EN 10219 S275J0H uye S275J2Hzvikamu zvinotonhora-zvakaumbwa zvakashongedzwa zvemakomba makomba akagadzirwa nesimbi isina-yakasanganiswa maererano ne EN 10219.

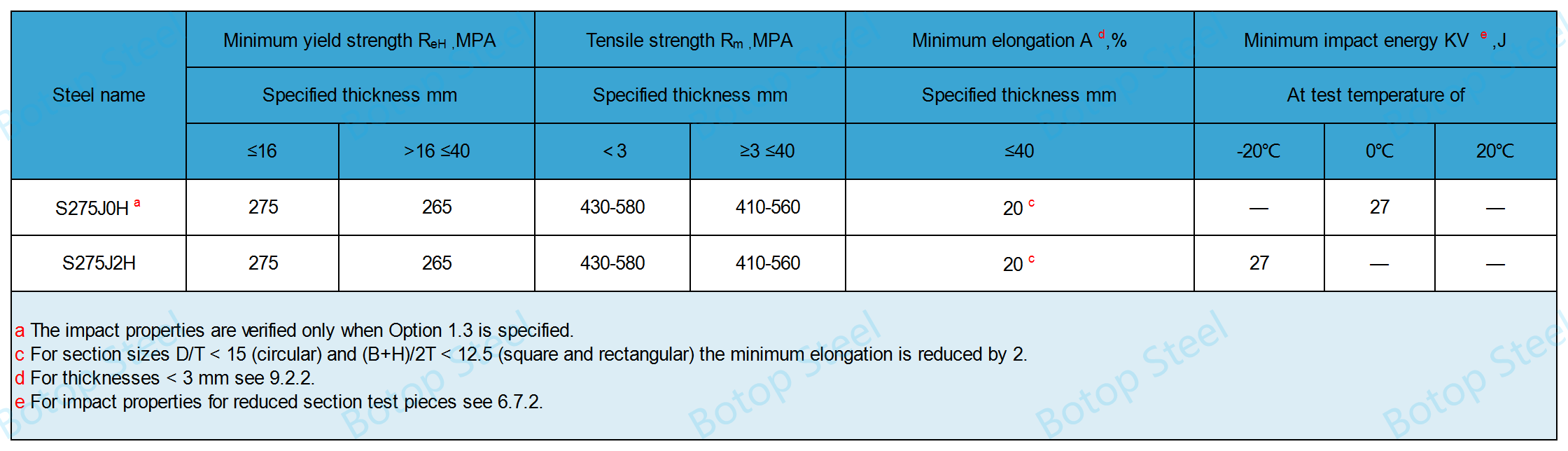

Ivo vese vane simba shoma regoho re275MPa (madziro ukobvu ≤16mm). Musiyano mukuru uri mukukanganisa zvivakwa: S275J0H ine simba shoma rekuita re27 J pa 0°C, ukuwo S275J2H ine simba rekuita shoma re27 J pa -20°C.

Inokodzera kunyorera muzvivakwa uye mainjiniya zvimiro zvinoenderana nekureruka mitoro.

BS EN 10219 ndiyo European Standard EN 10219 yakagamuchirwa neUK.

Wall ukobvu ≤40mm, Outer dhayamita ≤2500mm.

CFCHS ichidimbu cheCold-Formed Circular Hollow Section.

Iyo EN 10219 yakajairwa inovhara dzakasiyana siyana dzakakomba zvimiro zvesimbi zvimiro, zvinosanganisira denderedzwa, sikweya, rectangular, uye oval, kuti ikwane zvakasiyana zvinodiwa zvekushandisa.

Botop Steelinyanzvi pakupa machubhu esimbi akatenderedza muchikamu chakasiyana-siyana uye maitiro kuti aenderane neyakasiyana siyana yekushandiswa kwemaindasitiri, kuve nechokwadi chekuti zvinodiwa nevatengi vedu zvinogona kuzadzikiswa.

Kubva pakavambwa muna 2014.Botop Steelrave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa rakanakisa, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa zvakasiyana-siyana zvekabhoni simbi mapaipi uye zvine hukama zvigadzirwa, kusanganisiraSMLS, ERW, LSAW,uyeSSAWpombi yesimbi, pamwe chete nemutsara wakakwana wepombi fittings uye flanges. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Isu tinotarisira kumisikidza hukama hwekushandira pamwe newe uye kugadzira ramangwana rekuhwina pamwe chete.

Simbi yakasvibirira yekugadzirwa kwezvikamu zvinotonhora-yakaumbwa negomba yakasvibiswa uye inofanirwa kusangana nemamiriro ekutumira.

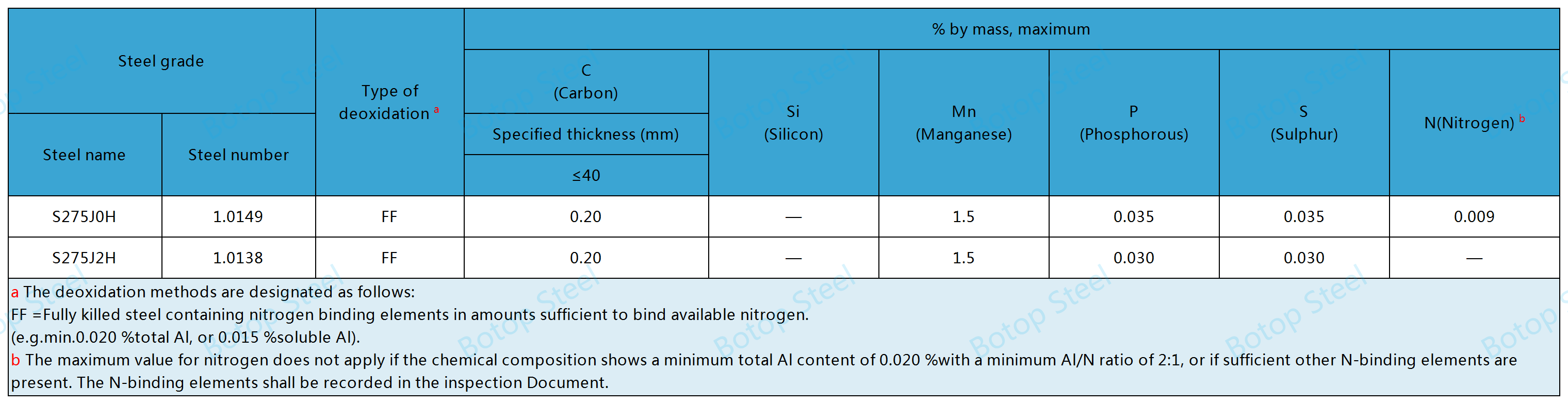

Izvo zvinoenderana nezvinodiwa zveS275J0H uye S275J2H ndizvoFF(Simbi yakaurayiwa yakazara ine nitrogen inosunga zvinhu muhuwandu hunokwana kusunga nitrogen inowanikwa (semuenzaniso min.0,020 % yakazara Al kana 0,015 % soluble Al)).

Delivery mamiriro: Yakakungurutswa kana yakajairika / yakajairika yakakungurutswa (N) yeJR, J0, J2, uye K2 masimbi.

Mapombi esimbi kune EN 10219 anogona kugadzirwa neaviriERW( electro resistance welding ) uyeSAW( submerged arc welding) maitiro ekugadzira.

Kugadzirwa kweERW machubhuine mukana wekukurumidza uye isingadhuri zvakanyanya uye inowanzosarudzirwa mapurojekiti anoda kugadzirwa kwakakura uye kudhura kwakanyanya.

ERWmachubhu anowanzo shandiswa kugadzira madhayamita madiki uye akatetepa madziro ukobvu, ukuSAWmachubhu anonyanya kukodzera madhayamita akakura uye madziro akakora. Ndapota sarudza rudzi rwakakodzera rwepombi yesimbi yeprojekti yako.

ERW mapaipi anogadzirwa zvinoenderana neEN 10219 haawanzo kuda mukati weld kuchekwa.

Izvi zvinodaro nekuti EN 10219 machubhu anonyanya kushandiswa mune zvimiro zvekushandisa, senge kuvaka uye mechaniki engineering, uko zvinodikanwa zvekutaridzika kwe weld zvinowanzoita zvishoma kuomarara pane midziyo yekumanikidza kana mapipe ekumanikidza. Nokudaro, chero bedzi simba uye kutendeseka kweweld kunosangana nezvinodiwa zveyero, mukati welds inogona kushandiswa pasina kuwedzera kutema.

Hapana kunotevera kupisa kurapwa kunoitwa, kunze kwekunge weld inogona kunge iri mune welded kana kupisa-kurapwa mamiriro.

Cast Analysis (Chemical Composition of Raw Materials)

Ose S275J0H uye S275J2H ane yakanyanya kabhoni yakaenzana kukosha (CEV) ye0.40%.

S725J0H uye S275J2H ine yakakura CEV ye0.4% inoratidzira zvirinani weldability ine njodzi shoma yekuomesa uye kutsemuka panguva yewelding.

Inogona zvakare kuverengerwa uchishandisa inotevera formula:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

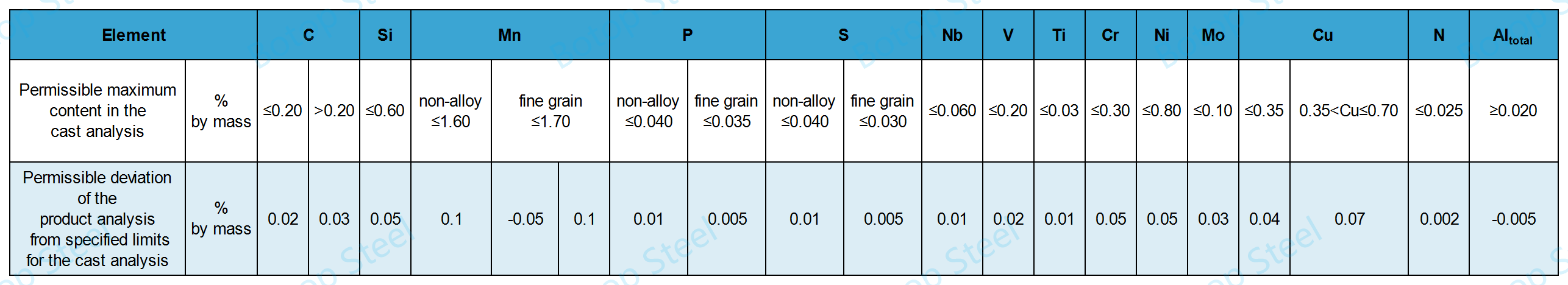

Product Analysis (Chemical Composition of Finished Products)

Panguva yekugadzirwa kwesimbi, chimiro chemakemikari chinogona kuchinja nekuda kwezvikonzero zvakawanda, uye kuchinja uku kunogona kukanganisa maitiro uye kunaka kwesimbi.

Iyo yekupedzisira yakapedzwa simbi pombi kemikari yemakemikari inofanirwa kuenderana nekemikari yekukanda uye kutsauka kwayo kunobvumidzwa.

Mechanical zvivakwa paramita zvinosanganisira goho simba, tensile simba, elongation, uye simba simba.

Kurerutsira kushushikana kunodarika 580 ℃ kana kweinopfuura awa imwe chete kunogona kukonzera kushata kwezvinhu zvemuchina.

Notes:

Kuyedzwa kwemhedzisiro hakudiwe kana ukobvu hwataurwa huri <6mm.

Izvo zvinokanganisa zvivakwa zveJR uye J0 mhando machubhu haaonekwe kunze kwekunge ataurwa.

EN 10219 Welds muERW simbi mapaipi anogona kuedzwa nekusarudza imwe yeinotevera.

TS EN 10246-3 kusvika padanho rekugamuchira E4, kunze kwekuti iyo inotenderera chubhu/pancake coil tekinoroji haitenderwe;

EN 10246-5 kusvika padanho rekugamuchira F5;

EN 10246-8 kusvika padanho rekugamuchira U5.

Kuverengerwa kwehuremu hwe theoretical hweEN 10219 machubhu anogona kuenderana nechubhu density ye7.85 kg/dm³.

M=(DT)×T×0.02466

M ndiyo huremu pahurefu hweyuniti;

D ndiyo yakataurwa kunze kwedhayamita, zvikamu mu mm;

T ndiyo yakatsanangurwa madziro ukobvu, mayunitsi mu mm.

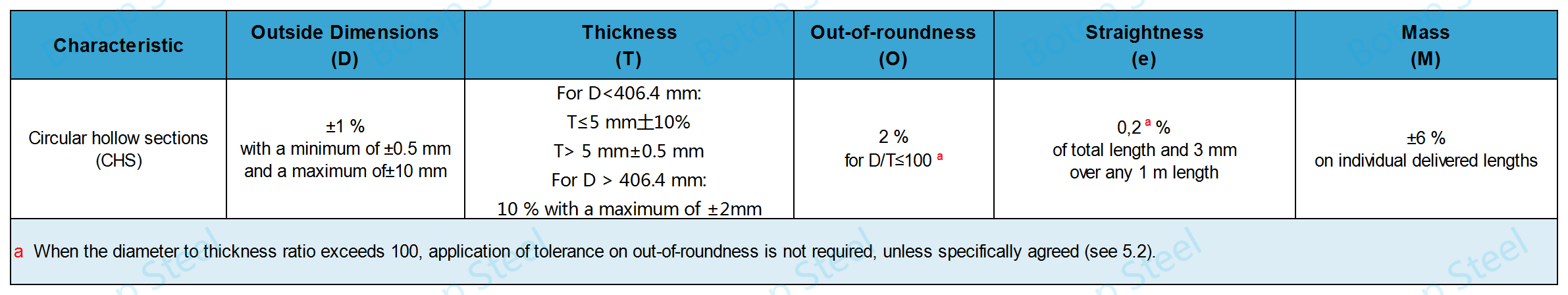

Kushivirira paChimiro, Kururama uye Misa

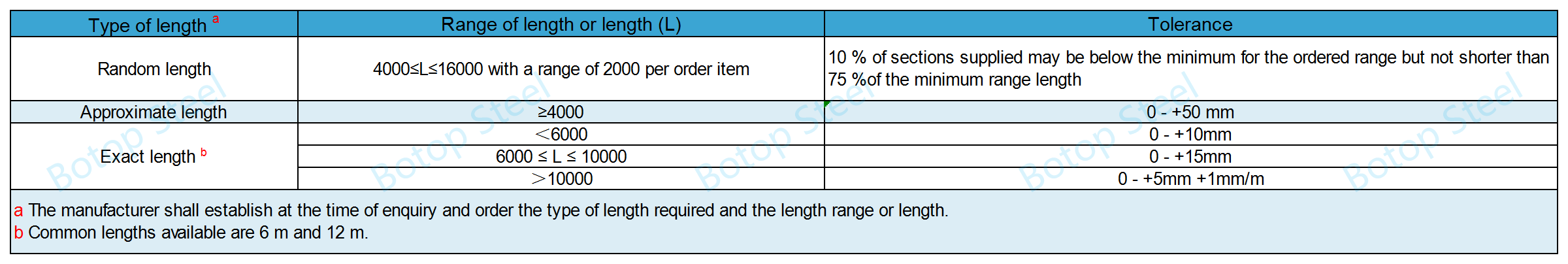

Kushivirira Kureba

Hollow chikamu machubhu anogadzirwa zvinoenderana neEN 10219 anogoneka.

Kana welding, kutonhora kutsemuka munzvimbo yeweld ndiyo njodzi huru sezvo ukobvu, simba nhanho, uye CEV yechigadzirwa ichiwedzera. Cold cracking inokonzerwa nekubatanidzwa kwezvinhu zvakati wandei:

mazinga akakwirira ehydrogen diffusible mu weld metal;

brittle chimiro munzvimbo inopisa-inopisa;

kwakakosha tensile stress concentrations mune welded joint.

Pamusoro pepombi yesimbi inofanirwa kuve yakatsetseka uye isina hurema hungakanganisa kushanda kwechigadzirwa, senge makatsemuka, makomba, makwara, kana ngura.

Mabumps, grooves, kana shallow longitudinal grooves yakagadzirwa nemaitiro ekugadzira inogamuchirwa chero bedzi iyo yakasara yemadziro gobvu iri mukati mekushivirira, kukanganisa kunogona kubviswa nekukuya, uye kugadziridzwa kwemadziro ukobvu kunosangana nehupamhi hudiki zvinodiwa.

Botop Steelhaingope machubhu emhando yepamusoro-soro zvinoenderana neEN 10219, inopawo huwandu hwakawanda hwesarudzo dzekuputira pamusoro pemachubhu esimbi kuti ienderane nezvinodiwa nevatengi vayo mumapurojekiti akasiyana einjiniya. Aya machira akagadzirwa kuti akwidziridze kushomeka kwemachubhu uye kuwedzera imwe dziviriro, nekudaro kuwedzera hupenyu hwavo hwesevhisi.

Hot-dip Galvanizing

3LPE (HDPE) Coating

FBE Coating

Varnish Coating

Paint Coating

Cement Weight Coating

Bridge components: Zvivako zvisiri zvekutanga zvinotakura zvinotakura zvinoshandiswa mumabhiriji, senge railings uye parapets.

Architectural mbiru: Makoramu anotsigira uye matanda anoshandiswa mukuvaka uye civil engineering.

Piping systems: pombi yekutakurwa kwezvinwiwa nemagasi, kunyanya mumashandisirwo anoda mwero wekushanduka uye kusagadzikana kwekuora.

Zvivakwa zvenguva pfupi: zvitsigiro zvenguva pfupi uye mafuremu akakodzera kuvaka uye engineering nzvimbo.

Aya maapplication anotora mukana weakanakisa mechanic zvivakwa uye weldability yeS275J0H uye S275J2H kusangana nezvinodiwa zvehuremu asi dzakagadzikana zvimiro.

ASTM A500:Chimiro Chekumisikidzwa KweCold-Yakagadzirwa Welded uye Seamless Carbon Steel Structural Tubing muRounds uye Shapes.

ASTM A501: Yakajairwa Kutsanangurwa Kwekupisa-Yakaumbwa Welded uye Seamless Carbon Steel Structural Tubing.

EN 10210: Kupisa kwakapedzwa kwechimiro chegomba zvikamu zveasiri-alloy uye yakanaka zviyo simbi.

EN 10219: Inotonhora yakaita welded structural hollow zvikamu zveasiri-alloy uye masimbi ezviyo.

JIS G 3466: Carbon simbi sikweya uye rectangular machubhu eyakajairwa chimiro.

AS/NZS 1163: Cold-formed structural simbi hollow zvikamu.

Aya mazinga anoshandiswa zvakanyanya kutenderera pasirese, uye anobatsira kuona kuti zvimiro zvesimbi machubhu zvinosangana nezvinodiwa zvinotarisirwa kuita mumashandisirwo einjiniya akasiyana. Paunosarudza muyero wepombi yesimbi, zvakakosha kufunga nezvezvido zvayo zvekushandisa, mitemo yedunhu, uye zvinodiwa zvekuita.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Pipe yesimbi

ASTM A671/A671M LSAW Simbi Pipe

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Simbi Pipe

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Giredhi X70 LSAW Simbi Pipe

EN10219 S355J0H Structural LSAW(JCOE) Simbi Pipe