ASTM A178machubhu esimbi machubhu emagetsi akaiswa welded (ERW) ecarbon uye carbon-manganese simbiinoshandiswa semachubhu ebhailer, mafiriji ebhailer, mafirita makuru, uye magumo ekuchengetedza.

Inokodzera machubhu esimbi ane dhayamita yekunze ye12.7-127mm uye ukobvu hwemadziro pakati pe0.9-9.1mm.

ASTM A178 machubhu akakodzera kupikisa welded machubhu anekunze madhayamita ari pakati pe1/2 - 5 mu [12.7 - 127 mm] uye ukobvu hwemadziro huri pakati pe0.035 - 0.360 mu [0.9 - 9.1 mm], kunyangwe mamwe saizi aripo echokwadi sezvinodiwa, kunze kwekunge machubhu aya achizadzisa zvimwe zvese zvinodiwa zveiyi tsanangudzo.

Kune mamakisi matatu ekutarisana nenzvimbo dzakasiyana dzekushandisa.

Giredhi A, Giredhi C, uye Giredhi D.

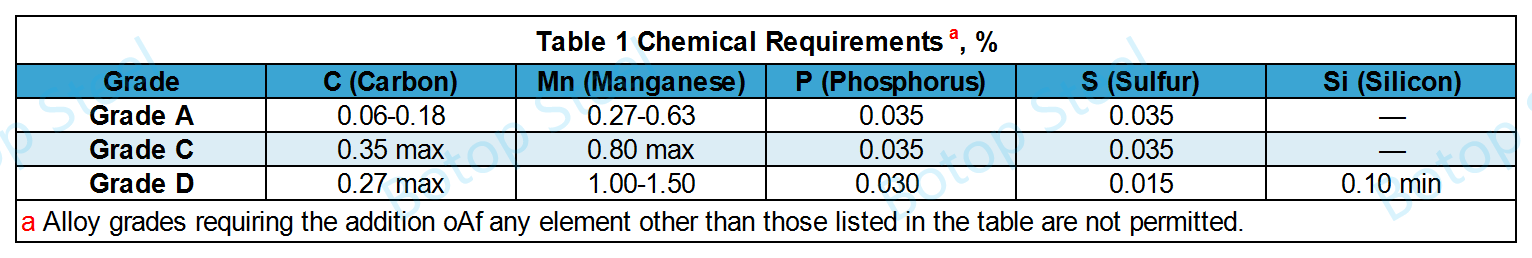

| Giredhi | Carbon Steel Type |

| Giredhi A | Yakaderera-Carbon Steel |

| Grade C | Medium-Carbon Steel |

| Grade D | Carbon-Manganese Steel |

Zvishandiso zvakapihwa pasi peichi chirevo zvichaenderana nezvinodiwa zveizvino edition yeSpecification A450/A450M. kunze kwekunge zvapihwa neimwe nzira pano.

Giredhi AuyeGrade Cusataure simbi chaiyo; sarudza mbishi yakakodzera sezvinodiwa.

Simbi yeGrade Dachaurayiwa.

Simbi yakaurayiwa inogadzirwa nekuwedzera deoxidizers (semuenzaniso, silicon, aruminiyamu, manganese, nezvimwewo) kusimbi yakanyungudutswa panguva yekugadzirwa kwesimbi, nokudaro kuderedza kana kubvisa okisijeni yesimbi.

Kurapa uku kunonatsiridza homogeneity uye kugadzikana kwesimbi, kunowedzera mashandiro ayo emagetsi, uye kunatsiridza kusadzivirirwa kwekuora.

Simbi dzakaurayiwa saka dzinoshandiswa zvakanyanya mumashandisirwo apo yakakwira dhigirii yehomogeneity uye yakanakisa michina zvivakwa zvinodikanwa, sekugadzirwa kwemidziyo yekumanikidza, boilers, uye mahombe ezvimiro zvikamu.

Machubhu esimbi anogadzirwa achishandisaERWkugadzira nzira.

ERW (Electric Resistance Welded)inzira yakanyatsokodzera kugadzira kabhoni simbi pombi.

Nezvakanakira zvesimba rekurudyi, rakatsetseka mukati nekunze, kukurumidza kugadzira kukurumidza, uye mutengo wakaderera, inoshandiswa zvakanyanya mumaindasitiri mazhinji uye ekuvaka.

ASTM A178pombi yesimbiinofanira kurapwa kupisapanguva yekugadzira. Inoshandiswa kuvandudza maitiro emagetsi uye kugadzikana kwemaitiro epombi, pamwe nekubvisa kushushikana kungangodaro kwakatangwa panguva yekugadzira.

Kana maputikidzwa, machubhu ese anofanira kupiswa patembiricha inosvika 1650°F [900°C] kana kupfuura uye achiteverwa nekutonhodzwa kwemhepo kana kuti mukamuri yekutonhodza yevira rinodzorwa-muchadenga.

Cold-drawn tubesichagadziriswa kupisa mushure mekupedzisira chando-draw pass patembiricha ye1200°F [650°C] kana kupfuura.

Kana kuongororwa kwechigadzirwa kuchiitwa, kuwanda kwekuongorora kunotarwa sezvinotevera.

| Classification | Inspection Frequency |

| Kunze dhayamita ≤ 3in [76.2mm] | 250 pcs / nguva |

| Kunze dhayamita > 3in [76.2mm] | 100 pcs / nguva |

| Siyanisa nechubhu kupisa nhamba | Nenhamba yekupisa |

Mechanical property inodiwa haishande kune tubhing idiki pane 1/8 in. [3.2 mm] mukati dhayamita kana 0.015 mukati. [0.4 mm] mukukora.

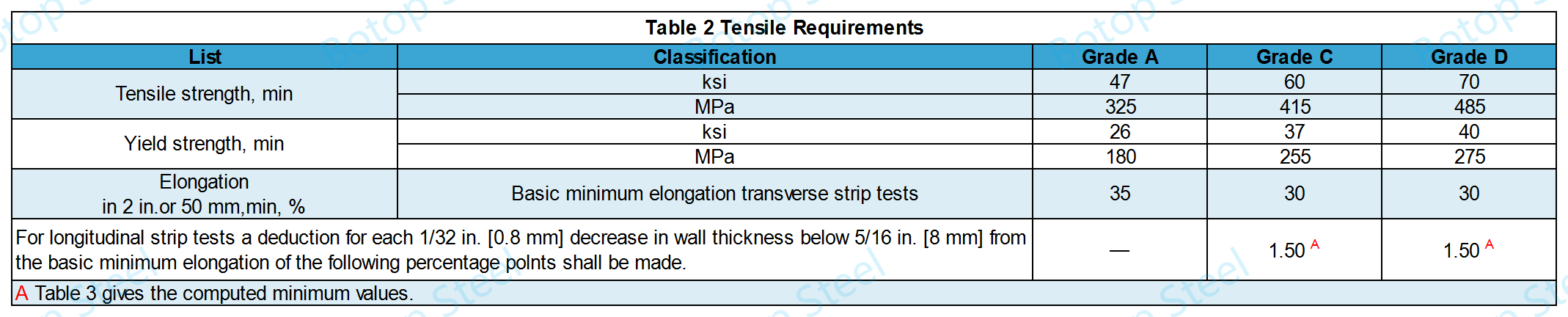

1. Tensile Property

KuMakirasi C neD, bvunzo dzekusimba dzichaitwa pamachubhu maviri mumujenya wega wega.

Kune yeGiredhi A tubing, kuyedza tenesi haiwanzo kudiwa. Izvi zvinokonzerwa nekuti Giredhi A tubing inonyanya kushandiswa kune yakaderera-kumanikidza uye yakaderera-tembiricha application.

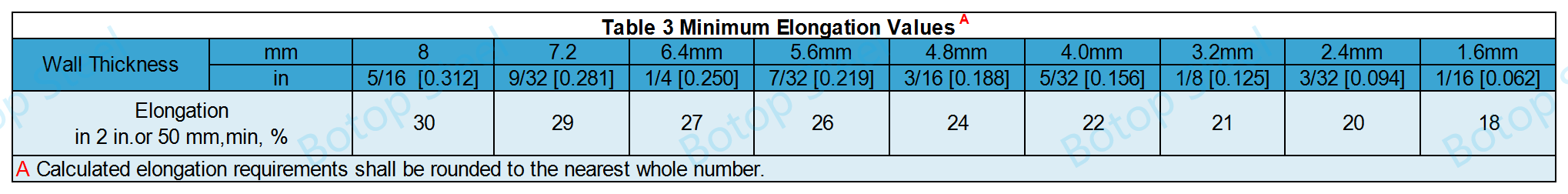

Tafura 3 inopa iyo yakaverengerwa midiki yekurebesa kukosha kune yega yega 1/32 mukati. [0.8 mm] kudzikira mukukora kwemadziro.

Kana iyo madziro emadziro epombi yesimbi isiri imwe yeiyi madziro emadziro, inogona zvakare kuverengerwa neformula.

Inch Units: E = 48t + 15.00kanaISI Units: E = 1.87t + 15.00

E = elongation mu2 in. kana 50 mm, %,

t= ukobvu hwemuenzaniso chaiwo, mukati. [mm].

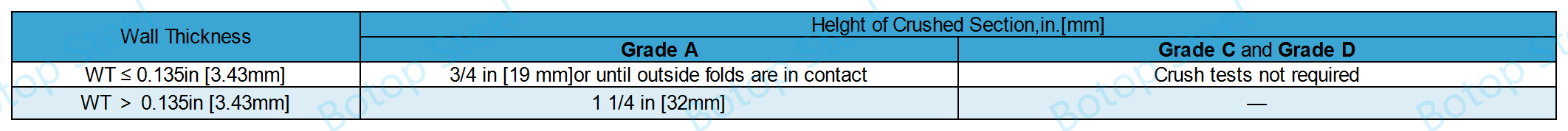

2. Crush Test

Extrusion tests inoitwa pazvikamu zvepombi 2 1/2 inches [63 mm] pakureba izvo zvinofanirwa kushingirira extrusion yelongitudinal pasina kutsemuka, kupatsanura, kana kupatsanura pane maweld.

Pachubhu isingasviki 1 in. [25.4 mm] kunze kwedhayamita, kureba kwemuenzaniso kunofanira kuva ka2 1/2 kuenzana kwekunze kwechubhu. Kutarisa kudiki kwepasi hakuzokonzeresa kurambwa.

3. Flattening Test

Iyo nzira yekuyedza inoenderana nezvinodiwa zvinoenderana neASTM A450 Chikamu 19.

4. Flange Test

Iyo nzira yekuyedza inoenderana nezvinodiwa zvinoenderana neASTM A450 Chikamu 22.

5. Reverse Flattening Test

Iyo nzira yekuyedza inoenderana nezvinodiwa zvinoenderana neASTM A450, Chikamu 20.

Hydrostatic kana kusaparadza magetsi kuyedzwa kunoitwa pane imwe neimwe pombi yesimbi.

Zvinodiwa zvinoenderana neASTM A450, Chikamu 24 kana 26.

Iyi inotevera data inotorwa kubva kuASTM A450 uye inosangana nezvinodiwa zve welded simbi pombi chete.

Uremu Kutsauka

0 - +10%.

Kutsauka Kwemadziro

0 - +18%.

Kunze Diameter Kutsauka

| Kunze Diameter | Kusiyana Kunobvumirwa | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1<OD ≤1½ | 25.4<OD ≤38.4 | ±0.006 | ±0.15 |

| 1½<OD<2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD<2½ | 50.8≤ OD<63.5 | ±0.010 | ±0.25 |

| 2½≤ OD<3 | 63.5≤ OD<76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Mushure mekuiswa mubhailer, chubhu inofanirwa kushingirira kuwedzera uye kukotama pasina kuputika kukanganisa kana kuputika pamawelds.

Iyo superheater tubing ichakwanisa kumirisana nezvose zvinodiwa zvekuforoma, welding, uye kubhenda maoperation pasina hurema.

Inonyanya kushandiswa mu boiler machubhu, boiler flue, superheater flues, uye magumo akachengeteka.

ASTM A178 Giredhi Atubing yakaderera kabhoni yemukati inopa iyo yakanaka weldability uye yakanyanya kuomarara kune maapplication ayo asiri pasi pekumanikidzwa kwakanyanya.

Inonyanya kushandiswa kune yakaderera-kudzvanya uye yepakati-tembiricha kunyorera senge yakaderera-kudzvanywa boilers (semuenzaniso, epamba boilers, diki hofisi chivakwa, s kana fekitori boilers) uye zvimwe zvinopisa kupisa munzvimbo dzakadzika-tembiricha.

ASTM A178 Giredhi Cine yakakwira kabhoni uye manganese zvirimo zvichipa iyi chubhu simba riri nani uye kudzivirira kupisa kune mamwe anodiwa ekushanda mamiriro.

Inokodzera kudzvanywa kwepakati uye yepakati tembiricha yekushandisa senge maindasitiri uye inopisa mvura boilers, iyo inowanzoda yakakwira madhiri uye tembiricha kupfuura epamba boilers.

ASTM A178 Giredhi Dmachubhu ane manganese akakwirira uye akakodzera silicon zvinyorwa kuti ape simba rakanakisa uye kudzivirira kupisa, zvichiita kuti dzigadzikane munzvimbo dzepamusoro-tembiricha uye dzakanyanya-kudzvanywa uye dzakakodzera kutsungirira zvakanyanya kushanda mamiriro.

Inowanzo shandiswa munzvimbo dzepamusoro-kudzvanywa uye nepamusoro-tembiricha, senge magetsi chiteshi boilers uye maindasitiri epamusoro.

1. ASTM A179 / ASME SA179: Seamless yakapfava simbi yekupisa exchanger uye condenser chubhu ye cryogenic service. Inonyanya kushandiswa munzvimbo dzakaderera dzekumanikidza, yakafanana mumakemikari uye michina zvivakwa kune ASTM A178.

2. ASTM A192 / ASME SA192: Seamless kabhoni simbi boiler machubhu mune yakanyanya kudzvanywa sevhisi. Inonyanya kushandiswa mukugadzira madziro emvura, economizers uye zvimwe zvinomanikidza zvikamu zve-ultra-high pressure boilers.

3. ASTM A210 / ASME SA210: Inovhara isina musono yepakati kabhoni uye alloy simbi boiler uye superheater machubhu ekupisa kwakanyanya uye epakati pressure boiler masisitimu.

4. DIN 17175: Seamless simbi machubhu uye mapaipi ekushandisa mukumanikidza kwakanyanya uye nepamusoro tembiricha nharaunda. Inonyanya kushandiswa mukugadzira mapombi eutsi kune boilers uye midziyo yekumanikidza.

5. EN 10216-2: Inotsanangura mamiriro ehunyanzvi emachubhu asina musono uye pombi dzeasiri-alloy uye alloy masimbi ane akatsanangurwa epamusoro-tembiricha zvivakwa zvekushandisa pasi pekumanikidzwa.

6. JIS G3461: Inovhara kabhoni simbi machubhu kune boilers uye kupisa exchangers. Inokodzera kune general low low and medium pressure heat exchange situations.

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro!

Kune chero kubvunza kana kudzidza zvakawanda pamusoro pezvipo zvedu, usazeza kutibata. Yako yakanaka simbi pombi mhinduro ingori meseji kure!