ASTM A53 ERWsimbi pombi ndizvoType Emune iyo A53 yakatarwa, inogadzirwa neyekupokana welding process, uye inowanikwa mune ese magiredhi A uye Giredhi B.

Iyo inonyanya kufanirwa nemakanika uye kumanikidza kushandiswa uye zvakare inowanzoshandiswa sechinangwa chakajairika chekufambisa chiutsi, mvura, gasi, uye mweya.

Zvakanakira ERW simbi pombi, akadaimutengo wakadererauyekugadzirwa kwepamusoro, ita kuti ive chinhu chesarudzo kune akawanda maindasitiri ekushandisa.

Botop Steelndeyepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe wakasiyana siyana wesimbi pombi mhinduro!

Heventory yedu yakanyatsochengetedzwa uye isu tinokwanisa kusangana nevatengi vedu nekukurumidza kudiwa kwehukuru hwakasiyana hwehukuru uye huwandu.

ASTM A53/A53M inosanganisira anotevera marudzi uye mamakisi:

Type E: Electric-resistance-welded, Magiredhi A uye B.

Type S: Pasina musono, Magiredhi A uye B.

Type F: Furnace-butt-welded, inoenderera yakasungwa Magiredhi A neB.

Type EuyeType Sndiwo marudzi maviri anoshandiswa zvakanyanya mupombi. Mukupesana ne,Type Finowanzo shandiswa kune madiki machubhu madiki. Nekuda kwekufambira mberi mune welding tekinoroji, iyi nzira yekugadzira inoshandiswa zvishoma.

Nominal Diameters: DN 6 - 650 [NPS 1/8 - 26];

Outer Diameter: 10.3 - 660 mm [0.405 - 26 mukati];

Wall ukobvu uye simbi pombi uremu machati:

Flat-end machubhu anogona kutariswa muTable X2.2;

Machubhu akaiswa tambo uye akabatanidzwa anogona kutariswa muTebhu X2.3.

ASTM A53 inobvumirawo kupihwa kwepombi nehumwe hukuru chero iyo pombi inosangana nezvimwe zvese zvinodiwa zveichi chirevo.

ERWinoshandiswa zvakanyanya kugadzira denderedzwa, sikweya, uye rectangular kabhoni uye yakaderera alloy simbi mapaipi.

Iyo inotevera kugadzira ndiyo nzira yekugadzira yekugadziradenderedzwa ERW simbi pombi:

a) Kugadzirira zvinhu: Zvinhu zvekutanga zvinowanzopisa-akaputirwa simbi coils. Makoiri aya anotanga kupepetwa uye kugerwa kusvika pahupamhi hunodiwa.

b) Kuumba: Zvishoma nezvishoma, kuburikidza nenhevedzano yemapumburu, tambo inoumbwa kuita yakavhurika denderedzwa tubular chimiro. Munguva iyi, mipendero yemucheka zvishoma nezvishoma inounzwa pedyo pamwe chete mukugadzirira welding.

c) Welding: Mushure mekugadzira tubular chimiro, mipendero yesimbi strip inopisa nekupikisa kwemagetsi munzvimbo yewelding. Iyo yakakwirira-frequency ikozvino inopfuudzwa kuburikidza nezvinhu, uye kupisa kunokonzerwa nekupikisa kunoshandiswa kupisa micheto kusvika pakunyunguduka kwayo, uye zvino inobatanidzwa pamwe chete nekumanikidzwa.

d) Kubvisa mari: Mushure mekuputika, weld burrs (yakawandisa simbi kubva kune welding) inobviswa kubva mukati nekunze kwepombi kuti ive nechokwadi chepamusoro mukati mepombi.

e) Saizi uye kureba kurongedza: Mushure mewelding uye deburring yapedzwa, machubhu anopfuudzwa nemuchina wekuisa saizi yekugadziriswa kwedimensional kuti ive nechokwadi chekuti anosangana nedhayamita chaiyo uye kutenderera zvinodiwa. Machubhu anozochekwa kuita hurefu hwakafanotemerwa.

f) Kuongorora uye kuyedzwa: Iyo pombi yesimbi ichaitwa kwakasimba kuyedzwa uye kuongororwa, kusanganisira ultrasonic kuyedzwa, hydrostatic test, nezvimwewo, kuve nechokwadi chekuti mhando yepombi yesimbi inosangana nezviyero uye zvakatemwa.

g) Kurapwa kwepamusoro: Pakupedzisira, pombi yesimbi inogona kuiswa kune mamwe marapirwo akadai seanopisa dip galvanizing, kupenda, kana mamwe marapirwo epamusoro kuti ape kuwedzera kwekudzivirira uye aesthetics.

Welds muType E kana Type F Giredhi Bpombi ichadziyirwa kana kubatwa neimwe nzira mushure mekudzikisira kuitira kuti untempered martensite isipo.

Kupisa kwekushisa kwekushisa kunofanira kunge kuri zvishoma1000°F [540°C].

Apo pombi inotonhora yakawedzerwa, kuwedzera hakufaniri kudarika1.5%yezvakatsanangurwa kunze kwedhayamita yepombi.

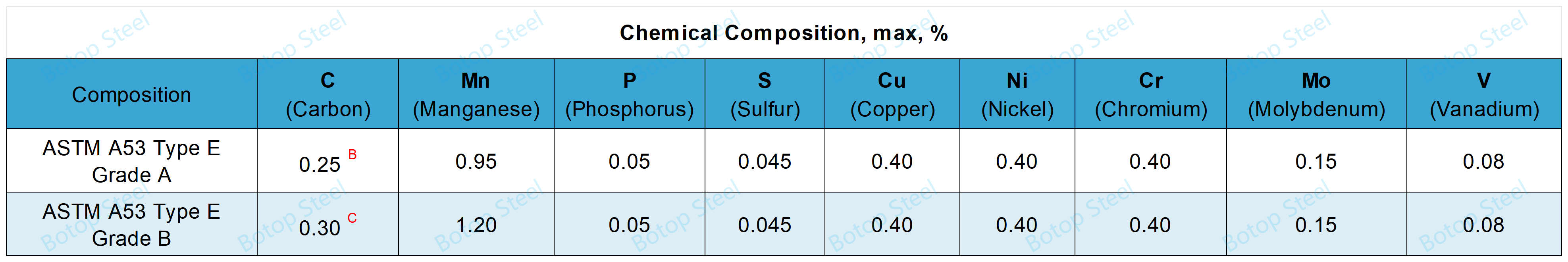

AZvinhu zvishanuCu, Ni, Cr, Mo,uyeVpamwe chete haifaniri kudarika 1.00%.

BPakudzikiswa kwega kwega kwe0.01% pazasi pekabhoni yakataurwa, kuwedzera kwe0.06% yemanganese pamusoro peiyo yakataurwa kunobvumidzwa kusvika pa1.35%.

CPakudzikiswa kwega kwega kwe0.01% pazasi pekabhoni yakataurwa, kuwedzera kwe0.06% yemanganese pamusoro peiyo yakataurwa kunobvumidzwa kusvika pa1.65%.

Tensile Property

| List | Classification | Giredhi A | Giredhi B |

| Kusimba simba, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Goho simba, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation mu50 mm [2 mukati.] | Cherechedza | A,B | A,B |

Cherechedza A: Hurefu hwehurefu mu2 mu[50 mm] huchave hwakatemwa neinotevera equation:

e = 625,000 [1940] A0.2/U0.9

e = kureba kwakaderera mu2 mukati kana 50 mm muzana, yakatenderedzwa kusvika muzana iri pedyo

A = idiki ye0.75 mukati2[500 mm2] uye chikamu chepakati-chepakati chechiratidzo chetension test, yakaverengerwa pachishandiswa dhayamita yekunze yepombi, kana hupamhi hwezita rechiratidzo chetension test uye kukora kwemadziro kwepombi, ine kukosha kwakaverengerwa kwakatenderedzwa kusvika padyo 0.01 mukati.2 [1 mm2].

U=yakatarwa simba shoma rekusimba, psi [MPa].

Cherechedza B: Ona Tafura X4.1 kana Tafura X4.2, chero ipi inoshanda, pahushoma hwehurefu hwekurebesa hunodiwa pamisanganiswa yakasiyana-siyana yetension test specimen size uye yakataurwa shoma yekusimba simba.

Bend Test

Papombi DN ≤ 50 [NPS ≤ 2], hurefu hwakakwana hwepombi huchakwanisa kukotamiswa ichitonhora kuburikidza ne90 ° kutenderedza cylindrical mandrel, iyo dhayamita yakapetwa kagumi nembiri kupfuura yakataurwa kunze kwedhayamita yepombi, pasina kugadzira mitswe pane chero chikamu uye pasina kuvhura weld.

Kaviri-yakawedzera-yakasimba(chikamu chehuremu:XXS) pombi pamusoro peDN 32 [NPS 1 1/4] haifaniri kuiswa pasi pemuedzo wekubhenda.

Flattening Test

Muedzo wekubata kumeso uchaitwa papombi yakasungwa pamusoro peDN 50 muhuremu hwakasimba (XS) kana kureruka.

Inokodzera Rudzi E, Giredhi A uye B; uye Type F, Grade B machubhu.

Seamless simbi machubhu haafaniri kuongororwa.

Nguva Yekuedza

Kune ese masaizi eType S, Type E, uye Type F Giredhi B piping, iyo yekuyedza kudzvanywa ichachengetedzwa kwehushoma hwe5s.

Iyo hydrostatic bvunzo ichaiswa, pasina kuvuza kuburikidza nemusono we weld kana muviri wepombi.

Test Pressures

Pipe-inopera pombiichaongororwa hydrostatic kune kumanikidzwa kunoshanda kwakapihwa mukatiTafura X2.2,

Pipe yakarukwa-uye-yakabatanidzwaichaongororwa hydrostatic kune kumanikidzwa kunoshanda kwakapihwa mukatiTafura X2.3.

Kune mapaipi esimbi ane DN ≤ 80 [NPS ≤ 80], kumanikidzwa kwekuedza hakufaniri kudarika 17.2MPa;

Pamapombi esimbi ane DN>80 [NPS>80], muedzo wekumanikidza haufanire kudarika 19.3MPa;

Dzvinyiriro dzepamusoro dzekuyedza dzinogona kusarudzwa kana paine zvakakosha zveinjiniya zvinodiwa, asi izvi zvinoda nhaurirano pakati pemugadziri nemutengi.

Kumaka

Kana iyo pombi yakaedzwa hydrostatic, iyo yekumaka inofanira kuratidza iyotest pressure.

Zvinotevera zvinodiwa zvinoshanda kune Type E uye Type F Giredhi B Pipe.

Seamless pombi ine zvimwe zvinodiwa izvo zvisina kukurukurwa mugwaro rino.

Miedzo Nzira

Mapaipi anogadzirwa neasina-kupisa-kutambanudza-kutambanudza uye macontraction michina: DN ≥ 50 [NPS ≥ 2], iyoweldsmuchikamu chega chega chepombi inoda kupasa isingaparadze magetsi bvunzo, uye nzira yekuyedza inofanirwa kuenderana neE213, E273, E309 kana E570standard.

Mapaipi eERW anogadzirwa nemuchina wekupisa-unodzora dhayamita: DN ≥ 50 [NPS ≥ 2]Chikamu chimwe nechimweyepombi ichaongororwa zvizere zvizere nekuongororwa kwemagetsi kusingaparadzi, izvo zvichange zvichienderana neE213, E309, kanaE570mipimo.

Ongorora: Kupisa Kuwedzera Kuwedzera Diameter Machine muchina unoramba uchitambanudza uye kusvina machubhu esimbi nema roller patembiricha yakakwira kugadzirisa madhayamita uye ukobvu hwemadziro.

Kumaka

Kana iyo tube yakave yakagadziriswa kuongororwa kusina kukanganisa, zvakakosha kuratidzaNDEpakumaka.

Misa

±10%.

Pipe DN ≤ 100 [NPS ≤ 4], yakayerwa sebhechi.

Mapombi DN> 100 [NPS> 4], akayerwa muzvidimbu zvimwechete.

Diameter

Nokuda kwepombi DN ≤40 [NPS≤ 1 1/2], kuchinja kweOD hakufaniri kudarika ± 0.4 mm [1/64 in.].

Papombi DN ≥50 [NPS>2], OD kusiyana hakufaniri kudarika ±1%.

Hukobvu

Ukobvu hwemadziro hushoma hurege kuva hushoma pane87.5%yezvakatarwa madziro ukobvu.

yakareruka pane yakawedzera-simba (XS) uremu:

a) plain-end pombi: 3.66 - 4.88m [12 - 16 ft], Kwete kupfuura 5% yehuwandu hwehuwandu.

b) kureba kwekaviri-random: ≥ 6.71 m [22 ft], Minimum avhareji urefu hwe10.67m [35 ft].

c) hurefu husina kurongeka: 4.88 -6.71m [16 - 22 ft], isingapfuuri 5% yehuwandu hwehurefu hwakarukwa hwakapihwa kuva majoini (zvidimbu zviviri zvakabatanidzwa).

Kuwedzera-kusimba (XS) uremu kana kurema: 3.66-6.71 m [12 - 22 ft], kwete kupfuura 5% yose yepombi 1.83 - 3.66 m [6 - 12 ft].

YeASTM A53 simbi pombi kupera inowanikwa mutema kana galvanized.

Nhema: Simbi tubing pasina chero kurapwa kwepamusoro, kazhinji inotengeswa zvakananga mushure mekugadzirwa kwemaitiro, kune izvo zvikumbiro uko pasina kuwedzera corrosion kuramba kunodiwa.

Mapaipi ane galvanized anofanirwa kuzadzisa zvinodiwa.

Process

Iyo zinc ichaputirwa mukati uye kunze neiyo inopisa-dip process.

Raw Material

Iyo zinc inoshandiswa pakupfekedza ichave chero giredhi rezinc rinoenderana nezvinodiwa zveSpecificationASTM B6.

Chitarisiko

Pombi ine galvanized ichave isina nzvimbo dzisina kuvharwa, mabubbles emhepo, flux deposits, uye coarse slag inclusions. Mapundu, mapundu, globules, kana huwandu hwakawanda hwezinc deposits izvo zvinokanganisa mashandisirwo akaitwa zvinhu hazvibvumidzwe.

Galvanized Coating Weight

Ichatemerwa ne peel test zvinoenderana neyeyedzo nzira ASTM A90.

Uremu hwekuputira hahufanire kunge huri pasi pe0.55 kg/m² [1.8 oz/ft²].

ASTM A53 ERW simbi pombiinowanzo shandiswa mune yakaderera kusvika yepakati-kumanikidza kunyorera senge mainjiniya einjiniya, kuvaka, uye mekiniki yechimiro pombi. Mamiriro ekushandisa akajairika anosanganisira kuendesa mvura, chipfunga, mweya, uye zvimwe zvinwiwa zvakaderera.

Nekukwenenzverwa kwakanaka, akakodzera kugadzira maoparesheni anosanganisira kukochekera, kukotama, uye kupeta.