API 5L Giredhi Bsimbi pombi inogadzirwa maererano nezvinodiwa zvinodiwa zveAPI 5Luye inoshandiswa zvakanyanya mumapombi ekufambisa masisitimu muindasitiri yemafuta negesi.

Giredhi Binogona zvakare kunziL245. Chimiro ndechokuti zvishoma goho simba pombi simbi iri245 MPa.

API 5L mutsetse pombi inowanikwa mune maviri chigadzirwa yakatarwa mamakisi:PSL1inonyanya kushandiswa mune yakajairwa masisitimu ekufambisa, nepoPSL2inokodzera mamiriro akanyanya kuomarara ane akakwira mechanic simba uye akanyanya kuomarara ekuyedza zviyero.

Iyo nzira yekugadzira inogona kuve isina musono (SMLS), electric resistance yakakandwa (ERW), kana arc yakanyungudutswa yakasungwa (SAW) kuti ienderane nekuisa kwakasiyana uye zvido zvekushandisa.

Botop Steelinyanzvi inogadzira gobvu-yakakomberedzwa hombe-dhayamita kaviri-mativi akanyura arc LSAW simbi pombi iri kuChina.

Nzvimbo: Guta reCangzhou, Ruwa rweHebei, China;

Total Investment: 500 mamiriyoni RMB;

Nzvimbo yefekitari: 60,000 square metres;

Gore negore simba rekugadzira: 200,000 matani eJCOE LSAW mapaipi esimbi;

Equipment: Advanced kugadzirwa uye kuedza michina;

Specialization: LSAW simbi pombi kugadzirwa;

Certification: API 5L yakasimbiswa.

API 5L Giredhi B Classification

Iyo yakakamurwa kuita akati wandei emhando dzakasiyana zvichienderana neakasiyana Chigadzirwa Specification Level (PSL) pamwe nemamiriro ekutumira.

Uku kupatsanurwa kunoita kuti kusarudzwa kwepiipi yemutsara wakakodzera kuve yakakosha kuzadzisa zvinodiwa zveimwe chirongwa uye zvinodiwa zvenzvimbo yekushanda.

PSL1: B.

PSL2: BR;BN;BQ;BM.

Anoverengeka akakosha PSL 2 simbi machubhu anoshandiswa kune yakakosha nharaunda yebasa.

Sour service environments: BNS; BQS; BMS.

Offshore service environment: BNO; BQO; BMO.

Zvikumbiro zvinoda longitudinal plastiki strain simba: BNP; BQP; BMP.

Delivery Conditions

| PSL | Delivery Condition | Pipe Grade/Simbi Giredhi | |

| PSL1 | Sezvo-yakakungurutswa, normalizing yakakungurutswa, thermomechanical yakakungurutswa, thermomechanical yakaumbwa, normalizing yakaumbwa, yakajairika, yakajairika uye yakatsamwa; kana, kanaakabvuma, kudzimwa uye hasha nokuda SMLS pombi chete | B | L245 |

| PSL 2 | As-akakungurutswa | BR | L245R |

| Normalizing akakungurutswa, normalizing kuumbwa, normalized, kana normalized uye kushatirwa | BN | L245N | |

| Kudzimwa uye kushatirwa | BQ | L245Q | |

| Thermomechanical yakakungurutswa kana thermomechanical yakaumbwa | BM | L245M | |

Mamiriro ekutakura epombi yesimbi anonyanya kureva kupisa kwekupisa kana mamwe marapirwo anoitwa pakupera kwekugadzirwa kwepombi yesimbi, uye marapirwo aya ane pesvedzero yakakosha pamichina yemagetsi, kushomeka kwemarara, uye kugadzikana kwechimiro chepombi yesimbi.

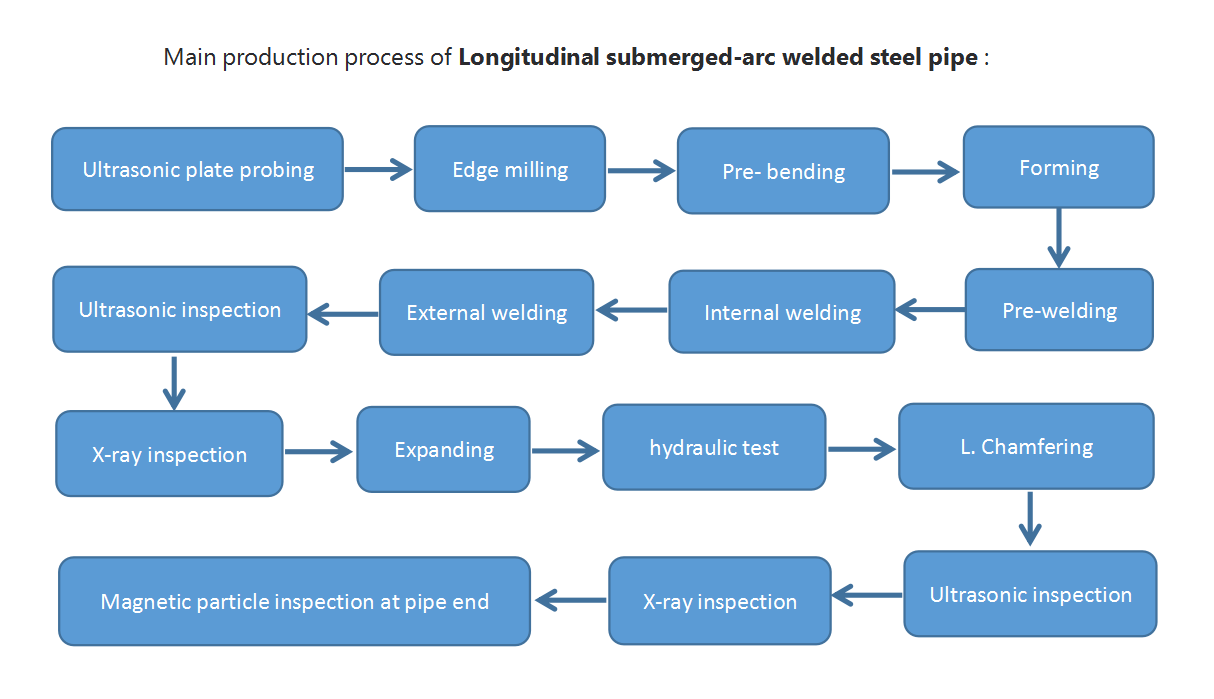

API 5L GR.B Steel Pipe Manufacturing Process

MuAPI 5L yakajairwa Giredhi B pombi inogona kugadzirwa uchishandisa imwe yemaitiro ekugadzira mune inotevera tafura.

| API 5L PSL1 Giredhi B | SMLS | LFW | HFW | SAWL | SAWH | COWL | COWH |

| API 5L PSL2 Giredhi B | SMLS | - | HFW | SAWL | SAWH | COWL | COWH |

Kuti uwane zvimwe nezve zvinoreva acronym Manufacturing process,tinya pano.

LSAWndiyo yakanyanya mhinduro yemapaipi makuru-diameter, makobvu-akavezwa nesimbi.

Chinhu chinosiyanisa chitarisiko ndiko kuvapo kweweld mune iyo longitudinal kutungamira kwepombi.

Pipe End Type

API 5L Giredhi B simbi pombi kupera marudzi anogona kusiyana muPSL1 uye PSL2.

PSL 1 Simbi Pipe End

Belled end; Plain end;Magumo akajeka ekubatanidza kwakakosha; Threaded end.

Belled end: Inogumira kumachubhu ane D ≤ 219.1 mm (8.625 mu) uye t ≤ 3.6 mm (0.141 mu) pamucheto wesokisi.

Magumo ane Threaded: Pombi ine shinda inogumira kuSMLS uye longitudinal seam welded pombi ine D <508 mm (20 mukati).

PSL 2 Steel Pipe End

Plain end.

Pakupera kwepombi inopera, zvinotevera zvinodiwa zvinofanirwa kuteverwa:

Kumagumo zviso zve t ≤ 3.2 mm (0.125 mu) plain end pombi inofanira kuchekwa.

Machubhu asina magumo ane t > 3.2 mm (0.125 mukati) anozoiswa beveled kuitira welding. Iyo bevel angle inofanira kuva 30-35 ° uye hupamhi hwemudzi wechiso chebevel inofanira kuva 0.8 - 2.4 mm (0.031 - 0.093 mukati).

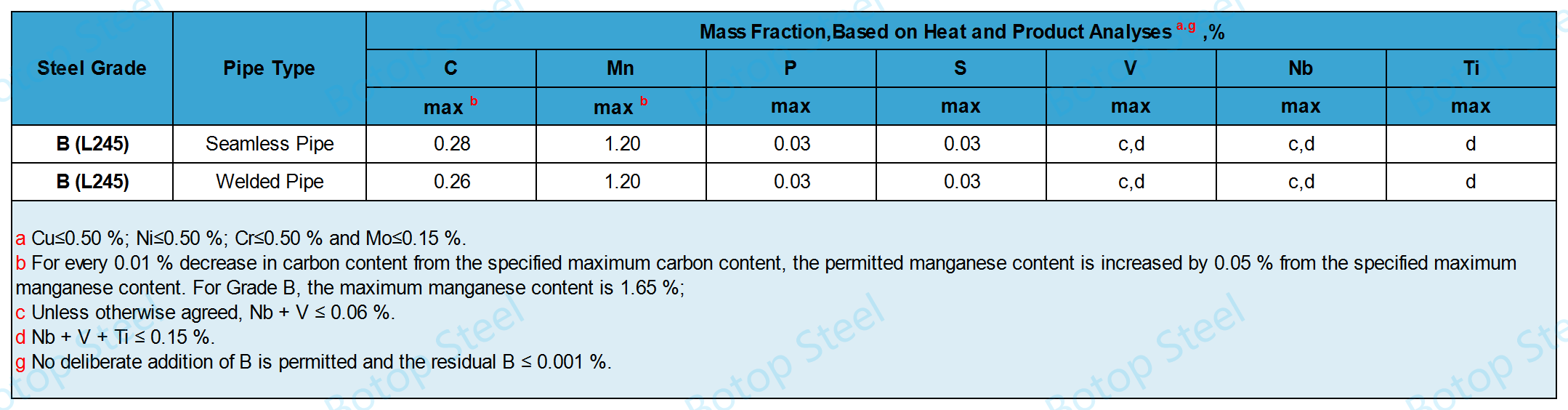

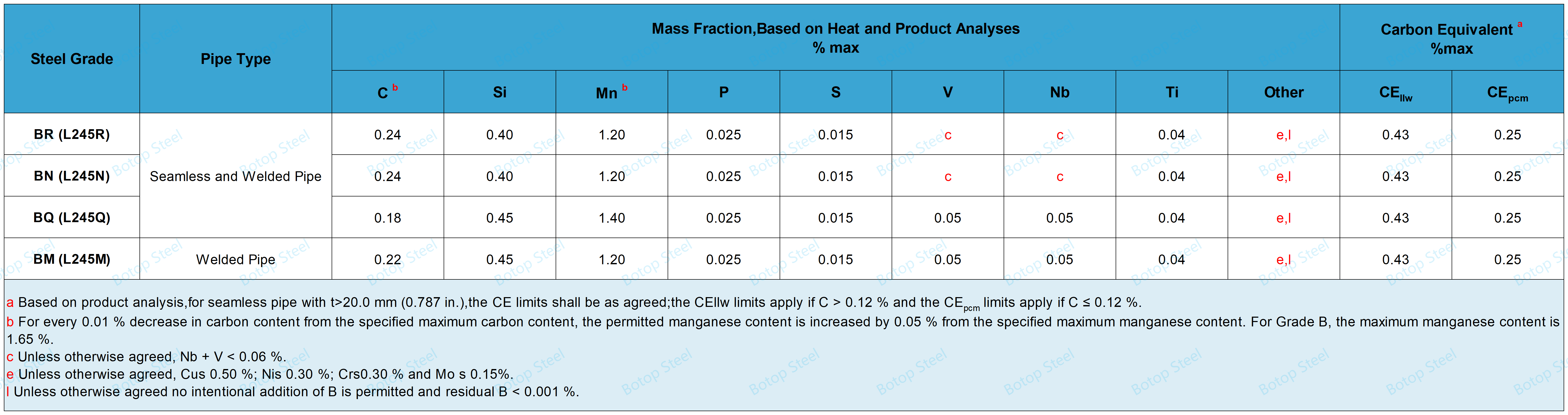

API 5L Giredhi B Chemical Kuumbwa

Mushonga wemakemikari wePSL1 uye PSL2 simbi pombi t > 25.0 mm (0.984 mu) ichagadziriswa nechibvumirano.

Kemikari Inoumbwa yePSL 1 Pipe ine t ≤ 25.0 mm (0.984 mukati.)

Kemikari Inoumbwa yePSL 2 Pipe ine t ≤ 25.0 mm (0.984 mukati.)

Ye PSL2 simbi pombi zvigadzirwa akaongororwa neKabhoni yemukati ye ≤0.12%, iyo kabhoni yakaenzana CEpcminogona kuverengerwa uchishandisa inotevera formula:

CEpcm= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

Ye PSL2 simbi pombi zvigadzirwa akaongororwa neKabhoni yemukati > 0.12%, iyo kabhoni yakaenzana CEllwinogona kuverengerwa uchishandisa formula iri pazasi:

CEllw= C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

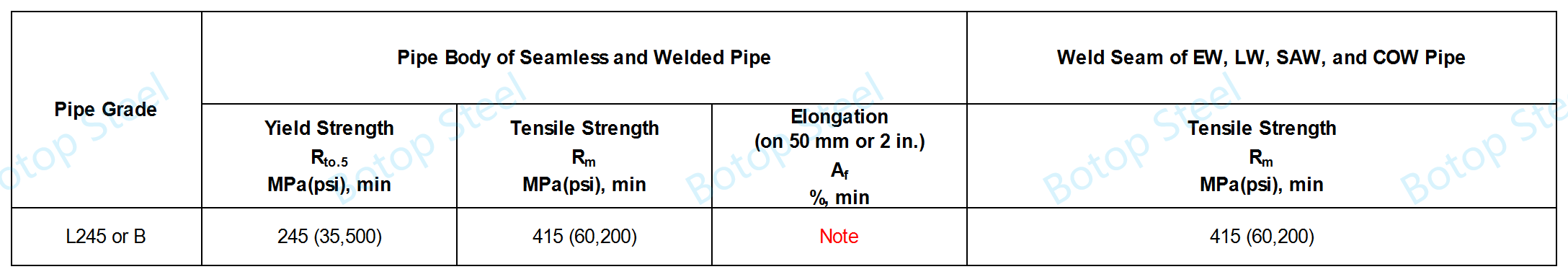

API 5L Giredhi B Mechanical Property

Tensile Property

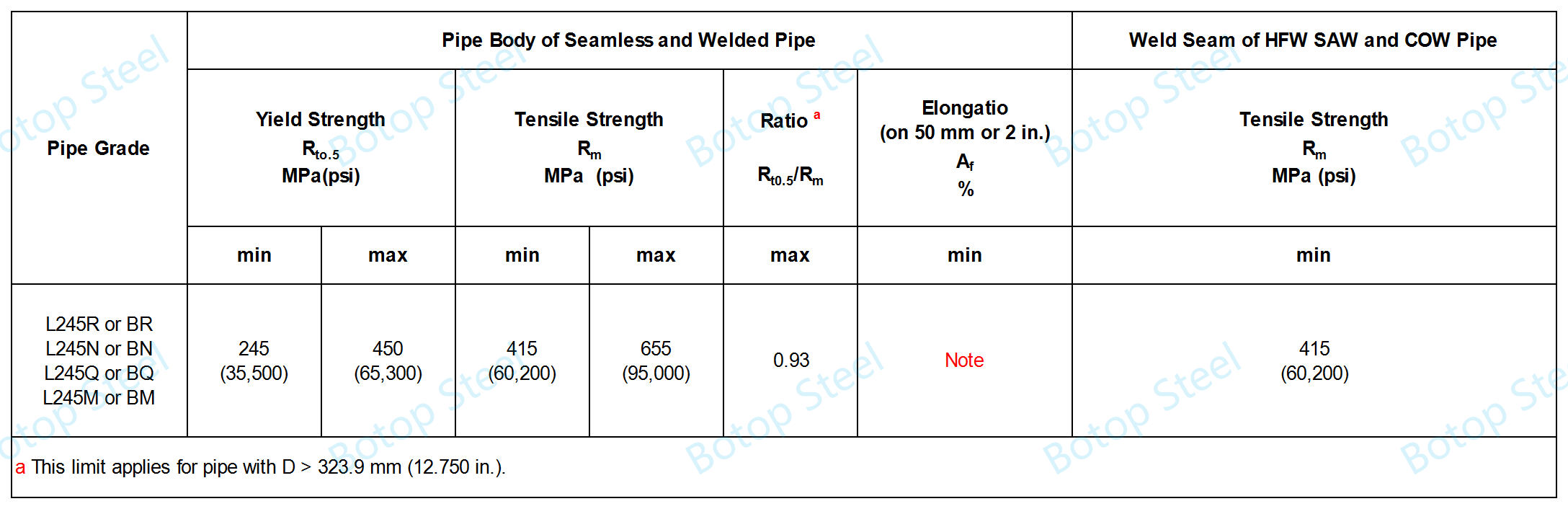

PSL1 GR.B Tensile Properties

PSL2 GR.B Tensile Properties

Cherechedza: Iyo yakatsanangurwa shoma elongation, Afichave sezvakatemwa uchishandisa inotevera equation:

Af= C × (Axc0.2/U0.9)

Cndeye 1940 yekuverenga uchishandisa SI units uye 625,000 pakuverenga uchishandisa USC mayunitsi;

Axc ndiyo inoshandiswa tensile test piece cross-sectional area, inoratidzwa mu square millimeters (square inches), sezvinotevera:

1) yedenderedzwa yemuchinjikwa-chikamu bvunzo zvidimbu, 130 mm2(0.20 mukati.2) ye 12.7 mm (0.500 in.) uye 8.9 mm (0.350 mukati) dhayamita bvunzo zvidimbu; 65 mm2(0.10 mukati.2) ye6.4 mm (0.250 in.) dhayamita bvunzo zvidimbu;

2) kune yakazara-chikamu bvunzo zvidimbu, zvishoma a) 485 mm2(0.75 mukati.2) uye b) nzvimbo yemuchinjikwa-chikamu chechidimbu chekuedza, T inotorwa uchishandisa iyo yakataurwa kunze kwedhayamita uye yakatsanangurwa madziro emadziro epombi, yakatenderedzwa kusvika padyo 10 mm.2(0.01 mukati.2);

3) yezvimedu zvebvunzo zvidimbu, zvishoma a) 485 mm2(0.75 mukati.2) uye b) nzvimbo yemuchinjikwa-chikamu chechidimbu chekuedza, inotorwa uchishandisa hupamhi hwakatarwa hwechidimbu chekuedza uye nehupamhi hwemadziro epombi, yakatenderedzwa kune iri pedyo 10 mm.2(0.01 mukati.2);

Undiyo yakataurwa shoma yekusimba simba, inoratidzwa mu megapascals (mapaundi per square inch).

Bend Test

Hapana chikamu chemuenzaniso chichatsemuka uye weld haizotsemuka.

Flattening Test

Hazvishande kune LSAW simbi pombi.

InokodzeraEW, LW,uyeCWkugadzira marudzi emachubhu.

Guided-bend Test

Ratidza chero makatsemuka kana kuputika mune weld simbi yakareba kupfuura 3.2 mm (0.125 mukati), zvisinei nekudzika.

Ratidza chero makatsemuka kana kutsemuka musimbi yemubereki, HAZ, kana mutsara wekusanganiswa wakareba kupfuura 3.2 mm (0.125 mukati) kana kudzika kupfuura 12.5 % yehukobvu hwataurwa.

CVN Impact Muedzo wePSL 2 Pipe

CVN (Charpy V-Notch) Impact bvunzo, yakajairwa bvunzo nzira yekuongorora kuoma kwezvinhu kana ichiiswa mukukurumidza kukanganisa mitoro.

Zvinotevera zvinodiwa zvinoshanda kumakiredhi ≤ X60 kana L415.

| CVN Yakatora Simba Zvinodiwa zvePipe Muviri wePSL 2 Pipe | |

| Yakatsanangurwa Kunze Diameter D mm (mu.) | Yakazara-saizi CVN Yakatorwa Simba min Kv J (ft.lbf) |

| ≤762 (30) | 27 (20) |

| >762 (30) kusvika 2134 (84) | 40 (30) |

DWT Muedzo wePSL 2 Welded Pipe

Avhareji yenzvimbo yekugera pamuyedzo ichave ≥ 85 % pa 0 °C (32 °F) tembiricha yekuyedza.

Kune machubhu ane kukora kwemadziro > 25.4 mm (1 mukati.), zvinodiwa zvekugamuchirwa zvebvunzo dzeDWT zvichakurukurwa.

Hydrostatic Test

Nguva Yekuedza

Ese saizi yemachubhu asina musono uye akaiswa simbi ane D ≤ 457 mm (18 in.):nguva yekuedza ≥ 5s;

Welded simbi pombi D > 457 mm (18 mukati.):nguva yekuedza ≥ 10s.

Test Frequency

Imwe neimwe pombi yesimbi.

Miedzo yekuedza

Iyo hydrostatic test pressure P yeaplain-end simbi pombiinogona kuverengerwa nekushandisa formula.

P = 2St/D

Sndiyo hoop stress. kukosha kwakaenzana neyakatsanangurwa kushoma goho simba resimbi pombi xa percent, muMPa (psi);

YeAPI 5L Giredhi B, iwo mapeji makumi matanhatu muzana eyeyedzo yekumanikidza bvunzo uye 70% yesarudzo yekumanikidza yekuyedza.

Nokuda kweD <88.9 mm (3.500 in.), hazvidiwi kuti kuedza kwekuedza kunopfuura 17.0 MPa (2470 psi);

Nokuda kweD> 88.9 mm (3.500 in.), hazvidiwi kuti muedzo wekuedza upfuure 19.0 MPa (2760 psi).

tndiko kutsanangurwa kwemadziro ukobvu, kunoratidzwa mumamirimita (inches);

Dndiyo yakataurwa kunze kwedhayamita, inoratidzwa mumamirimita (inches).

Nondestructive Inspection

Zvemachubhu eSAWnzira mbiri,UT(ultrasonic test) kanaRT(radiographic testing), inowanzoshandiswa.

ET(electromagnetic test) haishande kune SAW machubhu.

Welded seams pawelded pombi dzemagiredhi ≥ L210/A uye madhayamita ≥ 60.3 mm (2.375 mukati) achaongororwa zvisina kukuvadza kuti akakora uye kureba kwakazara (100 %) sezvakatsanangurwa.

UT kuongororwa kusingaparadzi

RT kuongororwa kusingakuvadzi

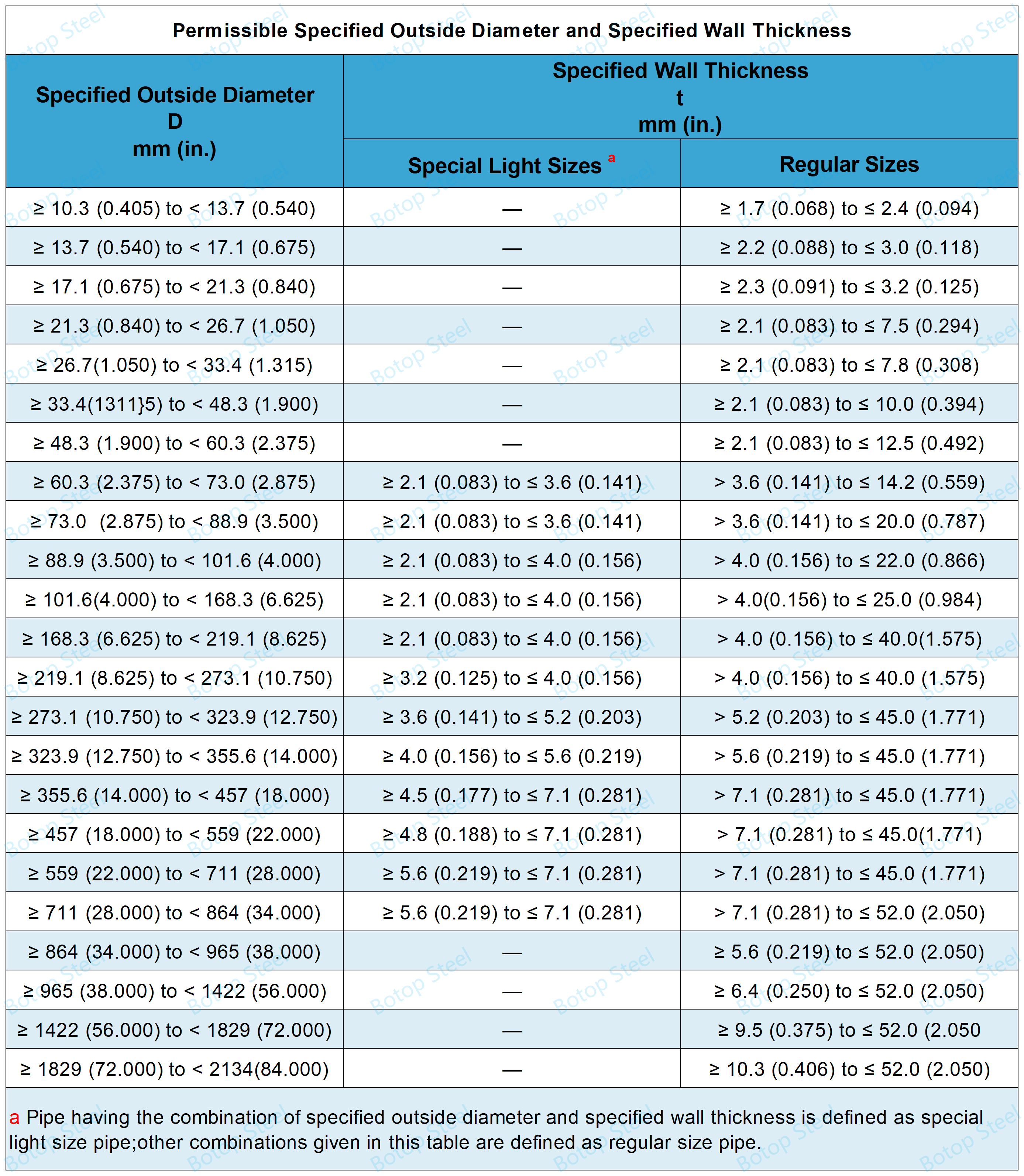

Taura Kunze Diameter uye Kukora Kwemadziro

Mitemo yakamisikidzwa yemadhayamita ekunze uye makobvu akatsanangurwa emadziro epombi yesimbi anopihwa mukatiISO 4200uyeASME B36.10M.

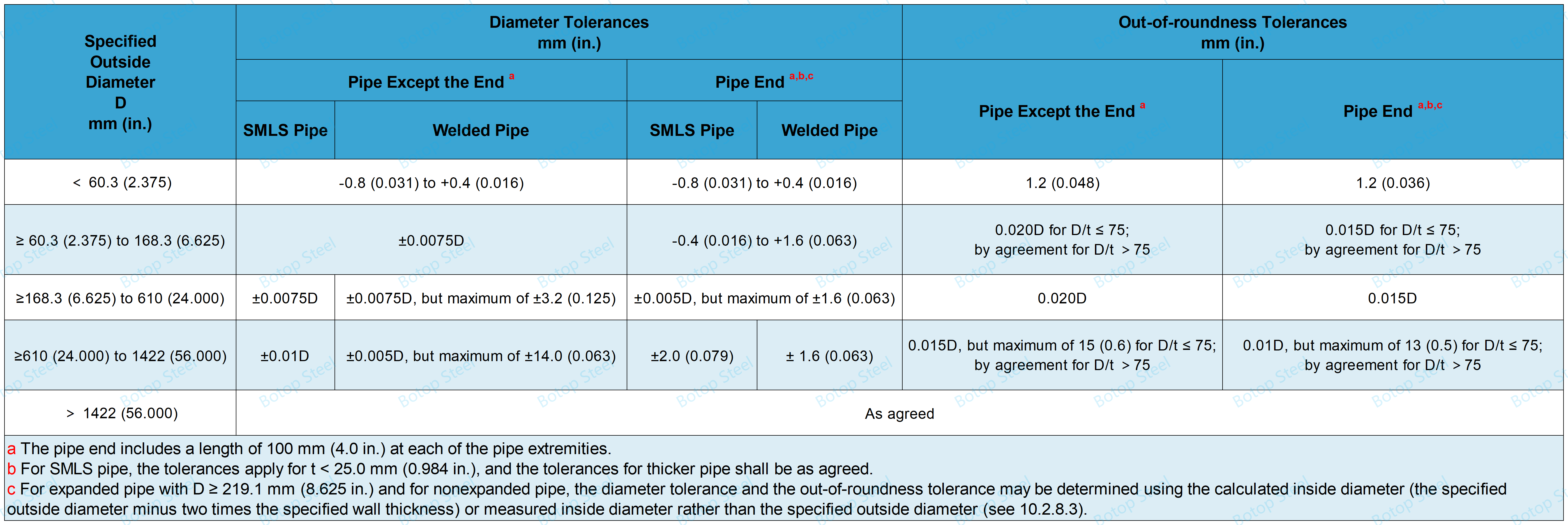

Dimensional Tolerances

Kushivirira kweDiameter uye Kunze-kwe-kutenderera

Iyo dhayamita yepombi yesimbi inotsanangurwa sedenderedzwa repombi mune chero ndege inotenderera yakakamurwa ne π.

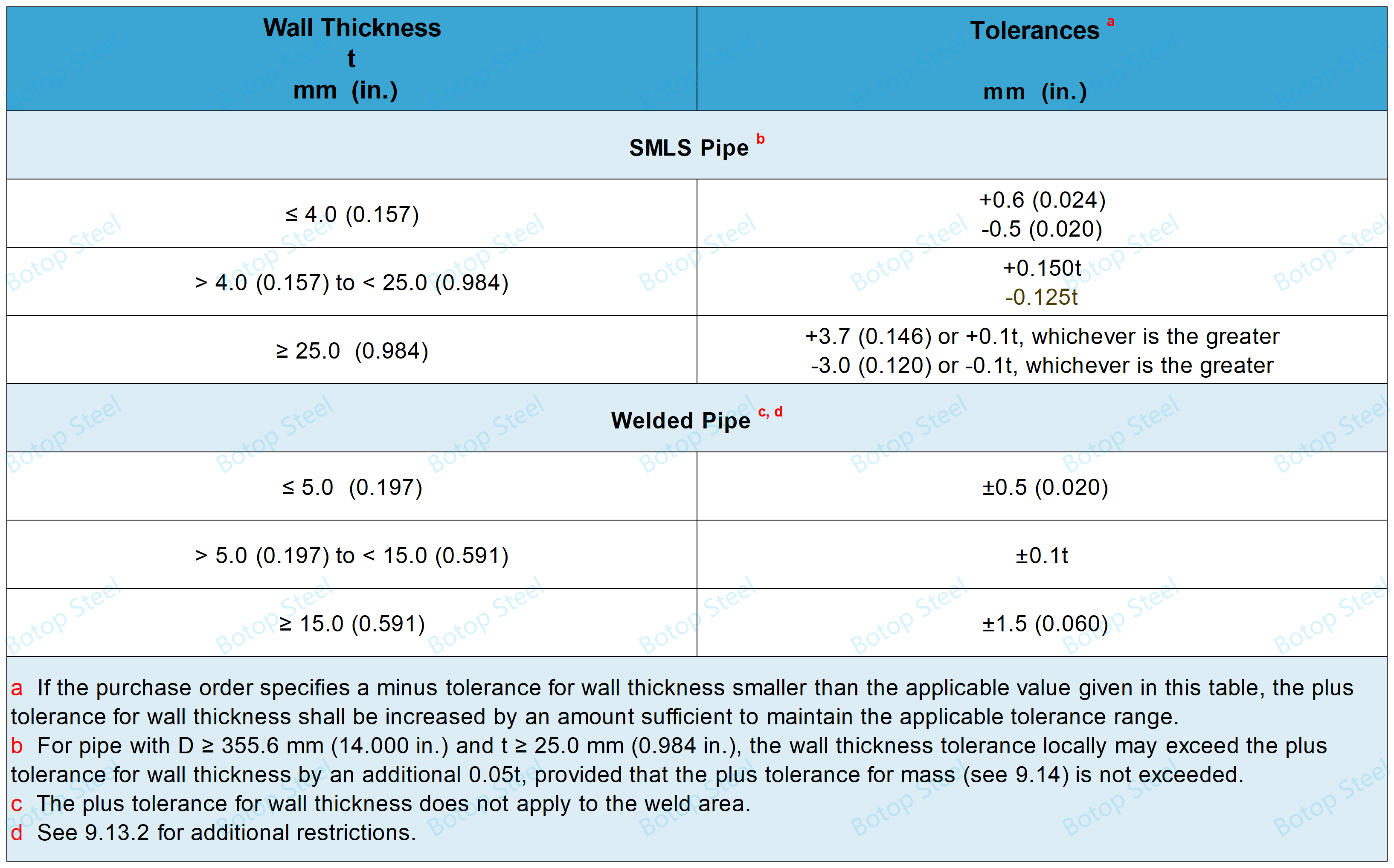

Kushivirira kweKukobvu Kwemadziro

Kushivirira Kwekureba

Hurefu hwakaenzanaichaunzwa mukati mekushivirira kwe ± 500 mm (20 in.).

Tolerances forkureba zvisina tsarukano

| Random Length Dhizaini m (ft) | Minimum Length m (ft) | Minimum Avhareji Yehurefu hweOdha Yega Yega Chinhu m (ft) | Maximum Length m (ft) |

| Yakarukwa-uye-yakabatanidzwa Pipe | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0) |

| Plain-end Pipe | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0) | 10.67 (35.0) | 13.72 (45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0) | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Kushivirira Kururama

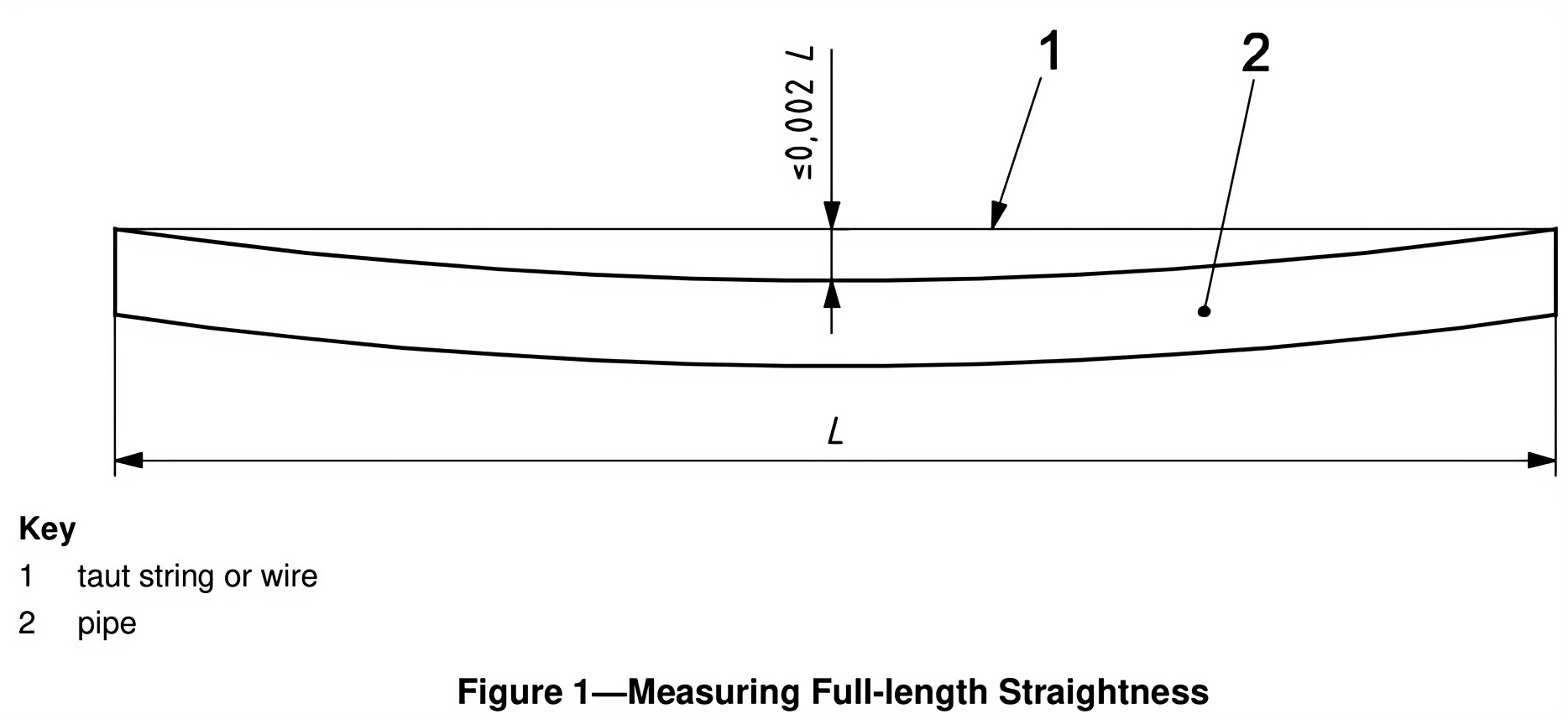

Kururama kutsauka pamusoro pehurefu hwose hwechubhu: ≤ 0.200 L;

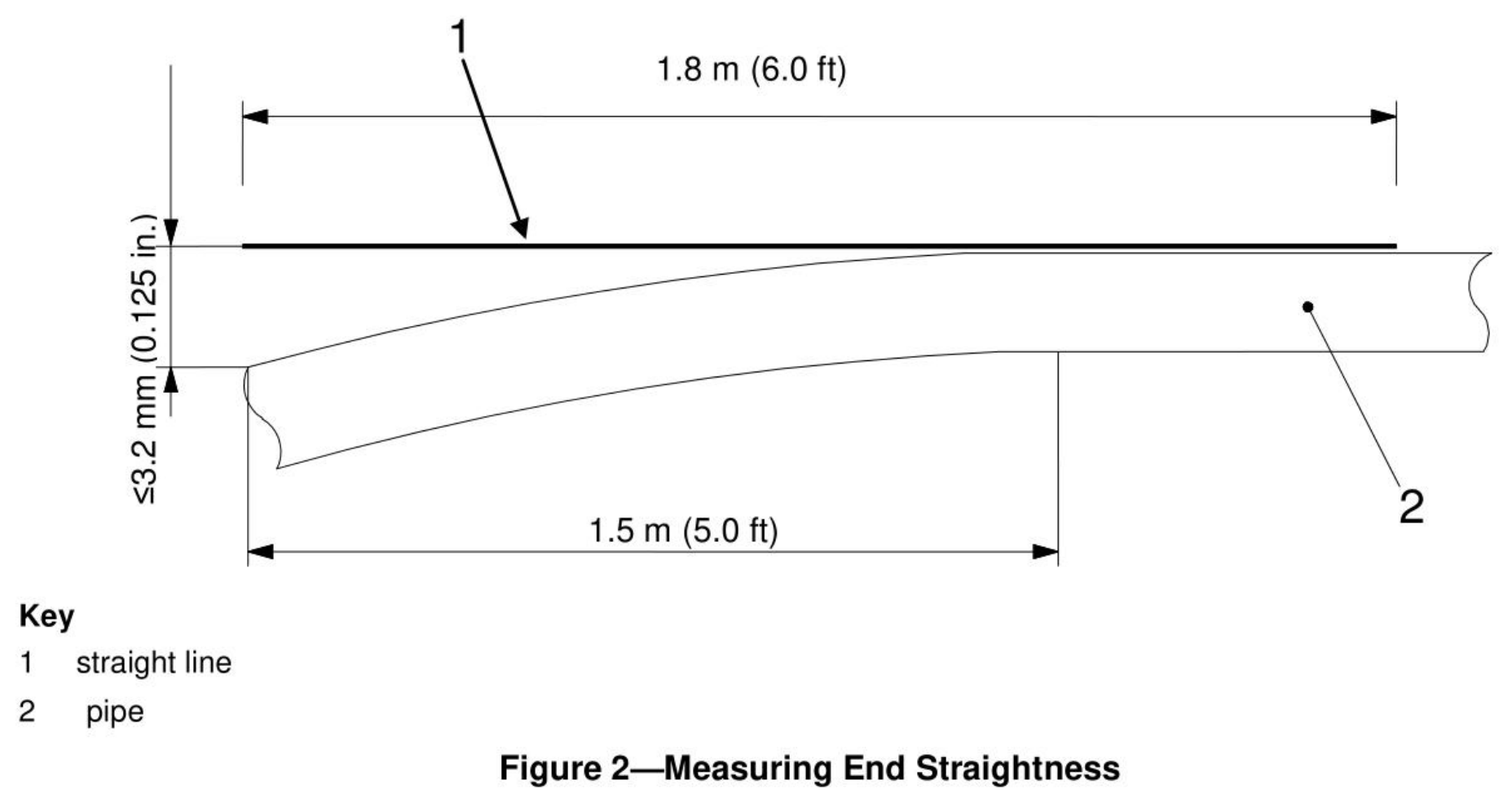

Kutsveyama kutsauka kwe1.5 m (5.0 ft) pombi kupera kwepombi yesimbi: ≤ 3.2mm (0.125 mukati).

Kushivirira Kururama

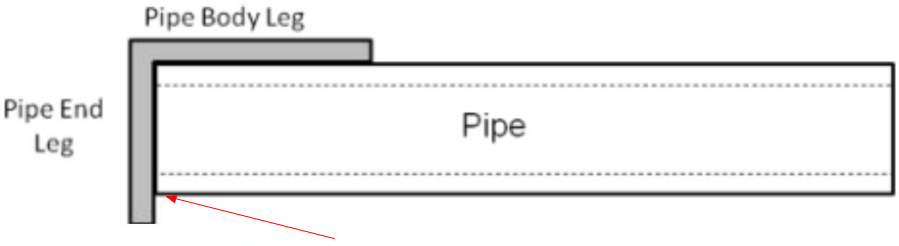

End squareness inotsanangurwa se square kusvika kumagumo epombi.

Iyo yekunze-ye-squareness ichave <1.6 mm (0.063 mukati.). Kubuda-kwe-squareness kunoyerwa semukana uri pakati pemagumo epombi uye gumbo rekupedzisira pombi.

Kushivirira kweWeld Seam

Yakanyanya Kubvumidzwa Radial OffsetyeSAW neCOW Pipe.

| Yakatsanangurwa Kukobvu Kwemadziro t mm (mu.) | Yakanyanya Kubvumidzwa Radial Offsetamm (mu.) |

| ≤ 15.0 (0.590) | 1.5 (0.060) |

| > 15.0 (0.590) kusvika 25.0 (0.984) | 0.1t |

| > 25.0 (0.984) | 2.5 (0.098) |

| aIyi miganho inoshanda zvakare kune strip / plate end welds | |

Maximum Inobvumirwa Weld Bead KurebayeSAW neCOW Pipe (Kunze kwePipe Inopera).

| Yakatsanangurwa Kukobvu Kwemadziro mm (mu.) | Weld Bead Height mm (mu.) maxim | |

| Internal Bead | External Bead | |

| ≤13.0 (0.512) | 3.5 (0.138) | 3.5 (0.138) |

| >13.0 (0.512) | 3.5 (0.138) | 4.5 (0.177) |

Iyo weld ichave neshanduko yakatsetseka kusvika pamusoro pepombi yesimbi yakatarisana.

Mapaipi ekupedzisira welds anofanirwa kugadzirwa kusvika pakureba kwe100 mm (4.0 mukati) neasara weld urefu hwe ≤ 0.5 mm (0.020 mukati.).

Kushivirira paMisa

Imwe neimwe pombi yesimbi:

a) kune yakakosha mwenje saizi pombi: -5.0% - +10.0%;

b) yepombi muGrade L175, L175P, A25, uye A25P: -5.0% - +10.0%;

c) kune mamwe ese mapaipi: -3.5% - +10.0%.

Pipe pamujenya(≥ 18 matani (20 matani) yeodha yakawanda):

a) kumakiredhi L175, L175P, A25, uye A25P: -3.5 %;

b) kune mamwe magiredhi ese: -1.75%.

API 5L GR.B Zvishandiso

API 5L Giredhi B simbi pombi imhando yepombi yemutsetse, inonyanya kushandiswa kutakura zvinwiwa zvakaita seoiri, gasi rechisikigo, uye mvura, uye chimwe chezvinhu zvinowanzoshandiswa muindasitiri yemafuta negesi.

Oiri uye gasi kutapurirana masisitimu: API 5L Giredhi B simbi pombi inowanzoshandiswa mumafuta uye gasi kudhirowa kwemunda uye kugadzirisa zvivakwa kutakura crude oiri uye gasi rechisikigo kuunganidza masisitimu kana kugadzirisa nzvimbo.

Mapaipi emvura: Mamwe marapirwo epamusoro, semabhandi kana machira, anogona kushandiswa kuvandudza kusakara kwavo kuti ashandiswe mukufambiswa kwemvura, kusanganisira kugovera mvura nemadiridziro.

Refineries: Munzvimbo dzekunatsa, API 5L Giredhi B simbi pombi inoshandiswa kutakura zvakasiyana-siyana zvemakemikari uye zvepakati zvakatorwa kubva kuchikamu chepadiki distillation yemafuta asina kuchena.

Kuvaka uye zvivakwa: Muindasitiri yekuvaka, yekuvaka mabhiriji, zvivakwa zvekutsigira, kana zvimwe zvakakosha mapurojekiti ezvivakwa, kunyanya panodiwa kutakurwa kwemvura kureba.

API 5L Giredhi B Yakaenzana

ASTM A106 Giredhi B: Seamless carbon steel tubing inowanzoshandiswa pakushanda kwepamusoro-kupisa, nemakemikari ekugadzirwa uye michina yemagetsi yakafanana neAPI 5L Giredhi B. ASTM A106 Grade B inowanzoshandiswa pakutakura kwemhepo inopisa yemvura, makemikari, uye zvigadzirwa zvepetroleum.

ASTM A53 Giredhi B: Iyi ndiyo imwe mhando yekabhoni simbi pombi, inogona kuvezwa kana isina musono, uye inoshandiswa zvakanyanya mumakanika, kuvaka, uye mamwe mainjiniya ekushandisa. Kunyangwe ichinyanya kushandiswa kune yakaderera-kudzvanywa uye tembiricha maapplication, mamwe emagetsi ezvivakwa maparamita akafanana neAPI 5L Giredhi B.

EN 10208-2 L245NB: Inoshandiswa kugadzira mapaipi ekutakura magasi anopfuta uye zvimwe zvinwiwa. L245NB (1.0457) isimbi yepakati-kusimba pombi ine michini yemidziyo yakafanana neAPI 5L Giredhi B.

ISO 3183 L245: Inoshandiswa mumasisitimu ekufambisa kwepombi muindasitiri yemafuta uye gasi.L245 muISO 3183 iri pedyo zvakanyanya mumidziyo kune API 5L Giredhi B uye inogona kushandiswa zvakasiyana.

Mamwe Masevhisi Atinogona Kupa

Botop Steelhaingope yemhando yepamusoro API 5L Giredhi B simbi pombi, asi zvakare inokupa iwe nhevedzano yekutsigira masevhisi, anosanganisira akasiyana-siyana anti-corrosion coating sarudzo, yakasarudzika yekurongedza mhinduro, uye yakazara logistics rutsigiro kuti tive nechokwadi chekuti tinokwanisa kuzadzisa zvaunoda zvakasiyana.

Isu takazvipira kugadzira imwe-stop sourcing chikuva iyo inokutendera iwe kuti uwane zviri nyore zvese zvigadzirwa nemasevhisi aunoda. Nemasevhisi edu ehunyanzvi uye akavimbika, unogona kupedzisa nhanho dzese dzepurojekiti yako zvine mutsindo uye pasina kunetseka, kuve nechokwadi chemhando uye kufambira mberi. Chinangwa chedu ndechekuva mudiwa wako akavimbika.

Anti-corrosion Coating

Botop Steelinopa huwandu hwakawanda hwekudzivirira kwekudzivirira coating sarudzo, kusanganisirapendi, galvanized,3LPE (HDPE), 3LPP,FBE, uye cementitious counterweights, kusangana nezvinodiwa zvakasiyana zvekushandisa zvepurojekiti yako.

kurongedza

Isu tinopa akasiyana-siyana ekurongedza sarudzo, anosanganisira mabhero, tarps, crates, uye pombi caps, iyo inogona kugadzirwa kuti isangane nezvido zvako.

Technical Support

Kambani yedu yakazvipira kupa yakazara tekinoroji yekutsigira masevhisi anofukidza ese matanho epurojekiti. Kubva pane pre-project kugadzirira nyoro kusvika pakati-project kutenga uye hurongwa hwekufambisa, kune post-project kugadzirisa uye kugadzirisa matambudziko, timu yedu nyanzvi inogona kukupa iwe mazano ehunyanzvi uye rutsigiro.

Chinangwa chedu ndechekukubatsira kutenga zvigadzirwa zvemhando yepamusoro uye zvinokwanisika muChina, kuve nechokwadi chekuti chirongwa chako chinofamba zvakanaka uye zvine mutengo. Tinotarisira kushanda newe kugadzira ramangwana rekuhwina.