Chithunzi cha ASTM A672ndi chitoliro chachitsulo chopangidwa kuchokera ku mbale yamtengo wapatali,Electric-Fusion-Welded (EFW)kwa utumiki wothamanga kwambiri pa kutentha kwapakati.

Navigation Mabatani

ASTM A672 Gulu la Gulu

Gulu la ASTM A672

Kukula kwa ASTM A672

Kutetezedwa Kuwotcherera

Kutentha Chithandizo

Chemical Components

Tension Test

Mayeso a Transverse-Guided-Weld-Bend

Mayeso a Pressure

Mayeso a Radiographic

Kulekerera kwapang'onopang'ono kwa ASTM A672

Mawonekedwe a ASTM A672

Zowonongeka ndi Kukonza

Chizindikiro cha ASTM A672

Kugwiritsa ntchito chitoliro chachitsulo cha ASTM A672

Zathu Zogwirizana

ASTM A672 Gulu la Gulu

Amasankhidwa molingana ndi mtundu wa mbale yomwe imagwiritsidwa ntchito popanga machubu achitsulo.

Magulu osiyanasiyana amayimira mitundu yosiyanasiyana yamankhwala komanso makina amakina osiyanasiyana azovuta komanso kutentha.

| Gulu la Pipe | Mtundu wa Chitsulo | Chithunzi cha ASTM | |

| Ayi. | Gulu | ||

| A 45 | mpweya wa carbon | A285/A285M | A |

| A50 | mpweya wa carbon | A285/A285M | B |

| A 55 | mpweya wa carbon | A285/A285M | C |

| B60 ndi | plain carbon, kuphedwa | A515/A515M | 60 |

| b65 ndi | plain carbon, kuphedwa | A515/A515M | 65 |

| B70 ndi | plain carbon, kuphedwa | A515/A515M | 70 |

| ku c55 | mpweya wamba, wophedwa, njere zabwino | A516/A516M | 55 |

| C60 ndi | mpweya wamba, wophedwa, njere zabwino | A516/A516M | 60 |

| c65 ndi | mpweya wamba, wophedwa, njere zabwino | A516/A516M | 65 |

| ndi c70 | mpweya wamba, wophedwa, njere zabwino | A516/A516M | 70 |

| D 70 | manganese-silicon, normalized | A537/A537M | 1 |

| D 80 | manganese-silicon, Q&TA | A537/A537M | 2 |

| h75 ndi | manganese-molybdenum, yokhazikika | A302/A302M | A |

| h80 ndi | manganese-molybdenum, yokhazikika | A302/A302M | B, C, kapena D |

| j80 ndi | manganese-molybdenum, Q&TA | A533/A533M | Cl-1B |

| j90 ndi | manganese-molybdenum, Q&TA | A533/A533M | Cl-2B |

| j100 ndi | manganese-molybdenum, Q&TA | A533/A533M | Cl-3B |

| L 65 ndi | molybdenum | A204/A204M | A |

| L 70 | molybdenum | A204/A204M | B |

| L 75 ndi | molybdenum | A204/A204M | C |

| n 75 | silicon - manganese | A299/A299M | A |

AQ&T = kuzimitsidwa ndi kupsya mtima.

ВGulu lililonse litha kuperekedwa.

Tikhoza poyamba kudziwa mtundu wa chitoliro chachitsulo ndi zilembo mu kalasi.

Magiredi oyambira ndi zilembo A, B, ndi C nthawi zambiri amawonetsacarbon steel pipe.

Magiredi oyambira ndi zilembo D, H, J, L, ndi N akuwonetsaaloyi chitsulo chitoliro.

Gulu la ASTM A672

Machubu amagawidwa molingana ndi mtundu wa chithandizo cha kutentha chomwe amalandira panthawi yopangira komanso ngati akuwunikiridwa ndi radiographical ndikuyesedwa kukakamizidwa.

| Kalasi | Kutentha mankhwala pa chitoliro | Radiography, onani zolemba: | Pressure test, onani cholemba: |

| 10 | palibe | palibe | palibe |

| 11 | palibe | 9 | palibe |

| 12 | palibe | 9 | 8.3 |

| 13 | palibe | palibe | 8.3 |

| 20 | kupsinjika kumachepetsedwa, onani 5.3.1 | palibe | palibe |

| 21 | kupsinjika kumachepetsedwa, onani 5.3.1 | 9 | palibe |

| 22 | kupsinjika kumachepetsedwa, onani 5.3.1 | 9 | 8.3 |

| 23 | kupsinjika kumachepetsedwa, onani 5.3.1 | palibe | 8.3 |

| 30 | zokhazikika, onani 5.3.2 | palibe | palibe |

| 31 | zokhazikika, onani 5.3.2 | 9 | palibe |

| 32 | zokhazikika, onani 5.3.2 | 9 | 8.3 |

| 33 | zokhazikika, onani 5.3.2 | palibe | 8.3 |

| 40 | wokhazikika komanso wokwiya, onani 5.3.3 | palibe | palibe |

| 41 | wokhazikika komanso wokwiya, onani 5.3.3 | 9 | palibe |

| 42 | wokhazikika komanso wokwiya, onani 5.3.3 | 9 | 8.3 |

| 43 | wokhazikika komanso wokwiya, onani 5.3.3 | palibe | 8.3 |

| 50 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | palibe | palibe |

| 51 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | 9 | palibe |

| 52 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | 9 | 8.3 |

| 53 | kuzimitsidwa ndi kupsya mtima, onani 5.3.4 | palibe | 8.3 |

Chisamaliro chapadera chiyenera kuperekedwa kwa kutentha kwa utumiki kuyembekezera posankha kalasi yoyenera ya zinthu.Onani mafotokozedwe a ASTM A20/A20M.

Kukula kwa ASTM A672

Makulidwe ovomerezeka: DN≥400mm[16 mu] ndi WT≤75mm[3 mu].

Kwa miyeso ina ya chitoliro, ngati ikukwaniritsa zofunikira zina zonse zamtunduwu, ingagwiritsidwenso ntchito.

Kutetezedwa Kuwotcherera

Misomali iyenera kukhala yowotcherera pawiri, yolowera kwathunthu.

Ma welds amapangidwa pamanja kapena okha ndi njira yamagetsi yokhudzana ndi kuyika kwazitsulo zodzaza.

Ma welds akhoza kuyesedwa pogwiritsa ntchito ma radiography ndipo akuyenera kutsatira zomwe zili mu Gawo VII UW-51 la ASME Boiler and Pressure Vessel Code.

Kutalika kwa weld sikudutsa 3 mm [1/8 mu].

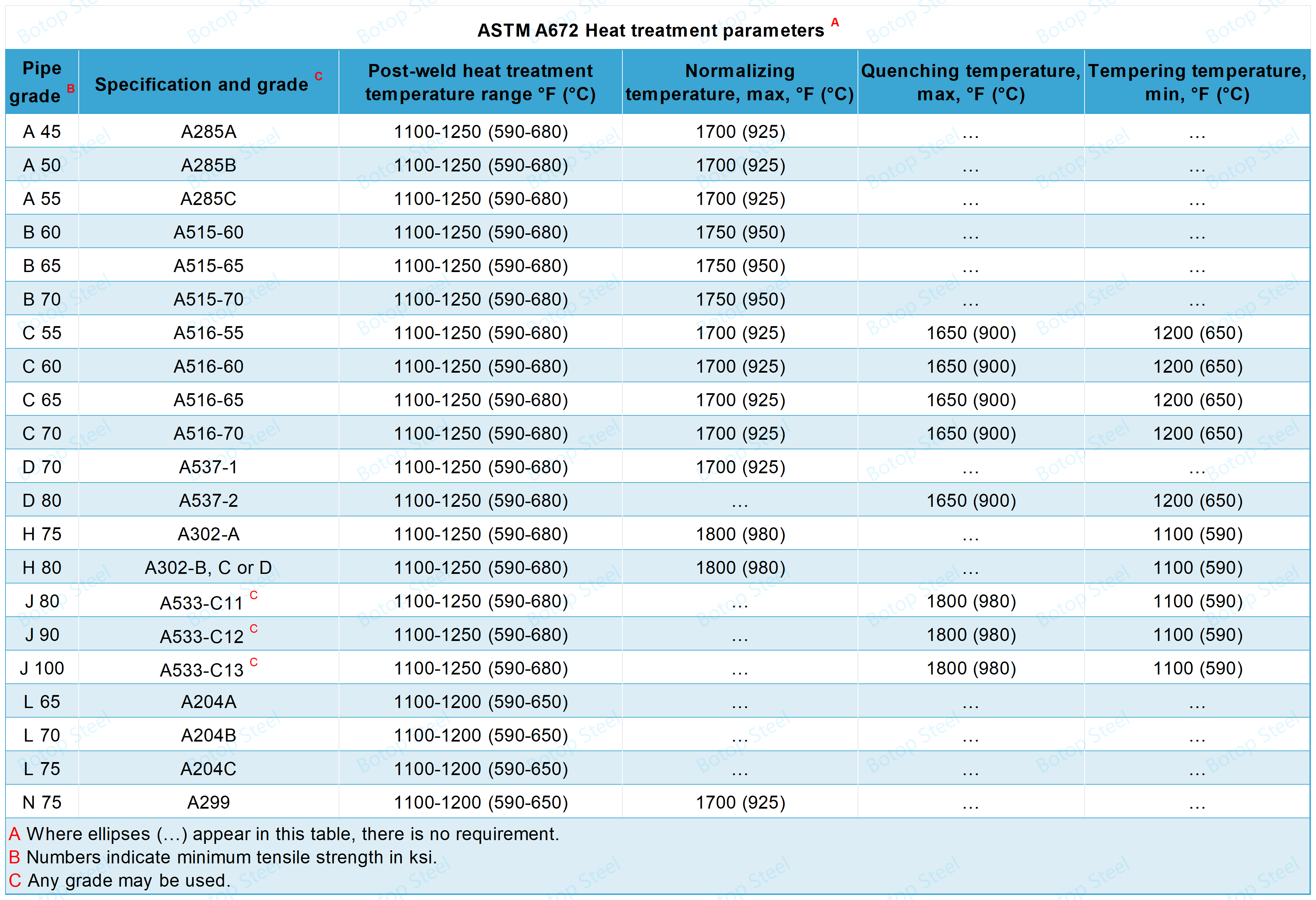

Kutentha Chithandizo

Makalasi onse kupatula 10, 11, 12, ndi13 azitenthedwa mu ng'anjo yoyendetsedwa mpaka ± 25 ° F [± 15 ° C]:

Makalasi 20, 21, 22, ndi 23

Chitolirocho chiyenera kutenthedwa mofanana mkati mwa kutentha kwa kutentha kwa pambuyo pa weld komwe kukuwonetsedwa mu Table 2 kwa osachepera 1 h / mu.Kukhuthala kwa [0.4 h/cm] kapena 1 h, kukulirapo ndi chiyani.

Makalasi 30, 31, 32, ndi 33

Chitolirocho chiyenera kutenthedwa mofanana ndi kutentha kwa austenitizing osiyanasiyana komanso osapitirira kutentha kwapamwamba komwe kumasonyezedwa mu Table 2 ndipo kenako kuzirala mumlengalenga kutentha kwa firiji.

Makalasi 40, 41, 42, ndi 43

Chitolirocho chiyenera kukhala chokhazikika.

Chitolirocho chiyenera kutenthedwanso ku kutentha komwe kwasonyezedwa mu Table 2 ngati kucheperako ndi kusungidwa pa kutentha kwa osachepera 0.5 h/in.[0.2 h/cm] wa makulidwe kapena kwa1/2h, chomwe chiri chachikulu, ndi choziziritsidwa ndi mpweya.

Makalasi 50, 51, 52, ndi 53

Chitolirocho chiyenera kutenthedwa mofanana ndi kutentha mkati mwa austenitizing osiyanasiyana ndipo osapitirira kutentha kwapamwamba kozimitsa komwe kukuwonetsedwa mu Table 2.

Pambuyo pake, tsitsani madzi kapena mafuta.Pambuyo pozimitsa, chitolirocho chiyenera kutenthedwanso mpaka kutentha kochepa komwe kukuwonetsedwa mu Table 2 ndikuchitidwa pamenepo.

Kutentha kwa kutentha kosachepera 0.5 h/inchi kukhuthala kwake kapena 0.5 h, kaya ndi yaikulu iti, ndi yoziziritsidwa ndi mpweya.

Chemical Components

Idzakhala udindo wa Mlengi kuyesa mankhwala zikuchokera mbale ndi welds kutsatira zofunika za mbale mfundo za zinthu analamula ndi ndondomeko kuwotcherera madipoziti zitsulo weld, motero.

Tension Test

Kuyesa pafupipafupi: chitsanzo chimodzi pagawo lililonse.

Njira Yoyesera: Zitsanzo zoyesera zidzapangidwa motsatira QW-150 mu Gawo IX la ASME Boiler ndi Pressure Vessel Code.Zitsanzo zidzayesedwa kutentha kwa chipinda molingana ndi Njira Zoyesera ndi Tanthauzo la A370.

Kuphatikiza pa Magiredi a Dxx, Hxx, Jxx, ndi Nxx mu Makalasi 3x, 4x, ndi 5x transverse tensile properties of the base plate, adzatsimikiziridwa pa zitsanzo zodulidwa kuchokera ku chitoliro chothira kutentha.

Zofunikira pazotsatira: Transverse amakokedwe katundu wa olowa welded adzakwaniritsa zofunika zochepa kuti mtheradi amakokedwe mphamvu ya zakuthupi mbale.

Mayeso a Transverse-Guided-Weld-Bend

Chiwerengero cha Mayesero: Mafupipafupi oyesera: kamodzi pa batch, zitsanzo ziwiri

Njira yoyesera: Zofunikira zoyesa za Njira Zoyesera ndi Tanthauzo A370, ndime A2.5.1.7 zidzakwaniritsidwa.

Kwa makulidwe a khoma pamwamba3/ 8mkati. [10 mm] koma kuchepera3/4mkati. [19 mm] Mayeso opindika mbali amatha kupangidwa m'malo moyesa nkhope ndi mizu.

Kwa makulidwe a khoma3/4mkati [mamilimita 19] ndi pamwamba pa zitsanzo zonse ziwirizi zidzayesedwa ku mbali yokhotakhota.

Zofunikira pazotsatira: Mayeso a bend adzakhala ovomerezeka ngati palibe ming'alu kapena zolakwika zina zopitirira1/8mkati [3 mm] mbali iliyonse alipo mu chitsulo chowotcherera kapena pakati pa weld ndi chitsulo m'munsi pambuyo kupinda.

Ming'alu yomwe imayambira m'mphepete mwa chitsanzo panthawi yoyesedwa, ndipo imakhala yochepa kuposa1/4mkati. [6 mm] kuyeza mbali iliyonse sikungaganizidwe.

Mayeso a Pressure

Makalasi X2 ndi X3 chitoliro adzayesedwa malinga Specification A530/A530M, Hydrostatic Test Requirements.

Mayeso a Radiographic

Kutalika konse kwa weld iliyonse ya Makalasi X1 ndi X2 kudzawunikidwa mozama motsatira ndikukwaniritsa zofunikira za ASME Boiler ndi Pressure Vessel Code, Gawo VIII, Ndime UW-51.

The radiographic kuyezetsa akhoza kuchitidwa pamaso kutentha mankhwala.

Kulekerera kwapang'onopang'ono kwa ASTM A672

| Masewera | Kulekerera Mtengo | Zindikirani |

| Kunja Diameter | ± 0.5% | Kutengera muyeso wozungulira |

| Kusazungulira | 1%. | Kusiyana pakati pa mainchesi akuluakulu ndi ang'onoang'ono akunja |

| Kuyanjanitsa | 1/8 mkati [3 mm] | Pogwiritsa ntchito nsonga yowongoka ya mamita atatu kuti mbali zonse zigwirizane ndi chitoliro |

| Makulidwe | 0.01 mkati [0.3 mm] | Kuchuluka kwa khoma kumachepera kuposa makulidwe otchulidwa mwadzina |

| Utali | 0-+0.5in [0-+13mm] | zopanda makina |

Mawonekedwe a ASTM A672

Chitoliro chomalizidwacho chizikhala chopanda zilema zovulaza ndipo chizikhala chomaliza ngati wantchito.

Zofunikira zomwezo monga mu ASTM A20/A20M pakumaliza kwa mbale zachitsulo.

Zowonongeka ndi Kukonza

Kutsimikiza Kwachilema

Muyezo wa ASTM A672 sunatchule milingo yovomerezeka ya zolakwika ndi njira zowunikira mapaipi ndipo nthawi zambiri zimatanthawuza miyezo yoyenera ya uinjiniya ndi machitidwe amakampani.

Zowonongeka zamkati: Zowonongeka zamkati zingaphatikizepo porosity, slag, inclusions, etc.

Zowonongeka zakunja: Zowonongeka zakunja zingaphatikizepo ming'alu, madontho, zokopa, ndi zina zotero.

Kuchotsa ndi Regrinding

Zowonongeka zapamtunda zitha kuchotsedwa pogaya mochulukira kapena kupanga makina ndi makulidwe otsalira osachepera 0.3 mm pansi pa makulidwe anthawi zonse.

Kupsinjika kwa regrind kuyenera kuphatikizidwa mofananamo pamalo ozungulira.

Kukonza Welding

Zowonongeka zidzachotsedwa ndi makina abwino kapena otenthetsera kudula kapena kuyika dicing ndikukonzekera kukonza mapanga otsekedwa.

ndikuwunikidwa molingana ndi ASME Boiler ndi Pressure Vessel Code, Gawo VIII, Ndime UW-51.

Kutalika konse kwa chitoliro chokonzedwa kumayenera kutenthedwa pambuyo pokonzedwa molingana ndi zofunikira za kalasi ya mapaipi.

Chizindikiro cha ASTM A672

Chizindikirocho chikhale ndi izi:

Chizindikiritso cha wopanga, monga chizindikiritso kapena logo.

Kufotokozera kwa chitoliro (kukula, makulidwe a khoma, etc.).

Gawo lazinthu kapena mtundu wa chitoliro.Chitsanzo: C60-22 (chidule cha kalasi: C60 ndi kalasi 22).

Muyezo wopangira chitoliro ndi ASTM A672.

Tsiku lopanga kapena nambala yopangira.

Kugwiritsa ntchito chitoliro chachitsulo cha ASTM A672

M'makampani amagetsi, ASTM A672 Electric Welded Steel Pipe imagwiritsidwa ntchito kwambiri popereka nthunzi m'ma boiler.

M'makampani opanga mankhwala, ASTM A672 welded zitsulo chitoliro nthawi zambiri amagwiritsidwa ntchito kunyamula mankhwala osiyanasiyana, asidi, ndi alkali solution, ndi media zina.

M'makampani amafuta ndi gasi, chitoliro chachitsulo cha ASTM A672 chimagwiritsidwa ntchito kunyamula mafuta osakhazikika, gasi, ndi zakumwa zina kapena mpweya.

Ndife apamwamba welded mpweya zitsulo chitoliro wopanga ndi katundu kuchokera China, komanso msokonezo zitsulo chitoliro stockist, kukupatsani osiyanasiyana zitsulo chitoliro njira!

Tags: ASTM a672, efw, mpweya zitsulo chitoliro, kalasi.

Nthawi yotumiza: Apr-23-2024