ASTM A519tubing ichagadzirwa nenzira isina musono uye ichapisa-yapera kana kutonhora-inopedzwa sezvakatsanangurwa.

Kumachubhu akatenderera ane dhayamita rekunze risingadarike 12 3/4 mukati (325 mm).

Simbi tubing inogona zvakare kugadzirwa mune sikweya, rectangular, kana mamwe maumbirwo sezvinodiwa.

ASTM A519 inogona kuiswa maererano nesimbi yesimbi:Carbon Steeluye Alloy Steel.

Carbon steelyakakamurwa kuitaLow Carbon MT(Mechanical Tubing),High Carbon SteeluyeDesulfurized kana Rephosphorized, kana zvese zviri zviviriCarbon Steel, kuti ienderane nezvinodiwa zvakasiyana zveindasitiri uye mamiriro ekushandisa.

Kana pasina giredhi rataurwa, vagadziri vane sarudzo yekupaMT1015 kana MTX1020mamakisi.

Kunze kwedhayamita: 13.7 - 325 mm;

Wall ukobvu: 2-100mm.

Simbi inogona kugadzirwa nenzira ipi zvayo.

Simbi inogona kukandwa mune ingots kana inogona kukanda tambo.

Machubhu achagadzirwa naseamless processuye ichave ichipisa-yapera kana kutonhora-yapera, sekutsanangurwa kwazvakaitwa.

Seamless simbi machubhu machubhu asina welded seams mukati.

Cold-finished tubeszvinokurudzirwa kune zvakakwirira zvinodiwa pakurongeka kwedimensional uye kunaka kwepamusoro.

Chinonyanya kunetsa ndechekuita-mutengo uye kuoma kwezvinhu,kupisa-kupedzwa kwesimbi pombiinogona kunge iri sarudzo yakakodzera.

Inotevera ndiyo nzira yekugadzira inopisa-yakakungurutswa seamless simbi pombi.

Mugadziri wesimbi achaongorora kupisa kwesimbi imwe neimwe kuti aone huwandu hwezvinhu zvakatsanangurwa.

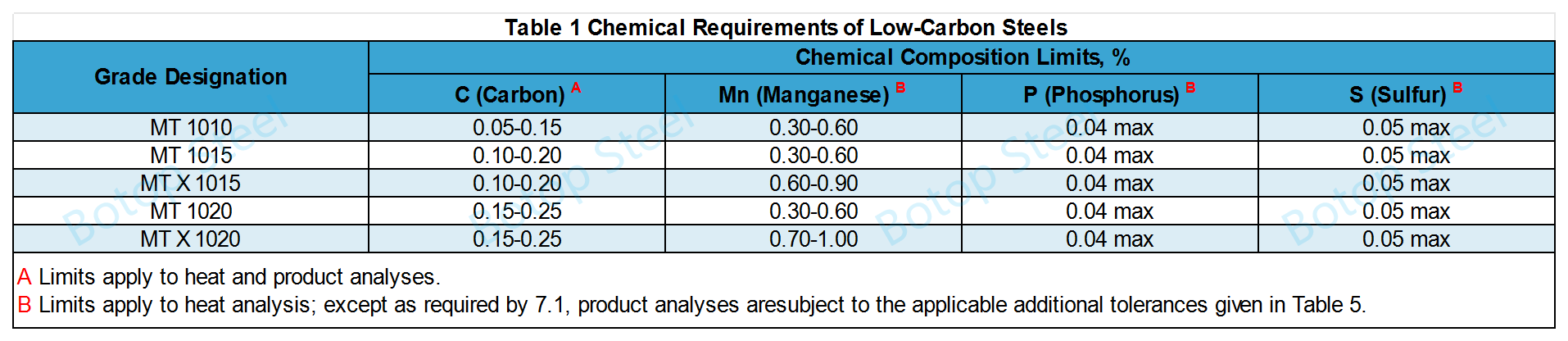

Tafura 1 Kemikari Zvinodiwa zveLow-Carbon Steels

Simbi yakapfava isimbi ine carbon content kazhinji isingadariki 0.25%. Nekuda kwekudzika kwayo kabhoni, simbi iyi ine ductility iri nani uye kugoneka uye haina kuomarara uye yakasimba kana ichienzaniswa nepamusoro-kabhoni simbi.

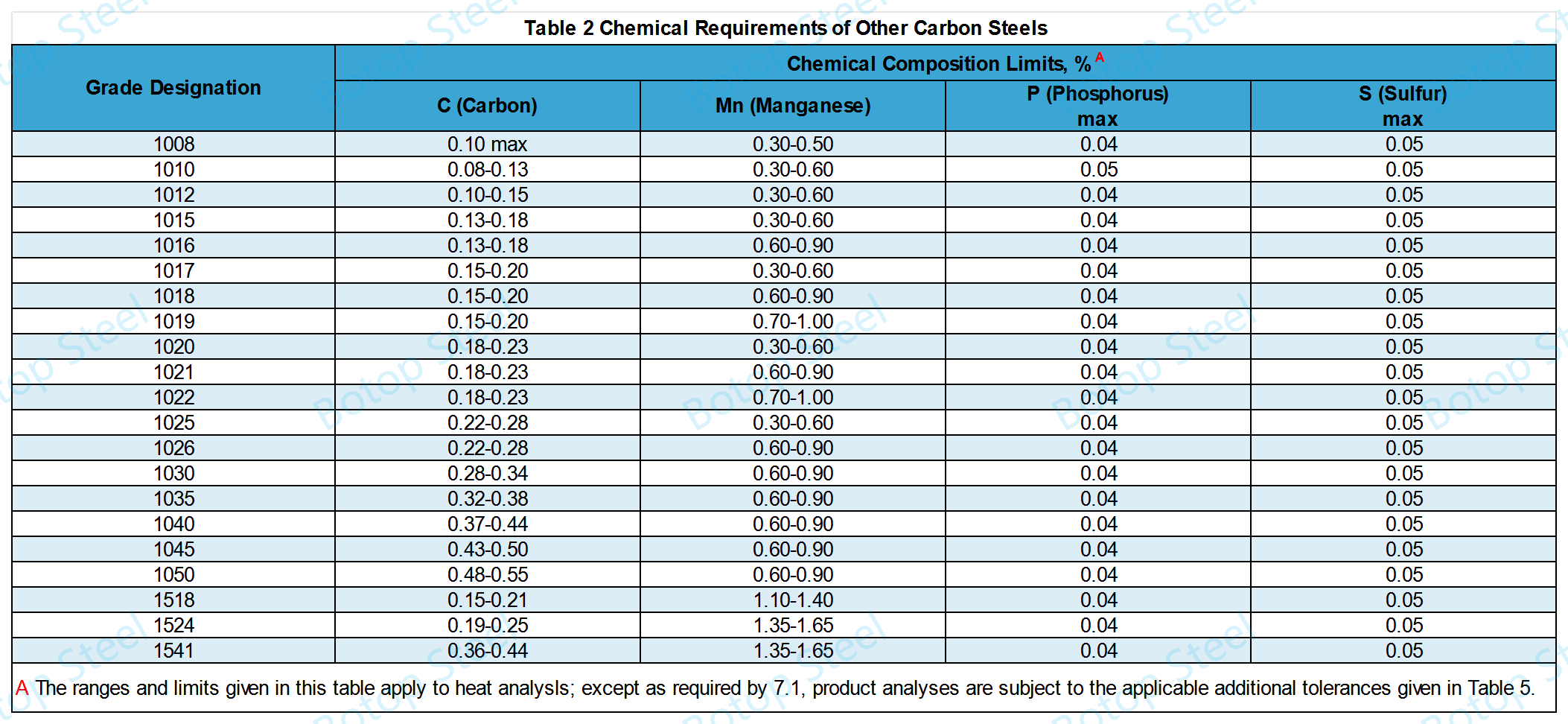

Tafura 2 Kemikari Inodiwa yemamwe Carbon Simbi

Masimbi epakati kabhoni: Iine pakati pe0.25% ne0.60% kabhoni, inopa kuomarara kwepamusoro uye simba uye inoda kurapwa kwekupisa kuvandudza zvivakwa.

High carbon steel: Iine pakati pe0.60% ne1.0% kana kupfuura kabhoni, uye inopa yakanyanya kuoma uye simba, asi yakaderera kuomarara.

Tafura 3 Kemikari Zvinodiwa zveAlloy Steels

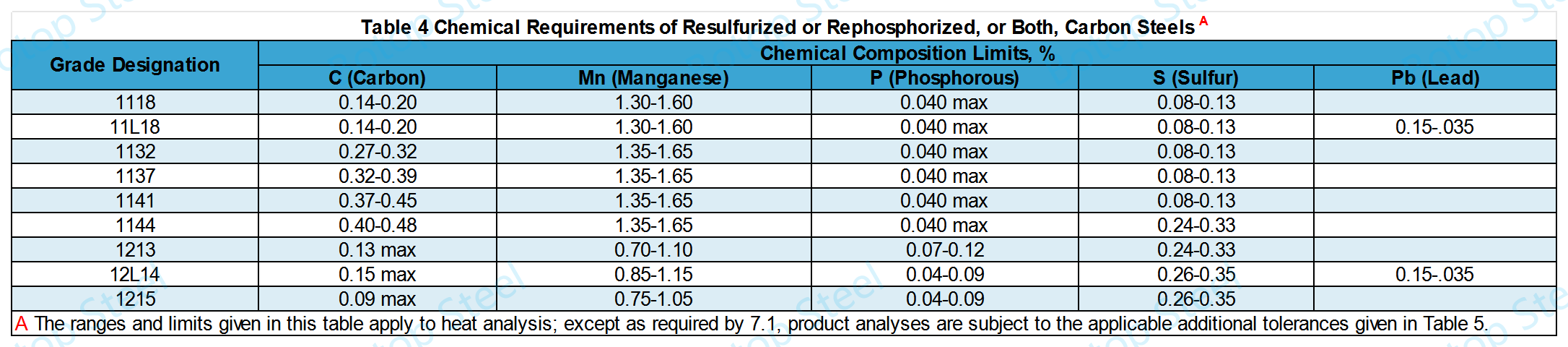

Tafura 4 Kemikari Zvinodiwa zveResulfurized kana Rephosphorized, kana Ose, Carbon Simbi.

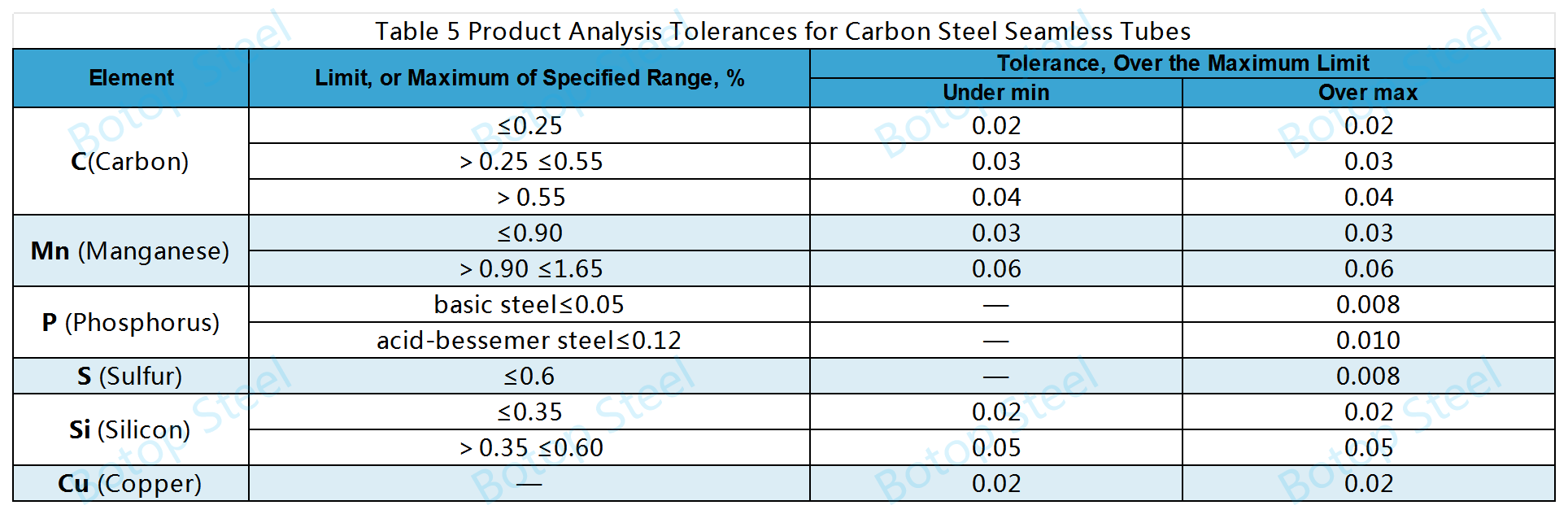

TABLE 5 Product Analysis Tolerances Pamusoro kana Pasi Yakatsanangurwa Range kana Limit

Mugadziri anofanirwa kungobvunzwa kuti aongorore chigadzirwa kana ichidikanwa nekuraira.

ASTM A519 inovhara zvinotevera zvinhu zvekuyedza:

Kuoma Muedzo; Tension Tests; Nondestructive Test; Flaring Test; Simbi Hutsanana uye Kuoma.

| Grade Designation | Pipe Type | Condition | Uitimate Simba | Goho Simba | Elongation mu2in.[50mm],% | Rockwell, Huoma B Chikero | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Carbon Steel | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Carbon Steel | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Carbon Steel | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Carbon Steel | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Carbon Steel | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized kana Rephosphorized, kana Zvose, Carbon Steels | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized kana Rephosphorized, kana Zvose, Carbon Steels | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Alloy Steels | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Alloy Steels | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-Kutonhora Yakashanda, SR-Stress Yakasunungurwa, A-Annealed uye N-Normalized.

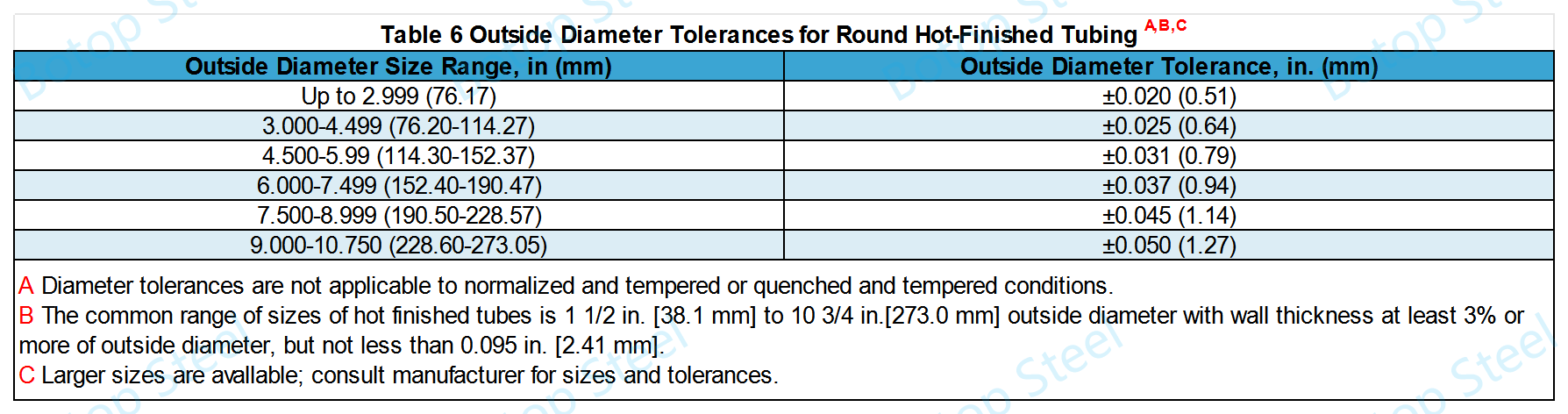

Kunze Diameter Kushivirira

Tafura 6 Kunze Diameter TolerancesyeRound Hot-Yakapedza Tubing

Tafura 12 Kunze Diameter Kushivirira kweGround Seamless Tubing

| Saizi kunze Diameter, mukati.[mm] | Kunze kweDiamita Kushivirira kweSizi uye Hurefu Zvakapihwa, mukati [mm] | |||

| Over | Under | Over | Under | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] apo L≤16ft[4.9m] | 0.000 | 0.004 [0.10] apo L>16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] apo L≤16ft[4.9m] | 0.000 | 0.006 [0.15] apo L>16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] apo L≤12ft[3.7m] | 0.000 | 0.006 [0.15] apo L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] apo L≤12ft[3.7m] | 0.000 | 0.006 [0.15] apo L≤16ft[4.9m] | 0.000 |

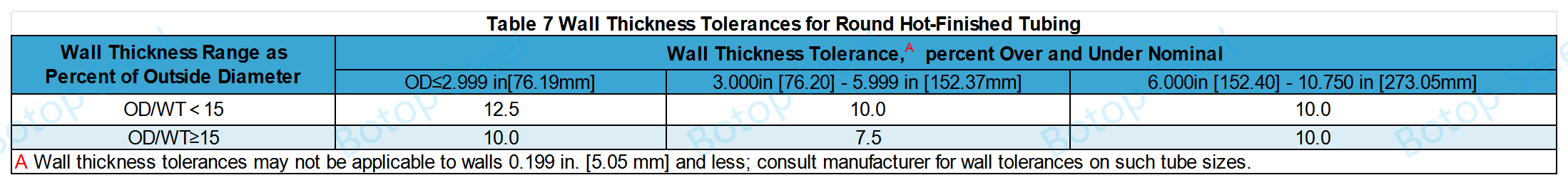

Wall Thickness Tolerance

Tafura 7 Rusvingo Ukobvu TolerancesyeRound Hot-Yakapedza Tubing

Tafura 10 Wall Kukobvu KushivirirayeRound Cold-Worked Tubing

| Wall Kukobvu Ranges sezvo Percent yeKunze Diameter | Wall Ukobvu Kushivirira Pamusoro uye Pasi Nezita,% | |

| OD≤1.499in[38.07mm] | OD≥1.500 mukati [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

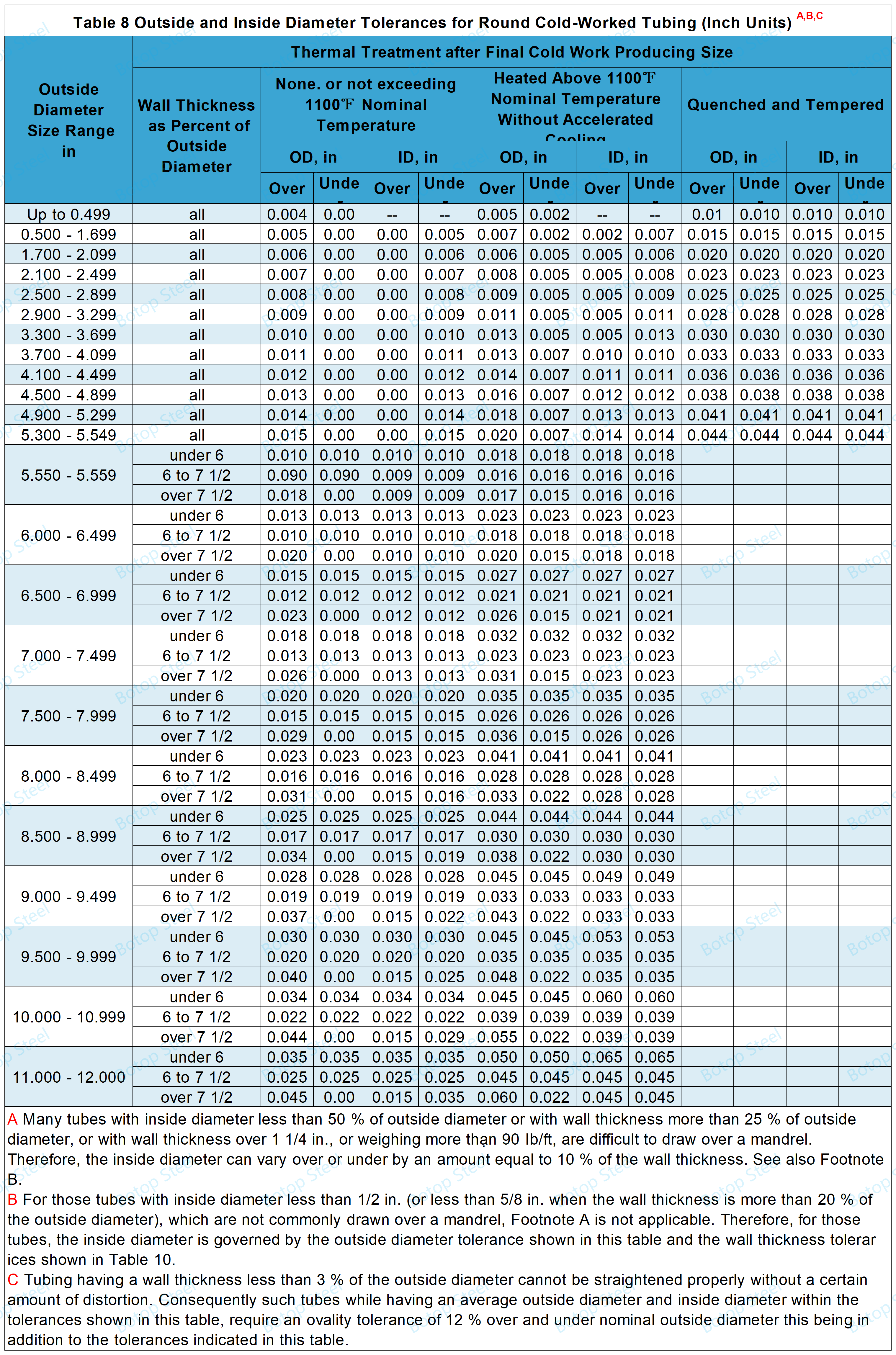

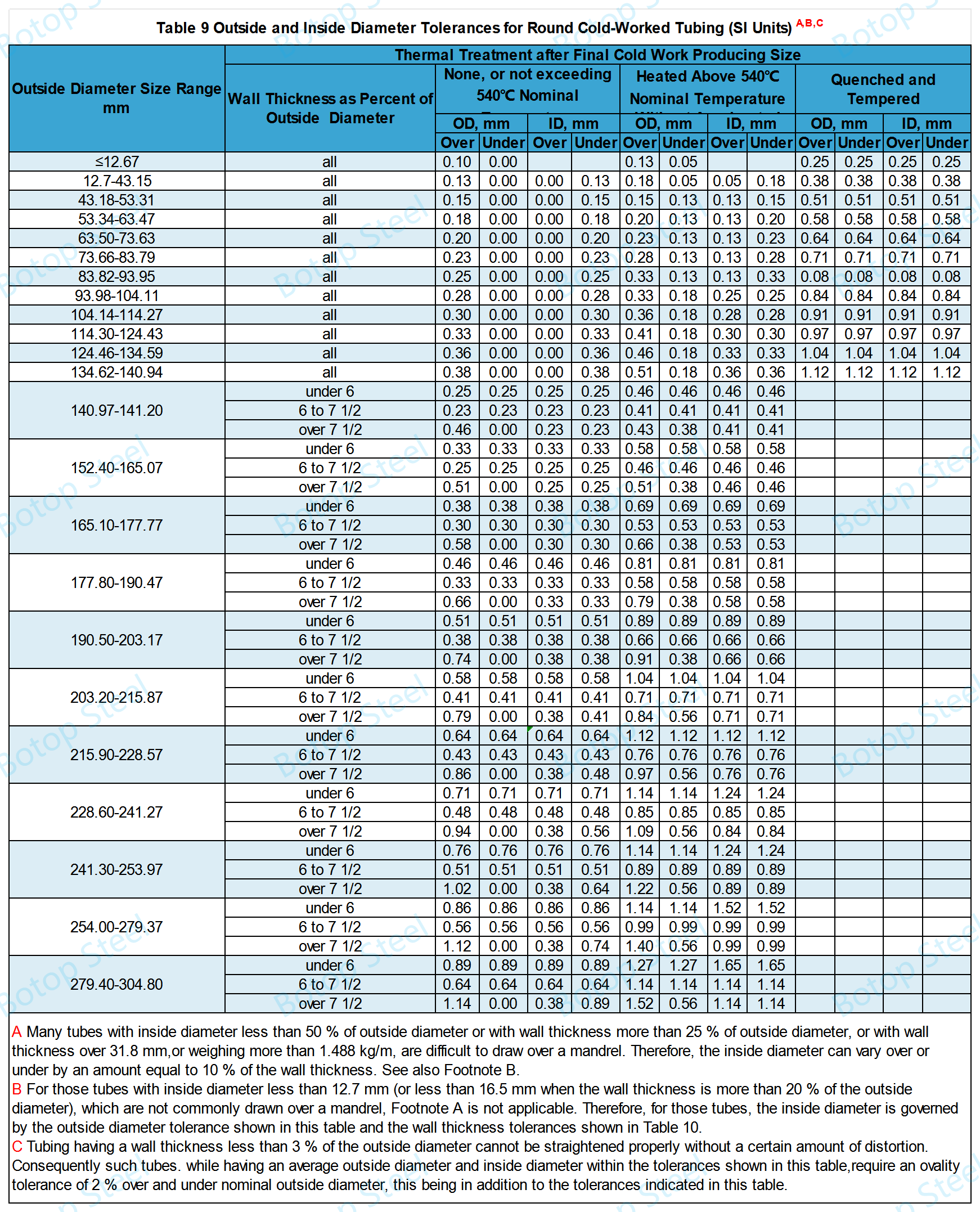

Kunze uye Mukati Diameter Kushivirira

Tafura 8 Kunze uye Mukati Diameter Tolerances yeRound Cold-Worked Tubing (Inch Units)

Tafura 9 Kunze uye Mukati Diameter TolerancesyeRound Cold-Worked Tubing (SI Units)

Kunze Diameter uye Wall Thickness Tolerance

Tafura 11 Kunze Diameter uye Kushivirira KwemadziroyeRough-Turned Seamless Simbi Tubing

| Yakatarwa Size Kunze Diameter, mukati [mm] | Kunze Diameter, mukati [mm] | Kukora kwemadziro, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Kureba Kushivirira

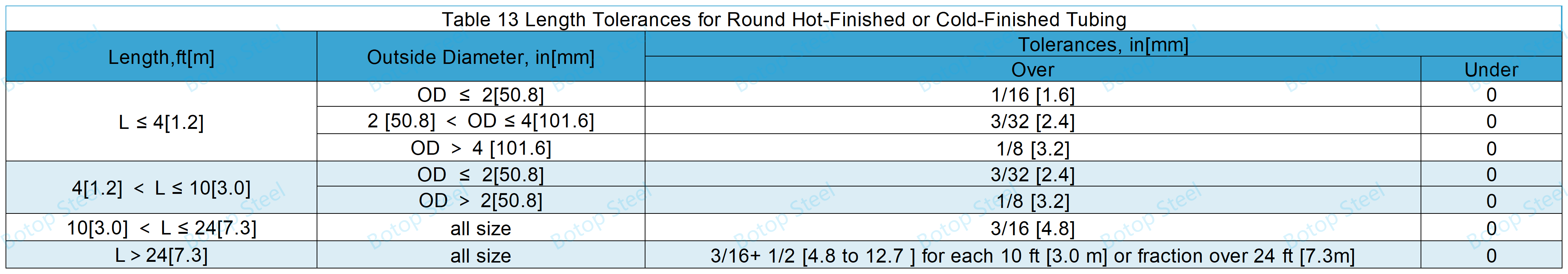

Tafura 13 Kureba KushivirirayeRound Hot-Yapedzwa kana Cold-Finished Tubing

Kururama Kushivirira

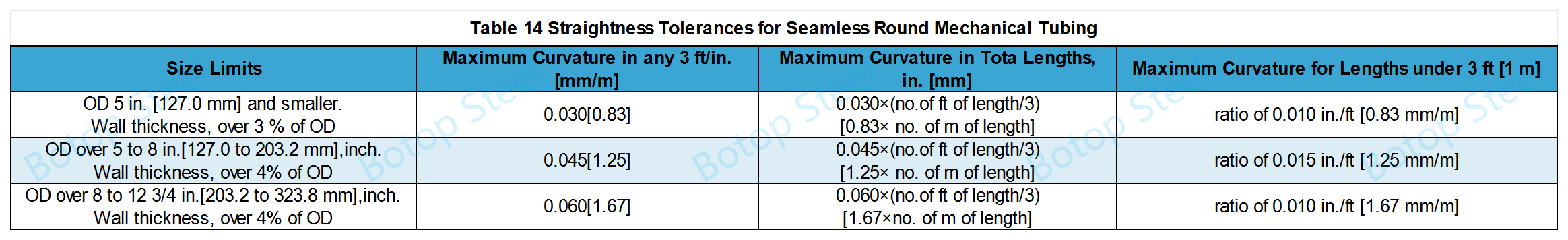

Tafura 14 Kururama KushivirirayeSeamless Round Mechanical Tubing

Iyo pombi inofanira kuputirwa nefirimu yemafuta isati yaumbwa kuti isaita ngura.

Ngura yekudzivirira mafuta inogonawo kuiswa kune mukati uye kunze kwenzvimbo yepombi.

Aviation uye aerospace: kugadzirwa kwezvinhu zvakakosha senge injini dzendege uye masisitimu ekutsigira ndege.

Indasitiri yemagetsi: midziyo yekuchera uye yakakwirira-kumanikidza boiler pombi kugadzira.

Kugadzira michina nemidziyo: Zvikamu zvakakosha zvinoumba huwandu hwakasiyana hwemaindasitiri muchina nemidziyo.

Midziyo yemitambo: Kugadzirwa kwepamusoro-kuita bhasikoro mafuremu uye zvimwe zvivakwa zvemitambo.

Kuvaka uye kuvaka: zvimiro zvekutsigira zvivakwa uye zvikumbiro munzvimbo dzakanyanya-kudzvanywa.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, nezvimwewo. Zvinhu izvi zvinogona kutorwa seyakaenzana neimwe kabhoni uye alloy simbi muASTM A519.

2. DIN 1629: St52, St37.4, etc. Inowanzo shandiswa pamagetsi uye maitiro ekugadzirisa, izvi zvakafanana nemhando dzakapfava dzesimbi muASTM A519.

3. JIS G3445: STKM13A, STKM13B, etc. Aya ndiwo carbon steel tubes anoshandiswa pamagetsi uye maitiro.

4. BS 6323:CFS 3, CFS 4, CFS 8, zvichingodaro. Aya machubhu esimbi asina musono uye akaiswa machubhu emotokari, mechanical, uye general engineering zvinangwa.

5. GB / T 8162: 20 #, 45 #, 40Cr, 20CrMo, etc. Seamless simbi machubhu uye pombi nokuda kwemaitiro akazara uye magadzirirwo emagetsi.

6. ISO 683-17: 100Cr6, zvichingodaro, inowanzoshandiswa mukugadzirwa kwekutakura, inogonawo kuwana kushandiswa muinjiniya yemagetsi uye ine maitiro akafanana kune mamwe masimbi alloy eASTM A519.

Paunenge uchisarudza chinhu chakaenzana, zvakakosha kuti utarise kune yakadzama kemikari kuumbwa uye mekiniki zvivakwa zvakatemwa kuti ive nechokwadi chekuti zvinhu zvakasarudzwa zvinosangana nezvinodiwa zvekushanda kwechimwe chishandiso.

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana. Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.