ASTM A513 simbiiyo kabhoni uye alloy simbi pombi uye chubhu yakagadzirwa kubva kune inopisa-yakakunguruswa kana inotonhora-yakakungurutswa simbi seyakagadzirwa neresistance welding (ERW) process, iyo inoshandiswa zvakanyanya mumhando dzese dzemakanika zvimiro.

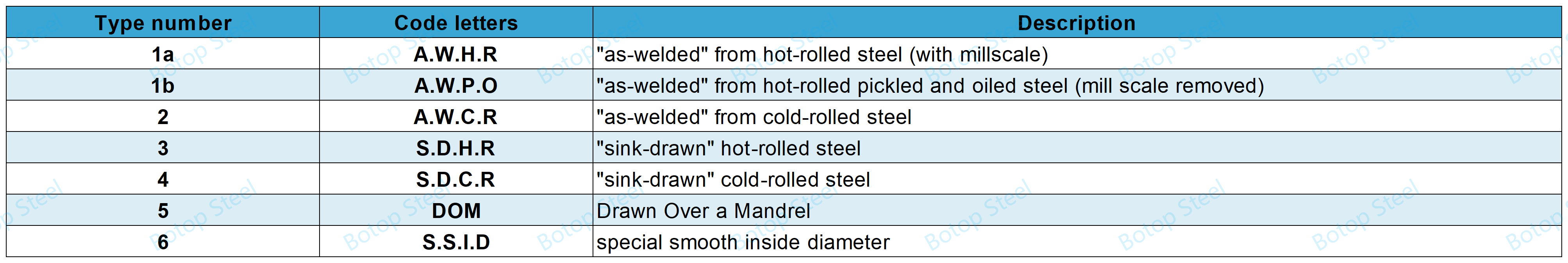

Rudzi rwekutanga runogona kukamurwa kuita 1a uye 1b.

Type 1a (AWHR): "se-welded" kubva kune inopisa-yakaputirwa simbi (ine mill scale).

Iyi fomu yepombi inobatanidzwa zvakananga kubva kune inopisa-yakakungurutswa simbi ine iron oxide (mill scale) inoumbwa panguva yekukunguruka. Iyi mhando yepombi inowanzoshandiswa mumashandisirwo apo kutendeseka kwepamusoro hakukoshese nekuti nzvimbo yacho ine mill scale.

Type 1b (AWPO): "se-welded" kubva kune inopisa-yakaputirwa yakanyungudutswa uye simbi yemafuta (mill scale yakabviswa).

Iyi fomu yepombi inosungirirwa kubva kune inopisa-yakaputirwa simbi yakabikwa uye yakazora uye inoratidzwa nekubviswa kweguyo. Iyo pickling uye mafuta ekuzora haingobvisi oxidation yepasi chete asi inopa imwe dziviriro yekuora uye mafuta panguva yekugadziriswa, zvichiita kuti pombi iyi ive yakakodzera kune maapplication anoda nzvimbo yekuchenesa kana kuomesa zvishoma.

Execution standard: ASTM A513

Material: Kupisa-yakakungurutswa kana Cold-rolled Steel

Rudzi nhamba: Type1 (1a kana 1b), Type2, Type3, Type4,Type5, Type6.

Giredhi: MT 1010, MT 1015,1006, 1008, 1009 nezvimwe.

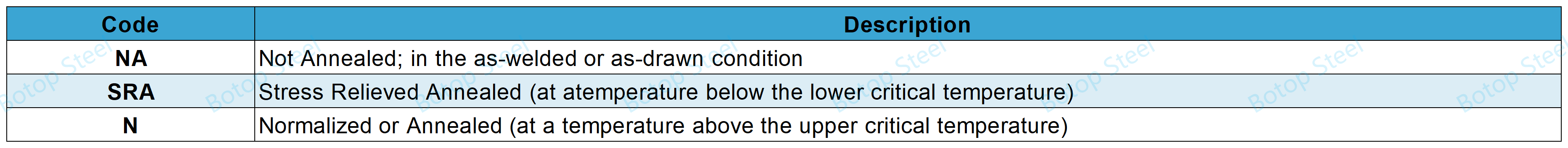

Kurapa kwekupisa: NA, SRA, N.

Kukura uye kukora kwemadziro

Hollow chikamu chimiro: Round, square, kana mamwe maumbirwo

Urefu

Huwandu hwese

Round

Sikweya kana rectangular

Mamwe maumbirwo

seyakakwenenzverwa, ine hexagonal, ine octagonal, yakatenderedzwa mukati uye ine hexagonal kana yeoctagonal kunze, ine mbabvu mukati kana kunze, katatu, yakatenderedzwa rectangular, uye D maumbirwo.

ASTM A513 Round Tubing Type 1 Magiredhi akajairwa ndeaya:

1008,1009,1010,1015,1020,1021,1025,1026,1030,1035,1040,1340,1524,4130,4140.

Hot-yakakungurutswa

Muchigadziro chekugadzira, simbi inopisa inotanga kupiswa pakupisa kwepamusoro, ichibvumira simbi kuti iparadzwe mumamiriro epurasitiki, izvo zvinoita kuti zvive nyore kuchinja chimiro uye ukuru hwesimbi. Pakupera kwekupisa kunopisa, zvinhu zvinowanzoyerwa uye zvakakanganiswa.

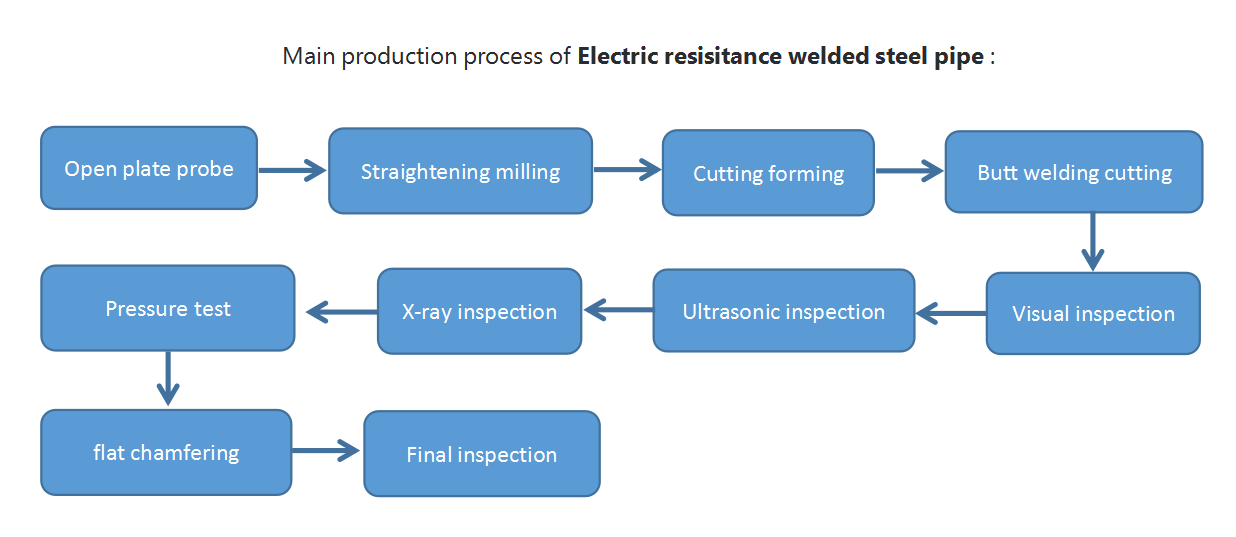

Machubhu achagadzirwa neelectric-resistance-welded (ERW)process.

ERW pombi magadzirirwo ekugadzira weld nekukochekera zvinhu zvesimbi kuita humburumbira uye kuisa kuramba uye kumanikidza pakureba kwayo.

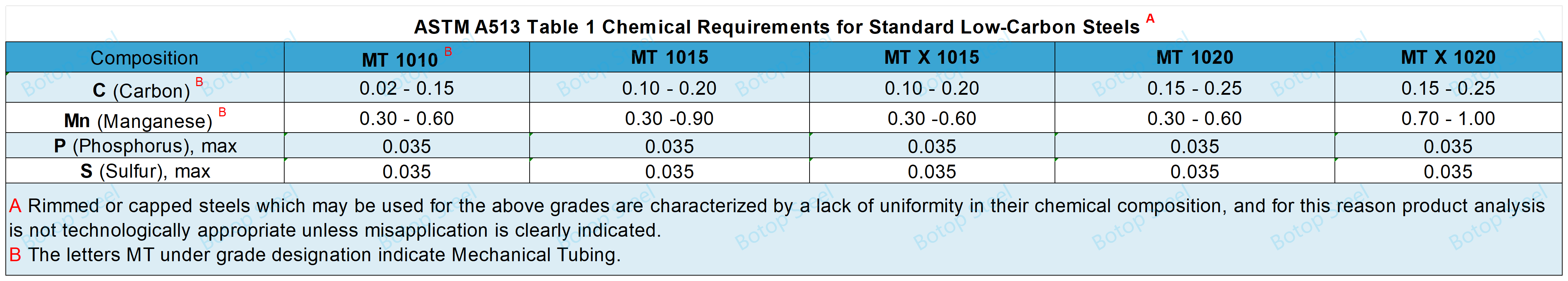

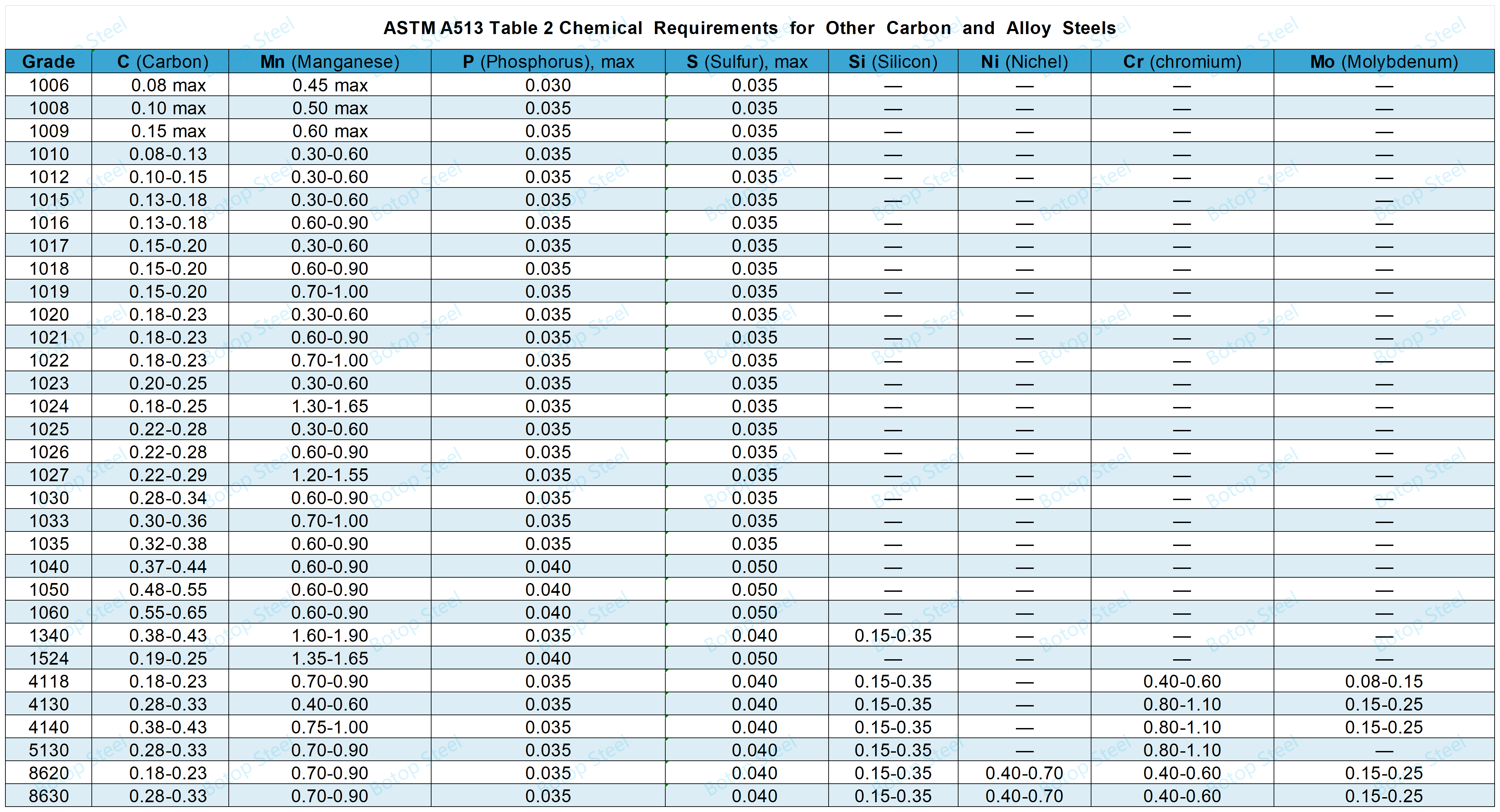

Simbi ichaenderana nezvinodiwa zvemakemikari zvinotsanangurwa muTafura 1 kana Tafura 2.

| Giredhi | Yied Simba ksi[MPa],min | Ultimate Strength ksi[MPa],min | Elongation mu2 mukati.(50 mm), min, | RB min | RB max |

| As-Welded Tubing | |||||

| 1008 | 30 [205] | 42 [290] | 15 | 50 | - |

| 1009 | 30 [205] | 42 [290] | 15 | 50 | - |

| 1010 | 32 [220] | 45 [310] | 15 | 55 | - |

| 1015 | 35 [240] | 48 [330] | 15 | 58 | - |

| 1020 | 38 [260] | 52 [360] | 12 | 62 | - |

| 1021 | 40 [275] | 54 [370] | 12 | 62 | - |

| 1025 | 40 [275] | 56 [385] | 12 | 65 | - |

| 1026 | 45 [310] | 62 [425] | 12 | 68 | - |

| 1030 | 45 [310] | 62 [425] | 10 | 70 | - |

| 1035 | 50 [345] | 66 [455] | 10 | 75 | - |

| 1040 | 50 [345] | 66 [455] | 10 | 75 | - |

| 1340 | 55 [380] | 72 [495] | 10 | 80 | - |

| 1524 | 50 [345] | 66 [455] | 10 | 75 | - |

| 4130 | 55 [380] | 72 [495] | 10 | 80 | - |

| 4140 | 70 [480] | 90 [620] | 10 | 85 | - |

RB inoreva Rockwell Hardness B Scale.

Izvo zvekuoma zvinodiwa zvinoenderana nemagiredhi chaiwo zvinogona kutariswa mutafura iri pamusoro yeRB.

1% yemachubhu ese mujenya rega rega uye asiri pasi pe5 machubhu.

Machubhu akatenderedzwa uye machubhu anoumba mamwe maumbirwo kana ari denderedzwa anoshanda.

Yese tubing ichapihwa hydrostatic bvunzo.

Chengetedza hushoma hwe hydro test pressure kwete pasi pe5s.

The pressure inoverengwa se:

P=2St/D

P= shoma hydrostatic test pressure, psi kana MPa,

S= inobvumirwa fiber kushushikana kwe14,000 psi kana 96.5 MPa,

t= kutsanangurwa kwemadziro ukobvu, mukati kana mm,

D= yakataurwa kunze kwedhayamita, mukati kana mm.

Icho chinangwa chebvunzo iyi kuramba machubhu ane hurema hunokuvadza.

Imwe neimwe chubhu ichaedzwa neasingaparadzi bvunzo yemagetsi zvinoenderana neKudzidzira E213, Dzidzira E273, Dzidzira E309, kana Dzidzira E570.

Outer Diameter

Tafura 4Diameter Tolerances yeRudzi I (AWHR) Round Tubing

Kukora Kwemadziro

Tafura 6Kushivirira Kwemadziro eRudzi I (AWHR) Round Tubing (Inch Units)

Tafura 7Kushivirira Kwemadziro eRudzi I (AWHR) Round Tubing (SI Units)

Urefu

Tafura 13Cheka-Kureba Kushivirira kweLathe-Cheka Round Tubing

Tafura 14Kureba Kushivirira kwePunch-, Saw-, kana Disc-Cut Round Tubing

Squareness

Tafura 16Kushivirira, Kunze Dimensions Square uye Rectangular Tubing

Maka mashoko anotevera nenzira yakakodzera patsvimbo imwe neimwe kana sumbu.

zita remugadziri kana mhando, saizi yakatarwa, mhando, nhamba yeodha yemutengi, uye iyi nhamba yakatarwa.

Barcoding inogamuchirwa senzira yekuwedzera yekuzivikanwa.

Iyo tubing haifaniri kuremara uye ichava nemagumo akafanana nemushandi.

Migumo yechubhu inofanira kuchekwa zvakanaka uye isina maburi kana micheto inopinza.

Yakakungurutswa Chip (yeRudzi 1a): Type 1a (yakananga kubva kune inopisa yakakungurutswa simbi ine akakungurutswa machipisi) kazhinji ine yakakungurutswa chip pamusoro. Ichi chimiro chepamusoro chinogamuchirwa kune mamwe maapplication apo yakakwirira yepamusoro yepamusoro haidiwi.

Yakabviswa Yakakungurutswa Chip (yeRudzi 1b): Type 1b (yakagadzirwa kubva kune inopisa yakakungurutswa yakanyungudutswa uye neoiri simbi ine akakungurutswa machipisi abviswa) inopa nzvimbo yakachena yezvishandiso zvinoda pendi kana nani pamusoro pemhando.

Tubing ichaputirwa nefirimu remafuta isati yatumirwa kuti idzore ngura.

Ko kurongeka kunofanira kutsanangura kuti tubing inotumirwa pasinamafuta ekubvisa ngura, iyo firimu yemafuta anokonzerwa nekugadzirwa acharamba ari pamusoro.

Inogona kudzivirira zvinobudirira pamusoro pepombi kuti isaita nehunyoro uye okisijeni mumhepo, nokudaro kudzivirira ngura uye marara.

Cheaper: The welding process ye inopisa yakakungurutswa simbi inoita kuti ASTM A513 Type 1 iwedzere kudhurika kana ichienzaniswa nezvigadzirwa zvinodhonzwa nechando.

Wide range of applications: ASTM A513 Type 1 inokodzera zvakasiyana-siyana zvekushandisa, zvinosanganisira zvimiro zvemukati, mafuremu, masherufu, nezvimwe. Kuita kwayo kwakasiyana-siyana munzvimbo dzakasiyana uye mabasa kunoita kuti ive sarudzo yakakurumbira kumaindasitiri akadai semotokari, kuvaka, uye muchina.

Excellent weldability: Mushonga wemakemikari weASTM A513 Type 1 wakanakira welding, uye unogona kuiswa welding uchishandisa nzira dzakajairwa welding, zvichiita kuti zvive zvakanyanya kushanda munzvimbo dzakasiyana dzekugadzira.

Simba rakanaka uye kuoma: Kunyangwe isina kusimba semamwe masimbi alloy kana simbi dzakagadziriswa, inosangana nezvinodiwa zvekupa simba rakakwana kune akawanda magadzirirwo uye emuchina maapplication. Kuenderera mberi kwekugadzirisa, sekurapa kwekupisa, kunogonawo kuvandudza michina yepombi kuti isangane nezvinodiwa.

Surface Finish: Type 1b inopa nzvimbo yakachena, iyo inobatsira mumashandisirwo panodiwa kupera kwakanaka kwepamusoro uye uko kupenda kana kumwe kugadzirira kwepamusoro kunodiwa.

ASTM A513 Type 1 inopa mwero wakanaka wemutengo, kuita, uye kuita kwakasiyana-siyana, zvichiita kuti ive yakakodzera kune akawanda emakanika uye zvimiro zvekushandisa uko inodhura-inoshanda tubing ine yakanaka mechanical properties inodiwa.

Inoshandiswa mukuvaka sezvivakwa zvinotsigira zvakaita sematanda nemakoramu.

Inoshandiswa mukugadzirwa kwezvikamu zvezvimiro zveakasiyana mishini michina, senge mabhengi uye shafts.

Frame uye zvivakwa zvekutsigira mumichina yekurima.

Inoshandiswa kugadzira masherufu esimbi uye masisitimu ekuchengetedza mumatura uye muzvitoro.

Isu tiri mumwe weanotungamira welded welded kabhoni simbi pombi uye isina musono simbi pombi vagadziri uye vatengesi kubva kuChina, nehupamhi hwemhando yepamusoro simbi pombi mu stock, isu takazvipira kukupa iwe uzere huzere hwesimbi pombi mhinduro.

Kuti uwane rumwe ruzivo rwechigadzirwa, ndapota inzwa wakasununguka kutibata nesu, isu tinotarisira kukubatsira iwe kuwana yakanakisa simbi pombi sarudzo pane zvaunoda!