuna mapaipi okhala ndi dzimbiri komanso kulimba kokwanira kuti asachite dzimbiri ndi madzi amchere komanso kutentha kochepa.

Kusintha kwa kapangidwe ka mankhwala: Pantchito yakunyanja, aloyi ya chitoliro nthawi zambiri imachulukitsidwa mu chromium (Cr), faifi tambala (Ni) ndi molybdenum (Mo) kuti ipititse patsogolo kukana kwa madzi a m'nyanja.Kuchuluka kwa ma micro-alloying element monga vanadium (V) ndi niobium (Nb) kungasinthidwenso kuti kukhale kolimba pakutentha kotsika.

| Table J.1—Mapangidwe Amankhwala a Chitoliro chokhala ndi t≤25.0 mm (0.984 in.) | ||||||||||||

| Kalasi yachitsulo | Chigawo Chachikulu Chotengera Kutentha ndi Kuwunika Kwazinthu max % | Mpweya Equivalenta max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Zinac | CEllw | CEPcm | ||

| SMLS ndi Welded Pipe | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | ndi, h | 0.42 | 0.23g |

| Welded Chitoliro | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | ndi, h | - | 0.22 |

Zambiri zitha kupezeka mu API 5L Appendix J.

Komanso, mankhwala zikuchokera zitsulo chitoliro zikhalidwe ntchito offshore mu API 5L X70 PSL2 ndi chimodzimodzi ndi zofunika chitoliro ntchito amafuna kotalika pulasitiki kupsyinjika.Maphwando omwe ali ndi chidwi atha kuyang'ana API 5L Zowonjezera N.

Mechanical Properties

API 5L X70 PSL1 Mechanical Properties

| Table 6-Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 1 Pipe | ||||

| Gulu la Pipe | Chitoliro cha Chitoliro cha Chitoliro Chopanda Msoko ndi Chowotcherera | Weld Seam ya EW, LW, SAW, ndi COW Pipe | ||

| Zokolola Mphamvua Rku.5 MPa (psi) | Kulimba kwamakokedwea Rm MPa (psi) | Elongation (pa 50 mm kapena 2 in.) Af % | Kulimba kwamakokedweb Rm MPa (psi) | |

| min | min | min | min | |

| L485 kapena X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

Zosintha zenizeni zitha kuwonedwa mu API 5L Table 6.

API 5L X70 PSL2 makina katundu

Machubu a PSL2 ogwiritsira ntchito mwapadera amasinthidwa makamaka kuti akhale ndi mankhwala, koma zofunikira zamakina ndizofanana.

| Gulu 7-Zofunikira pa Zotsatira za Mayeso a Tensile a PSL 2 Pipe | |||||||

| Gulu la Pipe | Chitoliro cha Chitoliro cha Chitoliro Chopanda Msoko ndi Chowotcherera | Weld Seam pa HFW SAW ndi Mtengo wa CoW | |||||

| Zokolola Mphamvua Rku.5 MPa (psi) | Kulimba kwamakokedwea Rm MPa (psi) | Chiŵerengeroac Rt0.5/Rm | Elongation (pa 50 mm kapena 2 mu.) Af % | Tensile Mphamvud Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L485Q kapena X70Q L485M kapena X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

Zosintha zenizeni zitha kuwonedwa mu API 5L Table 7.

Njira Zoyesera

| Gulu Loyesa | Njira Yoyesera |

| Chemical Composition | ISO 9769 kapena ASTM A751 |

| Mechanical Properties | ISO 6892-1 kapena ASTM A370 |

| Kuyesedwa kwa Hydrostatic | API 5L 10.2.6 |

| Mayeso Osawononga | API 5L Zowonjezera E |

| Kupinda Mayeso | ISO 8491 kapena ASTM A370 |

| Kuwongolera Bend Test | ISO 5173 kapena ASTM A370 |

| Mayeso a Flattening | ISO 8492 kapena ASTM A370 |

| CVN Impact Test (PLS2) | Chithunzi cha ASTM A370 |

| Mayeso a DWT(PSL2) | API 5L3 |

Mapulogalamu a API 5L X70

Mapaipi amafuta: amagwiritsidwa ntchito ponyamula mafuta osapsa kapena zinthu zoyengedwa bwino, makamaka poyenda mtunda wautali kudutsa madera kapena pansi pamadzi.

Mapaipi a gasi: kusonkhanitsa ndi kugawa gasi wachilengedwe, kuphatikiza zoyendera mtunda wautali komanso malo opanikizika kwambiri.

Ntchito zamapangidwe: Chitoliro chachitsulo cha API 5L X70 chimagwiritsidwanso ntchito pama projekiti apadera monga nsanja zakunyanja kapena zida zothandizira mwamphamvu kwambiri.

Ntchito zamafakitale: Njira zoyendera zamadzimadzi m'mafakitale amankhwala, zoyenga, ndi zina.

Malo ogwiritsira ntchito mwapadera: Kukana kwa dzimbiri kwa API 5L X70 chitoliro chachitsulo kumapangitsa kuti ikhale yoyenera kugwiritsidwa ntchito m'malo osiyanasiyana apadera, makamaka m'malo owononga acidic komanso akunyanja.

Zathu Zogwirizana

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Chitoliro Chachitsulo cha Carbon

Pipe End Processing

Kudula chitoliro

Anti- dzimbiri zokutira: kanasonkhezereka, utoto, 3PE, FBE, etc.

Ndife mmodzi wa kutsogolera welded mpweya zitsulo chitoliro ndi zitsulo opanga msokonezo chitoliro ndi ogulitsa ku China, ndi osiyanasiyana apamwamba zitsulo chitoliro katundu, ife tadzipereka kukupatsani uthunthu wa mayankho chitoliro zitsulo.Kuti mudziwe zambiri za mankhwala, chonde omasuka kulankhula nafe, tikuyembekezera kukuthandizani kupeza bwino zitsulo chitoliro options pa zosowa zanu!

Tags: X70, API 5l x70, ai 5l, ogulitsa, opanga, mafakitale, ogulitsa, makampani, ogulitsa, kugula, mtengo, quotation, zambiri, zogulitsa, mtengo.

Nthawi yotumiza: Apr-14-2024