ASTM A335 P11simbi pombi isimbi isina musono ferritic yakaderera alloy simbi pombi yepamusoro-tembiricha sevhisi, UNS zita K11597.

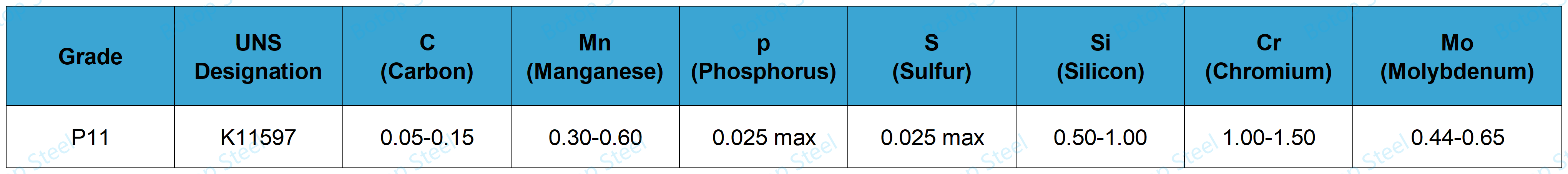

P11 is a chromium-molybdenum alloy ine chromium content ye 1.00-1.50% uye molybdenum ye 0.44-0.65%.

Inowanzo shandiswa mumaboilers, superheaters, uye zvinopisa kupisa muzviteshi zvemagetsi uye zvidyarwa zvemakemikari.

Izvo zvinodiwa zvehunyanzvi zveASME SA335uyeASTM A335zvakafanana, saka kuti zvive nyore kuratidza, isu tichashandisa "ASTM A335" kureva aya maviri zviyero.

Material: ASTM A335 P11 pombi yesimbi isina musono;

OD: 1/8"- 24";

WT: maereranoASME B36.10zvinodiwa;

Purogiramu: SCH10, SCH20, SCH30,SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 uye SCH160;

Identification: STD, XS, XXS;

Customization: Non-standard pombi saizi dziripowo, customized saizi anowanikwa pakukumbira;

Urefu: Yakananga uye yakasarudzika kureba;

IBR Certification: Tinogona kubata yechitatu-bato rekuongorora sangano kuti titore IBR certification zvinoenderana nezvaunoda, masangano edu ekuongorora ekubatana ari BV, SGS, TUV, nezvimwewo;

End: Flat kupera, beveled, kana composite pombi kupera;

Surface: Chiremba pombi, pendi, uye kumwe kudzivirira kwenguva pfupi, kubvisa ngura uye kukwenenzverwa, galvanized uye mapurasitiki akaputirwa, uye kumwe kuchengetedzwa kwenguva refu;

Packing: Wooden kesi, simbi bhandi kana simbi waya kurongedza, epurasitiki kana simbi pombi end dziviriro, nezvimwe.

Kunze kwekunge zvatsanangurwa neimwe nzira muA335, zvinhu zvakapihwa pasi peichi chirevo zvichaenderana nezvinodiwa zveiyozvino edition yeSpecification.A999/A999M.

ASTM A335 simbi pombi inofanira kuvaisina musono. Seamless simbi machubhu anopa kuvimbika kwakanyanya uye kufanana kana akaiswa pasi pekudzvanywa uye tembiricha nharaunda.

Seamless inogona kunyatso kurongedzerwa seinotonhora inodhonzwa uye inopisa kupera, zvichienderana neiyo chaiyo application uye saizi.

Kudhirowa kutonhora kunowanzo shandiswa kune madhayamita madiki kana machubhu anoda kurongeka kwepamusoro uye kunaka kwepamusoro. Kupisa kunopisa kunowanzo shandiswa kugadzira mapaipi makuru esimbi akatwasuka uye akakora.

Pazasi pane inoyerera chati yekugadzira nzira yekupisa-yakapera seamless simbi pombi.

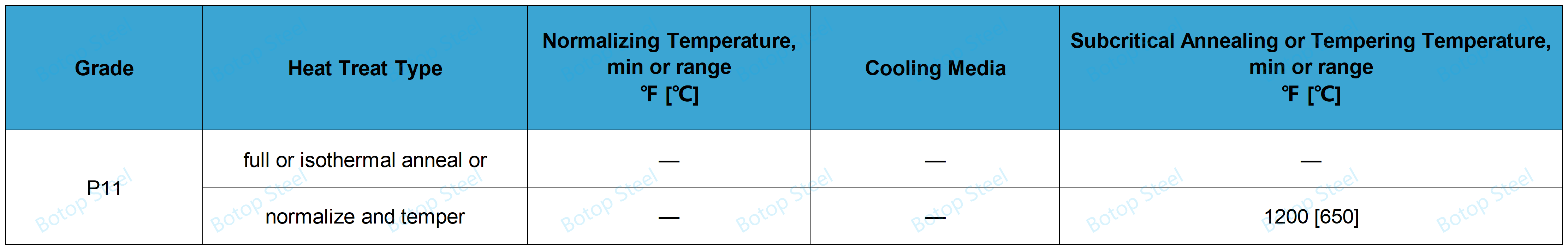

Kurapa kwekupisa kweP11 zvinhu zvinogona kunge zvakazara kana isothermal annealing kana kudziya mushure mekugara, uye kana yakajairika nekudziya, tembiricha yekudziya inofanira kunge iri 1200 ° F (650 ° C).

Kubva mukugadzirwa kwemakemikari, tinogona kuona izvo zviri nyoreP11 ndeye chromium-molybdenum alloy.

Chromium-molybdenum alloys ikirasi yesimbi ine chromium (Cr) uye molybdenum (Mo) sechinhu chikuru chinosanganisa zvinhu. Kuwedzerwa kwezvinhu izvi kunowedzera zvakanyanya kusimba, kuomarara, kupfeka kuramba, uye kushorwa kwesimbi. Pakupisa kwepamusoro, Cr-Mo alloys inokwanisa kuchengetedza yakanaka michina zvinhu uye yakagadzikana chimiro.

Cr: inovandudza oxidation kuramba uye corrosion kuramba kwealloy, inobatsira kuumba yakasimba oxide firimu, uye inodzivirira zvinhu kubva kune corrosive media.

Mo: Inowedzera simba re alloy, kunyanya pakupisa kwepamusoro, inovandudza kutsika kwekukwira, uye inowedzera simba repamusoro rekushisa kwezvinhu.

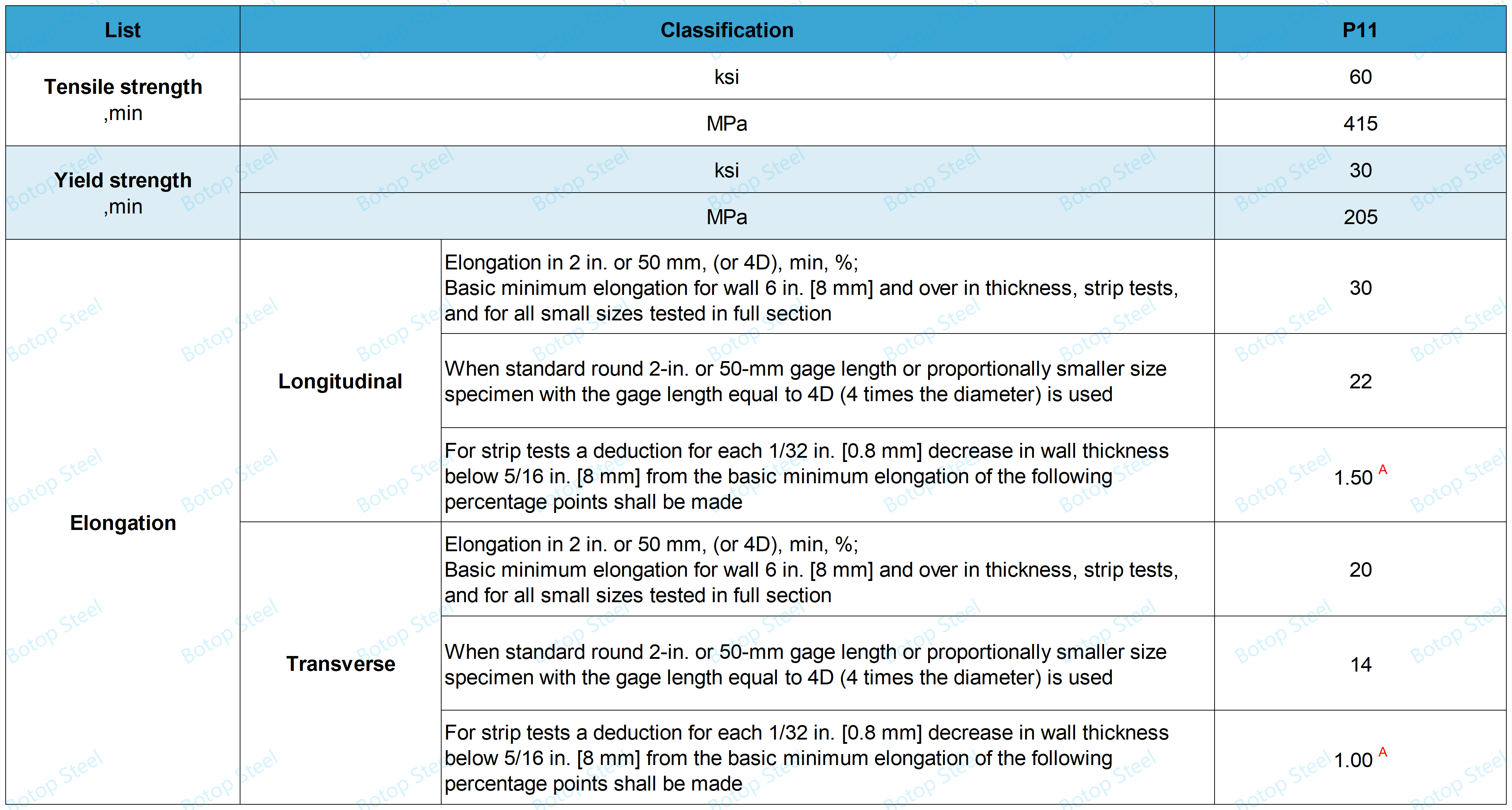

1. Tensile Property

Iyo tensile bvunzo inowanzoshandiswa kuyera iyobereka simba, tensile simba,uyeelongation yesimbi pombi yekuyedza chirongwa, uye inoshandiswa zvakanyanya muzvinhu zvezvinhu zvebvunzo.

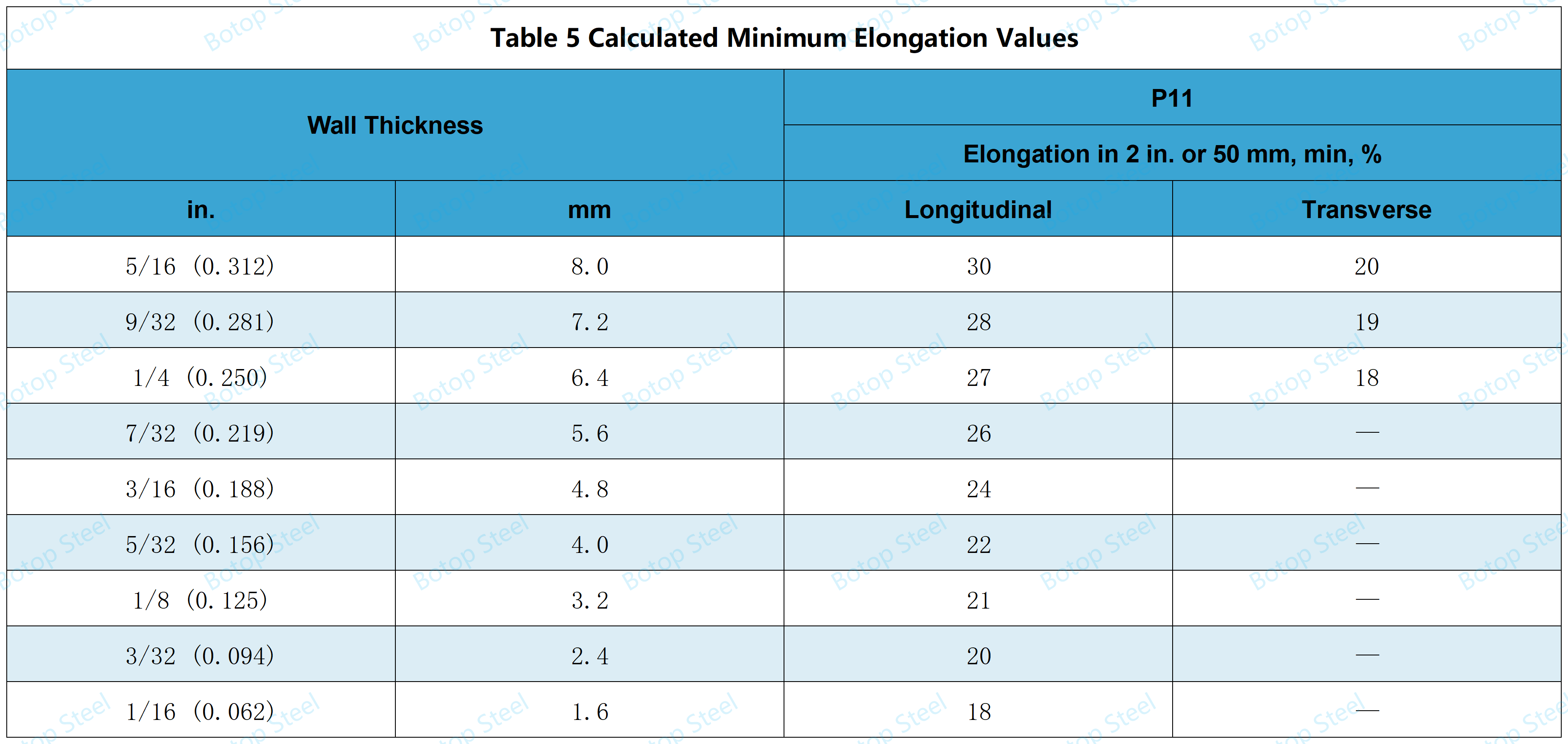

ATafura 5 inopa huwandu hwakaverengerwa hudiki.

Ipo ukobvu hwemadziro huri pakati pehuviri huviri huri pamusoro, hudiki hwehurefu hwekurebesa hunotarwa neinotevera fomula:

Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

kupi:

E = elongation mu2 in. kana 50 mm, %,

t = ukobvu chaihwo hwezvienzaniso, in. [mm].

2. Kuoma

Giredhi P11 pombi haidi kuomarara kuyedzwa.

A reference hardness value inopiwa pazasi.

Annealed condition:

Kuoma kunowanzova pakati pe150 ne200 HB.

Normalized uye kushatirwa mamiriro:

Kuoma kunotangira pa170 kusvika pa220 HB.

Mamiriro akaomeswa uye ane hasha:

Kuoma kunogona kusvika pa250 kusvika 300 HB kana kudarika, zvichienderana nekupisa kwekushisa uye nguva.

3. Optional Experimental Programs

Zvinhu zvinotevera zvekuedza hazvidiwi bvunzo zvinhu, kana zvichidikanwa zvinogona kutsanangurwa nekutaurirana.

Product Analysis

Flattening Test

Bend Test

Metal Chimiro uye Etching Miedzo

Photomicrographs

Photomicrographs yeIndividual Pieces

Iyo P11 hydrotest ichaenderana nezvinodiwa zvinotevera.

Kunze dhayamita>10in. [250mm] uye ukobvu hwemadziro ≤ 0.75in. [19mm]: iyi inofanira kunge iri hydrostatic test.

Mamwe saizi ekuongororwa kwemagetsi asingaparadze.

Izvi zvinotevera hydrostatic bvunzo zvinodiwa zvinounganidzwa kubva kune zvinodiwa zveASTM A999:

Kune ferritic alloy simbi uye Stainless simbi machubhu, madziro anoiswa pasi pekumanikidzwa kusiri pasi pe.60% yezvakatarwa zvishoma goho simba.

Iyo hydro test pressure ichachengetwa kweinenge 5spasina kuvuza kana kumwe kukanganisa.

Hydraulic pressureinogona kuverengerwa uchishandisa formula:

P = 2St/D

P = hydrostatic test pressure mu psi [MPa];

S = pombi madziro kushushikana mu psi kana [MPa];

t = kutsanangurwa kwemadziro ukobvu, zita remadziro ukobvu zvinoenderana neyakatsanangurwa ANSI hurongwa nhamba kana 1.143 nguva yakataurwa kushomeka kwemadziro ukobvu, mukati. [mm];

D = inotsanangurwa kunze kwedhayamita, kunze kwedhayamita inoenderana neyakatsanangurwa ANSI pombi saizi, kana dhayamita yekunze yakaverengerwa nekuwedzera 2t (sezvinotsanangurwa pamusoro) kune yakataurwa mukati dhayamita, in. [mm].

Pombi imwe neimwe ichaongororwa nenzira isingaparadzi yekuongorora maererano neKudzidziraE213, DzidziraE309, kana kuti DzidziraE570.

Kusiyana Kunobvumirwa muDiameter

Yepombi yakarairwa kutimukati dhayamita, iyo dhayamita yemukati haifaniri kusiyana kupfuura ± 1% kubva kune yakatsanangurwa mukati dhayamita.

Kusiyana Kunobvumirwa muKukobvu Kwemadziro

Kuyera kwemadziro kuyerwa kuchaitwa uchishandisa mechanic calipers kana yakanyatso calibrated nodestructive yekuyedza michina yekurongeka kwakaringana. Muchiitiko chekupokana, kuyerwa kwakatarwa uchishandisa mechanical calipers kuchakunda.

Ukobvu hwemadziro hudiki uye dhayamita yekunze kuti iongororwe kutevedzera zvinodiwa nepombi yakarairwa neNPS [DN] uye nhamba yehurongwa inoratidzwa mu.ASME B36.10M.

Inowanzo shandiswa mumaboilers, superheaters, uye zvinopisa kupisa muzviteshi zvemagetsi uye zvidyarwa zvemakemikari.

Maboilers: P11 inoshandiswa zvakanyanya pakuvaka mabhoilers nekuda kwekudzivisa kwayo kutonhora kwakanyanya uye kudzvinyirira, kunyanya muzvikamu zvinotarisana nekupisa kwakanyanya uye kudzvinyirira.

Superheater: Inoshandiswa kuwedzera tembiricha yehutsi kuti iwedzere kuwedzera kushanda kwemafuta. p11 inovimbisa kuti simba uye kusimba kwezvinhu zvinochengetwa kunyange pakupisa kwakanyanya.

Heat exchangers: P11 inowedzera kuonda uye kupisa kwepamusoro-kupisa kwevanopisa kupisa, nokudaro kunatsiridza kuvimbika nekuchengetedzwa kwemidziyo.

Piping systems: Sisitimu dzepombi muzvirimwa zvemakemikari kazhinji dzinoda kutakura mvura inodziya yakanyanya kana chipfunga. kusimba kwepamusoro-tembiricha uye yakanaka michina yeP11 inoita kuti ive yakakodzera kune izvi zvikumbiro.

a) ASTM A335 P11 yakaenzana nei?

GB/T 5310: 12CrMo;

DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

BS 3604: 10CrMo9-10;

JIS G3462: STPA23;

GOST 550-75: 12Kh1MF.

b)P11 isimbi yakaderera-alloy here?

Hongu, P11 isimbi yakaderera alloy.

Low alloy simbi isimbi-kabhoni alloy kwakawedzerwa chinhu chimwe kana kupfuura chinosanganisa (semuenzaniso, chromium, molybdenum, nickel, zvichingodaro), ine yakazara alloying element yezvinhu kazhinji kubva pa1 kusvika pa5%.

c)Chii chinonzi tensile simba reASTM A335 P11?

Minimum tensile simba re415 MPa [60 ksi].

d)Chii chinonzi goho simba reASTM A335 P11?

Simba shoma shoma re205 MPa [30 ksi].

e) Ndeipi muganho wekushisa weASTM A335 P11?

Munzvimbo dzine oxidizing: Tembiricha yehukuru hwesevhisi inowanzoita 593°C (1100°F).

Munzvimbo dzisiri-oxidizing: tembiricha yepamusoro yebasa ingangoita 650°C (1200°F) inogona kuwanikwa.

f)Iyo A335 P11 ine magineti here?

Iyo ine magineti pakudziya kwekamuri. Ichi chivakwa chinogona kubatsira mune mamwe maapplication, senge kana zvinhu zvichidikanwa kuti zvienderane nemagineti yekuona michina.

g)Chii mutengo weASTM A335 P11?

Mitengo inosiyana nemusika, taura nesu kuti uwane quote chaiyo.