JIS G 3444: Imiyoboro ya karubone yuburyo rusange.

Iragaragaza ibisabwa ku miyoboro ya karubone ikoreshwa mu bwubatsi n’ubwubatsi, nkiminara yicyuma, scafolding, ibirundo fatizo, ibirundo fatizo, hamwe n’ibirundo birwanya kunyerera.

STK 400umuyoboro wibyuma nimwe murwego rusanzwe, hamwe nubukanishi bwa aimbaraga zingana zingana na 400 MPana aimbaraga nkeya zitanga umusaruro wa 235 MPa. Imbaraga zayo zubaka kandi zirambakora ibikwiye kubikorwa byinshi bitandukanye.

Ukurikije imbaraga ntarengwa zingutu zicyuma kigabanijwemo ibyiciro 5, aribyo:

STK 290, STK 400, STK 490, STK 500, STK 540.

Intego rusange Diameter yo hanze: 21.7-1016.0mm;

Ikirundo cyibirundo hamwe nibirundo byo guhagarika inkangu OD: munsi ya 318.5mm.

| Ikimenyetso cy'amanota | Ikimenyetso cyibikorwa byo gukora | |

| Uburyo bwo gukora imiyoboro | Uburyo bwo kurangiza | |

| STK 290 | Nta nkomyi: S. Kurwanya amashanyarazi gusudira: E. Butt yasuditswe: B. Arc yikora irasudira: A. | Bishyushye birangiye: H. Ubukonje burangiye: C. Nkuko kurwanya amashanyarazi byasudutse: G. |

| STK 400 | ||

| STK 490 | ||

| STK 500 | ||

| STK 540 | ||

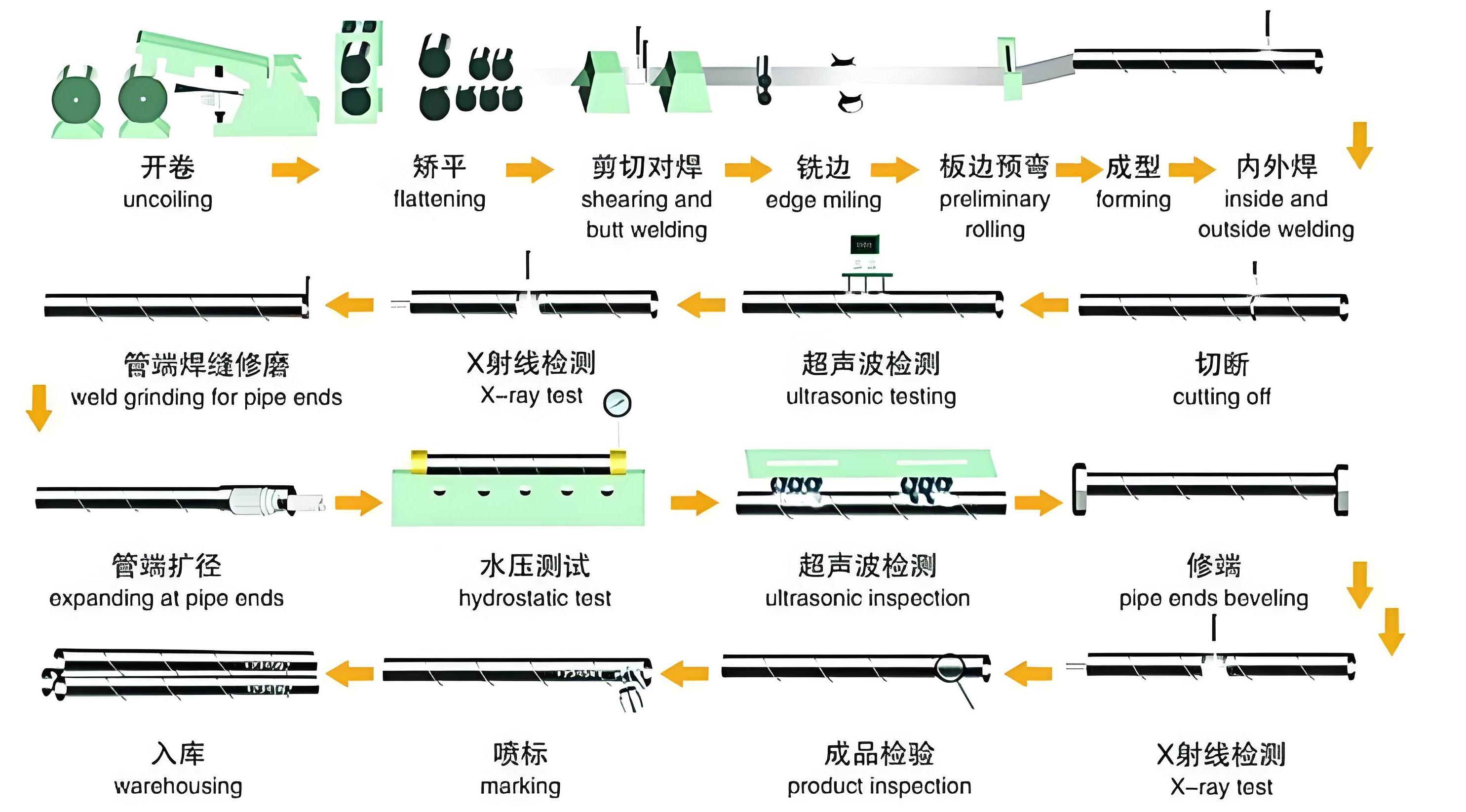

Imiyoboro igomba gukorwa hifashishijwe uburyo bwo gukora imiyoboro nuburyo bwo kurangiza bwerekanwe.

By'umwihariko, barashobora gushyirwa mubice birindwi bikurikira, bityo hitamo ubwoko bukwiranye nibikenewe bitandukanye:

1) Umuyoboro ushyushye urangije ibyuma: -SH

2) Icyuma gikonje cyuzuye cyuma kitagira ibyuma: -SC

3) Nkumuriro wamashanyarazi weld wicyuma: -EG

4) Amashanyarazi ashyushye arangije amashanyarazi asudira ibyuma: -EH

5) Gukonjesha gukonje kwamashanyarazi gusudira ibyuma: -EC

6) Umuyoboro w'icyuma usudira: -B

7) Automatic arc gusudira ibyuma: -A

| Ibigize imitia% | |||||

| Ikimenyetso cy'amanota | C (Carbone) | Si (Silicon) | Mn (Manganese) | P (Fosifore) | S (Amazi) |

| max | max | max | max | ||

| STK 400 | 0.25 | - | - | 0.040 | 0.040 |

| aIbikoresho bivanze bitashyizwe muri iyi mbonerahamwe nibintu byerekanwe na “-” birashobora kongerwaho nkuko bikenewe. | |||||

STK 400ni ibyuma bya karubone nkeya hamwe no gusudira neza no gukora kubikorwa byubaka bisaba gusudira. Fosifore na sulferi bigenzurwa kurwego rwo hasi kugirango bifashe kugumana ubukana muri rusange hamwe nakazi keza. Nubwo indangagaciro zihariye za silicon na manganese zitatanzwe, zirashobora guhindurwa mumipaka yemewe kugirango hongerwe imitungo yicyuma kurushaho.

Imbaraga za Tensile na Yield Point cyangwa Stress Stress

Imbaraga zingana za weld zikoreshwa muburyo bwikora arc welded tubes. Nibikorwa byo gusudira SAW.

| Ikimenyetso cy'amanota | Imbaraga | Tanga ingingo cyangwa ibimenyetso byerekana | Imbaraga zingana muri weld |

| N / mm² (MPA) | N / mm² (MPA) | N / mm² (MPA) | |

| min | min | min | |

| STK 400 | 400 | 235 | 400 |

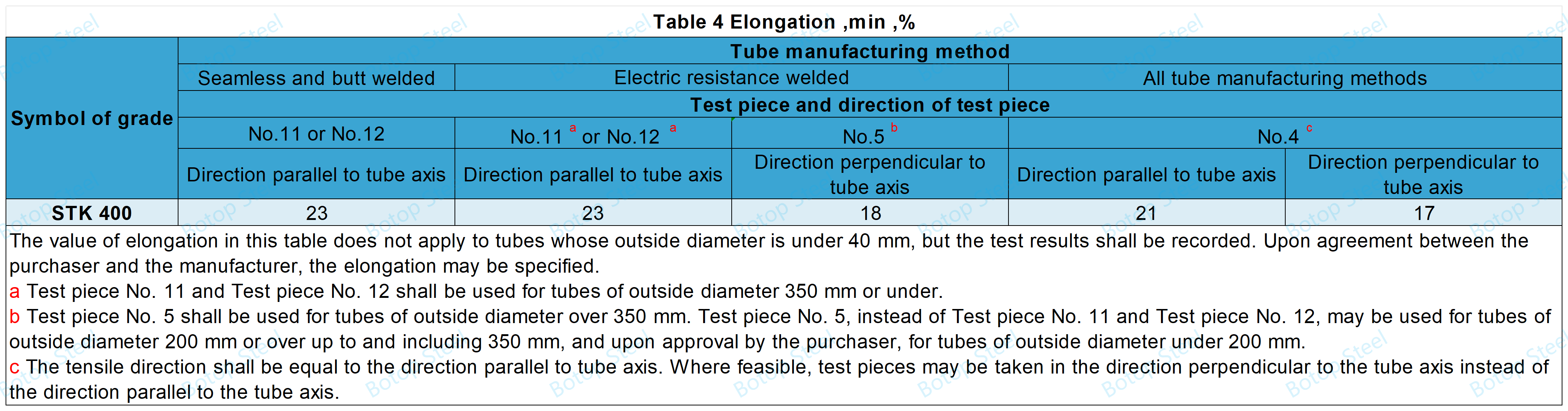

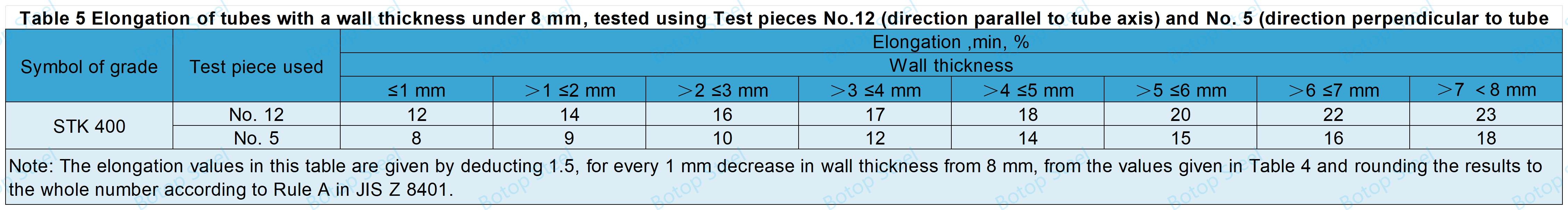

Kurambura JIS G 3444

Kurambura bijyanye nuburyo bwo gukora imiyoboro irerekanwa mu mbonerahamwe ya 4.

Ariko, mugihe ikizamini cya tensile gikozwe kuri Piece No 12 cyangwa Ikizamini No.5 cyavanywe mu muyoboro uri munsi ya mm 8 z'ubugari bw'urukuta, kuramba bigomba gukurikiza Imbonerahamwe 5.

Ku bushyuhe bwicyumba (5 ° C kugeza kuri 35 ° C), shyira icyitegererezo hagati yamasahani abiri aringaniye hanyuma ukande cyane kugirango ubitondekanye kugeza intera H ≤ 2 / 3D hagati yamasahani, hanyuma urebe niba hari ibice.

Ku bushyuhe bwicyumba (5 ° C kugeza 35 ° C), hinduranya urugero hafi ya silinderi byibuze inguni ya 90 ° hamwe na radiyo ntarengwa yimbere itarenze 6D hanyuma urebe icyitegererezo cyacitse.

Ibizamini bya Hydrostatike, ibizamini bidasenya gusudira, cyangwa ibindi bizamini bigomba kumvikana hakiri kare kubisabwa bijyanye.

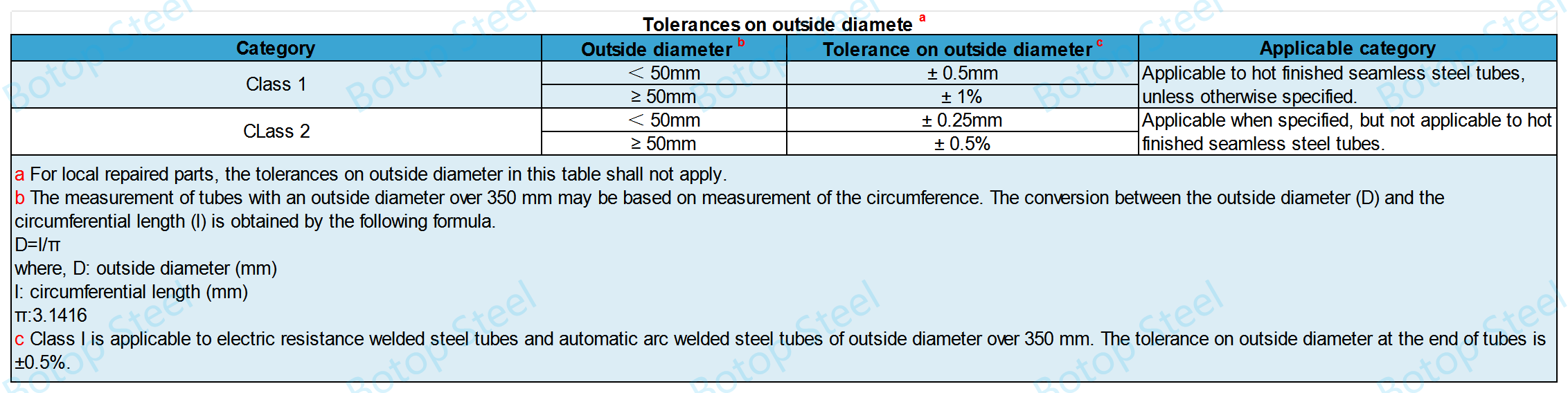

Hanze ya Diameter Tolerance

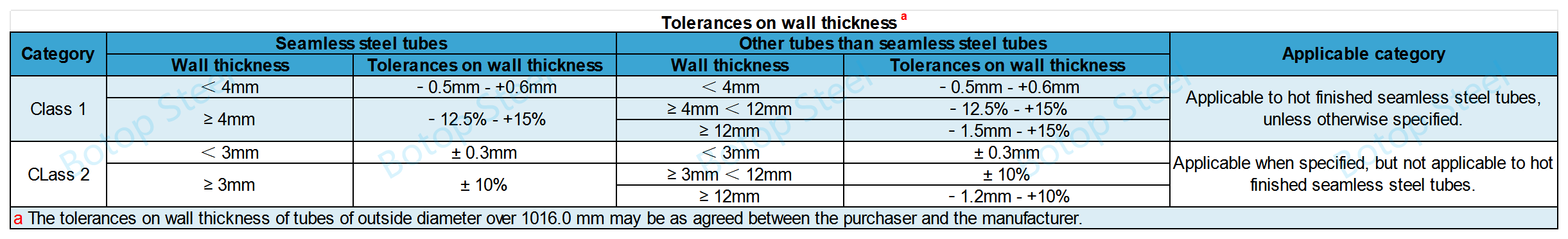

Ubworoherane bw'Urukuta

Ubworoherane

Uburebure ≥ uburebure bwerekanwe

Imbere ninyuma yumuringa wicyuma ugomba kuba woroshye kandi utarangwamo inenge zitabangamiye ues.

Buri muyoboro w'icyuma ugomba gushyirwaho amakuru akurikira.

a)Ikimenyetso cy'amanota.

b)Ikimenyetso cyuburyo bwo gukora.

c)Ibipimo.Diameter yo hanze n'ubugari bw'urukuta bizashyirwaho ikimenyetso.

d)Izina ryuwabikoze cyangwa amagambo ahinnye.

Iyo gushyira akamenyetso ku muyoboro bigoye kubera ko diameter yacyo yo hanze ari nto cyangwa iyo bisabwe n'abaguzi, ikimenyetso gishobora gutangwa kuri buri mugozi w'igituba hakoreshejwe uburyo bukwiye.

Kurwanya ruswa nka coat ikungahaye kuri zinc, epoxy coatings, irangi, nibindi birashobora gukoreshwa hejuru yimbere cyangwa imbere.

STK 400 itanga uburinganire bwiza bwimbaraga nubukungu, bigatuma biba byiza mumishinga myinshi yubwubatsi nubwubatsi.

STK 400 ibyuma bikoreshwa cyane mubikorwa byubwubatsi kandi birakwiriye cyane cyane gukoreshwa nkibintu byubatswe nkinkingi, ibiti, cyangwa amakadiri mumazu yubucuruzi nuburaro.

Irakwiriye kandi kubiraro, kubaka inkunga, nindi mishinga isaba imbaraga ziciriritse nigihe kirekire.

Irashobora kandi gukoreshwa mukubaka uburinzi bwumuhanda, amakarita yumuhanda, nibindi bigo rusange.

Mu nganda, STK 400 irashobora gukoreshwa mugukora amakadiri hamwe nuburyo bwo gushyigikira imashini nibikoresho bitewe nubushobozi bwiza bwo gutwara imizigo no gukora.

GB / T 3091: Q235B;

ASTM A500: Icyiciro A,Icyiciro B., naIcyiciro C.;

EN 10219: S235;

BS 4360: Icyiciro cya 43A;

Nyamuneka menya ko mugihe ibi bipimo bisa mubikorwa no mubikorwa, hashobora kubaho itandukaniro rito mubigize imiti yihariye hamwe nibikoresho bimwe na bimwe bya mashini.

Mugihe cyo gusimbuza ibikoresho, ibisabwa byihariye byibipimo bigomba kugereranwa muburyo burambuye kugirango ibikoresho byatoranijwe byujuje ubuziranenge bwa tekiniki n’umutekano byumushinga.

Kuva yashingwa mu 2014, Botop Steel yabaye iyambere mu gutanga imiyoboro ya karubone mu majyaruguru y’Ubushinwa, izwiho serivisi nziza, ibicuruzwa byiza, ndetse n’ibisubizo byuzuye.

Isosiyete itanga imiyoboro inyuranye y’ibyuma bya karubone n’ibicuruzwa bifitanye isano na byo, birimo icyuma, ERW, LSAW, hamwe n’icyuma cya SSAW, ndetse n’umurongo wuzuye w’ibikoresho bya flanges na flanges.

Ibicuruzwa byayo bidasanzwe birimo kandi amavuta yo mu rwego rwo hejuru hamwe na austenitis ibyuma bitagira umuyonga, bigenewe guhuza ibyifuzo byimishinga itandukanye.