BS EN 10210 S275J0Hinzvimbo inopisa-yakapera mhango yesimbi yesimbi yakagadzirwaBS EN 10210mumhando dzakasiyana dzedenderedzwa, mativi mana, rectangular, kana ovhari chikamu maumbirwo.

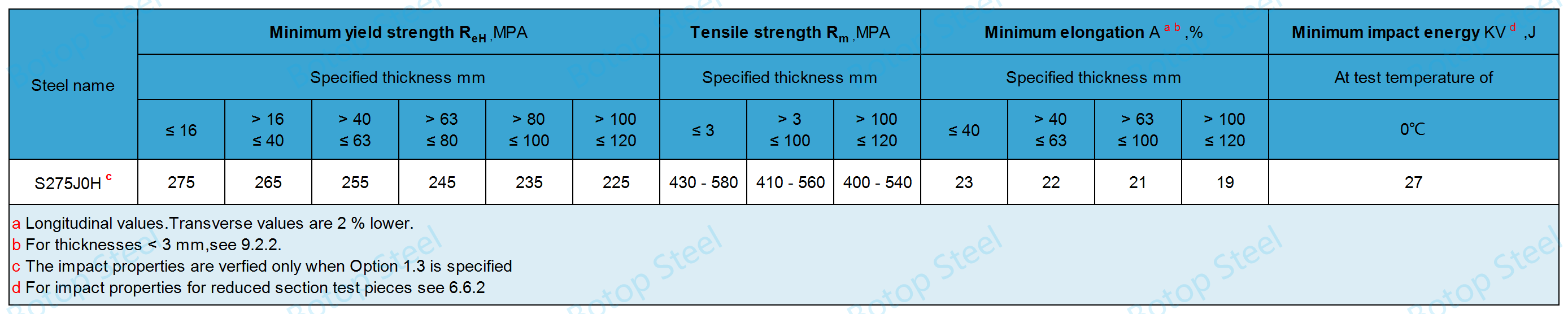

S275J0H zvinhu zvinoratidzwa nekushomeka kwegoho simba re275 MPa pakukora isingapfuuri 16 mm; simba rayo shoma rekuita rinenge risingaite 27 J pa 0 ℃.

S275J0H ndeyemhando yekabhoni simbi, nhamba yesimbi1.0149, iyo ine maitiro akanaka uye maitiro ekugadzirisa, anonyanya kushandiswa muzvivako zvekuvaka, asi zvakare anoshandiswa kune zvisingaregi-kutakura zvikamu, zvinogona kupa mukuchengetedza kugadzikana kwemaitiro uye kusimba kunobva pakuzadzikiswa kwemari shoma inobatsira.

Ongorora: Zvese zvinodiwa muBS EN 10210 zvinoshandawo kune EN 10210 uye saka hazvidzokororwe pano.

Mazita egiredhi muBS EN 10210 anopihwa zvinoenderana ne EN 10027-1 uye nhamba dzesimbi dzakapihwa zvinoenderana ne EN 10027-2.

| Zita resimbi | Nhamba yesimbi | Simbi Type | Zita resimbi | Nhamba yesimbi | Simbi Type |

| S235JRH | 1.0039 | carbon steel | S275NH | 1.0493 | carbon steel |

| S275J0H | 1.0149 | carbon steel | S275NLH | 1.0497 | carbon steel |

| S275J2H | 1.0138 | carbon steel | S355NH | 1.0539 | carbon steel |

| S355J0H | 1.0547 | carbon steel | S355NLH | 1.0549 | carbon steel |

| S355J2H | 1.0576 | carbon steel | S420NH | 1.8750 | alloy simbi |

| S355K2H | 1.0512 | carbon steel | S420NLH | 1.8751 | alloy simbi |

| S460NH | 1.8953 | alloy simbi | |||

| S460NLH | 1.8956 | alloy simbi |

Kuti uwane rumwe ruzivo nezve zvinorehwa nemabhii nenhamba mumagiredhi,unogona kudzvanya pano.

Kukora kwemadziro ≤120mm.

Circular: Kunze madhayamita kusvika 2500 mm;

Square: Kunze zviyero kusvika 800 mm x 800 mm;

Rectangular: Kunze zviyero kusvika 750 mm x 500 mm;

Elliptical: Zviyero zvekunze kusvika pa500 mm x 250 mm.

Isu tine hunyanzvi mukupa akasiyana siyana eRound Hollow Structural Steel Pipe, kana uine chero zvaunoda, ndapota inzwa wakasununguka kutibata, tichitarisira kushanda pamwe newe!

LSAW welded simbi mapaipi anonyanya kugadzirwa nekugadzira mahwendefa esimbi mumachubhu vachishandisa JCOE molding process, inoteverwa newelding uchishandisa kaviri-sided submerged arc.DSAW) welding tekinoroji, uye inopedzwa kuburikidza nehuwandu hwekuongorora uye marapirwo.

Iwe unosarudza sei nzira yekugadzira yakakodzera? Ndeupi mutsauko uye zvakanakira pombi yesimbi isina musono, LSAW, yakanyura arc welding, uye yakanyudzwa arc welding? Uye ndeupi huwandu hwehukuru hwemaitiro ega ega? Unogona kudzvanya iyi link kuti uione.

Unhu JR,J0, J2 uye K2 -kupisa kwapera;

Hunhu N uye NL - yakajairwa. Normalized inosanganisira normalized rolled.

| Steel grade | Type ye deoxidationa | % nehuwandu, huwandu | |||||||

| C (Kabhoni) | Si (Silicon) | Mn (Manganese) | P (Phosphorous) | S (Sarufa) | Nb,c (Nitrogen) | ||||

| Zita resimbi | Nhamba yesimbi | Ukobvu hunotsanangurwa (mm) | |||||||

| ≤40 | >40≤120 | ||||||||

| S275J0H | 1.0149 | FN | 0.20 | 0.22 | - | 1.5 | 0.035 | 0.035 | 0.009 |

aFN = Rimming simbi haibvumidzwe;

bZvinotenderwa kudarika zvakatarwa zvinopihwa kuti pakuwedzera kwega kwega kwe0.001 % N the P, max. zvemukati zvakare zvakaderedzwa ne0.005%. Iyo N yemukati yekuongorora yakakandwa, zvisinei, haingave inopfuura 0.012%;

cKukosha kwenitrogen hakushande kana kemikari ichiratidza huwandu hushoma hwese hweAl content ye0.020 % ine chiyero cheAl/N che2:1, kana kana zvimwe zvakakwana zveN-binding zvinhu zviripo. Iyo N-inosunga zvinhu icharekodhwa muChinyorwa Chekuongorora.

Iyo mechanic zvimiro zve BS EN 10210 inosanganisira simba regoho, kusimba kwesimba, kurebesa, uye kukanganisa zvivakwa.

Zvikamu zvisina makomba zvichange zvine nzvimbo yakatsetseka inoenderana nekugadzira nzira inoshandiswa; mabumps, cavities, kana shallow longitudinal grooves inokonzerwa nekugadzira maitiro anotenderwa, chero ukobvu huri mukati mekushivirira.

EN 10210 Simbi pombi nzvimbo dzakakodzera kupisa dip galvanizing.

EN 10210 haidi hydrostatic pressure kuyedzwa kwepombi dzesimbi.

Izvi zvinodaro nekuti iyo EN 10210 yakajairwa zvigadzirwa zvinonyanya kushandiswa kune zvimiro uye kwete zvemapombi masisitimu anoda kumanikidzwa.

Kana hydrostatic pressure test ichidikanwa, referensi inogona kuitwa kune EN 10216 (seamless simbi machubhu) kana EN 10217 (welded simbi machubhu) zviyero.

Iko hakuna chinosungirwa chinodiwa muchiyero kuita NDT pane hollow chikamu simbi mapaipi.

Kana NDT ichiitwa pane welded simbi pombi, zvinotevera zvinodiwa zvinogona kutaurwa.

Magetsi Welded Zvikamu

Pamachubhu esimbi akatenderedzwa neburi machubhu iERW.

Unogona kusarudza imwe yeinotevera nzira dzekuyedza dzekuyedza.

a) EN 10246-3 kusvika padanho rekugamuchira E4, kunze kwekuti iyo inotenderera chubhu/pancake coil tekinoroji haitenderwe;

b) EN 10246-5 kusvika padanho rekugamuchira F5;

c) EN 10246-8 kusvika padanho rekugamuchira U5.

Yakanyura Arc Welded Zvikamu

Kune denderedzwa hollow chikamu simbi machubhu iLSAW uye SSAW.

Iyo weld seam yeakanyudzwa arc welded hollow zvikamu zvichayedzwa zvinoenderana neEN 10246-9 kusvika kugamuchirwa level U4 kana neradiography zvinoenderana neEN 10246-10 ine mufananidzo wemhando kirasi R2.

Kuti uwane rumwe ruzivo rwakadzama pane zvinodiwa zvine chekuita nedimensional tolerances,ndapota tinya pano kuti uwane rumwe ruzivo.

EN 10025 - S275J0;

JIS G3106 - SM400B;

CSA G40.21 - 300W;

Paunenge uchisarudza iyo EN 10210 S275J0H yakaenzana, kuenzanisa kwakadzama kwemakemikari ekuumbwa uye michina zvivakwa zvinofanirwa kuitwa kuve nechokwadi chekuti zvinhu zvakasarudzwa zvinosangana nezvinodiwa zveprojekiti.

Kubva pakavambwa muna 2014.Botop Steelrave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa rakanakisa, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.